8

TapcoTools.com 800.521.8486

8

TapcoTools.com 800.521.8486

6

10013

10021

10227

12263

12264

ASSEMBLY

10227

ASSEMBLY

10020

10225

10015

11409

12396

10008

10021

12293

Adjustable

* This kit replaces the Track Bearing Kit 11393. Both are still available for purchase.

** Please contact Customer Service if these parts need to be replaced.

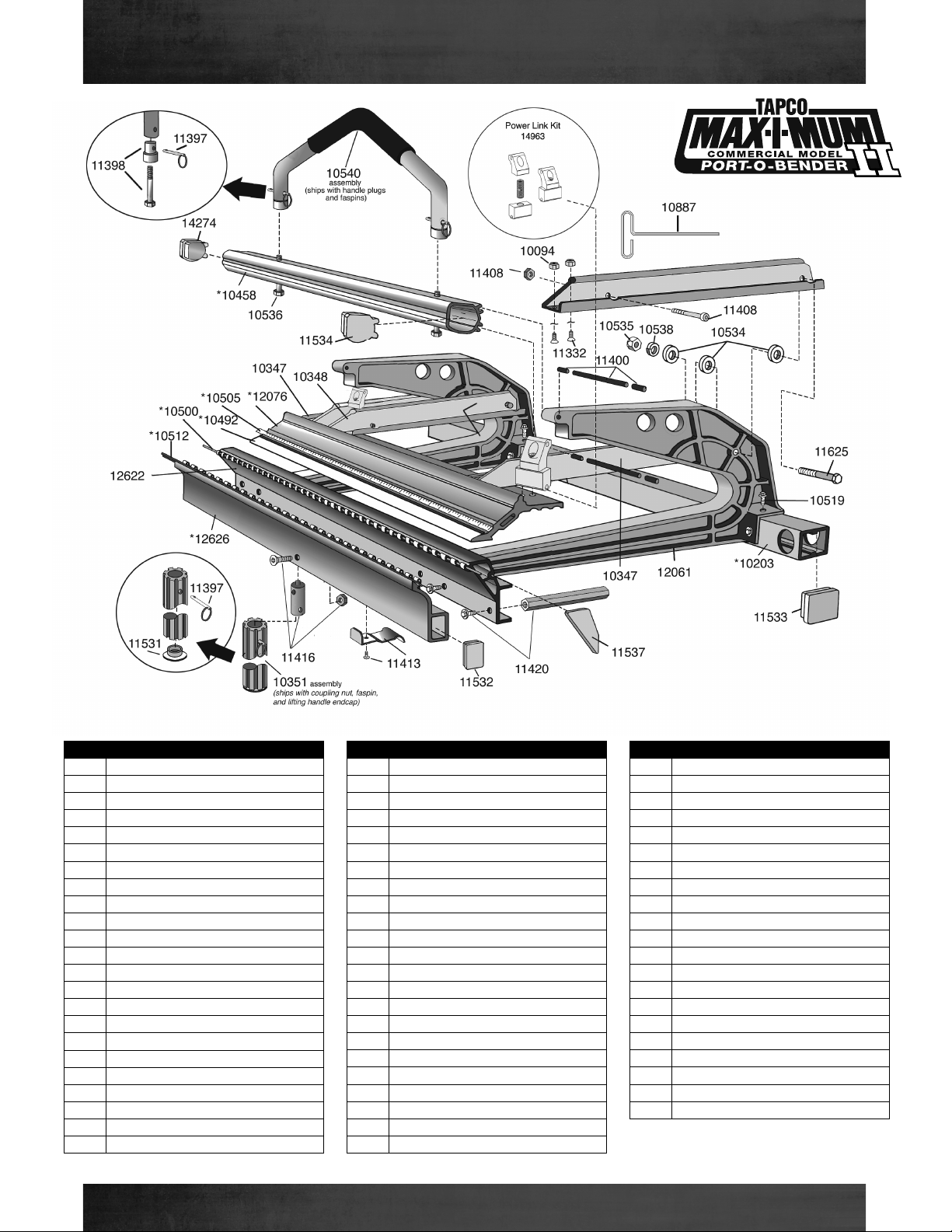

Item# Description

10225 Bridge

10008 Handle

12264 Adjustable MAX Cut-O Body

11409 Cut-O Guide Bearing Kit

(2) Guide Bearing 10016

(2) 5/16" Roll Pin 10015

12396 FlangeTrack Bearing Kit*

(2)Wide FlangeTrack Bearing 12334

(2) 1/4-20 x 5/8" Hex Button

Hd Screw 12364

11393 Track Bearing Kit (not shown)

(2)Track Bearing 10012

10021 1/4-20 x 1" Hex Button Hd Screw

10020 1/4-20 x 5/8" Hex Button HD Screw

10013 1/4-20 x 1-1/4" Button Hd Screw

10227 MAX Knife Assembly**

Knife (10226), Bearing (10231)

Nut (10232), .125 Shim

10349 Coupling Nut (hook, not shown)

10519 1/4-20 X 3/4" Hex Wash Hd Screw

(not shown)

11404 Material Stop Kit (not shown)

(2) Material Stop 10740

(2) 1/4-20 Knurled Knob 10776

(2) Cut-OTape Measure 10023

12263 Adjusting Nut

12293 1/4-20 X 1 1/2 Socket Head Cap Screws

4 Secure the tape measures in place by“punching”

down the edge of the pivot arm onto the tape

measure. Use a standard nail set or punch.

IMPORTANT! Read this safety information

before using product.

1. Always keep hands and ngers clear of the knives

during all phases of use.

2. If using both hands to push tool through material,

ensure hands are not in the path of the exiting

material as it leaves the rear area of the tool.

3. Remove cut-o from anvil prior to bending

material. Failure to do so can cause the tool to fall

from brake resulting in tool damage or personal

injury to user.

4. Never use tool to cut material not rmly clamped

in brake.

LIST OF PARTS:

(1) Adjustable MAX Cut-O,

(2) Material Stop Kit #11404,

(2) Coupling Nut Kit #11420,

(1) Storage/Coupling Nut,

(1) Hinge Clip Kit #11413,

(1) 10-24 x 5/8" Phillips screw.

Tools Needed for Initial Set Up:

hammer, punch or nail set,

9/16" wrench, Phillips screw driver. 1 Disconnect the Hemming Handle from your Bender

by releasing the Faspins. This will allow the Bender to

fully open making it easier to slide Cut-O Stops onto

the Pivot Arms.

2 Slide material stop onto Pivot Arms from rear as

shown. Note: Recommended locations are on the

second castings in from each end of your bender.

3 Slide measuring tapes into Pivot Arm slots from rear of

Pivot Arm till they stop.Tape measures take into account

1½" dierence between the bending edge and the shear

point of Cut-O for accurate cuts.

Pivot Arm

Casting

IMPORTANT:

5" mark on tape

measure should

be inserted first.

Open Bender as wide

as possible.

Hemming

Handle

Faspin

Setup for Adjustable MAX Cut-Off and Parts