TBEI Rugby LR-2066 User manual

TRUCK BODIES & EQUIPMENT INTERNATIONAL, Inc.

Website: www.rugbymfg.com

E-mail: [email protected]

Phone: 1-800-869-9162 03 5839

MODEL LR-2066 &

LR-2866A HOIST

INSTALLATION AND

OPERATION MANUAL

To Be Filled In By Installer

HoistSerial#:

Pump Installation and

Operation Manual #:

InServiceDate:

Dealer:

Address:

City,StateZIP:

Dealer Phone Number:

Use this manual ONLY if installing or operating a model LR-2066 or LR-2866A hoist. This manual should

be kept in the glove compartment of the truck for reference when needed.

Original Revision: March 1, 1996

Current Revision: G November 5, 2007

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 2 of 21

"HYDRAULIC SYSTEM"

The hydraulic system supplied with a given hoist manufactured by TBEI-Rugby is made up of

components (pump, valves, reservoir, hoses, cylinder, etc.) that are designated to be compatible with

each other.

WARNING: If you substitute hydraulic components, it is your responsibility to BE SURE they are

compatible with the other components supplied by TBEI-Rugby. Incompatible

hydraulic components may cause failure of the hoist that, in turn, could damage the

vehicle, damage other property, and cause human injury or death.

All TBEI-Rugby's liability and warranty for a given hoist will be voided, if it is determined by TBEI-

Rugby, that substituted hydraulic components were incompatible with those supplied by TBEI-Rugby.

Several hoist parameters are given in the following table, these parameters are given as a general

guide. To ensure component compatibility, consult TBEI-Rugby.

HOIST MODEL LR-2066

LR-2866A

“MAXIMUM”

HYDRAULIC FLOW

RATE (GPM)

18 GPM

“MAXIMUM”

PRESSURE FOR

RAISING PORTION OF

DUMP CYCLE (PSI)

3200 PSI

“MAXIMUM”

PRESSURE FOR

LOWERING PORTION

OF DUMP CYCLE (PSI)

1000 PSI

WARNING: Adjusting the hydraulic pressure to more than the recommended setting may cause the

hoist to fail during the dumping of a load. This could cause damage, serious injury, or

death. Never adjust the pressure on your own. Consult the manufacturer if the

hydraulic pressure is in question. Have only a qualified person set the hydraulic

pressure. Never adjust the pressure to more than the recommended amount.

NOTE: A manual for the hydraulic system is supplied separate from this manual. Refer to the

hydraulic system manual for details on the installation and operation of the hydraulic

system.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 3 of 21

"WARNINGS"

WARNING: Installing or operating this hoist without first understanding the proper installation and

operation procedures can lead to serious injury or death. Always read and understand

fully all installation and operation manuals before installing or operating this

equipment.

WARNING: Welding, oxy-fuel cutting, or grinding sparks can cause fuel to ignite that in turn can

lead to injury or death. Always take adequate steps to avoid ignition of fuel from fuel

tanks when welding, grinding, or oxy-fuel cutting during equipment installation.

WARNING: Heat from the truck's exhaust system can cause hydraulic component failure and may

lead to a fire that could cause injury or death. Always install equipment in locations

where heat from the exhaust system will not damage any hydraulic component.

WARNING: Being under a raised body can result in serious injury or death should the body

unexpectedly descend. Never position yourself or allow others to position themselves

under a loaded body. Always prop the unloaded body up using the body prop or body

props supplied. Remember body props are to be used only on an unloaded body.

When two props are provided, both props must be used.

WARNING: Malfunctioning equipment can cause property damage, injury or death. Always have

faulty equipment repaired before continuing its use. Consult the manufacturer if

required.

WARNING: Overloading of a body can cause vehicle or body component damage or an accident

which may cause injury or death. Never exceed the gross vehicle weight (GVW) or the

gross axle weight (GAW) rating of your vehicle.

WARNING: The inadvertent shorting of the vehicle's electrical supply can cause a fire or equipment

damage that could lead to injury or death. Always disconnect the vehicle battery prior

to installing, servicing, or repairing the power unit.

WARNING: Damage to brake lines during equipment installation, or installing bolts or equipment in

such a way that the line will rub and become damaged can lead to brake failure which

can cause an accident and can lead to severe injury or death. Always take adequate

steps to prevent brake line damage during installation and isolate brake lines from

installed equipment.

WARNING: Connecting the hoist to a hydraulic system with more pressure (psi) or flow (gpm) than

is recommended by the hoist manufacturer can cause the hoist to fail during the

dumping of a load. This could lead to damage, serious injury, or death. Be sure you

have the correct pressure and flow.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 4 of 21

