Tavistock Kinetic SKN0601 Parts list manual

KINETIC & LOGIC

THERMOSTATIC SHOWER BAR VALVE

Installation & aftercare instructions

Please retain for future reference

KINETIC BAR SHOWER VALVE

SKN0601

KINETIC BAR SHOWER VALVE

SKN0706

TMV2 / Buildcert Ref No: RRTAV6 TMV2 / Buildcert Ref No: RRTAV7

REF: KH.TAV.BSV10 | 07.10 V3.00

LOGIC BAR SHOWER VALVE

SLG1302

LOGIC BAR SHOWER VALVE

SLG1407

TMV2 / Buildcert Ref No: RRTAV13 TMV2 / Buildcert Ref No: RRTAV14

INTRODUCTION

Your bar shower valve is a thermostatic mixer which incorporates a thermo-regulating cartridge to assure users

of consistent showering temperatures. The valve has been designed & manufactured to comply with BS EN

1287:1999 & BS EN 1111:1999.

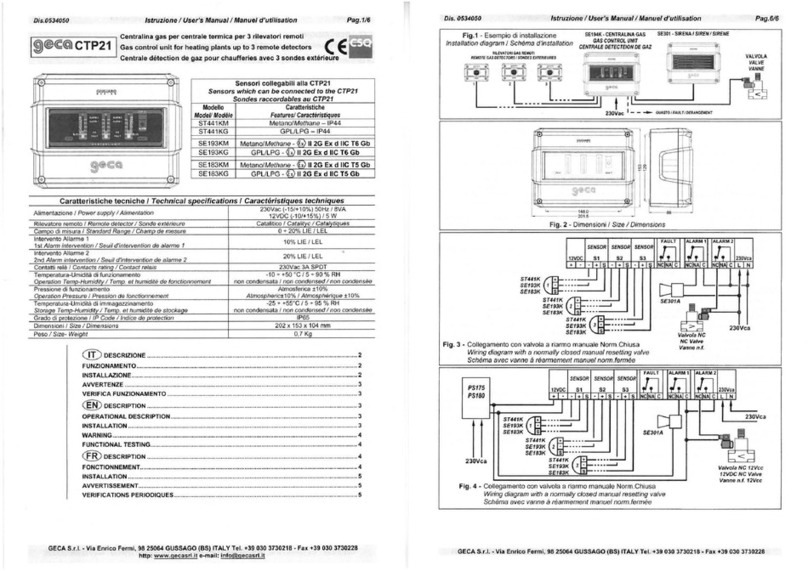

OPERATING CONDITIONS OF USE

Before installation the operating conditions of use must be checked. The table below contains details of the

necessary conditions of operation. If your water supply cannot meet these conditions then the valve cannot be

guaranteed to operate as a Type 2 TMV2 certified shower valve. This valve is suitable for use in both low

pressure (BS 1287) and high pressure (BS 1111) operating conditions with the following systems:

• Gravity fed Hot & Cold (equal pressures)

• Gravity fed Hot & mains Cold (differential pressure – max ratio 3:1)

• Unvented systems

• Gas combination boiler

• Pumped system

Note: On gravity systems the minimum Vertical distance (Drop) from the underside of the cold water storage

tank to the shower valve must be 3 metres.

CONDITIONS OF USE FORTYPE 2 VALVES

NOTE:

Valves operating outside these conditions cannot be guaranteed by the Scheme to operate as Type 2 valves.

Recommended outlet temperatures

The BuildCert TMV scheme recommends the following set maximum mixed water outlet temperatures for use

in all premises:

41°C for showers;

The mixed water temperatures must never exceed 46°C.

The maximum mixed water temperature can be 2°C above the recommended maximum set outlet

temperatures.

NOTE:

46°C is the maximum mixed water temperature from the bath tap. The maximum temperature takes account

of the allowable temperature tolerances inherent in thermostatic mixing valves and temperature losses in metal

baths.

It is not a safe bathing temperature for adults or children.

The British Burns Association recommends 37 to 37.5°C as a comfortable bathing temperature for children. In

premises covered by the Care Standards Act 2000, the maximum mixed water outlet temperature is 43°C.

The thermostatic mixing valve will be installed in such a position that maintenance of the TMV and its valves

and the commissioning and testing of the TMV can be undertaken.

The fitting of strainers is recommended as close as is practicable to the water supply inlets of the thermostatic

mixing valve.

SERVICE INTERVALS

Subsequent frequency can be determined with reference to previous test results. Where no significant deviation

was recorded the test interval can be made equal to the maximum recorded interval to that point.

Note. Check valve and strainer servicing must be conducted at each test interval.

