TC Communications TC3720 User manual

Notice!

Althougheveryefforthasbeenmadetoinsurethatthismanualiscurrent

and accurate as of date of publication, no guarantee is given or implied

that this document is error free or accurate with regard to any specifica-

tion. TC Communications, Inc. reserves the right to change or modify

the contents of this manual at any time without prior notification.

TC3720

Self-Healing Industrial

Ethernet Fiber Optic Switch

User's Manual

© COPYRIGHT 1992-2007. ALL RIGHTS RESERVED.

MODEL:

S/N:

DATE:

TC Communications, Inc. 17881 Cartwright Road - Irvine, CA 92614

- 2 -

TC3720

User's Manual

Rev. 1.5

Table Of Contents

Chapter 1 - Overview ...................................................................................................4

Features .............................................................................................................................................. 4

Standards ............................................................................................................................................ 4

Description.......................................................................................................................................... 4

Fiber Optic Specifications ................................................................................................................ 5

Transmission Distances (typical) .............................................................................................. 5

Launch Power & Sensitivity ....................................................................................................... 5

Front Panel Connectors, DIP Switches and LED Indicators ....................................................... 7

Rear Panel Connectors, DIP Switches and Reset Button ........................................................... 8

Chapter 2 - Installation ................................................................................................9

Unpacking the Unit ............................................................................................................................ 9

Equipment Location .......................................................................................................................... 9

Dry Contact Alarm Relay................................................................................................................... 9

Power Supply...................................................................................................................................... 9

Power Up Test .................................................................................................................................... 9

Installation Procedure Summary ...................................................................................................10

Using the TC3720's as Regular Optical Switches (None SHR)................................................10

Chapter 3 - Hardware Configuration........................................................................... 11

Self-Healing Ring (SHR) ID Setting ..............................................................................................11

Hardware SHR ID Settings .............................................................................................................11

Examples: To Set the SHR ID.........................................................................................................11

Bench Test ........................................................................................................................................12

Configuring the Master Unit...........................................................................................................12

Configuring the Slave Units ...........................................................................................................13

Chapter 4 - Software Configuration............................................................................ 14

Configuring the TC3720's ..............................................................................................................14

Site Map.............................................................................................................................................15

Configure Basic ...............................................................................................................................16

Configure IP Settings......................................................................................................................17

Configure Port Settings ..................................................................................................................18

Port State ....................................................................................................................................19

Speed/Duplex .............................................................................................................................19

Ingress Limit...............................................................................................................................19

Egress Limit ................................................................................................................................19

Flow Control................................................................................................................................19

SHR Status Report ..........................................................................................................................21

Error Status Report .........................................................................................................................23

Login Settings ..................................................................................................................................24

Console Port Settings .....................................................................................................................26

Console Help ....................................................................................................................................27

"Show" Command.............................................................................................................................28

Telnet Settings .................................................................................................................................29

Chapter 5 - PC IP Configuration ................................................................................ 30

Chapter 6 - Troubleshooting ...................................................................................... 31

General ..............................................................................................................................................31

All LEDs are Off................................................................................................................................31

Alarm LED .........................................................................................................................................31

Other LEDs .......................................................................................................................................31

Optic Cable Types............................................................................................................................31

Calculating the Fiber Optic Loss Budget .....................................................................................31

- 3 -

TC3720

User's Manual

Rev. 1.5

Chapter 7 - Specifications.......................................................................................... 32

Electrical............................................................................................................................................32

Optical................................................................................................................................................32

Visual Indicators...............................................................................................................................32

Alarm ..................................................................................................................................................32

Power Sources.................................................................................................................................32

Temperature......................................................................................................................................32

Physical (Standalone/Rackmount Unit) .......................................................................................32

Appendix - A.............................................................................................................. 33

Return Policy ....................................................................................................................................33

Warranty ............................................................................................................................................33

Appendix - B.............................................................................................................. 34

Setting the Self-Healing Ring IDs on the TC3720's ...................................................................34

