TB Wood's WFC1000 Series Manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Motor Drive

MANUFACTURER DATA SHEET

TB Wood's

WFC1000/2000/4000

Manufacturer:

Model Number:

PDF File: Doc_000071_Cover.pdf

Covers: Doc_000072_Covers.mdb

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

WFC1000 Series – 1 HP

WFC2000 Series – FHP to 25 HP

WFC4000 Series – 1 to 75 HP

Installation, Operation and

Maintenance Instructions

for CE Marked Version

TB WOOD’S INCORPORATED

Chambersburg, Pennsylvania

Form 1226D

®

Quality Made

in the U.S.A.

®

WFCHT

AC Inverter

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

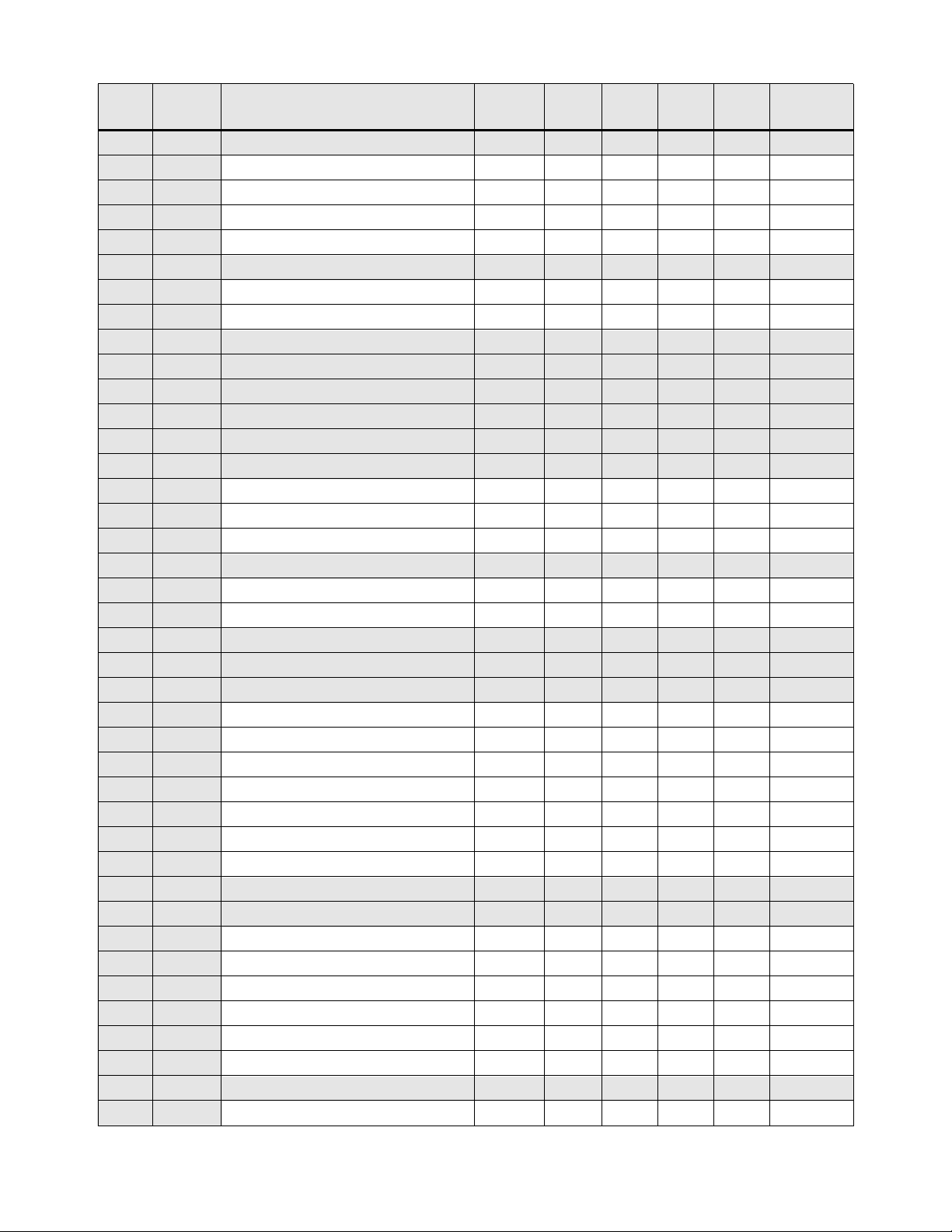

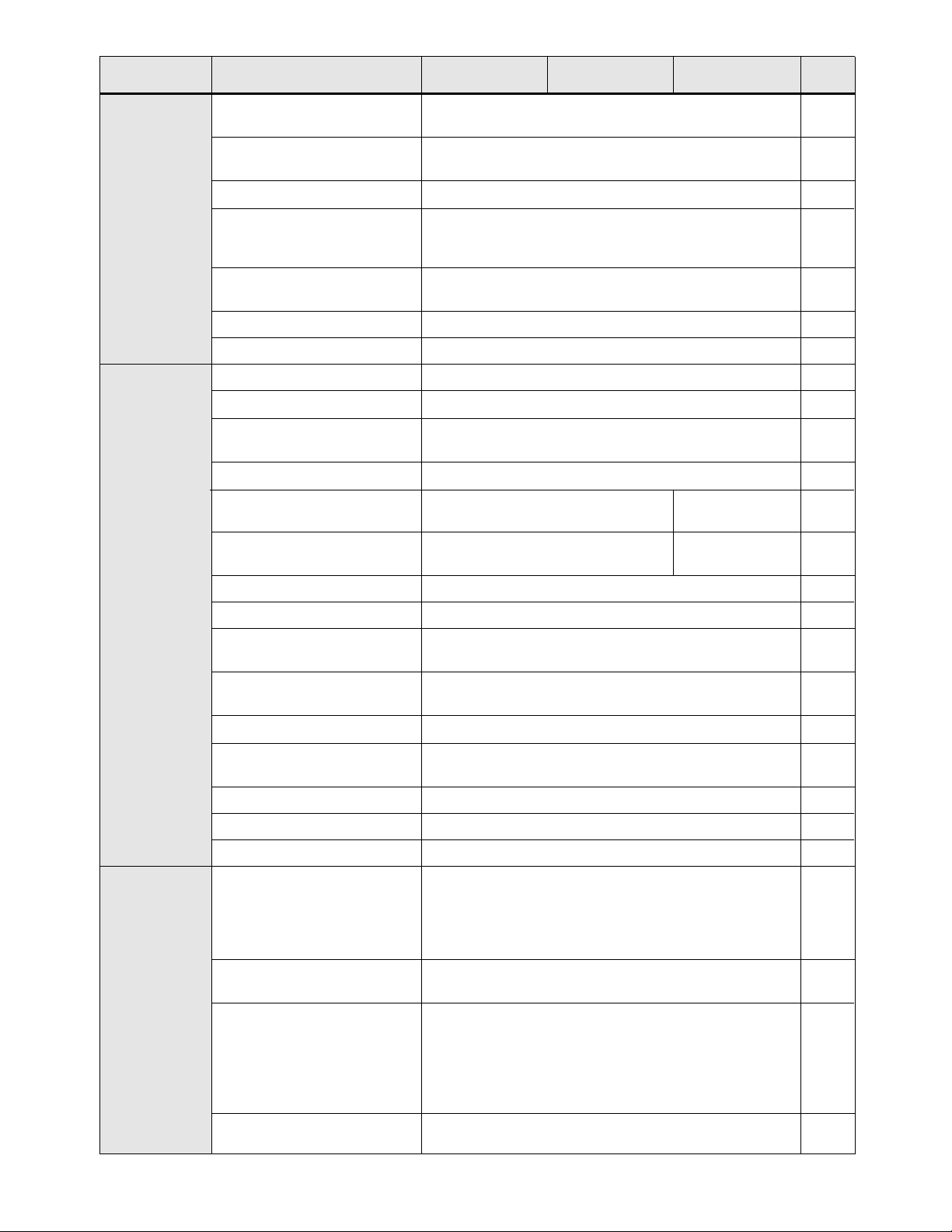

Program Code Summary (Level 1-2)

