14 Ver_2-08-22

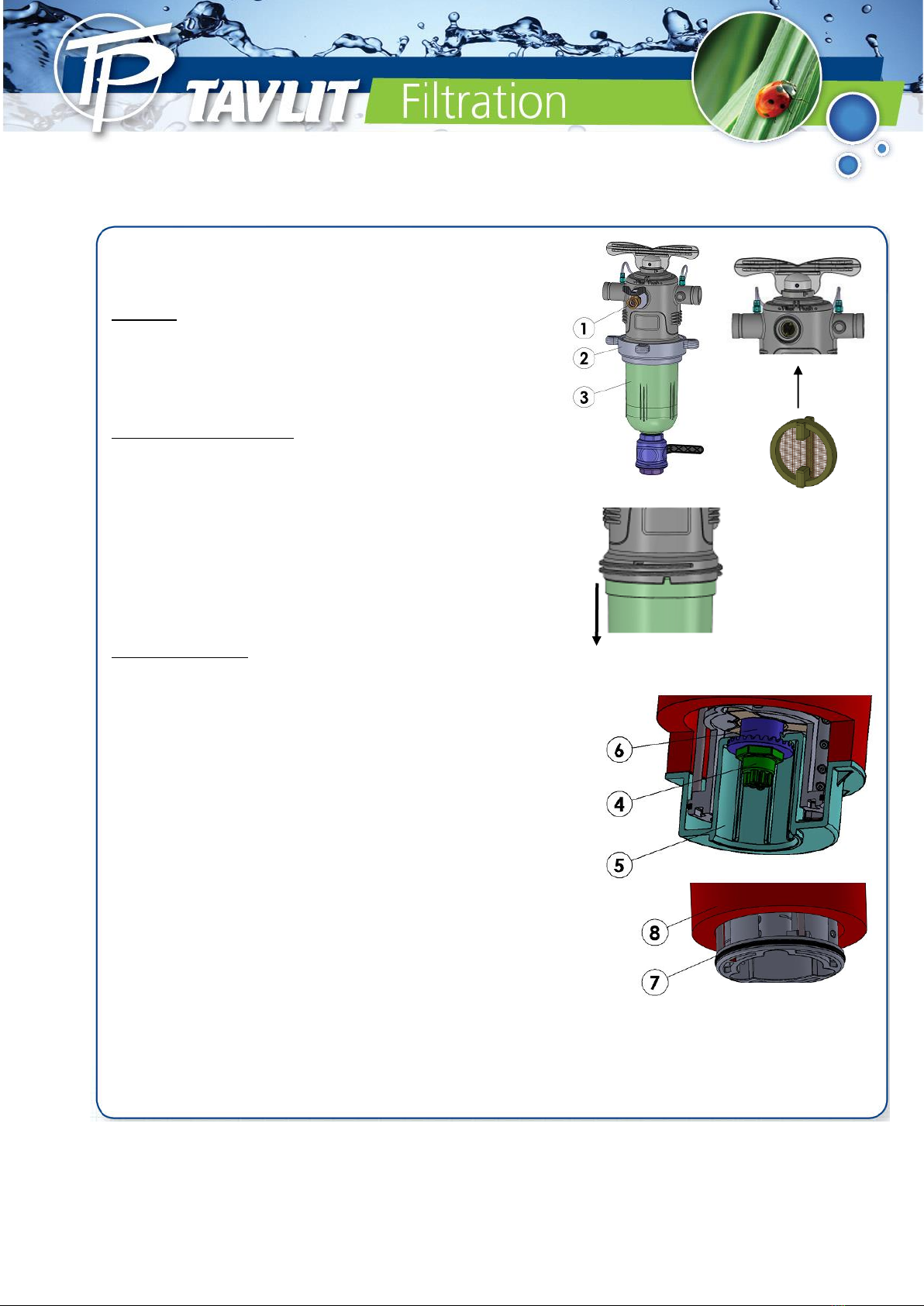

TDS - Proper flushing of discs

It is recommended to clean the discs before and after irrigation season to ensure proper functioning of the filter

for many years. Manual flushing is required when the filter is clogged and flushing process does not clean it

properly.