If the recorded mixed water temperature is greater than > 2°K from the initial recorded settings or the set point

cannot be reached / stabilised further action is required.

It is important to establish that the incoming water supplies still satisfy the initial guidance and also that no

additional draw off variation that could affect performance has occurred.

The material selection for this valve has excellent resistance to scale build up and is designed such that there

are no serviceable parts beyond items 1 & 2 as described previously.

In the very unlikely event that initial performance cannot be achieved, and all external parameters are correct,

the unit may require replacement.

10-YEAR GUARANTEE

HIGH PRESSURE LOW PRESSURE

Maximum Static Pressure - BAR

Flow Pressure, Hot & Cold - BAR

Hot SupplyTemperature - °C

Cold SupplyTemperature - °C

10

0.5 to 5

55 to 65

Equal to or less than 25°C

10

0.1 to 1

55 to 65

Equal to or less than 25°C

We have complete confidence in this Tavistock product and as such it is offered with a 10-year guarantee

against defects in manufacture. This valve must be fitted by a competent installer. If in doubt seek advice from

a qualified professional.

The guarantee requires that this product be used in the manner for which it was intended and that it is installed

& maintained in accordance with the fitting instructions and local water bylaws. The guarantee covers products

in domestic use only.

Always ensure this product is fully tested before concealing valves into the wall. On installation ensure that the

valve and valve inlet threads can be removed or serviced in accordance with TMV2 regulations. The guarantee

is invalidated should the valve be damaged by water borne debris. Make sure that supply pipes are clear of

any debris prior to installation, this is particularly important on new plumbing installations. In the unlikely event

that this product should fail during the guarantee period we will either replace the faulty part or the complete

unit as appropriate.

This guarantee excludes normal wear and tear. This guarantee covers failure of the thermostatic cartridge

within the first 2 years of purchase only. Replacement cartridges are available to purchase by contacting the

Tavistock Customer Service team. Failure to follow the terms outlined above will invalidate this guarantee.

Proof of purchase will be required to validate any guarantee claims.

VALVE INSTALLATION GUIDELINES AND COMPLIANCE

The valve must be installed so that it is readily accessible for commissioning and maintenance in accordance

with the TMV2 scheme. The valve must be installed with isolation valves on both the hot and cold water

systems as close as possible to the valve; so as to allow the valve to be commissioned and tested correctly.

The valve is fitted with integral check valve cartridges which command the water supply, therefore the

thermostatic valve is protected against cross-flow due to unbalanced line pressures as required by the Water

Supply (Water Fittings) Regulations 1999.

Most problems associated with the operation of thermostatic shower valves are caused by debris in the new

pipe work getting into the thermostat. These problems are easily avoided by thoroughly flushing the pipe work

BEFORE the shower valve is fitted.

WATER SUPPLY - (WATER FITTINGS) REGULATIONS 1999

This valve complies with the requirements of the above regulations and installation should be carried out in

strict compliance with them.

MOUNTING BAR SHOWER VALVES

There are two methods of mounting the bar shower valve using the components supplied. These methods are

detailed on the following pages. Please read the information below to determine the most suitable option for

your installation:

Option 1 - Cranked connector

This option requires a 1/2” BSP female adapter (not supplied) to connect the cranked connectors to the pipe

work. This method is clip mounted and requires that the pipe work the valve is connected to be supported and

be rigid.

Option 2 - Wall fixed connectors

This option requires a suitably strong wall construction to support the weight of the valve. Suitable wall fixings

must be used (not supplied).

COMMISSIONING

It is important that incoming water supplies conform to the requirements specified for pressure and

temperature. Assure that supply water conditions satisfy any guidance information for the control of bacteria

and that the designation of the supplied valve suits the application. Do not continue commissioning until

supplies are correct and stable considering variation caused by other service users.

Use a calibrated thermometer for testing incoming and mixed water.

1. Record temperature of the incoming hot and cold supply.

2. Record temperature of mixed discharge at maximum draw off rate.

3. Record temperature of mixed discharge at minimum draw off rate.

4. Isolate the cold water supply and measure the mixed water temperature as the cold water failure device

reacts. This should deviate by no more than + 2°C of the initial maximum set point. Restore the cold supply

and measure the stabilised mixed water temperature. This must not deviate by more than + / - 2°C of the

initial set recorded result. Record these findings.

5. Record the measuring equipment used for the measurements.

The above records must be retained and updated during the service life of the TMV.

If there is a residual flow during the commissioning or the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of the water seeping from the valve is no more than 2oC

above the designated maximum mixed water outlet temperature setting of the valve.