- 4 -

TC3720

User's Manual

Rev. 1.5

Chapter 1 - Overview

Features

pSelf-Healing or Redundancy Capable (recover time is less than 250ms (when connected

in a ring setup)

pOne Management Port for Advanced Configurations and Status Monitoring

pSix 10/100 Full/Half Duplex Auto-Negotiation Twisted RJ-45 Ports

pTwo 100 Full Duplex Fiber Optic Pair Ports

pConverts Twisted Pair Media (RJ-45) to Fiber Optics

pRate Limiting or Bandwidth Control on Copper Ports

pMDI/MDIX Auto Detection and Operation on Copper Ports

pMultimode (1310nm) and Single Mode (1310nm/1550nm)

pStandard Single Mode Distances 50km (optional 100km)

pHardened Temperature (-40oCto 80oC) - Optional

pStandalone/Rackmount

pAlarm Relay

pWeb-Based/Serial Configuration

Standards

IEEE 802.3, 802.3u, and 802.3x

Description

Intended for Multidrop Self-Healing Ring (SHR) topologies, the TC3720 Ethernet Fiber Optic Switch

interconnectsuptosix10/100Mdevicesateachdrop.Theringcanconsistofeithermultimodeorsinglemode

fibers or CAT5 UTP cables. Fault recovery time is less than 250 milliseconds.

The TC3720 offers a sophisticated Self-Healing Ring scheme. Fault conditions are detected on both Tx and

Rx, upstream and downstream of each unit, and automatically re-routed to maintain Ring integrity.

A Web-based configuration user interface is provided to view and change network settings such as IP

Address,Subnet,Gateway, Speed,Half/FullDuplex,Name,Password andotherparameters.Italso monitors

the fiber ring status, alarm conditions, fault locations for local and remote units. The TC3720 can also be

configured through a serial console (Out-of-Band).

The TC3720’s store-forward switching technology eliminates the congestion problem inherent to the

contention-oriented Ethernet CSMA/CD protocol. This improves predictable response times under heavy

network loads. Previously, expensive routing technology was used to alleviate congestion from heavy traffic

loads.

The TC3720 offers two multimode (1300nm) or single mode (1300/1550nm) ports and six independent

Ethernet 10/100-Base Auto-Sensing switched ports. As options, there are two versions (Model TC3720T)

for extreme temperature applications (-20° to 70°C, -40° to 80°C).

Power is 12VDC, optional 24VDC, -48VDC, 125VDC or 115/230VAC. Power redundancy is standard on

12VDC. The unit is 19" rack mountable. Optical connectors can be ST, FC or SC.

- 5 -

TC3720

User's Manual

Rev. 1.5

Multimode Model

Transmitter: LED; typical Launch Power -17.0 dBm* (1310nm, @62.5/125µm)

Receiver: PIN Diode; typical Sensitivity -33.0 dBm* (1310nm, @62.5/125µm)

Optic saturation level -11.0 dBm*(1310nm, @62.5/125µm

Loss Budget: 1310nm Multimode @62.5/125µm 15 dB

Distance: 1310nm Multimode, @62.5/125µm up to 4km distance*

Wavelength: 1310nm Multimode

Connector: SC

ST

Single Mode 1310nm, 20km Model

Transmitter: FP Laser; typical Launch Power -15 to -7 dBm* (1310nm, @9/125µm)

Receiver: PIN Diode; typical Sensitivity -34.0 dBm* (1310nm, @9/125µm)

Optic saturation level -3 dBm*(1310nm, @9/125µm)

Loss Budget: 1310nm Single Mode, @9/125µm 19 dB

Distance: 1310nm Single Mode, @9/125µm up to 20 km distance*

Wavelength: 1310nm Single Mode(LASER)

Connector: ST

FC

SC

Single Mode 1310nm, 75km Model

Transmitter: FP Laser; typical Launch Power -3 to +2dBm* (1310nm, @9/125µm)

Receiver: PIN Diode; typical Sensitivity -36.0 dBm* (1310nm, @9/125µm)

Optic saturation level -3 dBm* (1310nm, @9/125µm)