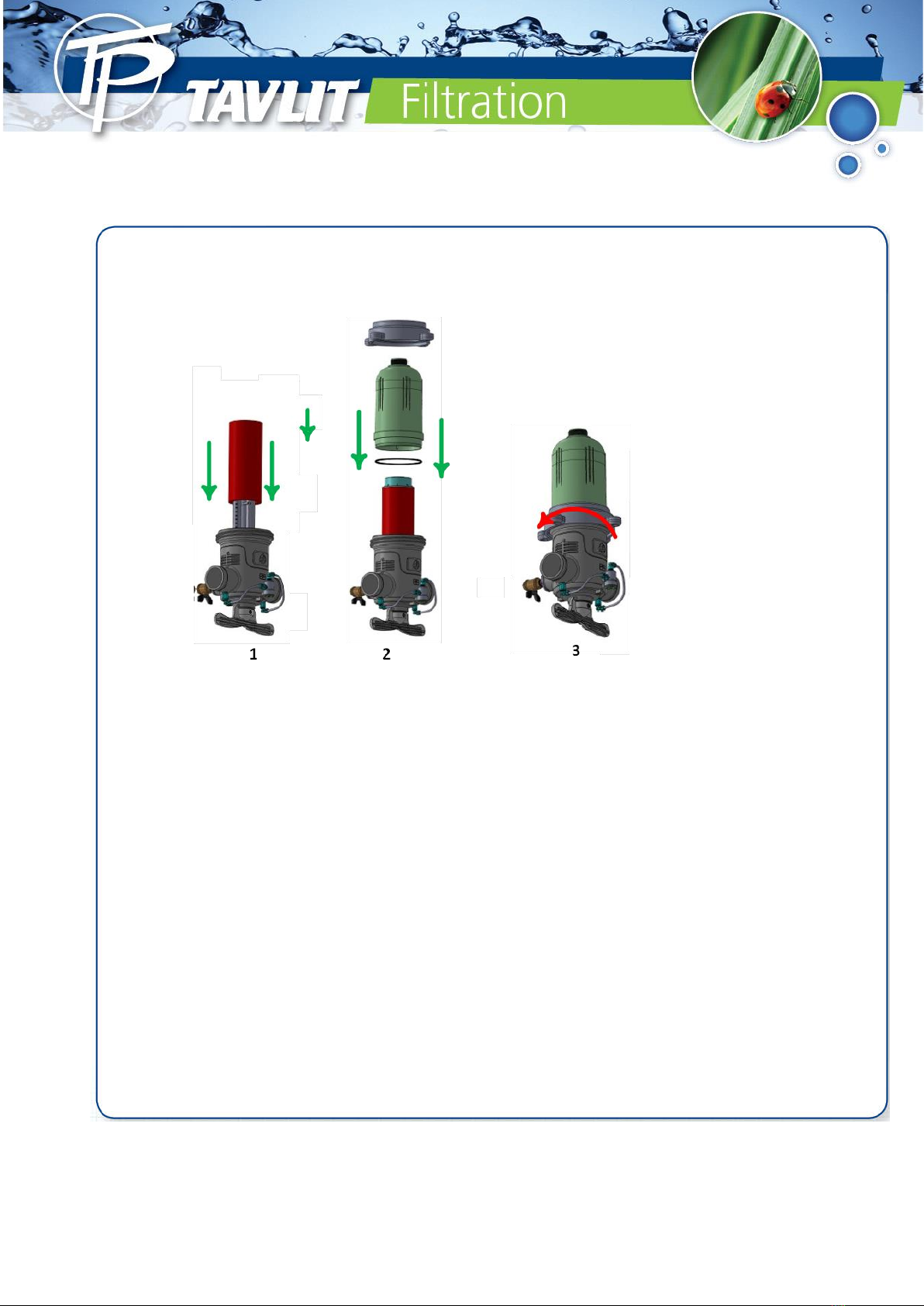

•Before opening the filter cup close the inlet valve of the system and release the pressure in the filter battery

by opening the drain valve.