01 MODEL Model Number 0-65000 Note 1 --- 1 25

02 RVLVL Software Revision 0-640 Note 1 --- 2 25

03 IRAT Rated Current 2-200 Note 1 A 2 25

05 SERNO Serial Number 0-65000 --- --- 2 25

06 REP Repair Date 0-65000 --- --- 2 25

07 FLT3 Last Fault --- --- --- 1 25

08 FLT2 2nd Fault --- --- --- 2 25

09 FLT1 1st Fault --- --- --- 2 25

12 FOUT Output Frequency 0-400 --- Hz 1 25

13 VOUT Output Voltage 0-100 --- % 1 25

14 IOUT Output Current 0-650 --- A 1 26

15 LOAD Drive Load 0-200 --- % 1 26

16 TORQ Load Torque 0-200 --- % 1 26

17 TEMP Inverter Temp 2-105 --- C 1 26

18 TIME1 Total Run Time 0-65000 --- h 2 26

19 TIME2 Power On Hours 0-65000 --- h 2 26

1B FLUX Magnetizing Current 0-100 --- % 2 26

21 MODE Input Mode 0-36 0 --- 1 26&27

24 FSEL Reference Select 0-19 0 --- 2 27

27 TLSEL Torque Limit Select 0-6 0 --- 2 28

31 FMIN Min. Frequency 0.00-400 0 Hz 1 28

32 FMAX Max. Frequency 20.00-400 60 Hz 1 28

33 F2 Preset Speed #2 - Jog 0.00-400 5 Hz 1 28

34 F3 Preset Speed #3 0.00-400 20 Hz 2 28

35 F4 Preset Speed #4 0.00-400 40 Hz 2 28

36 F5 Preset Speed #5 (Note 2) 0.00-400 60 Hz 2 28

37 F6 Preset Speed #6 (Note 2) 0.00-400 0 Hz 2 28

38 F7 Preset Speed #7 (Note 2) 0.00-400 0 Hz 2 28

39 FTL Min. Frequency in Torque Limit 0.00-400 10 Hz 2 29

41 RSEL Ramp Selector 0-7 0 --- 2 29

42 ACC1 Acceleration Time #1 0.10-600 3 s 1 29

43 DEC1 Deceleration Time #1 0.10-600 3 s 1 29

44 ACC2 Acceleration Time #2 0.10-600 1 s 2 29

45 DEC2 Deceleration Time #2 0.10-600 1 s 2 29

46 DECTL Torq. Limit Response Time 0.10-30 1 s 2 29

47 DCBRK DC Brake Time 0-5 0.2 s 2 29

48 DCVLT DC Brake Voltage 0-15 Note 1 % 2 30

51 VSEL V/Hz Characteristic Selector 0-6 0 --- 2 30

52 BOOST Torque Boost 0-25 Note 1 % 1 30

53 FKNEE V/Hz Knee Frequency 26-640 60 Hz 2 31

Name Description Data

Range

Factory

Setting

Units Access

Level See

Page Customer

Setting

#

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

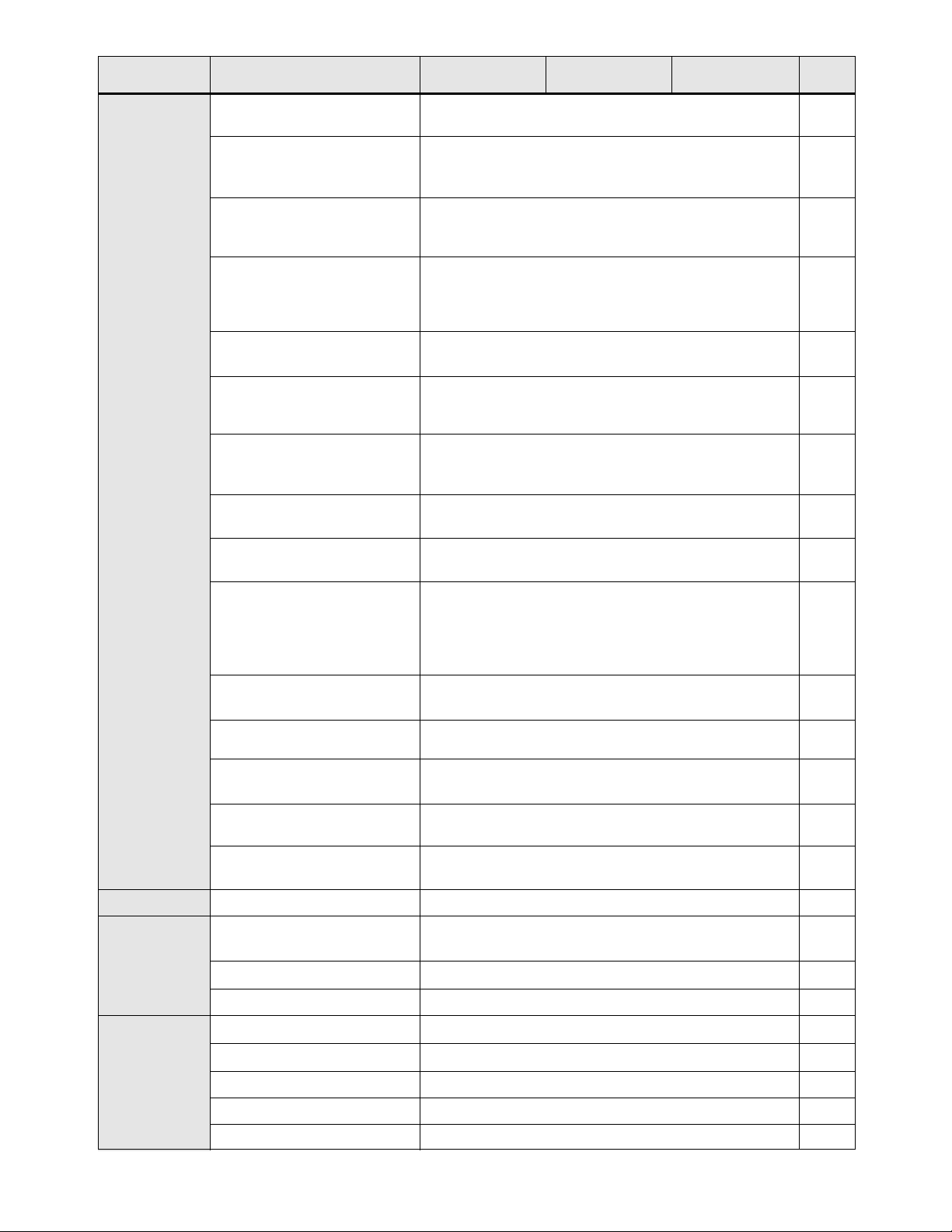

54 SKBND Skip Freq. Hysteresis Band 0.20-20 1 Hz 2 31

55 SK1 Skip Frequency #1 0.00-400 0 Hz 2 31

56 SK2 Skip Frequency #2 0.00-400 0 Hz 2 31

57 SK3 Skip Frequency #3 0.00-400 0 Hz 2 31

58 SK4 Skip Frequency #4 0.00-400 0 Hz 2 31

59 MVOLT Rated Motor Voltage 185-480 Note 1 V 2 31

5B IMAG Rated Magnetizing Current 15-85 Note 1 % 2 31

61 LTLF Load Torque Limit Forward 5-150 150 % 2 31

62 LTLR Load Torque Limit Reverse 5-150 150 % 2 31

63 RTLF Regenerative Torq. Limit FWD 5-110 80 % 2 31

64 RTLR Regenerative Torq. Limit REV 5-110 80 % 2 31

65 SLIP Slip Compensation 0-10 0 % 1 32

66 STAB Current Stability 0-4 2 --- 2 32

67 TOL Timed Overload Trip Point 0-100 0 % 1 32

68 NRST Restart Number 0-8 0 --- 2 33

69 DRST Restart Delay 0-60 0 s 2 33

6A TOLC Timed Overload Characteristic 0-7 0 --- 2 33

70 MCAL Meter Calibration 0-255

Set to 10VDC

--- 1 33

71 METER Analog Meter Output 0-7 1 --- 1 33

72 ST1 Auxiliary Output #1 0-11 6 --- 2 34

73 ST2 Auxiliary Output #2 0-11 3 --- 2 34

74 ST3 Auxiliary Output #3 0-11 7 --- 2 34

75 STR Auxiliary Relay (Fault) 0-11 2 --- 1 34

77 MOL Motor Overload Input 0-1 0 --- 2 34

81 PRGNO Special Program Number 0-65000 0 --- 2 34-39

82 START Inverter Start Options 0-7 0 --- 2 39

83 PWM Carrier Frequency Selector 0-8 1 --- 2 40

84 DISP Display Option Full Setting 0-65000 0 --- 2 42

85 UNITS Display Units ALPHA RPM_1 --- 2 42

86 LANG Display Language 0-3 0 --- 2 43

87 ACODE Security Access Code 0-999 0 --- 2 43

88 FRO Frequency Reference Output 0-1 0 --- 2 43

A2 RATIO Master Slave Speed Ratio (Note 2) 0-200 100 % 2 43

B1 OPTNO Option Board Number 0-6 0 --- 2 43

Cx CNTLx Event Control (1-9)

BINARY (8)

0 --- 2 34-39

Ex ECNTx Event Counts (1-9) 0-65535 0 --- 2 34-39

Name Description Data

Range

Factory

Setting

Units Access

Level See

Page Customer

Setting

#

Notes: 1. Default value is model dependent.