Loss Budget: 1310nm Single Mode, @9/125µm 33dB

Distance: 1310nm Single Mode, @9/125µm up to 75km distance*

Wavelength: 1310nm Single Mode (LASER)

Connector: ST

FC

SC

Single Mode 1550nm, 75km Model

Transmitter: DFB Laser; typical Launch Power -10 to -1dBm* (1550nm, @9/125µm)

Receiver: PIN Diode; typical Sensitivity -34.0 dBm* (1550nm, @9/125µm)

Optic saturation level 0 dBm* (1550nm, @9/125µm)

Loss Budget: 1550nm Single Mode, @9/125µm 24dB

Distance: 1550nm Single Mode, @9/125µm up to 75km distance*

Wavelength: 1550nm Single Mode (LASER)

Connector: ST

FC

SC

Fiber Optic Specifications

*Launch power, sensitivity and distance are listed for reference only. These numbers may vary.

- 6 -

TC3720

User's Manual

Rev. 1.5

Single Fiber, 50km Model

Transmitter: Typical Launch Power -8 to -3 dBm* (1310nm/1550nm, @9/125µm)

Receiver: PIN Diode; typical Sensitivity -33.0 dBm* (1310nm/1550nm, @9/125µm)

Optic saturation level -3 dBm*

Loss Budget: 1310nm/1550nm Single Mode, @9/125µm 29 dB

Distance: 1310nm/1550nm Single Mode, @9/125µm up to 50km distance*

Wavelength: 1310nm/1550nm Single Mode

Connector: SC Only

*Launch power, sensitivity and distance are listed for reference only. These numbers may vary.

- 7 -

TC3720

User's Manual

Rev. 1.5

Front Panel Connectors, DIP Switches and LED Indicators

Figure 1. TC3720's Front Panel View

MadeinU.S.A.

TCCOMM.COM

10/100BASESELF-HEALINGETHERNETSWITCH

Rx

Tx

100BASE-FX

FULL/COL

F1/1X100M

MSTR/SLVE

ALARM

LINK/ACT

F2/2X

3

2

1456

F2

F1

Rx

Tx

100BASE-FX

FULL/COL

100M

LINK/ACT

B

A

P

W

R

V

c

c

1

V

c

c

2

SixRJ-4510/100MbpsPorts

forthetwistedpairconnection.

F1andF2

OpticReceivers

andTransmiters

F1

F2

1234

1234

SHRF2/2X

DISALMF1/1X

LEDStatusIndicatorsfor

TwistedPairPorts1through6:

FullDuplex/CollisionIndicato

r

L

E

D

.

:whentheTwistedPai

r

portisoperatingat100Mbps.

-whentheTwistedPairporti

s

operatingat10Mbps.

:

-whentheporti

s

operatingatfullduplex.

-

-whencollisions

o

c

c

u

r

.

:whentheTwiste

d

P

a

i

r

porthasestablishedavalid

l

i

n

k

.

-

100M“Solidlylit”

“Off”

FULL/COL“Solidlylit”

“Flashing”

LINK/ACT“Solidlylit”

“”

“Off”

Flashing

“Off”

whentheportisopera

t

i

n

g

athalfduplex.

whenthereisEt

h

e

r

n

e

t

Activitythroughtheport.

-whennoelectricalsign

a

l

i

s

detectedontheRJ-45conne

c

t

o

r

s

LEDStatusIndicators

forFiberOpticChannels1and2:

FullDuplex/Collision

IndicatorLED:

:

:

-when

connectionisgood.Duplex

modeofF1orF2isfixedto

Fullduplex.

:whenthefiberoptic

porthasestablishedavalid

opticallink(bothTx&Rx).

-

100M

FULL/COLLit

LINK/ACTSolidlylit

Lit

“Flashing”

“Off”

whenconnectionisgood.Spee

d

ofF1orF2isfixedto100Mb/sec.

whenEthernet

Activityatthefiberopticport

isdetected.

-whennoopticallinkis

established.