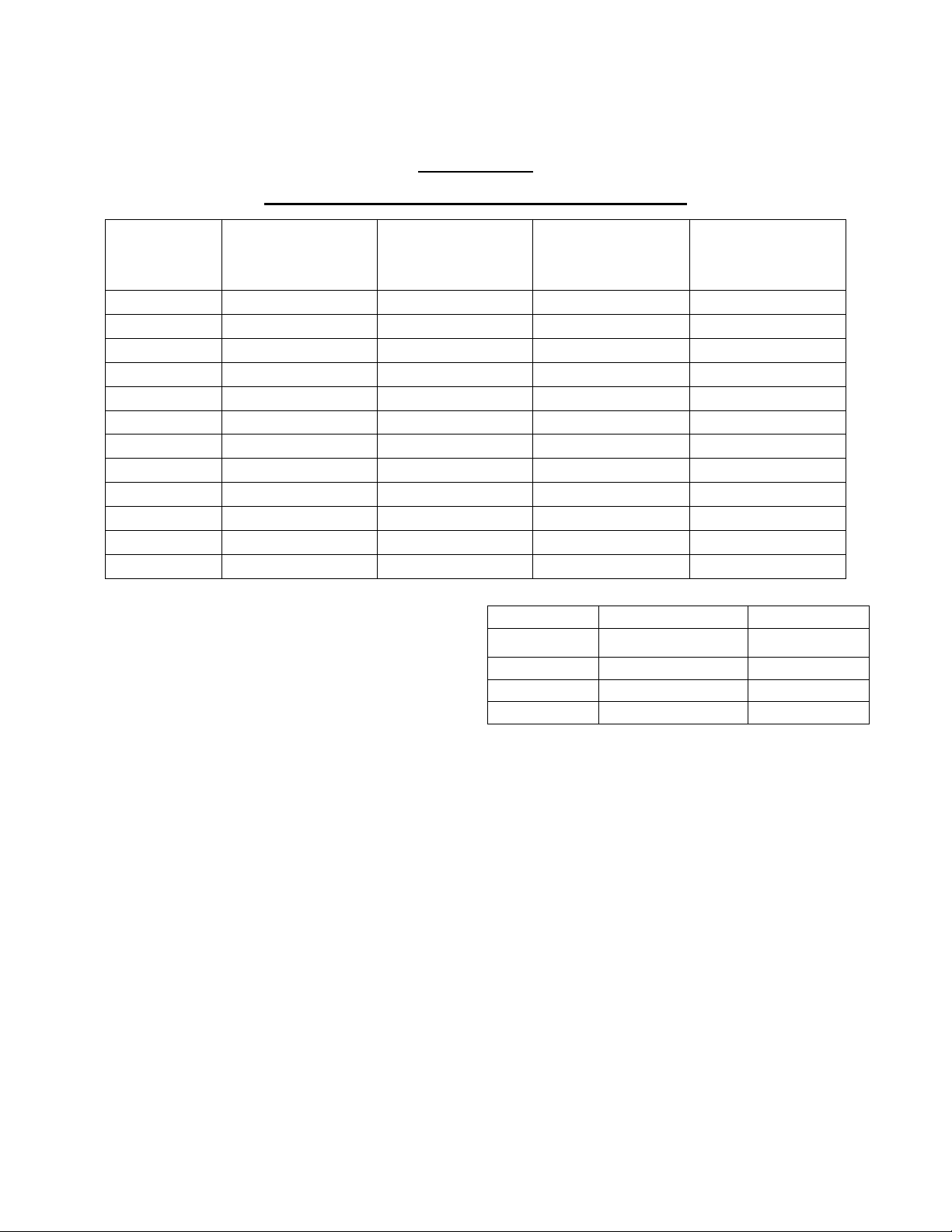

FIGURE 1

Capacities are based on the following:

1. Water level non-diminishing loads.

2. The hydraulic relief pressure set at the maximum 3,200 psi (see page 2 of this manual).

IMPORTANT: Because of variations in applications, the data contained in this sheet is provided only

as a general guide.

IMPORTANT: NR stands for Not Recommended. Contact TBEI-Rugby Engineering before using in

an application listed as NR.

0

&7

:%

$3352;

67$1'$5'