2. Parameter adjustable while drive is in the run mode.

See Section 5 for parameters accessible in Level 3 (SIO control).

See page numbers.

Program Code Summary (Con.’t.)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

TABLE OF CONTENTS Page

Section 1 – General Information

1.1 Preface.......................................................................................................................................... 1

1.2 Inspection...................................................................................................................................... 1

1.3 Control Identification Number........................................................................................................ 1

1.4 Control Specifications ................................................................................................................... 2

1.5 Input/Output Ratings..................................................................................................................... 5

1.6 AC Inverter Fundamentals............................................................................................................ 6

1.7 Description of Operation ............................................................................................................... 6

Section 2 – Installation Instructions

2.1 Rules for Installation...................................................................................................................... 7

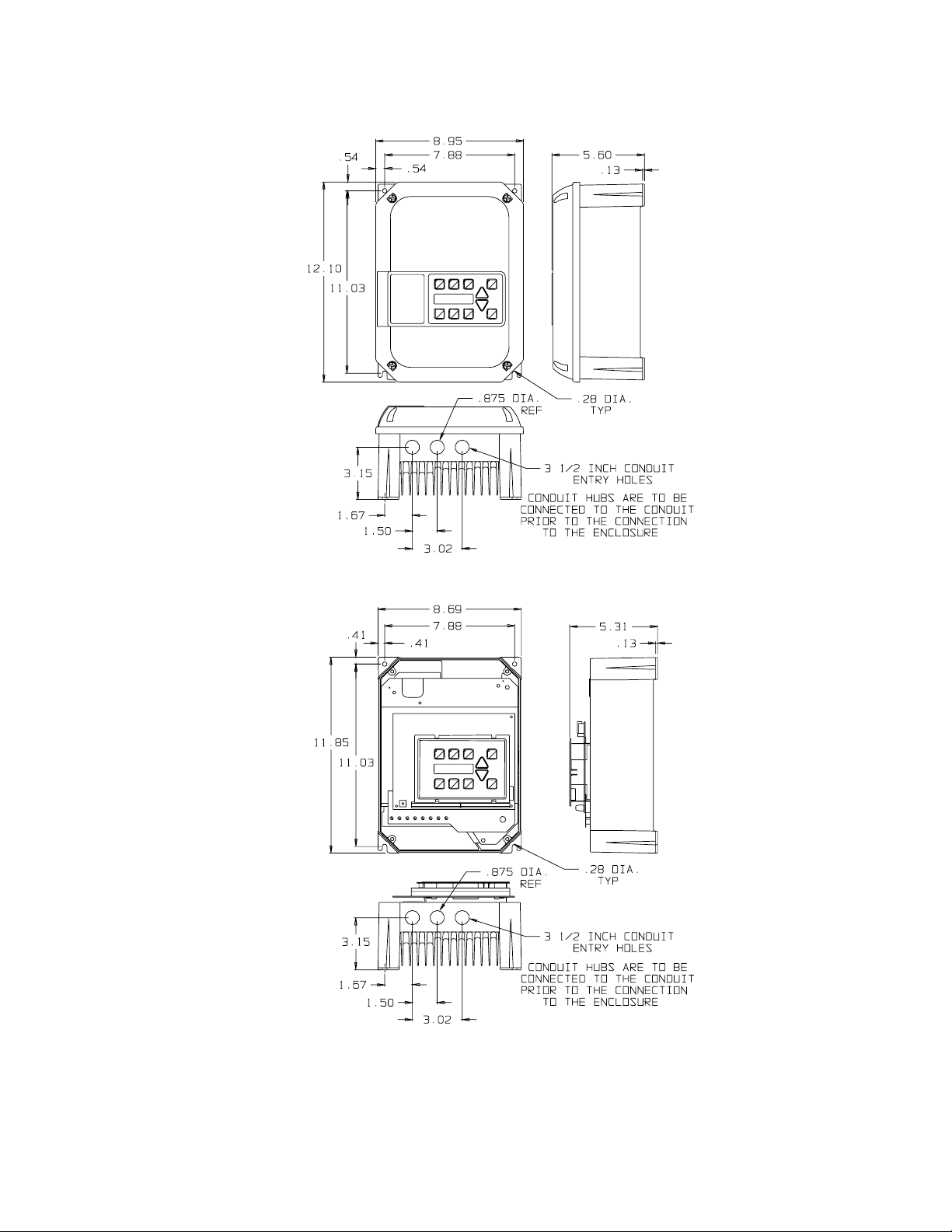

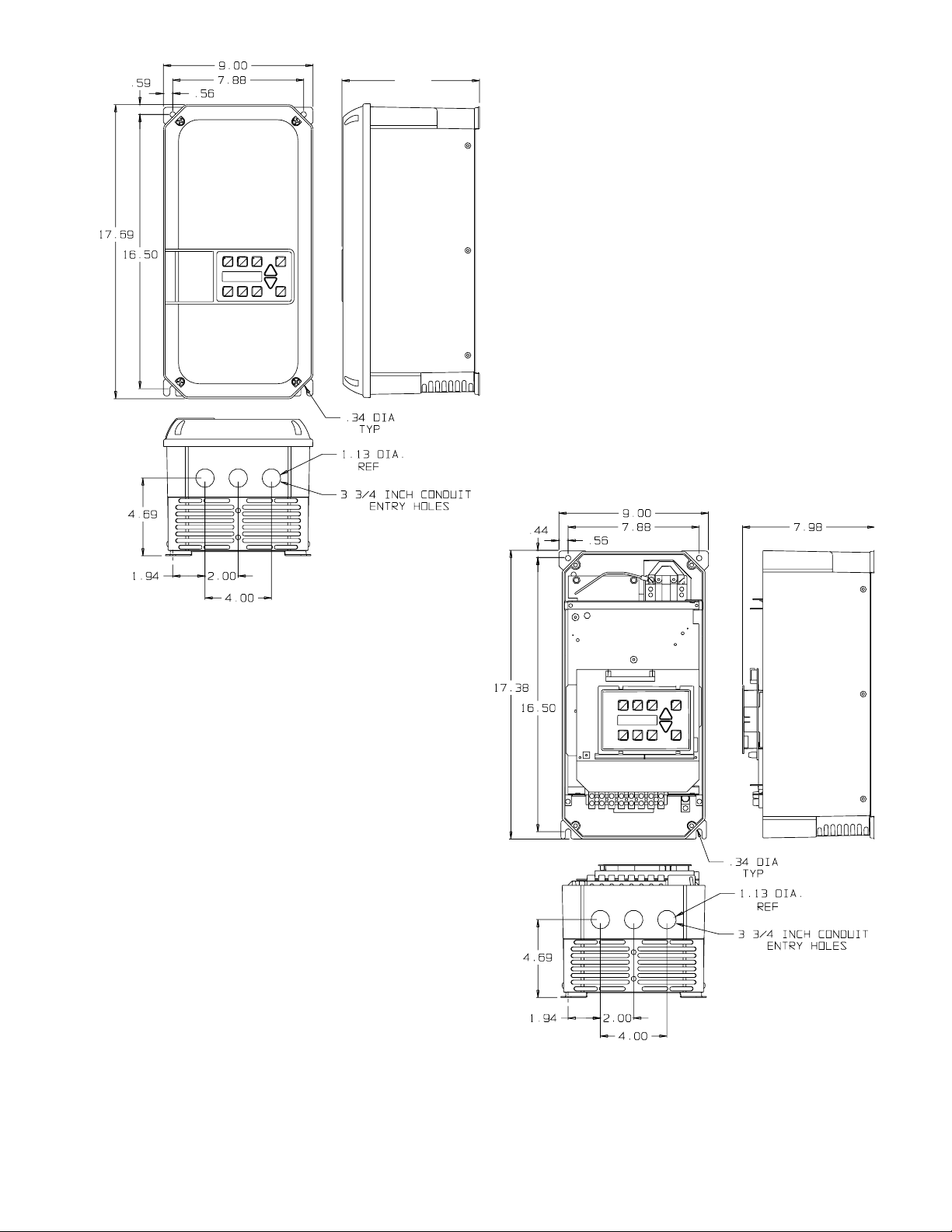

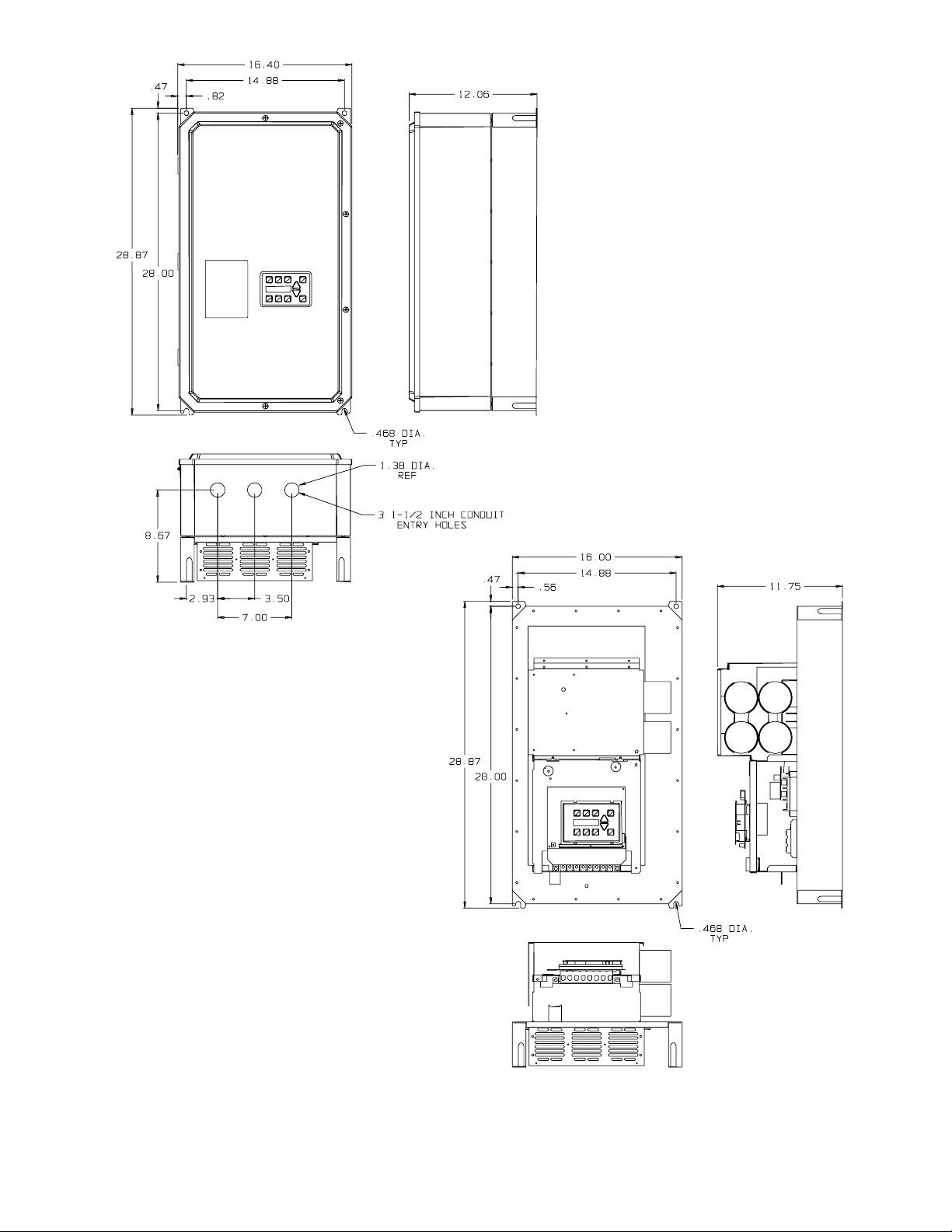

2.2 Dimensional Data.......................................................................................................................... 8

2.3 Input AC Line Requirements......................................................................................................... 12

2.4 Inverter Watt Loss......................................................................................................................... 13

2.5 Line Fuse or Circuit Breaker Sizing............................................................................................... 13

2.6 Wiring Practices............................................................................................................................ 13

2.7 Reducing Current Surges.............................................................................................................. 14

2.8 Function and Use of Terminals..................................................................................................... 15

2.9 Environment Considerations......................................................................................................... 17

Section 3 – Setup/Getting Started

3.1 General Information ...................................................................................................................... 18

3.2 Digital Keypad............................................................................................................................... 18

3.3 Operation Mode ............................................................................................................................ 19

3.4 Program Mode .............................................................................................................................. 20

3.5 Status (LED) Indicators................................................................................................................. 20

3.6 Description of Displays.................................................................................................................. 21

3.7 Operating Tips............................................................................................................................... 23

3.8 Quick-Start – Running the Motor................................................................................................... 23

3.9 High Torque Setup Procedure ...................................................................................................... 24

Section 4 – Level 1/Level 2 Parameters

4.1 Programming................................................................................................................................. 25

4.2 Parameter Descriptions................................................................................................................. 25

Section 5 – Level 3 Parameters

5.1 Program Code Summary .............................................................................................................. 44