DipSwitches:

:Self-HealingRing;

Up:Disable

(TheTC3720canbeusedasaregularopticalswitch

bysettingtheSHRdipswitchtotheup“Off”position.)

SHR

Note:

Down:Enable

:Usedtodisablethealarmbuzzeranddrycontactrelayalarm

Up:AlarmenableDown:Alarmdisable

:Up:SelectfiberportF1

Down:Selectcopperport1Xtoformthering(futurerelease)

:Up:SelectfiberportF2

Down:Selectcopperport2Xtojointhering(futurerelease)

DISALM

F1/1X

F2/2X

PowerStatus&OperatingVoltageStatus

:DCpowersupplyfromPWRBjac

k

:+5VDCoperating

voltagepowersupply

PWRA

:DCpowersupplyfromPWRAjac

k

PWRB

Vcc1andVcc2

ALARM“Off”

“Flashing”

MSTR/SLVE“Off”

“On”

F1/1X“Off”

“On”

“Flashing”

F2/2X“Off”

“On”

“Flashing”

:-normaloperation(F1/X1&F2/2X

connectionsaregood).

-when:-F1/1XorF2/2X

connectionislostonanySlaveorwhenlocal

orremoteconnectionislostontheMaster.

-IfLEDsF1/1X,F2/2Xarelit&ALARMisflashingon

theMaster,theremoteconnectionislost.Check

thestatusbyaccessingtheMaster’sWebpage.

-IfLEDsF1/1XorF2/2Xisflashing(any)and

ALARMisflashing,thelocalconnectionislost.

:whenconfiguredasaSlave.

-whenconfiguredasaMaster.

:whenSTPisdisabled.

-whenSTPisenabledandF1/1X

connectionisgood.

-whenSTPisenabledandF1/1X

connectionislost.

:whenSTPisdisabled.

-whenSTPisenabledandF2/2X

connectionisgood.

-whenSTPisenabledandF2/2X

connectionislost.

- 8 -

TC3720

User's Manual

Rev. 1.5

Rear Panel Connectors, DIP Switches and Reset Button

Figure 2. TC3720's Rear Panel View

ALM

RLY1

PWR

AALM

RLY2

PWR

B

+-+-

24VDC

12VDC48VDC

PowerAandB

Connectors

DryContact

RelayConnectors

R

e

a

r

P

a

n

e

l

D

i

p

S

w

i

t

c

h

e

s

:

U

s

e

t

h

e

s

e

d

i

p

s

w

i

t

c

h

e

s

t

o

s

e

t

th

e

S

e

l

f

-

H

e

a

l

i

n

g

R

i

n

g

I

D

(

)

S

H

R

I

D

an

d

t

o

s

e

t

t

h

e

u

n

i

t

a

s

o

r

M

a

s

t

e

r

S

l

a

v

e

NotUsed

SerialDB9port

:

(9600-8-N-1);9600B

a

u

d

,

8databits,noparity,

&1stopbit

ResetButto

n

:

Usedtorese

t

t

h

e

u

n

i

t

b

a

c

k

t

o

t

h

e

c

u

r

r

e

n

t

hardwarese

t

t

i

n

g

s

;

1.Unplugthe

p

o

w

e

r

t

o

t

h

e

u

n

i

t

.

2.Pushand

h

o

l

d

t

h

e

“

R

e

s

e

t

B

u

t

t

o

n

.

”

3.Whilehold

i

n

g

t

h

e

b

u

t

t

o

n

i

n

,

P

l

u

g

t

h

e

powerbac

k

“

O

n

”

t

h

e

n

r

e

l

e

a

s

e

t

h

e

b

u

t

t

o

n

.

