=

c

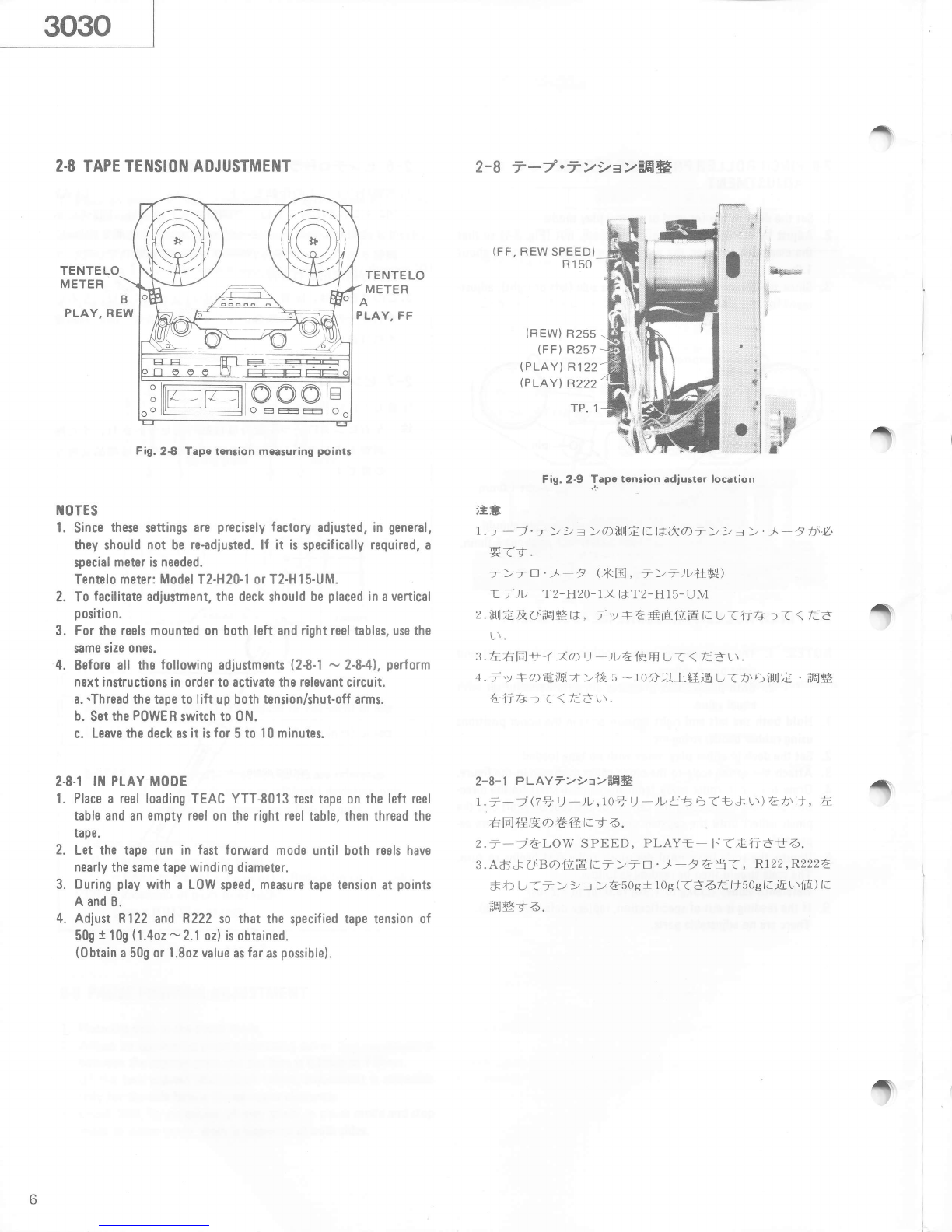

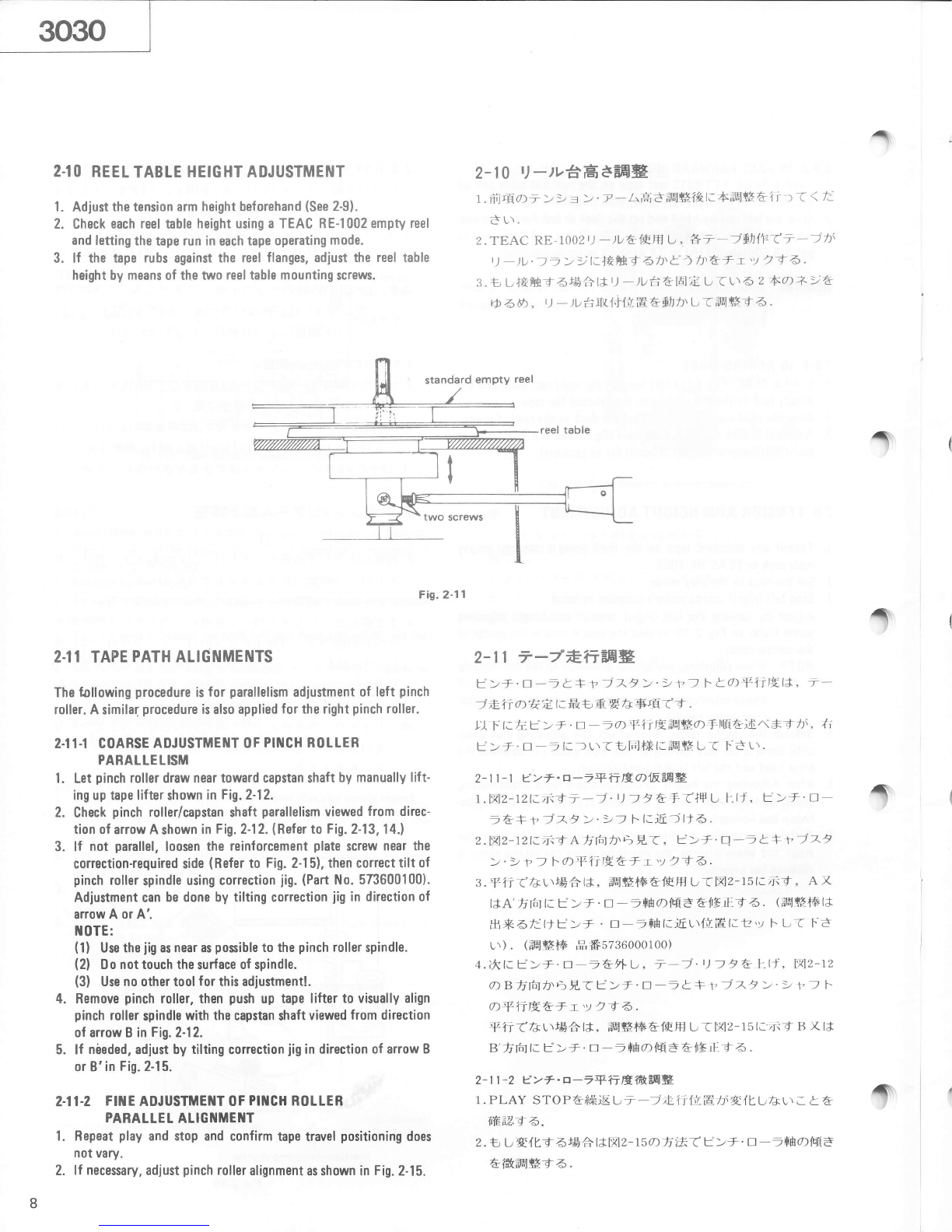

2.8-3 ItU FAST FOBWABD MODE

1. Load a TEAC YTT-9013 test tape on the left reel table and an

empty reel on the right reel table, then thread the tape.

2. stop the left reer by hand and set the deck in fast fonaard mode.

3. Adjust R257 to obtain a t00g to l20g (3.boz -4.2ozl value at

point A (0btain a I l0g or 3.g oz value as far as possible).

REMARK: Back tension in fast forward (or fast rewindl is auto_

matically set when tape speed is adjusted as in paragraph

2-12_2.