Temperature readings should be taken at the normal flow rate after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be re-commissioned and re-tested in accordance with the

manufacturers' instructions.

The installation of thermostatic mixing valves must comply with the requirements of the Water Supply (Water

Fittings) Regulations 1999.

IN SERVICE TESTING & MAINTENANCE

It is a requirement that all TMV2 approved valves shall be verified against the original set temperature results

once a year. When commissioning/testing is due the following performance checks shall be carried out.

Measure the mixed water temperature at the outlet.

The mixed water temperature at the terminal fitting must never exceed 46oC.

Carry out the cold water supply isolation test by isolating the cold water supply to the TMV, wait for five

seconds if water is still flowing check that the temperature is below 46oC.

If there is no significant change to the set outlet temperature (±2°C or less change from the original settings)

and the fail-safe shut off is functioning, then the valve is working correctly and no further service work is

required.

Notes

If there is a residual flow during the commissioning or the annual verification (cold water supply isolation test),

then this is acceptable providing the temperature of the water seeping from the valve is no more than 2oC

above the designated maximum mixed water outlet temperature setting of the valve.

Temperature readings should be taken at the normal flow rate after allowing for the system to stabilise.

The sensing part of the thermometer probe must be fully submerged in the water that is to be tested.

Any TMV that has been adjusted or serviced must be re-commissioned and re-tested in accordance with the

manufacturers' instructions.

The installation of thermostatic mixing valves must comply with the requirements of the Water Supply (Water

Fittings) Regulations 1999.

297mm

G1/2" BSP

129mm

150mm

KINETIC BOTTOM OUTLET BAR VALVE SHOWN

FITTING OPTION 1

1. Determine the correct position and orientation for the shower and screw the cranked connectors (2) into

the appropriate water supplies finished with a ½” BSP female adapter (not supplied). Hot on the left, cold

on the right with outlet positioned on the underside of body with SKN0601 or on the top of the body with

SKN0706.

2. Screw the shrouds/flanges (1) onto the cranked connectors.

3. To fit the body onto the wall, place the washers (3) into the connecting nuts (4) and tighten to the cranked

connectors (2). The connecting nuts (4) are secured to the mixer body by the retaining nuts (5). Note: No

back nuts or fixing plates are supplied. This shower valve is clip mounted it needs to be connected to and

supported by rigid pipe work.

TROUBLE-SHOOTING

If you require further assistance beyond the guide below contact the help line on 01225 303 900

AFTERCARE INSTRUCTIONS

Whilst this item has a high quality durable finish, it should nevertheless be treated with care. Surfaces should

be cleaned using only a soft damp cloth and clean water & dried using a soft cotton cloth. Bath / shower

cleaning products, even non-scratch ones could damage the finished surface.

MAINTENANCE

We advise that the valves, check valves and filters be regularly serviced particularly in hard water areas. The

check valves along with the filters are contained in the retaining nut. The water supplies must be isolated

remotely from the valve before removal. To access the check valves unscrew the connecting nuts joining the

mixer to the cranked connectors. Unscrew the retaining nuts (left hand thread) from the mixer and check their

conditions then reassemble and turn on water supply.

TMV2 approved valves shall be tested against the original set temperature results once a year. When testing is

due the following performance checks shall be carried out.

1. Measure the mixed water temperature at the outlet.

2. Carry out the cold fail-safe shut off test by isolating the cold water supply to the TMV, wait for 5 seconds if

water is still flowing check that the temperature is below 46 degrees C.

3. If there is no significant change to the set outlet temperature (+/- 2°C or less change from the original

setting) and the fail safe shut off is functioning, then the valve is working correctly and no further service

work is required.

If further maintenance should be required contact Tavistock for details. Please see contact details on the back

page of this document.

Problem

Shower will not run hot enough when first installed

Cold water running back through the valve into the hot

water system.

Solution

Maximum temperature needs adjusting, see temperature

setting guide

Check and clean the check valve cartridges and filters

located under the check valves.

1 2 3 4

MAX cut

diameter = 45mm

KINETIC BOTTOM OUTLET BAR VALVE SHOWN

FITTING OPTION 2

1 2 43

MAX cut

diameter = 45mm

15mm pipe

Olive

Fully tighten the threaded connector

so the olive compresses and rmly

locks the pipe in position.

Threaded connector

Cranked connector

Connecting nut

Check valve

Flow valve

Retaining nut - containing lters

(left hand thread)

KINETIC BOTTOM OUTLET BAR VALVE SHOWN

KINETIC BOTTOM OUTLET BAR VALVE SHOWN

1. 2.