4.Themost

willberes

t

o

r

e

d

.

c

u

r

r

e

n

t

h

a

r

d

w

a

r

e

s

e

t

t

i

n

g

s

(115/230VAC)

Powerplug

ManagementRJ-45

P

o

r

t

:

Usedforadvanced

c

o

n

f

i

g

u

r

a

t

i

o

n

s

a

n

d

StatusMonitoringsu

c

h

a

s

:

PortSpeed/Duple

x

PortRateLimitting

SHRConfiguratio

n

s

SHRStatusMonit

o

r

i

n

g

•

•

•

•

- 9 -

TC3720

User's Manual

Rev. 1.5

Chapter 2 - Installation

Unpacking the Unit

Before unpacking any equipment, inspect all shipping containers for evidence of external damage caused

during transportation. The equipment should also be inspected for damage after it is removed from the

container(s). Claimsconcerningshipping damage shouldbemadedirectly to thepertinentshippingagencies.

Any discrepancies should be reported immediately to the Customer Service Department at TC Communi-

cations, Inc.

Equipment Location

The TC3720 should be located in an area that provides adequate light, work space and ventilation. Avoid

locating it next to any equipment that may produce electrical interference or strong magnetic fields, such as

elevator shafts and heavy duty power supplies. As with any electronic equipment, keep the unit from

excessive moisture, heat, vibration and freezing temperatures.

Dry Contact Alarm Relay

Two terminal block connectors on the rear panel (labeled "ALM

RLY1," & "ALM RLY2") provide for the dry contact relay alarm

(see Figure 2). Normally in the OPEN position, any loss of optical

signal will trigger an alarm condition and force the switch to the

CLOSED position. This relay can be used in conjunction with an

external device to monitor the condition of the fiber optic links.

Power Supply

Standard input power is 12V DC @500mA for the TC3720. The power plug is a terminal block connector

with positive & negative polarity indicated on the rear panel of the unit. Two connectors, labeled "PWR A"

& "PWR B" are provided for a built-in power redundancy feature. While only one connection is required

to power the unit, both connectors can be used simultaneously. When power redundancy is utilized, both

power "A" & "B" share the load. If one power supply fails, the other will take over the full load. Alternate

power sources are available as an option (see Chapter 7 - Specifications).

Should an external power adapter need to be replaced, use one with the following specifications: 12V DC

@500mA. You may order it directly from TC Communications.

Power Up Test:

Apply power by plugging the power plug into any power jack on the rear panel. After the power is applied,

the following LED status should be observed from the front panel.

After power up, if no LEDs are lit, refer to Chapter 6 (Troubleshooting).

1. The "PWR A" or "PWR B" LEDs on the front panel will light according to which power jack (A or B)

is connected. Both LEDs will light when power redundancy is utilized.

2. Both "Vcc1" and "Vcc2" LEDs should be solidly lit, indicating an adequate operating voltage is being

derived from the power source.

3. The "100M" & "FULL/COL" LEDs for both F1 and F2 should be solidly lit. The "LINK/ACT" LED

should be Off since there is no Ethernet or optical activity.

4. The "ALARM," "F1/1X," and "F2/2X" LEDs should be flashing indicating that there is no fiber optic

cables connected.

Note: On power up, if the self-healing function is disabled with front panel dip switch #1 in the "Up" position,

the "ALARM" LED will flash and the "F1/1X," and "F2/2X" LEDs will be off. All other LEDs will

behave as indicated above.

(Continue next page)

DryContactRelay

AlarmSwitch

To remote alarm status indicator

Max switch voltage: 100VDC

Switch current: 0.5Amp

Max carry current: 1.2Amp

Contact resistance: 0.2Ohm

Reply switch specifications

- 10 -

TC3720

User's Manual

Rev. 1.5

Installation Procedure Summary (Continue)

To install the TC3720 units, you must first configure them for your specific application (for example, the setup

onfigure4).Regardless of how the units areconfigured,eachunitinthe ring must have a uniqueSelfHealing

Ring (SHR) ID.

There are two ways to configure the TC3720's to be installed in the SHR setup. By hardware configurations

or software configurations.

A. Hardware configurations: If the units are configured using hardware configurations with the DIP

switches on the rear panel, there is a limit to the SHR ID hardware settings. The maximum number of

SHR ID's that can be used are 128 (see Appendix B), therefore the SHR can be connected with a

maximum of 128 units when hardware settings are used. (Generally, hardware configurations are used

when bench testing the units). See Chapter 3 (Hardware Configuration).