5.2 Programming................................................................................................................................. 44

5.3 Parameter Descriptions................................................................................................................. 45

Section 6 – Applications

6.1 Connection Diagrams.................................................................................................................... 50

6.2 Options and Accessories .............................................................................................................. 52

6.3 Application Hints ........................................................................................................................... 53

Section 7 – Troubleshooting

7.1 Fault Codes................................................................................................................................... 54

7.2 Troubleshooting ............................................................................................................................ 55

7.3 Maintenance and Inspection......................................................................................................... 56

7.4 Replacement Parts........................................................................................................................ 57

Section 8 – Appendix A

8.1 Additional Publications.................................................................................................................. 59

8.2 Hassle Free Warranty................................................................................................................... 59

Section 9 – Appendix B – RFI Suppression and WLF Line FIlters

Section 1....................................................................................................................................... 60

Section 2....................................................................................................................................... 61

Section 3....................................................................................................................................... 62

Section 4....................................................................................................................................... 65

Section 5....................................................................................................................................... 66

Section 10 – Appendix C

CE Declaration of Conformity........................................................................................................ 68

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1

SECTION 1

GENERAL INFORMATION

1.1 Preface

This manual contains the specifications, installation instructions, description of operation, and troubleshooting

procedure for the WFCHT Series AC Inverters. Before installing the drive, read this manual carefully to ensure

correct installation and maximum performance. The information contained herein is considered current with

the release of version 4.2 (02-RVLVL) of the drive software.

1.2 Inspection

A. Upon receipt of the product, unpack the AC inverter and carefully inspect for any damage sustained in

transit (depression in the enclosure, damage to parts, missing parts). If damage is apparent, the freight or

express agent should be notified within 15 days of receipt of the product and a request be made that he

make an inspection of the merchandise; then a claim should be filed against the carrier. For UPS shipment

damage, save the box and packing material and notify TB Wood’s Incorporated immediately.

B. Next remove the AC inverter cover, if supplied, and inspect for any loose screws, nuts, or connectors.

C. Read the technical data plate and verify the correct horsepower size for the application and note the input

voltage and current required for the inverter.

D. If the inverter is to be stored for a long period of time, repack the inverter and store in a clean, dry place,

free from direct sunlight or corrosive fumes, and in a location where the ambient temperature will not be

less than -20° C (-4° F) nor more than 60° C (140° F).

1.3 Control Identification Number

A systematic numbering system is used to define all WFCHT models by torque output, input voltage rating,

horsepower rating, and enclosure type. This model number appears both on the shipping carton label and the

technical data label on the enclosure. A model number code is also accessible in the Level 1 programming

mode. (Refer to Section 4.2.)