02817,1*

5(9(56(

02817,1*

5($5

+,1*(

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 5 of 21

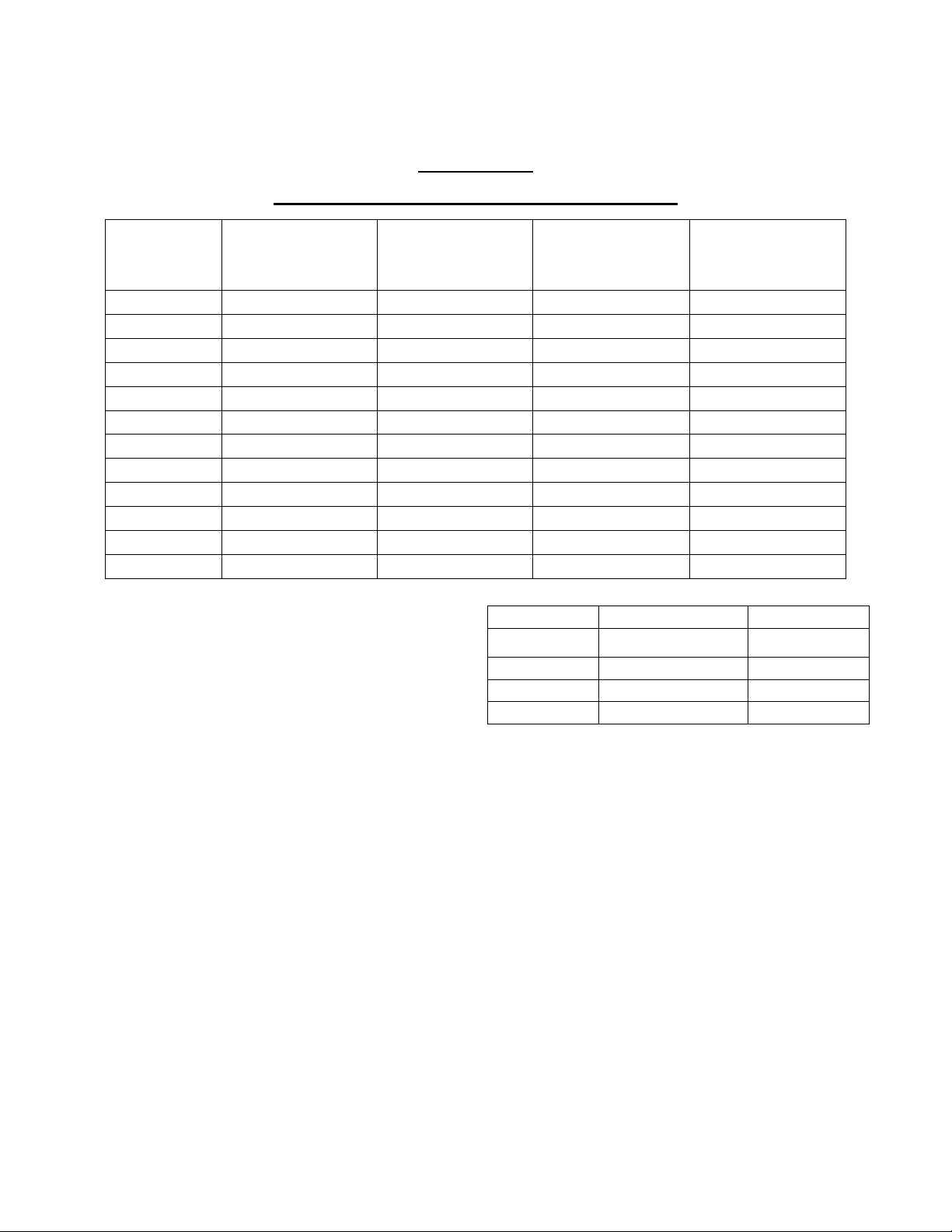

TABLE A

LR-2066 APPLICATION CHART

BODY

LENGTH OVERHANG

CAPACITY

40° DUMP

ANGLE

CAPACITY

45° DUMP

ANGLE

CAPACITY

50° DUMP

ANGLE

12’ 24” 37.8 TONS 34.0 TONS 30.9 TONS

12’ 12” 30.3 TONS 27.2 TONS 24.7 TONS

14’ 36” 37.8 TONS 34.0 TONS 30.9 TONS

14’ 24” 30.3 TONS 27.2 TONS 24.7 TONS

14’ 12” 25.2 TONS 22.6 TONS 20.6 TONS

15’ 36” 33.6 TONS 30.2 TONS 27.4 TONS

15’ 24” 27.5 TONS 24.7 TONS 22.4 TONS

15’ 12” NR 20.9 TONS 19.0 TONS

16’ 36” 30.3 TONS 27.2 TONS 24.7 TONS

16’ 24” NR 22.6 TONS 20.6 TONS

18’ 36” NR NR 20.6 TONS

18’ 24” NR NR 17.6 TONS

LR-2066 REVERSE STANDARD

M DUMP ANGLE M

108.75” 40° 111.25”

97.25” 45° 99.75”

88.00” 50° 90.50”