2-84 ItT BEWIND MOOE

1. Load a TEAC yTT-9013 testtape on the right reel table and the

empty reel on the left reel table, then thread the tape.

l. !,9.0 the right reel by hand and ser the deck in the rewind mode.

3. Adjust R255 ro obtain a l00g to l20g (3.502 -4.2ozlvalueat

point B (0btain a l00g or 3.goz as far is possible).

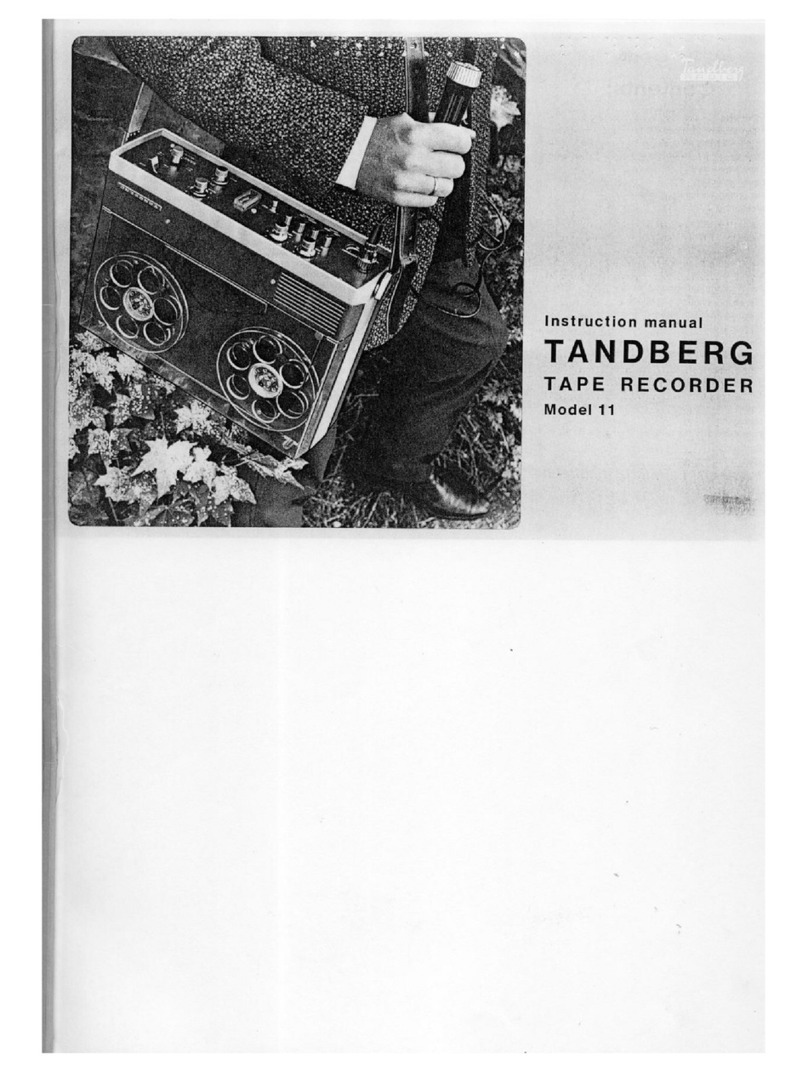

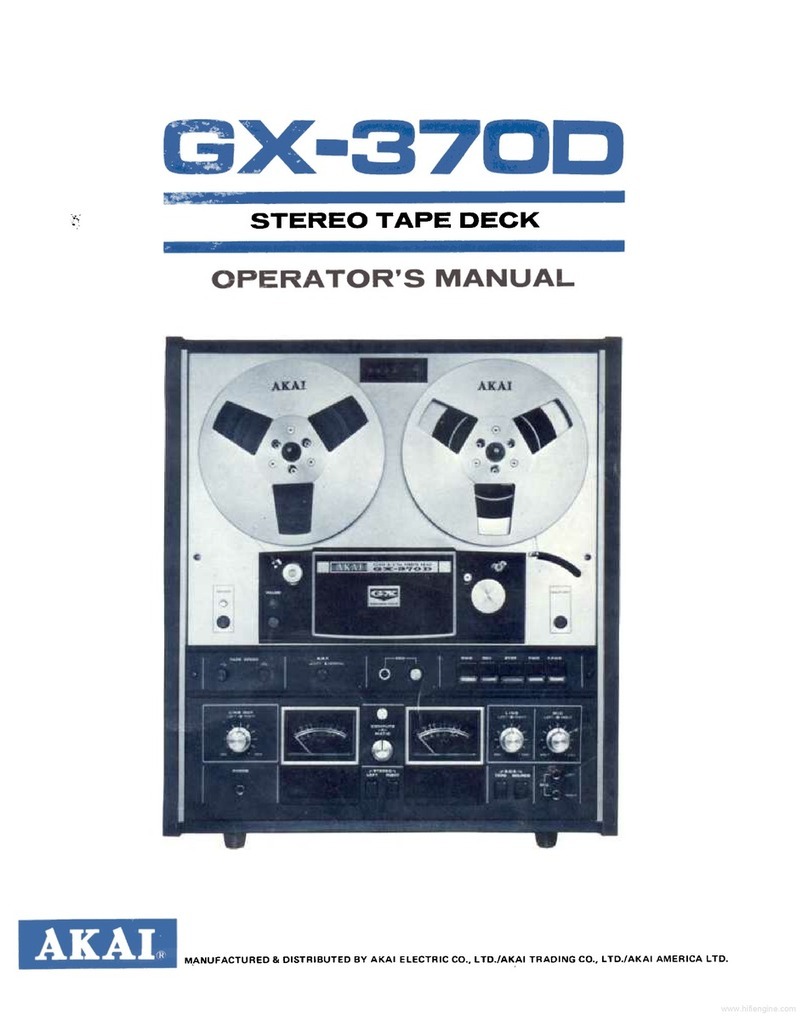

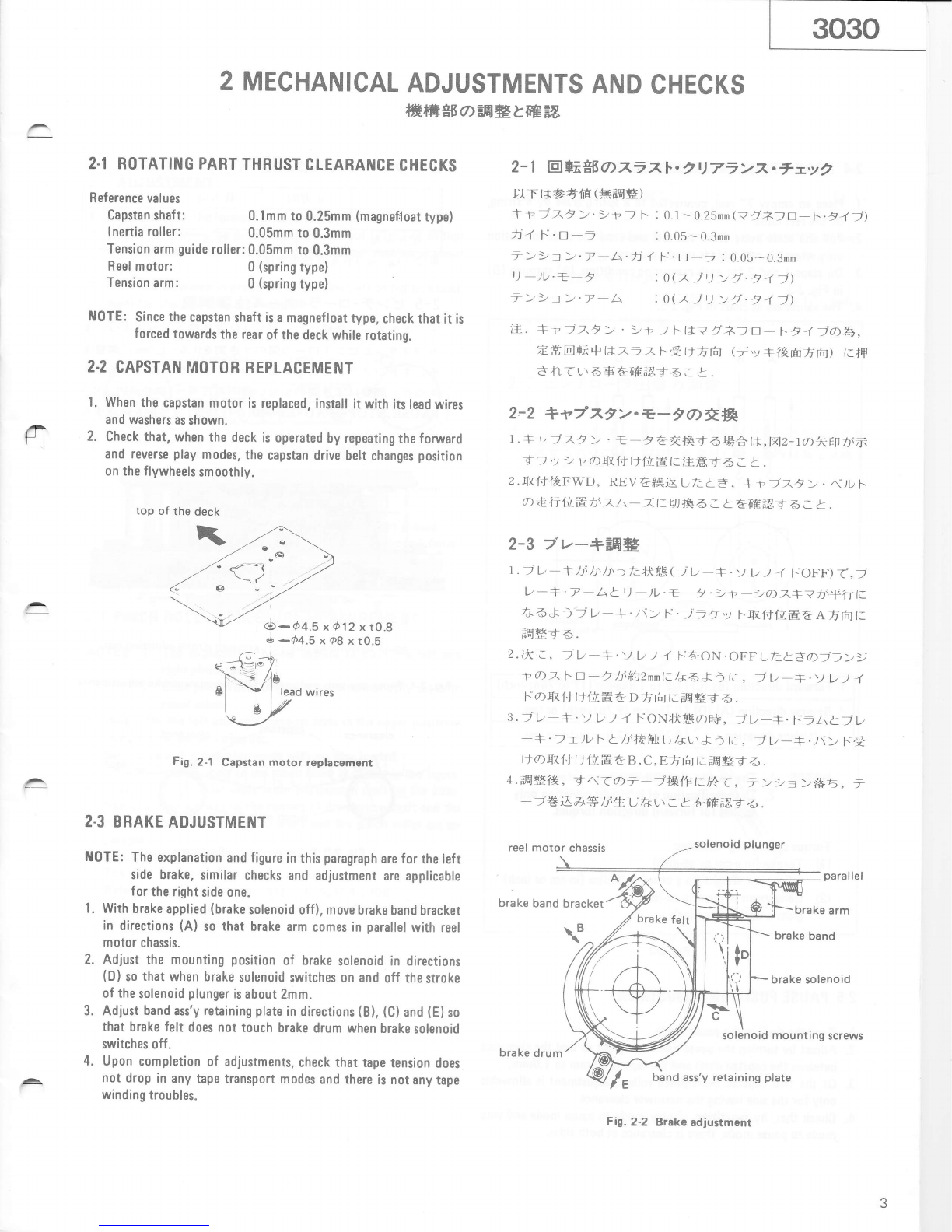

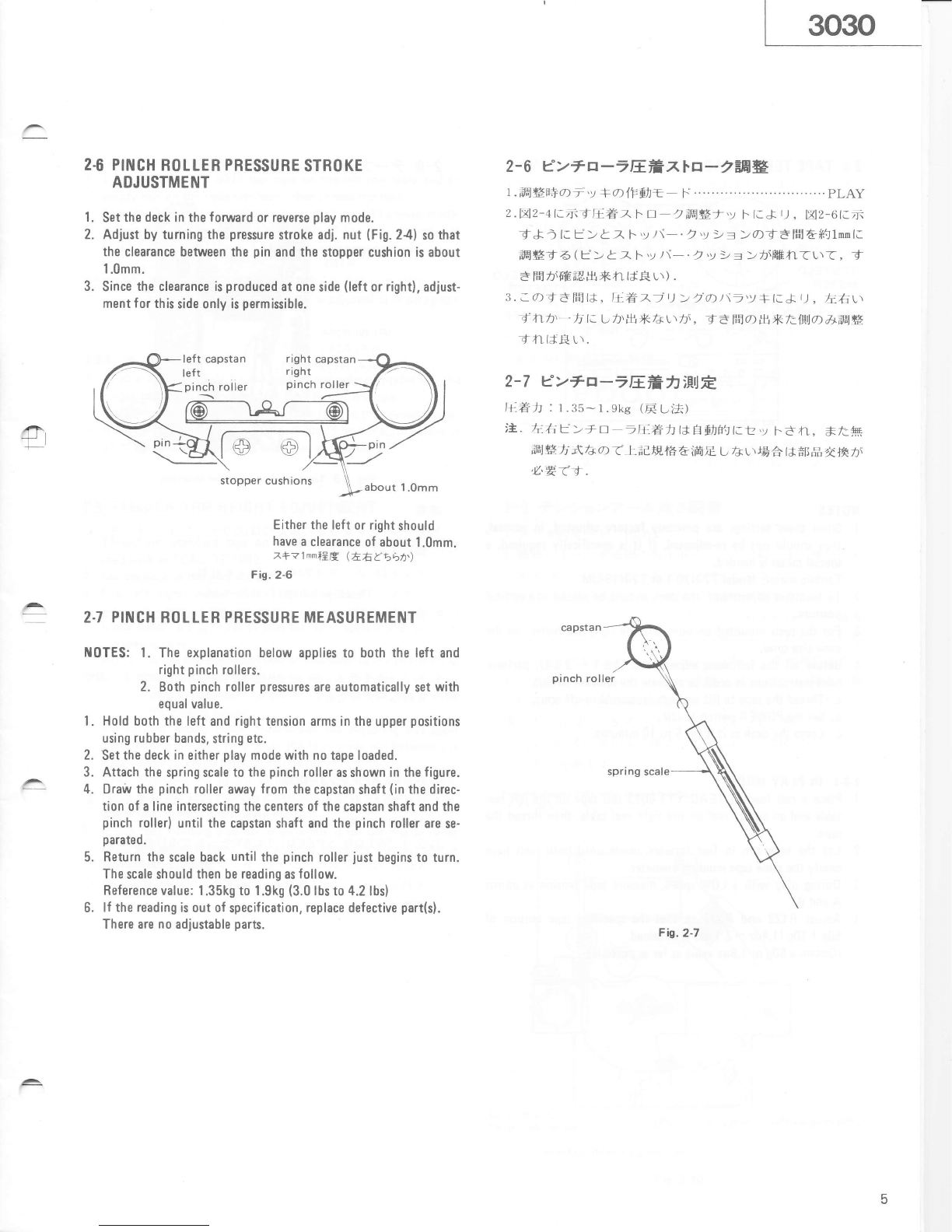