This control number describes a constant torque, WFCHT

adjustable frequency control in a chassis configuration, rated

7.5 HP, with input voltage of 230 VAC.

The different horsepower ratings available and code for each

rating are as follows:

TABLE 1.3

*Input voltage, output voltage is 230 VAC 3 phase.

WF C 2 007-5 A HT

WFCHT Adjustable Frequency ______________________

Torque-C = Constant _____________________________

Input Volts 1 = 115 VAC ____________________________________

2 = 230 VAC _______

4 = 460 VAC _______

Horsepower 007-5 = 7-1/2 HP (See Table 1.3 below.)_____________________________

Housing – A = Chassis__________________________________________________

B = NEMA 1_______

C = NEMA 4_______

HT = High Torque_______________________ CODE HP 115V* 230V 460V

000-7 3/4 X

001-0 1XXX

002-0 2XX

003-0 3XX

005-0 5XX

007-5 7-1/2 X X

010-0 10 X X

015-0 15 X X

020-0 20 X X

025-0 25 X X

030-0 30 X

040-0 40 X

050-0 50 X

060-0 60 X

075-0 75 X

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

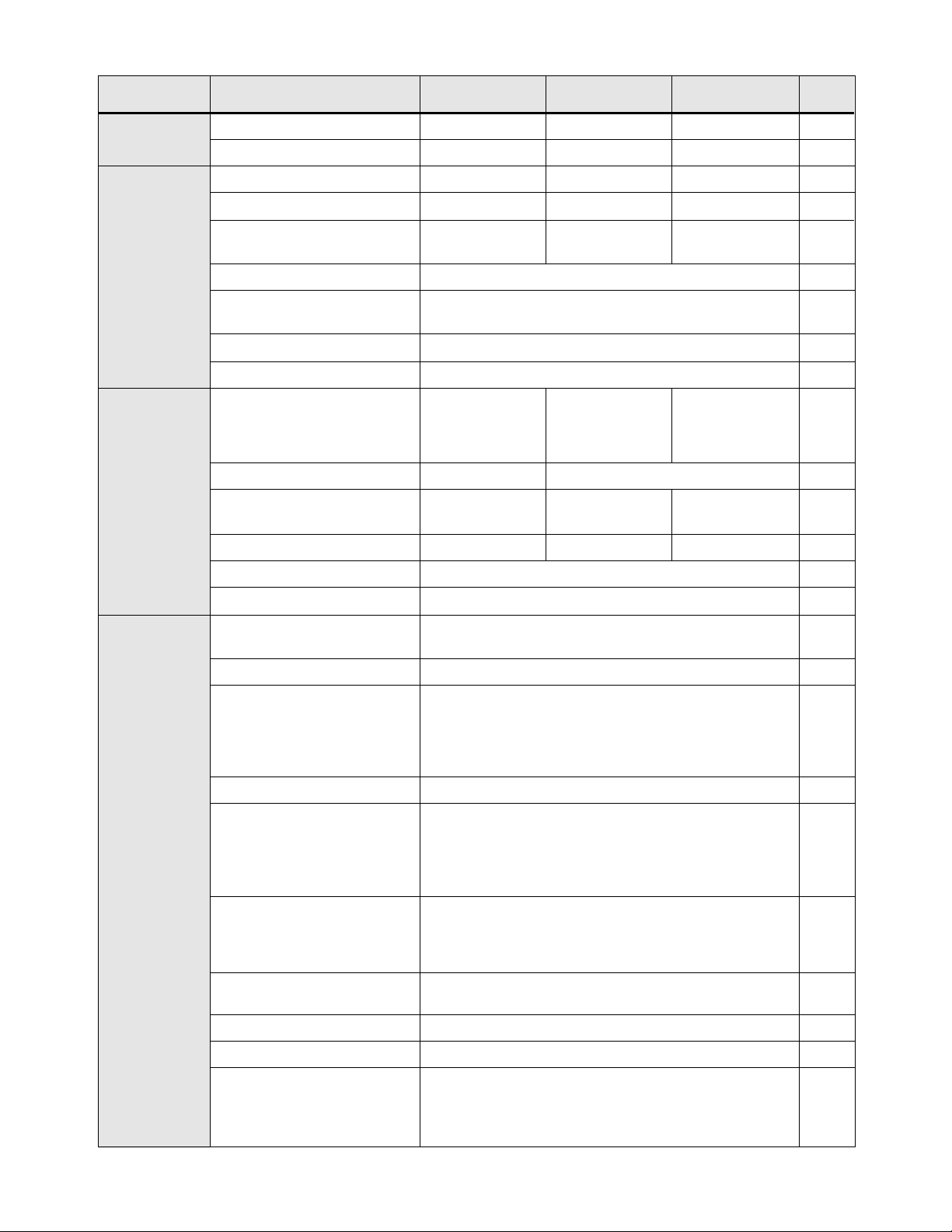

1.4 WFCHT Series Control Specifications

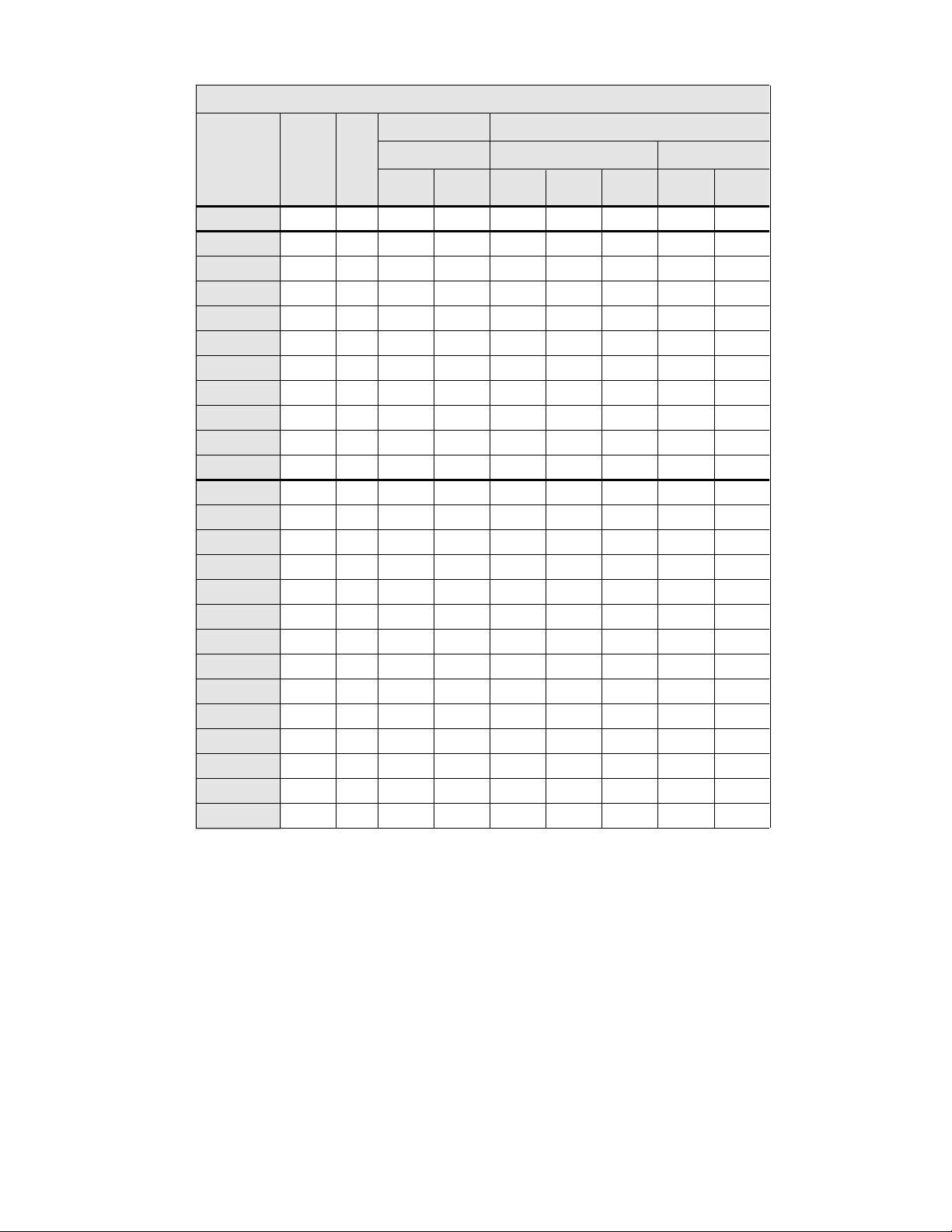

Model Series WFC1000 WFC2000 WFC4000

Horsepower (HP) CT/VT 1 0.75-25 1-75/1-100 5

Kilowatt (kW) 0.75 0.55-19 0.75-56 –

Capacity (kVA) 1.6 1.2-30 1.5-196 5

Continuous Amps 4.0 3-75 2-121 5

Output Voltage 3.5-230 VAC 3Ø3.5-230 VAC 3Ø7.0-460 VAC 3Ø–

(Source limited)