DUMP CLASS: 70

CONVERSION CLASS: G

Two Cylinders, 6” Piston, 20” Stroke

8.38” Mounting Height

7” long beams recommended

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 6 of 21

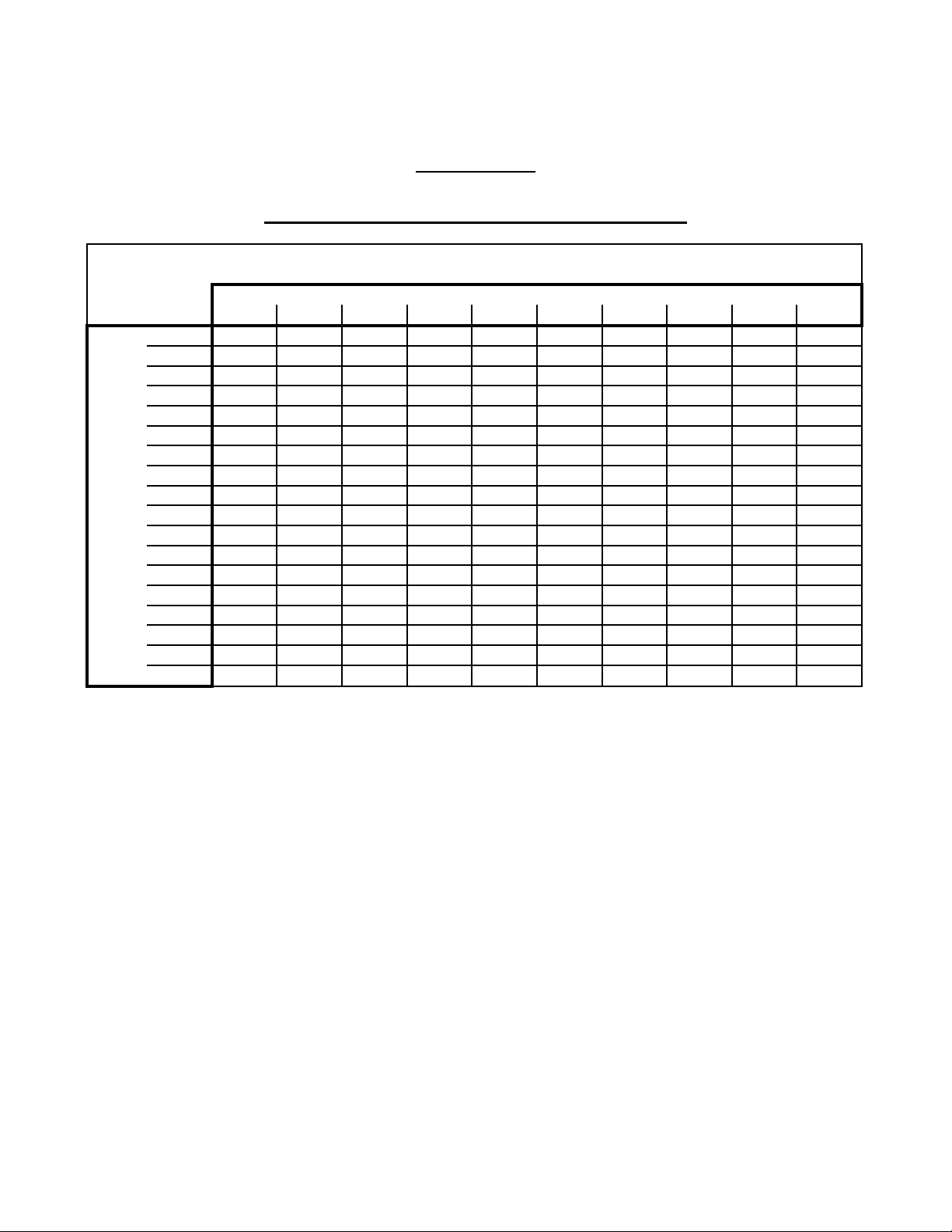

TABLE A

LR-2866A APPLICATION CHART

BODY

LENGTH OVERHANG

CAPACITY

40° DUMP

ANGLE

CAPACITY

45° DUMP

ANGLE

CAPACITY

50° DUMP

ANGLE

17’ 30” 36.0 TONS 32.2 TONS 29.2 TONS

17’ 24” 33.2 TONS 29.8 TONS 27.0 TONS

18’ 42” 39.2 TONS 35.2TONS 31.9 TONS

18’ 36” 36.0 TONS 32.2 TONS 29.2 TONS

19’ 42” 36.0 TONS 32.2 TONS 29.2 TONS

19’ 36” 33.2 TONS 29.8 TONS 27.0 TONS

20’ 42” 33.2 TONS 29.8 TONS 27.0 TONS

20’ 36” 30.8 TONS 27.6 TONS 25.0 TONS

20’ 30” 28.8 TONS 25.8 TONS 23.4 TONS

20’ 24” 27.0 TONS 24.2 TONS 21.9 TONS

22’ 48” 30.8 TONS 27.6 TONS 25.0 TONS

22’ 42” 28.8 TONS 25.8 TONS 23.4 TONS

LR-2866A REVERSE STANDARD

M DUMP ANGLE M

139.75” 40° 142.00”

124.75” 45° 127.25”

113.00” 50° 115.25”

DUMP CLASS: 90

CONVERSION CLASS: J

Two Cylinders, 6” Piston, 28” Stroke

10.38” Mounting Height

9” long beams recommended

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 7 of 21

"INSTALLATION INSTRUCTIONS"

1. Mark the location for the rear hinge. This location should be immediately behind a truck cross

member, approximately 45" behind the center of the trunion. Refer to Figure 1 and the charts

for the specific hoist model you are installing.

NOTE: If a distance of 54" is exceeded between the rear hinge and the center of the trunion,

additional reinforcement of the truck frame will be required.