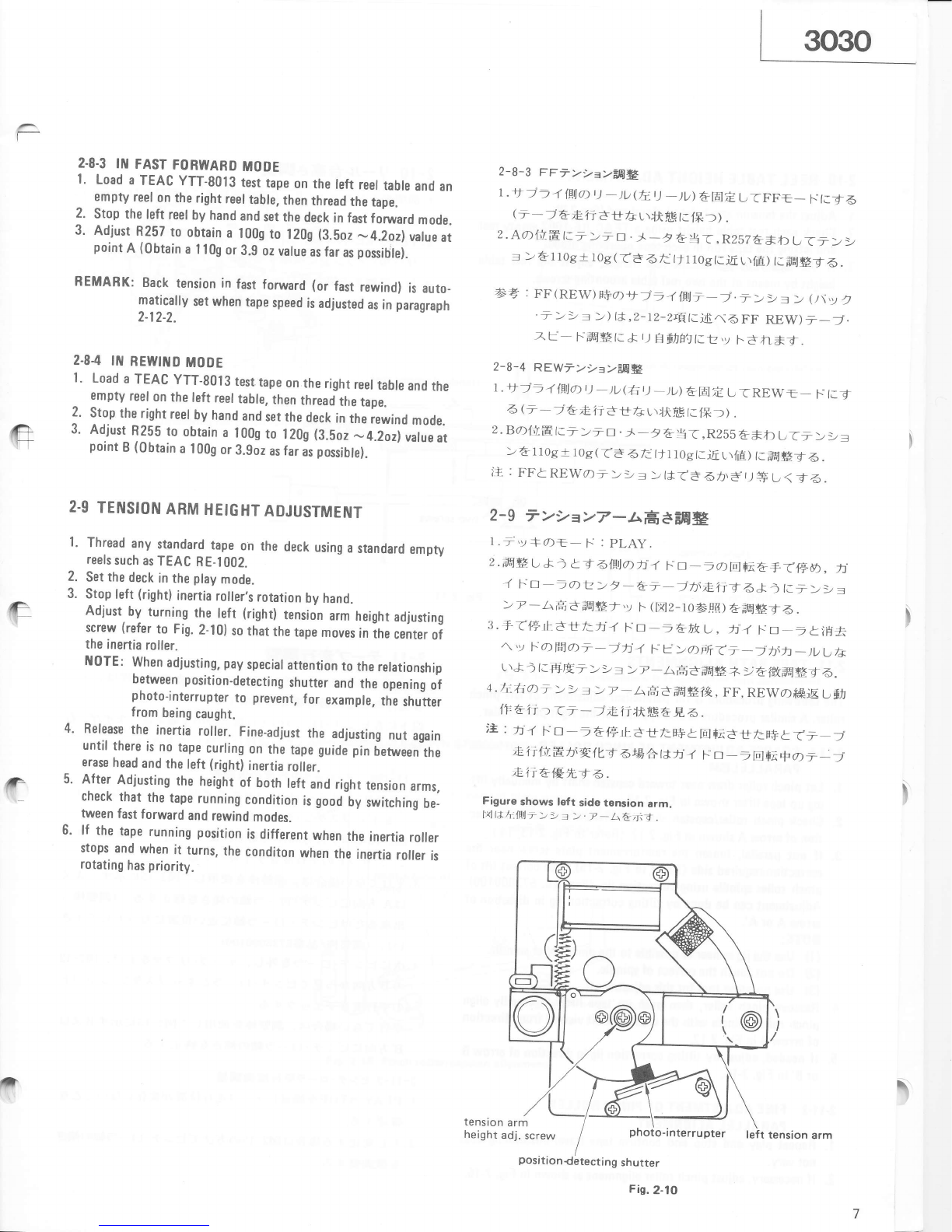

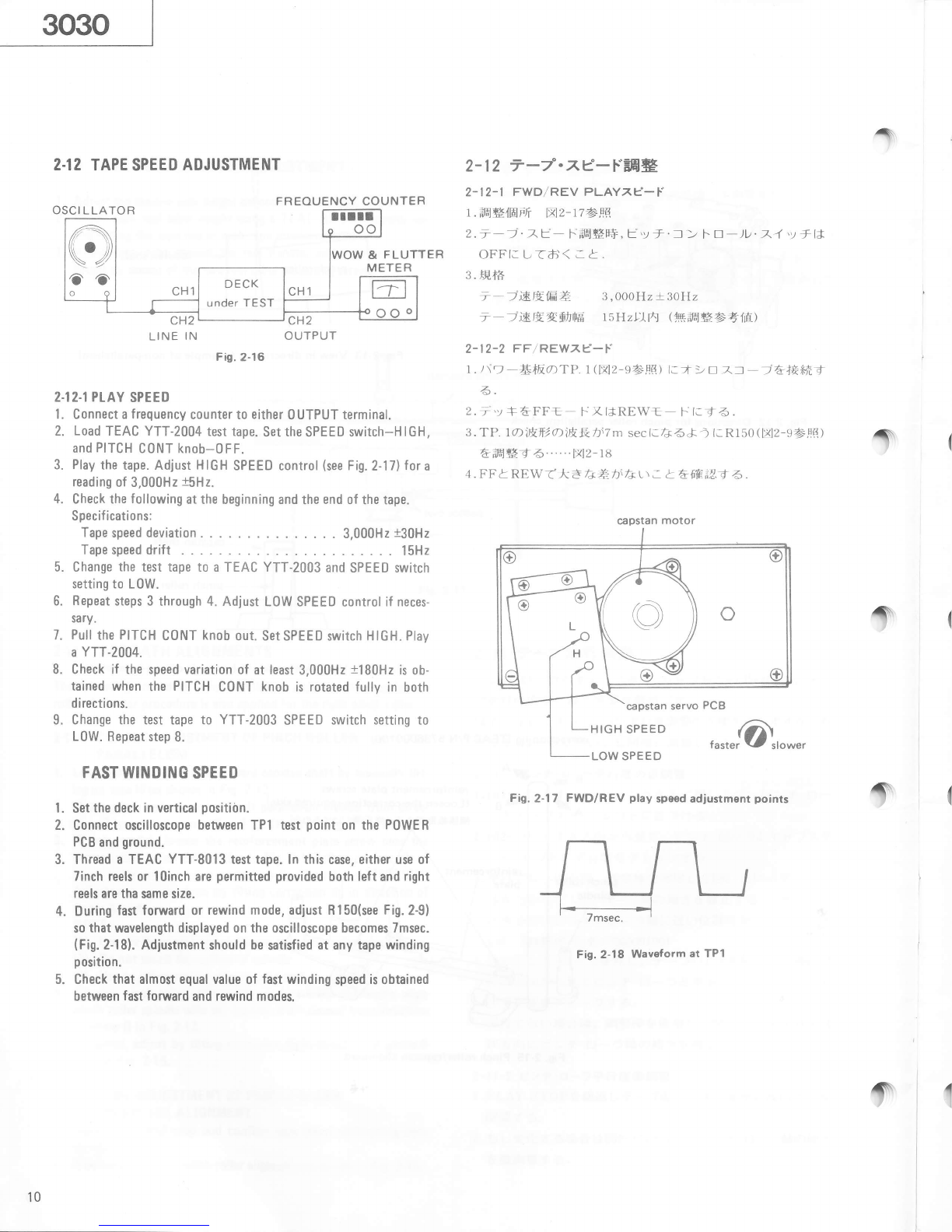

2.9 TENSION ARM HEIGHT ADJUSTMENT

1. Thread any standard tape oh the deck using a standard empty

reels such as TEAC RE-1002.

2. Set the deck in the play mode.

3. Stop left (right) inertia roller's rotation by hand.

Adjust by turning the left (right) tension arm height adjusting

screw (refer to Fig. 2-10) so that the tape moves in the center of

the inertia roller.

II0TE: When adjusting, pay special attention to the relationship