Frequency Range Programmable 0.1-400 Hz 28, 39

Overload Capacity @ 150% for 60 Seconds

40° C Ambient 120% for 90 Seconds 32, 33

Running Torque 150% at 2Hz 30

Efficiency @ Rated Output Greater than 95% –

Input Voltage 115 VAC 1Ø200-230 VAC 1Ø5, 12

(3Øinputs all 3-wire) (FHP-2 HP) 380-460 VAC

200-230 VAC 3Ø3Ø

(3-25 HP)

Voltage Tolerance ±10% -10%; +15% 12

Input Current @ Maximum 9.7 4.8-95 2.2-152.8 5

Rated Output (AC amperes)

KVA @ 50/60 Hz 1.2 1.1-38.1 1.8-122 5

Input Frequency 50/60 Hz ±10% –

Phase Imbalance 2% maximum 12

Control System Sensorless Vector Pulse Width Modulation with

Application Specific Integrated Circuit –

Frequency Range 4000:1, 0.1-400 Hz (Programmable) 28, 31

Frequency Command 0-10 VDC or 0-2 VDC (100 k Ω)

Selections 4-20 mA (237 Ω)

0-1 kHz or 0-10 kHz pulse train 15, 27

Digital Keypad

RS485 Serial Communication Link

Frequency Resolution 0.01 Hz –

Frequency Stability Analog +0.2%

0-1 kHz pulse train +0.4%

0-10 kHz pulse train +0.1% –

Keypad +0.1%

RS485 Port +0.1%

V/Hz Ratio Programmable using FKNEE function

(0.01 Hz resolution)

230 VAC output models – 0.36 to 8.84 31

460 VAC output models – 0.72 to 17.69

Acceleration/Deceleration Programmable – 0.1 to 600 seconds to maximum

Ramps frequency (primary and alternate available) 29

Minimum Frequency Programmable – 0.5 to 400 Hz (0.01 Hz increments) 28

Maximum Frequency Programmable – 20 to 400 Hz (0.01 Hz increments) 28

Torque Limit Four Quadrant Programmable – 5 to 150%

torque (motoring mode); 5 to 110% torque

(regenerative mode) Individual program settings for 28, 31

FWD run, FWD regen, REV run, & REV regen.

See

Page

Applicable

Motor Output

Inverter

Output

Ratings

@ 110%

Motor Ratings

Inverter Input

Ratings

Control

Specifications

TABLE 1.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3

Model Series WFC1000 WFC2000 WFC4000

Torque Limit Deceleration Programmable – 0.1 to 30 Seconds 29

Rate

Minimum Frequency in Programmable – 0.5 to 400 Hz 29

Torque Limit

Torque Boost Programmable to suit requirements plus Autoboost 30

Dynamic Braking 30-200% of drive rating (10 sec. max.) standard –

Consult factory for model specific data.

Additional capacity available by adding external DB kits.

Adjustments Over 100 parameters can be monitored with –

over 80 user adjustments

PWM Frequencies Two settings available 39

Agency Listing UL®and cUL®Listed; CE Marked –

Charge Indicator Indicates the presence of potentially lethal bus voltage 15

Ground Fault All models fully protected –

Output Short Circuit All models fully protected –

(Line-to-Line)

Electronic Motor Overload Programmable Inverse Time Overload Trip 32, 33

Overvoltage Trip Level 407 VDC 815 VDC –

(on DC bus)

Undervoltage Trip Level 180 VDC 400 VDC –

(on DC bus)

Torque Limit 4 Quadrant – Independently Programmable 28, 31

Program Lockout User definable security access code 42

Line Start Lockout Prevents automatic startup when line power 39

is applied (defeatable by programming)

Overtemperature Drive will shut down if heat sink temperature –

exceeds rating

DB Failure Drive will sense circuit failure and shut down –

Error/Fault Messages 19 fault codes 53

6 warning displays

Fault Storage Last three (3) faults stored. Most recent displayed. 25

Line Transient Limit 2 KV. Maximum (less than 40 microsecond duration) –

External MOL Contact Compatible with NC fault contact 17

Operating Controls 1. Keypad: Forward, Reverse, Jog, Stop, Program, 18

Shift, Enter, Local/Remote and Up/Down Arrows.

2. Terminal strip: See typical connection 16

diagrams or consult factory.

3. RS485 Serial Input/Output (SIO) Link. 43

LED Indicators Forward, Reverse, Jog, Stop, Bus Charged 20

and CPU Active

Display 2 – lines of 16 characters, Back-Lit

alphanumeric for all modes of operation.

Programmable to display in English, French, 21, 40

Spanish or German.

Any engineering units such as RPM, FPM, &

GPM are supported.

Auxiliary Relay Programmed as Fault Relay. Can be 17, 34

programmed to signal one of eleven conditions

See

Page

Control

Specifications

(continued)

Protection

Features

Operating

Features

TABLE 1.4 (Con’t.)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4

Model Series WFC1000 WFC2000 WFC4000

Programming Levels Level 1 – Operator Level 2 – Engineer 25, 43

Level 3 – Engineer with SIO

Parameter Block 00 Model #, software revision, rated current, heat –

Drive Data sink temp. trip point, mfg. serial #, repair

date code, & fault log.

Parameter Block 10 Output frequency, voltage, motor current, motor load, –

Status torque, drive temperature, elapsed time since power

applied, & total hours of operation.

Parameter Block 20 Definition of the LOCal/REMote keypad button in –

Control reference to the keypad, terminal strip, & the SIO link.

Also, various speed and torque references are

contained within this block.

Parameter Block 30 Various speed setpoints of the inverter. –

Frequencies

Parameter Block 40 Ramp time selections (the time from start –

Ramps to maximum frequency FMAX or

from FMAX to stop)

Parameter Block 50 V/Hz curves, boost, minimum frequency at –

Voltage/Frequency full voltage, & skip frequencies.

Characteristics

Parameter Block 60 Torque limit setpoints, slip compensation, overload –

Torque Limit trip point, & auto-restart parameters.

Parameter Block 70 METer output, open collector output, & –

I/O Definition fault relay definitions.

Parameter Block 80 Storage & Retrieval of standard or custom programs, –

Program Options complete reset to factory settings, auto-restart, line

start lockout, PWM selection, display of engineering

units, alternate display languages, & customer

access code storage.

Parameter Block 90 BAUD or communication rate, slave address, watch- –

RS485 Serial Link Options dog timer, & retrieval of SIO generated fault codes.

Parameter Block A0 Speed Ratio & various parameters relative to the –

Option Parameters calibration of WPC option cards

Parameter Block B0 Option Board Identification and various parameters –

Option Parameters relative to the calibration of WPC option cards

Parameter Block C0 Used with program sequencer to 35

Event Control Bytes control drive operation

Parameter Block E0 Used with program sequencer to 35

Event Count Bytes control drive operation

Chassis, NEMA 1, NEMA 4 NEMA 4 standard thru 50/60 HP –

Chassis/NEMA 1 In separate enclosure protected from dust, 7

moisture and corrosive fumes.

NEMA 1 Indoor protected from dust, moisture and corrosive fumes 7, 17

NEMA 4 Indoor protected from direct sunlight 7, 17

Operating Temperature Chassis – 0° C to 50° C NEMA 1/4 – 0° C to 40° C –

Storage Temperature -20° C to +60° C –

Humidity 90% RH or less, noncondensing (chassis controls) –

Vibration 0.6 G Maximum –

Elevation Less than 3,300 feet without derating –

See

Page

Programming

Construction

Mounting

Location

Ambient

Conditions

TABLE 1.4 (Con’t.)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

5

1.5 WFCHT INPUT/OUTPUT RATINGS

NOTES:

(1) Required data for sizing input wiring.