2. Referring to Figure 2, cut a notch as shown.

NOTE: To determine the

height of the notch, subtract the

distance from the bottom of the

long-sill to the top of chassis

frame from 4-5/8”. Typically,

this will be about 3-1/4”.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 8 of 21

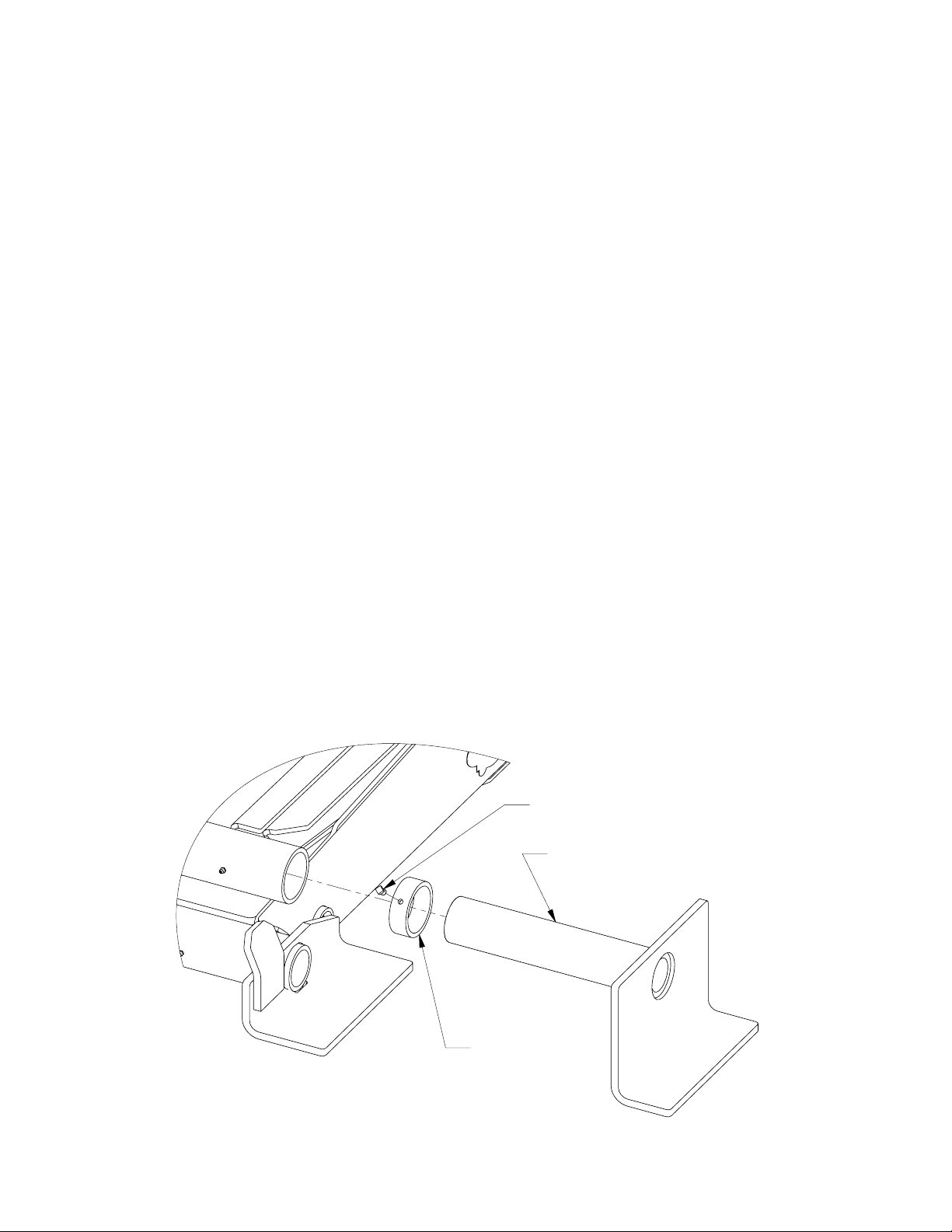

3. Position the rear hinge angle in the notch cut in Step 2. The rear hinge angle is 38 1/16" wide

and should be centered side to side in the notch as illustrated in Figure 3. Weld the rear hinge angle to

each of the truck chassis frame rails.

NOTE: This hinge assembly is designed for a truck longsill spacing of 34" and is not

recommended for any other width.

NOTE: The distance between the rear hinge shaft center and the saddle center is referred to as

the "M" dimension. In Table A, the "M" dimension for several dump angles are

tabulated.

NOTE: Moving the hoist rearward or forward along the truck frame will affect the hoist's

performance. A forward movement will reduce the dump angle and will increase

capacity while a rearward movement will increase the dump angle and reduce capacity.

NOTE: If an obstruction can not be cleared by moving the hoist forward or rearward, the hoist

may be reverse mounted as shown in Figure 1.

/,)7,1*6+$)7$66(0%/<

/2&.&2//$5

6(76&5(:

4. Locate the hoist on the truck frame, making sure to center the hoist right and left, and to square

the hoist with the truck frame. This hoist is designed to rest on the truck frame as shown in

Figure 1. A small portion of the hoist extends below the truck frame level. The hoist may

have to be moved forward or rearward to avoid obstructions below the frame level.

5. Slide a lock collar onto each lifting shaft. Slide a lifting shaft with collar into each end of the

hoist lifting tube. See Figure 4.

FIGURE 4

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 9 of 21

6. When the hoist is positioned, place a mounting angle under each side of the hoist saddle.

Secure each mounting angle to the truck frame by drilling three 17/32" dia. holes and installing

three 1/2" screws, three 1/2" lock washers, and three 1/2" nuts. Torque all 1/2” fasteners to 90

ft-lb. See Figure 5.

7. Weld each saddle bracket to the corresponding mounting angle. See Figure 5.

NOTE: Do not weld the hoist or mounting angle to the truck frame.