Note:Softwareconfigurationswill overwrite thehardware settings forSHR ID andfor Master/Slave (refer

to chapter 4 for software configurations). The reset button on the rear panel can be used to return the unit

to the current hardware settings.

B. Software Configurations: The units are configured through the Management port (RJ-45 connector

on the rear panel of the switches). See Chapter 4 (Software Configuration).

Note:If you want to configure the IP address, username, or password, you can also use the Console port

(DB9 connector on the rear panel). Refer to console port settings on page 26.

Using the TC3720's as Regular Optical Switches (SHR Disabled)

The TC3720 units can be used as regular optical switches by disabling the self-healing ring function. They

can be used for point to point applications using either fiber port 1 (F1) or fiber port 2 (F2). For example, as

shown on the diagram below.

To set the TC3720's as regular optical switches, simply set the front panel DIP switch #1 (SHR) to the up

"Off" position. Refer to dip switches on figure 1.

B

B

A

A

PWR

PWR

VCC

VCC

MadeinU.S.A.

MadeinU.S.A.

TCCOMM.COM

TCCOMM.COM

10/100 BASE ETHERNET FIBER SWITCH

10/100 BASE ETHERNET FIBER SWITCH

Rx

Rx

Tx

Tx

100 BASE-FX

100 BASE-FX

3

3

2

2

1

1

F/0

F/0

FULL/COL

FULL/COL

100M

100M

LINK/ACT

LINK/ACT

4

4

M

a

d

e

in

U

.S

.A

.

TCCOMM.COM

10/100 BASE SELF-HEALING ETHERNET SWITCH

RxTx

100 BASE-FX

FULL/COL

F1/1 X100M

MSTR/S LVE

ALARM

LINK/ACT

F2/2 X

321 4 5 6F2F1

RxTx

100 BASE-FX

FULL/COL

100M

LINK/ACT

B

A

P

W

R

V

c

c

1

V

c

c

2

F1

F2

1 2 3 4

1 2 3 4

SHR F2/2X

DISALMF1/1X

10/100Base-T Industrial Ethernet

Fiber Optic Switch (4Tx + 1Fx)

- 11 -

TC3720

User's Manual

Rev. 1.5

Self Healing Ring (SHR) ID Setting

The Self Healing Ring (SHR) can be connected with a maximum of 128 units. The ID setting can be

configured with either hardware or software (each unit must have a unique ID). Hardware configuration

is limited to the default IP addresses. Therefore, it is generally used for bench testing.

Note:Software configurations will overwrite the hardware settings for SHR ID and for Master/Slave (see

chapter 4 for software configurations). The reset button can be used to return the unit to the current hardware

settings.

Hardware SHR ID Settings

Dip switches 1-7 on the rear panel of the unit are used to configure the SHR ID's. They represent bit numbers,

#1, least significant and #7, most significant. The values(1, 2, 4, 8, 16, 32, and 64) for setting the SHR ID are

represented by the bit number exponent of 2 (see table 1 and figure 3). Also refer to Appendix B.

Chapter 3 - Hardware Configuration

Examples: To set the SHR ID

ID=1: Set dip switch 1 to the down position and the rest to the up position.

ID=2: Set dip switch 2 to the down position and the rest to the up position.

ID=3: Set dip switches 1 and 2 to the down position and the rest to the up position.

ID=4: Set dip switch 3 to down the position and the rest to the up position.

ID=5: Set dip switches 1 and 3 to the down position and the rest to the up position.

ID=6: Set dip switches 2 and 3 to the down position and the rest to the up position.

ID=7: Set dip switches 1, 2 and 3 to the down position and the rest to the up position.

ID=8: Set dip switch 4 to the down position and the rest to the up position.

ID=9 to 127: Please refer to the SHR ID Setting Tables on Appendix B.

Dip switch 8: The Slave/Master dip switch (each ring can only have 1 Master) is used to set the unit

as a Master or a Slave. Master: Set to down position. Slave:Set to up position.