(2) CT Amps = Value stored in parameter 03-IRAT. Each model is capable of continuous operation at VT amps

rating. Required data for sizing motor wiring.

(3) For chassis models, ratings are for 1 minute @ +50°C. (40°C external ambient when enclosed.)

(4) Control rated for 110% of motor rating (continuous).

(5) For single phase applications greater than 5 HP, consult factory.

(6) Motor thermal overload relay rating – 1.1 x continuous motor nameplate amps. (Necessary only in multi-

motor applications.)

(7) If the KVA rating of the power source exceeds ten times this value, the use of an isolation transformer or a

line inductor is recommended.

WFC

HT

RATINGS BY MODEL NUMBERS

INPUT RATINGS MAXIMUM MOTOR RATINGS

CONTINUOUS

KVA

(7) AMP

(1) KVA CT.

AMPS (2) VT.

AMPS (2) KVA AMPS

Control

Model

Number

WFCHT

HP

CT/VT

Ø

(5) CONTINUOUS 1 MIN @ 40° C (3)

TABLE 1.5

1001-0 1/1 1 1.6 13.9 1.4 3.6 4.0 2.1 5.4

2000-7 0.75/0.75 1 1.4 6.1 1.1 2.8 3.1 1.7 4.2

2001-0 1/1 1 1.6 7.1 1.4 3.6 4.0 2.1 5.4

2002-0 2/2 1 3.3 14.4 2.7 6.8 7.5 4.1 10.2

2003-0 3/3 3 4.2 10.4 3.8 9.6 10.6 5.7 14.4

2005-0 5/5 3 7.0 17.6 6.1 15.2 16.7 9.1 22.8

2007-5 7.5/7.5 3 10.7 26.9 8.8 22.0 24.2 13.2 33.0

2010-0 10/10 3 13.6 34.2 11.2 28.0 30.8 16.8 42.0

2015-0 15/15 3 21.6 54.3 16.7 42.0 46.2 25.0 63.0

2020-0 20/20 3 27.2 68.2 21.5 54.0 59.4 32.3 81.0

2025-0 25/25 3 34.7 86.9 27.1 68.0 74.8 40.6 102.0

4001-0 1/1 3 1.8 2.2 1.6 2.0 2.2 2.4 3.0

4002-0 2/2 3 3.4 4.3 2.9 3.7 4.1 4.4 5.6

4003-0 3/3 3 4.9 6.2 4.4 5.5 6.1 6.6 8.3

4005-0 5/5 3 8.6 10.8 7.2 9.0 9.9 10.8 13.5

4007-5 7.5/10 3 12.8 16.0 10.4 13.0 14.3 15.5 19.5

4010-0 10/15 3 17.7 22.2 14.3 18.0 19.8 21.5 27.0

4015-0 15/20 3 24.7 31.0 19.1 24.0 26.4 28.7 36.0

4020-0 20/25 3 30.2 37.9 23.9 30.0 33.0 35.9 45.0

4025-0 25/30 3 39.7 49.8 31.1 39.0 42.9 46.6 58.5

4030-0 30/40 3 45.3 56.8 35.9 45.0 49.5 53.8 67.5

4040-0 40/50 3 61.4 77.1 48.6 61.0 67.1 72.9 91.5

4050-0 50/60 3 75.5 94.7 59.8 75.0 82.5 89.6 112.5

4060-0 60/75 3 90.0 112.0 71.0 90.0 98.0 106.4 133.5

4075-0 75/100 3 111.0 134.0 88.0 110.0 121.0 131.5 165.0

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

6

1.6 AC Inverter Fundamentals

The principle of operation of the WFCHT, or any AC inverter, is to provide both an adjustable voltage and an

adjustable frequency to the AC motor. The WFCHT automatically maintains the required volts/hertz ratio,

allowing the AC motor to run at its optimum efficiency and providing rated torque capability throughout the

motor’s speed range. The basic formula that relates the output frequency to motor speed is:

Ns = 120 x f Ns = Synchronous Speed (RPM)

P f = Frequency (Hertz)

P = Number of Poles in Motor

For Induction Motors:

Motor RPM = Synchronous Speed – Motor Slip (RPM)

The number of poles of a particular motor, and the amount of slip for a given load torque, are set by the

motor’s design and manufacturer.

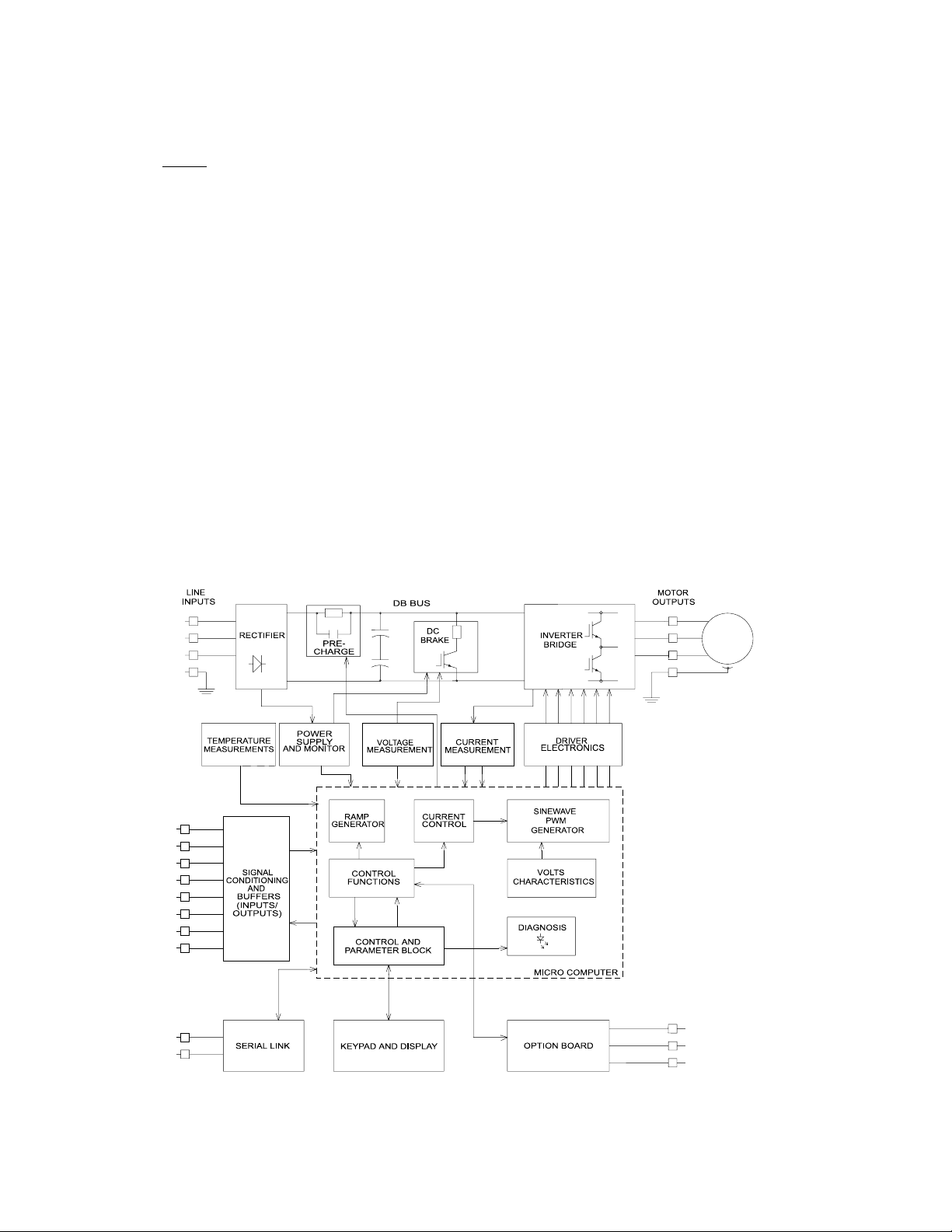

1.7 Description of Operation

The primary functional blocks of the inverter are outlined in Figure 1.7.