6$''/($66(0%/<

02817,1*$1*/(

758&.)5$0(

187

%2/7

/2&.

:$6+(5

NOTE: The hoist saddle must set directly on the truck frame. If rivet interference is

encountered, counter sink the rivet head into the hoist saddle.

FIGURE 5

8. Position and secure the liner (sleeper) to the truck frame. The LR-2066 hoist requires at least

8 3/8" of clearance above the truck frame. As an example, if 7" long beams are on the truck

body, a liner of at least 1 3/8" will be required to gain enough room, 8 3/8", for mounting the

LR-2066. Similarly, a LR-2866A requires 10 3/8" of clearance.

9. Position the body with the long beams (just long beams if they are separate from the body)

onto the truck frame.

NOTE: A clearance of at least 2" is required between the truck cab and the closest point on the

truck body.

10. Position the rear hinge brackets against the long beams. Once in position, weld the rear hinge

brackets to the body long beams by welding all edges where the rear hinge bracket contacts the

long beam.

11. Position a lifting shaft sub-assembly and flats next to each channel long beam. Refer to figure

6. Slide each of the lifting shafts all the way against the inside of the long beam. Weld the

lifting shaft angles to secure the shaft to the long beam as shown in Figure 6. With the shaft

secured, slide the lock collars against the hoist lifting tube and lock them there by tightening

the set screw (see Figure 4 and 6). Torque the setscrew to 24 ft-lb.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 10 of 21

/,)7,1*6+$)7

68%$66(0%/<

6758&785$/&+$11(/

/21*6,//

[

[)/$7

+2,67

6$''/(

+2,6772%2'<$77$&+0(17'(7$,/)256758&785$/

&+$11(//21*6,//$1'02817,1*+(,*+7

+2,6772%2'<$77$&+0(17'(7$,/)256758&785$/

&+$11(//21*6,//$1'02817,1*+(,*+7

6758&785$/&+$11(/

/21*6,//

[

[)/$7

/,)7,1*6+$)7

68%$66(0%/<

+2,67

6$''/(

+2,6772%2'<$77$&+0(17'(7$,/)256758&785$/

&+$11(//21*6,//$1'02817,1*+(,*+7

6758&785$/&+$11(/

/21*6,//

/,)7,1*6+$)7

68%$66(0%/<

[

[)/$7

+2,67

6$''/(

FIGURE 6

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 11 of 21

12. Install all grease fittings. For grease fitting locations in the hoist, refer to Figure 11. Torque

each grease fitting to 70 in-lb. Grease all grease fittings on both the hoist and the rear hinge.

13. Install the body prop. Refer to the "BODY PROP" section of this manual.

14. Install the hydraulic system. Cycle the hoist several times to rid the hydraulic circuit of air.

IMPORTANT: Several different types of hydraulic components are used to power this hoist. All

hydraulic systems supplied by TBEI-Rugby have an installation and operation manual

included with them. For installation and operation information, refer to the Installation

and Operation Manual for your particular hydraulic components. BE SURE to read

and understand this manual and the installation and operating instructions included with

the hydraulic system before you attempt to operate this hoist.

WARNING: Installing or operating this hoist without first understanding the proper installation and

operation procedures can lead to serious injury or death. Always read and understand

fully all installation and operation manuals before installing or operating this

equipment.

NOTE: Before operating the hoist, read the "OPERATION" section of this manual

WARNING: If it is necessary to work on the hoist or body while in the raised position, ALWAYS

block the unloaded body up securely with the body prop or body props.

15. Place a complete operation manual in the glove compartment of the truck. This manual MUST

BE available for reference by the operator when needed.

WARNING: If the hydraulic system used to power this hoist was supplied by TBEI-Rugby, an

operation manual will be included with the hydraulic components. The operation

manual for this hydraulic system MUST BE supplied to the operator.

WARNING: If the hydraulic system used to power this hoist was supplied by someone other than

TBEI-Rugby, an operation manual for this hydraulic system MUST BE obtained and

supplied to the operator.

16. Install all decals. Refer to "DECAL LOCATION" section of this manual.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 12 of 21

"BODY PROP"

NOTE: In order to comply with paragraph 10 of Federal Regulation #1926.601, all TBEI-

Rugby hoists will be sold with one body prop. It is the responsibility of the installer to

determine whether one body prop is sufficient. The following information will help in

making that determination.

The body prop is designed for use only when the body is empty. The purpose of the

body prop is to hold an empty body in the raised position when performing

maintenance or inspection on the hoist, body, or any component that requires working

under an empty body.

Some applications may require 2 or more body props to support the empty body. To

determine how many body props your application requires, refer to the following

information.

WARNING: Being under a raised body can result in serious injury or death should the body

inadvertently descend. Never position yourself or allow others to position themselves

under a loaded body. Always prop the unloaded body up using the body prop/s

supplied. Remember, body props are to be used only on an unloaded body. When

two props are provided, both props must be used.

WARNING: Do not use body prop to support a loaded body!

WARNING: Do not perform maintenance under a raised body without first blocking the empty body

up with the body prop/s.