between position-detecting shutter and the opening of

photo-interrupter to prevent, for example, the shutter

from being caught.

4. Release the inertia roller. Fine_adjust the adjusting nut again

until there is no tape curling on the tape guide pin between the

erase head and the left (right) inertia roller.

5. After Adjusting the height of both left and right tension arms,

check that the tape running condition is good by switching be_

tween fast forward and rewind modes.

6. lf the tape running position is different when the inertia roiler

stops and when it turns, the conditon when the inertia roller is

rotating has priority.

2-8-3 FF7>2e>=:dl*

1.'ti-4|F.\at.) -)tJ(Eu _)D) atrt U<FF=_ t-.trr5

( i - i t +_1- d t rs Lr#i f-E t. f+ I ) .

2. AaltE I.- >- D . J_ _ t & \7,R257 & *b t T _ > >

= > t ltog + 10g ( t g a t: ttl 10s t.iE. r\1d) lr 6gq 5 .

aa : FF(REW)Wo)tj-_t ftrlj-j. ->> = > (/\,y j

. - > > = >) I*,2_72-zrFt.i6^6 FF REW) r_7.

7.u l-.;iEgt..k u HsrF!t.Ev t_dfi*d.

2-8-4 REWT>!=>EB*

1.ti-4lFtlat.) -)D(x71.) _)t )6Hf t, rREW=_ F t.d

4 (= t & rt.fi tt td.r\)DiLq t.{*l) .

2. Bo)[XEI.- >, D. )_ _ t & liT,R2556 *b l:T i > ) =

> t tt}g + r0g ( t6 6 fc 111 tOg tti[ urifi ) tr 694 5 .

i+. : FFSREWd)t> j/= >l3:t6.6r\- U+ U < T6.

2-9 7>>=>7-L.A+EH#

f .i.y.FO=- F :pLAy.

2.ffi# l, e. - xt 3l1tl.: h 4 ts E - - alpld,^& +< tr..r, fi

-r h.tr -oE>t_tj )h\rt.ftt6&)t.j>)=

> p - 1lF,d AEISJ-,y F (Blz-r\+Hil &ffi#-{ 6.

3. +f{Frtd11 t:h -( ts E - - tfh. L,,i-l t-. tr _- tiH*

^'y f a ffra- - i fi 4 I- L > aFfr< = _ ) h\h _ )t, U f+

L\A ) l.BE- ) )t = )t 7 - Ata'dffig + jl,& lffiffilgt 6.

4.thD-)) = ):p -A€:dffi#1*., FF, REWr)ffiE tJ$,

lF6: 1i'> T - - ) rt.Tr ltffi& n 6 .

i*. : h'( t- D * - &E tldiltE+- E*ndlitrF*t < t _ j

rt.1iln-Eh\qILt 6t+.*ttti-r F. ! --tEl$x +a j_J

+J re@%t 6 .

Figure shows left side tansion arm.

I'xl l* lr.lF.tli > > = >. p - A&it .

\

ctension arm

height adj. screw

positiondetecting shutter

Fis.2-1o

left tension arm