The ultimate goal of any inverter is to accept fixed voltage and frequency from a power source and convert this

power into variable voltage and frequency to control a three phase AC induction motor. The WFCHT does this

and much more. It allows the user to interface into the very powerful electronics necessary to provide variable

speed control of the motor, in a very friendly fashion.

Signals can be introduced to the terminal strip for full or partial control of the inverter. The powerful serial input

output (SIO) link is available for total communication and programming. The keypad provides total control of

programming and drive operation.

FIGURE 1.7

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

7

SECTION 2

INSTALLATION AND ENCLOSURE DIMENSIONS

2.1 General Rules for Installation

Improper installation of the inverter will greatly affect its life. Be sure to observe the following points when

selecting a mounting location.

A. Do not install the inverter in a place subjected to high temperature, high humidity, or excessive vibration.

(Consult Table 1.4 for temperature, humidity and maximum vibration limits.)

B. Mount the unit vertically and do not restrict the airflow to the heat sink fins on the back of the control. The

fan and fins allow cooling of internal components. Any air restriction could greatly reduce the life of the

inverter, as well as resulting in nuisance over temperature trips.

C. The WFCHT generates heat. Allow sufficient space around the unit, as shown in the illustration. If mounted

in an enclosure with other equipment, be sure to allow at least five (5) inches of space on each side for

adequate ventilation.

D. For totally-enclosed chassis models (fins inside the enclo-

sure), consult TB Wood’s Incorporated for enclosure sizing

and mounting instructions.

E. Do not mount the WFCHT near heat generating equipment or

in direct sunlight.

F. Explosion proof Applications – Part of the criteria for an

explosion proof rating is that the motor is designed and

tested to ensure that its outer surface temperature does not

exceed prescribed levels. These limits can be easily

exceeded if the motor is operated from an AC inverter. A few

manufacturers of explosion proof motors have received UL®

certification for their products when used on AC inverters.

These motors have very strict operating speed limits and

other disclaimers to protect the companies in case an

accident occurs involving their product. Explosion proof

motors that are not rated for inverter use lose their

certification when used for variable speed. Due to the many

areas of liability that may be encountered when dealing with

these applications, the following statement of Company

Policy applies:

TB Wood’s Incorporated AC Inverter products are sold for suitability with explosion proof AC motors rated

for use with PWM inverters. These motors must be UL listed for use with either TB Wood’s AC inverters or

with PWM inverters and used within the specified speed ranges and carrier frequencies. TB Wood’s

accepts no responsibility for any direct, incidental or consequential loss, cost or damage associated with

the misapplication of our AC products in these applications. In any misapplication, the purchaser expressly

agrees to assume all risk of loss, cost or damage that may arise. TB Wood’s Incorporated will not

knowingly approve the application of their AC inverters with motors not rated for such applications.

G. Line Starting – WFCHT is designed to provide controlled starting and stopping of AC motors by use of the

keypad or external contacts connected to the control terminal strip. WFCHT may also be started by applying

AC power to terminals L1, L2, and L3. The inverter has line-start-lockout as a standard feature, to prevent

automatic starting when line power is applied. This provision can be defeated by appropriate programming.

The inverter may be started once every two minutes in this mode.

H. Chassis Model Installation -- The Chassis style WFCHT series is shipped with the keypad attached to the

inverter, but it can be removed and attached to an enclosure front cover or remote station (See Section

6.2). Note: CE specifications require that any system component housed within an enclosure,

cannot have an attached operator control. Therefore, the keypad must be removed from the

inverter and attached to an enclosure panel to maintain CE compliance in these cases.

FIGURE 2.1

MORE

THAN

5 IN.

MORE

THAN

5 IN.

MORE

THAN

5 IN.

MORE

THAN

5 IN.

®

WFC

HT AC

INVERTER

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

8

2.2 Dimensional Data

The following pages show the dimensional data for the NEMA 4 and chassis style WFCHT Inverters. Use this

data and the General Rules for Installation to select a suitable mounting location.

FHP-5 HP

NEMA 4 & CHASSIS MODELS

FIGURE 2.2

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

9

7.5-10 HP 230 VAC

7.5-20 HP 460 VAC

NEMA 4 & CHASSIS MODELS

FIGURE 2.3

8.33

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

10

15-20 HP 230 VAC

25-30 HP 460 VAC

NEMA 4 & CHASSIS MODELS

FIGURE 2.4

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

11

25 HP 230 VAC

40-75 HP 460 VAC (NEMA 1/NEMA 4 MODELS)

40-75 HP 460 VAC (CHASSIS MODELS)

FIGURE 2.5

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2.3 Input AC Line Requirements

The allowable AC line voltage fluctuation is -10% to +15% of nominal line voltage. A supply voltage above or

below these limits could cause the inverter to trip out with either an overvoltage or an undervoltage fault.

NOTE:

Caution must

be exercised

when applying

WFCHT Invert-

ers on low line

conditions.

For example, a WFC2000 Series Inverter will operate properly on a 208 VAC line. However, the maximum

output voltage will be limited to 208 VAC. If the motor is rated for 230 VAC line voltage, higher motor currents

and increased heating will result. Ensure that the voltage rating of the motor matches the applied line

voltage.

If other than 60 Hz output can be tolerated, proper volts/hertz can be programmed into the inverter by the 53-

FKNEE and 32-FMAX parameters. If you are unsure about this feature, consult Section 4.2 or the factory.

Phase voltage imbalance of the input AC source can cause unbalanced currents and excessive heat in the

input rectifier diodes and in the DC bus capacitors of the WFCHT. Phase imbalance is calculated by the

following method:

Assume: The voltage from L1 to L2 = La

The voltage from L2 to L3 = Lb

The voltage from L1 to L3 = Lc

The average line voltage = Lavg

Determine the absolute value of the difference between each of the line voltages (La, Lb, & Lc) and Lavg.

(Subtract the two values and disregard the sign of the result.) Consider the results of this calculation to be

Laa, Lba, & Lca.

Phase Imbalance (%) = Laa + Lba + Lca x 100%

2 (Lavg)

Example:

Measured phase voltages of 230, 235, & 240 would result in a calculated phase imbalance of 2.1%.

If the resulting phase imbalance exceeds 2%, consult your local power company or plant maintenance

personnel and ask them to investigate this problem and recommend methods of correcting this condition.

Phase imbalance can be damaging to motors running Across-the-Line also. A 2% imbalance requires a 5%

derating factor on the motor, 3% imbalance requires a 10% derating, 4% requires an 18% derating.

CAUTION: NEVER USE POWER-FACTOR IMPROVEMENT CAPACITORS ON THE WFCHT MOTOR

TERMINALS, M1, M2, AND M3, OR DAMAGE TO THE INVERTER’S SEMICONDUCTORS WILL RESULT.

A. Single Phase Operation

Certain models of WFCHT series AC inverters are designed for single phase input. The output is still 230

VAC, three phase; therefore, do not connect single-phase motors to the inverter’s output terminals

as damage may occur.

Models WFC1001-0 (115 VAC), WFC2000-7 (230 VAC), WFC2001-0, and WFC2002-0 are designed

specifically for single phase input. For other requirements, please contact the factory.

B. Line Starting

WFCHT is designed to provide controlled starting and stopping of AC motors by use of the keypad or

external contacts connected to the control terminal strip. WFCHT may also be started by applying AC power

to terminals L1, L2, and L3. The inverter has line-start-lockout as a standard feature, to prevent automatic

starting when line power is applied. This provision can be defeated by appropriate programming. The

inverter may be started once every two minutes in this mode.

12

WARNING

DISCONNECT POWER BEFORE SERVICING THIS CONTROL.

HAZARDOUS VOLTAGES EXIST UNTIL CHARGE LIGHT GOES OUT.

AVERTISSEMENT

COUPER L’ALIMENTATION AVANT D’ENRERENORE LE DEPANNAGE DU SYSTEME ELECTRIQUE.

VOLTAGE DANGEUREUX EXISTE TANT QUE LA LUMIERE INDICATRICE RESTE ALLUMÉ.

Input Power Transformer Rating

Lavg = La + Lb + Lc

3

Rated HP FHP 1 2 3 5 7-1/2 10 15 20 25 30 40 50 60 75

Minimum 2 2 4 5 9 13 18 25 31 40 46 62 76 90 112

KVA Rating

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

This manual suits for next models

2

Table of contents