WARNING: Do not use a body prop that is bent or otherwise damaged. A damaged body prop will

have a reduced holding capacity, and may break when used to hold up the body. This

could cause serious injury or death. Replace a damaged body prop before using it.

WARNING: Be sure to install the body prop according to the “INSTALLATION OF BODY

PROP” section of this manual.

The following is a step by step procedure to determine how many body props are required for this

application.

1. The TBEI-Rugby Part Number 03 0703 body prop is to be used with this hoist. Determine if

this is the body prop you have by referring to Figure 7.

2. Determine the "P" value referring to Figure 8. The "P" value is the horizontal distance between

the rear hinge and the prop.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 13 of 21

3. Determine the "X" value referring to Figure 8. The "X" value is the horizontal distance

between the body center of gravity and the rear hinge when the body is empty and down. Be sure to

include any items attached to the body such as toolboxes or other structures when determining the

center of gravity.

FIGURE 7 FIGURE 8

4. On the left side of Chart 1, pick the "P" value for your application. On the top of the same

chart, pick the "X" value for your application. Below the "X" value and to the right of the "P" value is

listed an amount of weight. This represents the maximum weight that the body can weigh and be

supported by only one body prop. If the body weights more than the amount listed, 2 body props will

be required. Contact TBEI-Rugby to order another body prop.

NOTE: If the body weighs more than 2 times the amount listed, another type of body prop

with more weight capacity will be required, as 2 body props will not support this

empty body.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 14 of 21

CHART 1

03 0703 BODY PROP CAPACITY

Distance Rear Hinge - Center of Gravity (X)

0-36 37-48 49-60 61-72 73-84 85-96 97-108 109-120 121-132 133-144

42-47 6,100 4,500 3,500 2,800 2,300 2,000 1,700 1,500 1,300 1,100

48-53 6,600 4,800 3,800 3,000 2,500 2,100 1,800 1,600 1,400 1,200

54-59 7,200 5,200 4,100 3,300 2,800 2,300 2,000 1,800 1,600 1,400

60-65 7,700 5,700 4,400 3,600 3,000 2,600 2,200 1,900 1,700 1,500

66-71 8,300 6,100 4,800 3,900 3,300 2,800 2,400 2,100 1,900 1,700

72-77 8,900 6,600 5,100 4,200 3,500 3,000 2,600 2,300 2,000 1,800

78-83 9,500 7,000 5,500 4,500 3,800 3,200 2,800 2,500 2,200 2,000

84-89 10,200 7,500 5,900 4,800 4,000 3,500 3,000 2,700 2,400 2,100

90-95 10,800 7,900 6,200 5,100 4,300 3,700 3,200 2,800 2,500 2,300

96-101 11,400 8,400 6,600 5,400 4,600 3,900 3,400 3,000 2,700 2,400

102-107 12,100 8,900 7,000 5,800 4,900 4,200 3,700 3,200 2,900 2,600

108-115 12,700 9,400 7,400 6,100 5,100 4,400 3,900 3,400 3,100 2,800

114-119 13,400 9,900 7,800 6,400 5,400 4,700 4,100 3,600 3,200 2,900

120-125 14,000 10,400 8,200 6,700 5,700 4,900 4,300 3,800 3,400 3,100

126-131 14,700 10,900 8,600 7,100 6,000 5,200 4,500 4,000 3,600 3,300

132-137 15,300 11,400 9,000 7,400 6,300 5,400 4,700 4,200 3,800 3,400

138-143 16,000 11,800 9,400 7,700 6,500 5,600 5,000 4,400 4,000 3,600

144+ 16,600 12,300 9,800 8,000 6,800 5,900 5,200 4,600 4,100 3,700

Distance Rear Hinge - Body Prop (P)

Maximum Body Weight per Body Prop

EXAMPLE: Using a 12' body that has an empty weight of 6,000 pounds. Body is installed with a

18" overhang. The prop is located 84" forward of the rear hinge. Assume the center of gravity

is 72" from the rear of the body. Subtract the overhang to get X=54". Using P=84-89, X=49-

60, the maximum body weight is 5,900 pounds. This application needs 2 body props.

Remember, this is an example only, and in no way means that this hoist is or is not acceptable

to use in this application.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 15 of 21

"INSTALLATION OF BODY PROP"

NOTE: The following steps are to be used as a guideline when installing the body prop. Since

trucks will vary according to their design it is not possible to be specific about every

aspect of the body prop installation.

1. Once the TBEI-Rugby hoist has been installed, raise the hoist up and temporarily block the

body up. Position the prop assembly against the truck frame as illustrated in Figure 8.

2. Fasten the body prop assembly base to the truck frame.

3. Position and fasten the prop hanger to the truck frame. Hanger must be installed so that when

the body is down the body prop leg will not bounce out of the hanger.

4. Position and weld the prop cup on the body as illustrated in Figure 9.

NOTE: To raise and lower body prop, see the "OPERATION OF BODY PROP" section of

this manual.

FIGURE 9

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 16 of 21

"DECAL LOCATION"

Two “DANGER” decals, as shown on this page are supplied with each hoist. These decals should be

positioned as shown in Figure 10. The part number of the “DANGER” decal is 03 6039.