SETTING THETEMPERATURE

The handle on the right of the valve controls the water temperature. To adjust the temperature:

1. Unscrew the handle arm (1) on the temperature handle (3) to reveal the handle grub screw (2). Using a

suitable allen key loosen the grub screw and carefully slide the handle off the thermostat spindle (5).

2. Remove the handle stop (4) from the thermostat spindle (5).

3. Rotate the thermostat handle (5) until the desired hot water temperature is reached. (TMV2 regulations

require a maximum temperature of no more than 44ºC)

4. Replace the handle stop (4) with the stop lug positioned just to the right of the cartridge stop (6). See

diagram below.

5. Replace the handle (3) back onto the thermostat spindle (5) and secure via the handle arm (2).

6. Test to ensure the desired maximum temperature is reached.

OPERATING

Increase flow

decrease

temperature

Increase

temperature

decrease flow

+

-

4

567

321

KINETIC BOTTOM OUTLET BAR VALVE SHOWN KINETIC BOTTOM OUTLET BAR VALVE SHOWN

This manual suits for next models

3

Table of contents

Popular Control Unit manuals by other brands

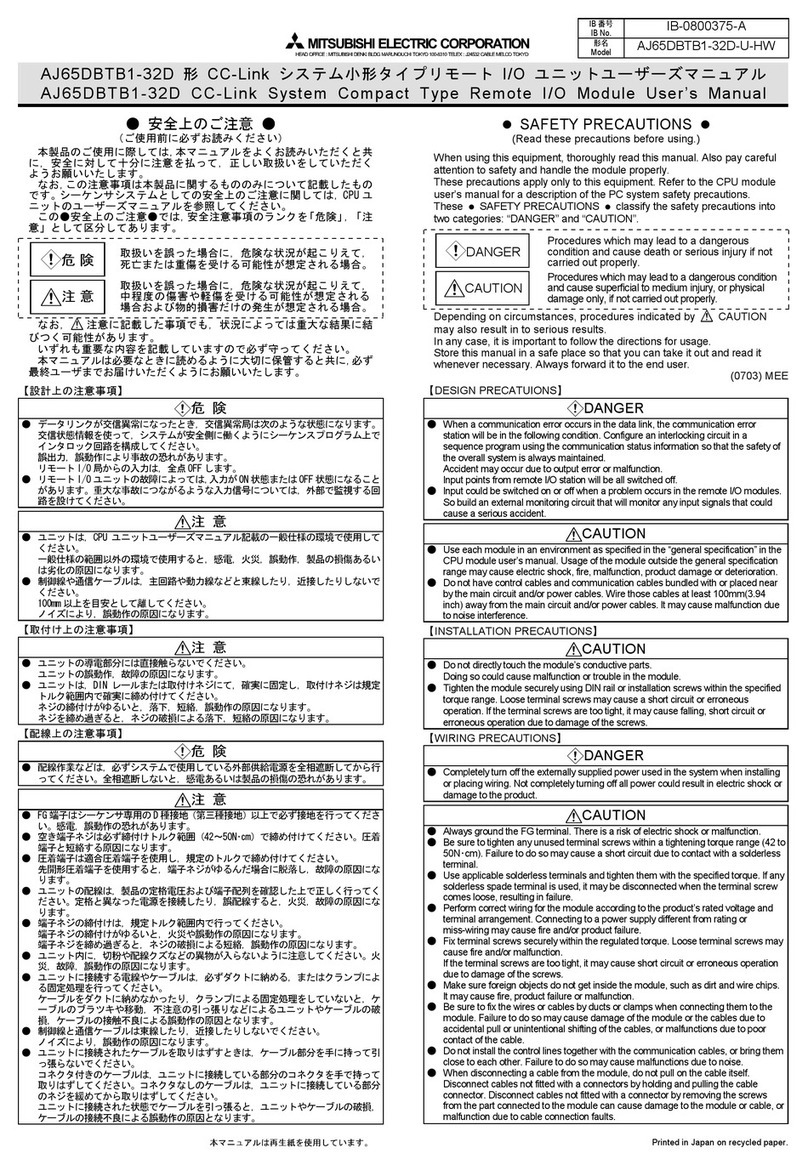

Mitsubishi Electric

Mitsubishi Electric AJ65DBTB1-32D user manual

Energeeks

Energeeks EG-MODPERS001 Quick installation guide

Edwards

Edwards LCPV16EKA instruction manual

BRUEL & KJAER

BRUEL & KJAER 3660-A-20 Series Setup guide

Emerson

Emerson Fisher FIELDVUE DVC6200 SIS Mounting instructions

Innodisk

Innodisk EMP2 SERIES user manual