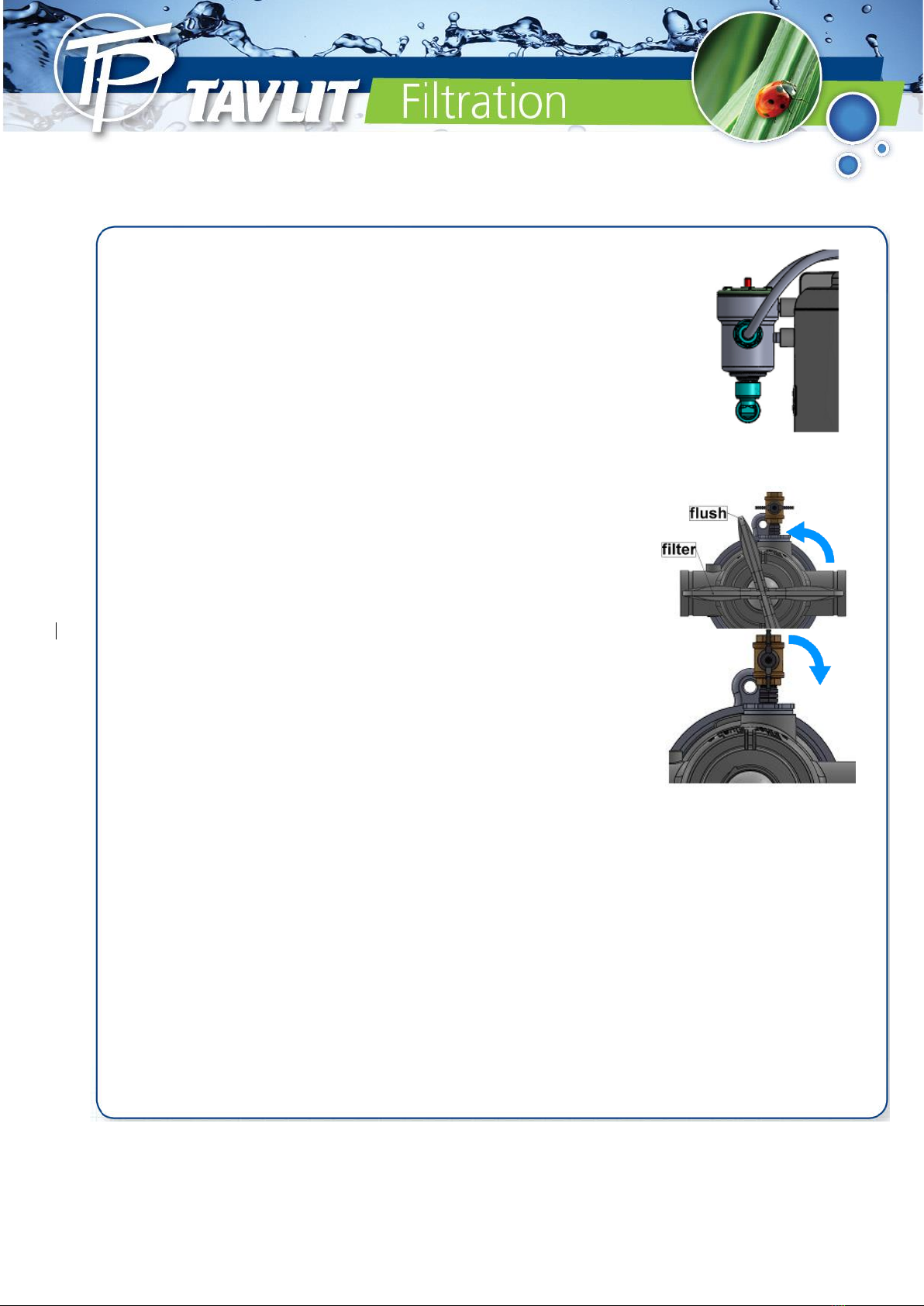

•Release the disc cap and when the discs are loose on the spine perform a manual flushing using a water

hose to flush the discs in high pressure directing the flow tangentially to the spine.

Never open the filter under pressure

•Dismentle discs from the spine.

•Visually check for twisted or worn out discs and replace if required.

•In case of chemical deposits on discs grooves, tie each disc set with a nylon rope and soak the discs into an

appropriate solution –see below. After treatment, rinse thoroughly with fresh water.

•Reassemble the discs on the spines and back in the filter, then close and tighten filter body. Ensure head

loss does not exceed 2-3m.

Detailed explanation of chemical treatment of the discs

Several types of deposits can clog the disc. These can be:

•Organic matter, it will be brown or green and will look like mocus.

•Metal oxide - iron in rust color or managanese in black color.

•Carbonaes - white or grey in color

•Combination of several deposits.

Perform cleaning in a properly ventilated area and use gloves, safety glasses and

protective clothes.

6.1 Preparing the solution for immersing the discs

For organic material use Sodium Hypoclorite

•Mix 5 liters of Hypoclorite (10% concentration) with 5 liters of water. The solution is 5% concentrated.

•Tie the discs with a rope and soak in the solution for 8 hours- then rinse with water thoroughly.

•After installing the discs back in the filter perform several flushing cycles.

For carbonate and iron deposits use Hydroclorite Acid.

•Mix 2 liters of Hypoclorite (30% concentration) with 10 liters of water. The solution is 5% concentrated.

•Tie the discs with a rope and soak in the solution for 8 hours- then rinse with water thoroughly.

For complex deposits

•In case the user is not sure about the type of the deposits he should run a test.

•Put several discs in Sodium ypocloride solution and seveal in a Hydroclorite Acid solution, (prepare the

solution as explained above).

•If one of the dolutions cleans the discs perform cleaning process in that solution.

•If none of the solutions cleaned the discs completely replace the discs that were immersed in the

Hypocloride acid into the Sodium Hypocloride and vise versa and watch which treatment cleaned the discs.

This is the process to follow with all discs.

•If none of the treatments cleaned the discs properly send several discs to a laboratory to get a diagnosis of

th edeposits and the proprer treatment needed in order to clean them.