FIGURE 10

WARNING: Missing or damaged decals can cause incorrect or unsafe operation of the hoist, which

can cause accidents, which may cause serious injury or death. If any decals are missing

or damaged, they must be replaced.

To obtain replacement decals, contact your TBEI-Rugby dealer or call 1-800-533-0494 or 1-800-869-

9162.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 17 of 21

"LUBRICATION"

IMPORTANT: All grease fittings should be greased at least twice annually. Refer to Figure 11 for

grease fitting locations. Failure to grease hoist will result in hoist failure. Hoist failure

due to lack of grease is not covered by the warranty.

IMPORTANT: Refer to installation and operation manual of the hydraulic system for hydraulic

system lubrication instructions.

1. Grease the 13 grease fittings in the hoist frame itself. Apply grease until excess grease can be

seen coming out the ends of the tubes. Refer to Figure 11 for grease fitting locations. Replace

any missing or broken grease fittings.

2. Grease the two grease fittings in the truck rear hinge.

3. Check oil level in the pump reservoir every time the oil is changed in the truck engine.

REMEMBER keep the oil clean. An annual oil change can prevent contaminants from

ruining your pump and hoist cylinder.

FIGURE 11:

LR-2066 or LR-2866A

GREASE ZERK LOCATIONS

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 18 of 21

"OPERATION OF BODY PROP"

WARNING: Being under a raised body can result in serious injury or death should the body

unexpectedly descend. Never position yourself or allow others to position themselves

under a loaded body. Always prop the unloaded body up using the body prop or body

props supplied. Remember, body props are to be used only on an unloaded body.

When two props are provided, both props must be used.

Below is a step-by-step procedure for using the body prop.

1. Raise body to sufficient height and shut off all power.

2. Grasp prop handle at arms length and rotate prop upwards.

3. Swing prop up to vertical position and push down until prop locks in line with support bracket

on the body.

4. Using inside-the-cab controls, lower body slowly until prop contacts prop cup.

CAUTION: Do not power hoist down while on prop.

5. To lower prop for normal operation, "reverse" the procedure of the above four steps.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 19 of 21

"OPERATION OF HOIST AND PUMP"

WARNING: Operating this hoist without first understanding the proper operation procedures can

lead to serious injury or death. Always read and understand fully all operation manuals

before using or operating this equipment.

WARNING: An operation manual for the hydraulic system should be available. The operation

manual for the supplied hydraulic system MUST BE read and understood before

operating this trailer.

WARNING: Being under a raised body can result in serious injury or death should the body

unexpectedly descend. Never position yourself or allow others to position themselves

under a loaded body. Always prop the unloaded body up using the body prop or body

props supplied. Remember, body props are to be used only on an unloaded body.

DANGER: 1. Stay out from under body when hoist is operating.

2. During dumping operations, no one must be allowed to stand in or move through the

area where the body and hoist operate or into an area where an upset load might fall.

3. Controls must be in a safe location and operator must remain at controls during the

dumping operation. Controls must be permanently located in truck cab or another

location where it is not possible to be under body during dumping operation.

4. Never leave body raised or partly raised while the truck is unattended or while

performing maintenance or service under body, unless body is braced to prevent

accidental lowering.

5. If hoist pump is direct engine driven by truck, always disengage drive when hoist is

not in use or when moving load.

6. Do not attempt to raise a loaded body when the vehicle is on un-level ground.

7. Never jerk or shock a raised body to loosen a stuck load.

WARNING: Freeing a stuck load during dumping, with the body raised, by jerking or shocking the

truck, may cause damage to the truck, serious injury or death. Never drive forward or

rearward and stop quickly with the load up or otherwise shock the load. If a load is

stuck in the body, lower the body, then free the load.

WARNING: Attempting to dump a load on un-level ground may cause the truck to over turn, and

can result in damage, serious injury or death. Always dump the load on ground that is

level front to rear as well as level side to side.

Model LR-2066 & LR-2866A Hoist Installation and Operation Manual

Stock No. 03 5839

Page 20 of 21

/53$576/,67

())(&7,9(

,7(0

3$57

'(6&5,37,21

47<

++&6&5(:;*53/7

++&6&5(:;*53/7

6(76&5(:;645+'3/1

187+(;*567/3/7

1871</2&.1(*567/

:$6+(5/2&.3/$7('

61$35,1*,17(51$/

),77,1**5($6(7+5($')250,1*

&</,1'(53,16+$)7%/$1./5

/2&.&2//$56+$)7

02817,1*$1*/(

)5$0(:(/'0(17/5

/,)7,1*6+$)7$66<',$

&</,1'(5;52'1(&.

This manual suits for next models

1

Other TBEI Chain Hoist manuals

Popular Chain Hoist manuals by other brands

Austlift

Austlift 103901 user manual

Dolezych

Dolezych DoLast Lever hoist DD Series Translation of original manual

WERKU

WERKU WK400220 instruction manual

VEVOR

VEVOR WX440-1 user manual

HADEF

HADEF 29/06E series Installation, operating and maintenance instructions

Parkside

Parkside P-SZ 250 Operation and safety notes