Note: The Master unit must be set to SHR ID = 0 (All SHR ID dip switches must be in the up position).

When using hardware configurations, the SHR ID = N will set the IP address to 192.168.254.[100+N].

For example, if the unit is set for SHR ID = 12, the IP address is 192.168.254.112.

Table 1. SHR ID Setting

Figure 3. SHR ID Setting

Dip

switch #

(Bit #)

Values for

setting the

SHR ID’s

1 2= 1

0

2 2= 2

1

3 2= 4

2

4 2= 8

3

5 2= 16

4

6 2= 32

5

7 2= 64

6

- 12 -

TC3720

User's Manual

Rev. 1.5

Bench Test

It is highly recommended to conduct bench tests before actual installation. Bench testing allows the user to

become familiar with the functions and features of the TC3720 in a controlled environment. Knowledge of

the TC3720's functions and features will facilitate installation and troubleshooting efforts later on.

Figure 4, depicts the connections, configurations and settings for the SHR setup of one Master and three

Slave units for bench testing using the hardware configurations. Follow the instructions below for the

configurations for the Master and Slave units.

Figure 4. Self-Healing Ring Connection Diagram

Configuring the Master unit:

1. Enable the SHR dip switch on the front panel by setting it to the down position.

2. Select the fiber ports to form the SHR (set the F1/1X and F2/2X dip switches on the front panel to the

up position).

3. Enable the MSTR dip switch on the rear panel to the down position.

4. Make sure that all the SHR ID dip switches are in the up position (SHR ID = 0)

5. To ensure that hardware settings are enabled, unplug the power to the unit, press and hold the reset

button on the rear of the unit, then plug in the power and release the reset button.

6. The ALARM LED will flash and the audible alarm will sound until the SHR is complete. If desired, the

audible alarm can be disabled by setting the DISALM dip switch on the front panel to the down position.

7. The MSTR/SLVE LED should be solidly lit.

Master

Slave 2

Slave N

Slave 1

Data

Data

Data

Data

Management

Manageme

n

t

Management

Management

Master:

SHR ID: 0

IP: 192.168.254.100

F2

F1

F1

F2

F2 F1

F2

F1

RX

RX

RX

RX

RX RX

RX

RX

TX

TX

TX

TX

TX TX

TX

TX

Slave1:

IP: 192.168.254.101

SHR ID: 1

- 13 -

TC3720

User's Manual

Rev. 1.5

Configuring the Slave units:

1. Enable the SHR dip switch on the front panel by setting it to the down position.

2. Select the fiber ports to form the SHR (set the F1/1X and F2/2X dip switches on the front panel to the

up position).

3. Enable the unit to be a Slave by setting the rear panel's SLVE/MSTR dip switch to the up position.

4. Make sure that at least one SHR ID dip switch is in the down position (Slave SHR ID must be unique.

See Appendix B: SHR ID Setting).

5. To ensure that hardware settings are enabled, unplug the power to the unit, press and hold the reset

button on the rear of the unit, then plug in the power and release the reset button.

6. The ALARM LED will flash and the audible alarm will sound until the SHR is complete. If desired, the

audible alarm can be disabled by setting the DISALM dip switch on the front panel to the down

position.

7. The MSTR/SLVE LED on the front panel should be off.

Repeat steps 1-5 for the remaining slave units.

After completing the configurations for the Master and Slave units:

1. Interconnect the switches in a ring setup using the fiber ports as shown in figure 4. The SHR must be

configured as a ring.

2. Connect the Fiber Ports F1 to F2 of adjacent unit (Rx to Tx and Tx to Rx) as shown in Figure 4.

The following LEDs status should be observed to verify the integrity of the units and all connections after

power up and all connections have been made as in figure 4:

On the Master unit: "ALARM" LED Off, "MSTR/SLVE" LED solidly lit, "F1/1X" and "F2/2X"

LEDs solidly lit, "100M" and "FULL/COL" LEDs solidly lit, "LINK/ACT" LED

solidly lit or flashing (as optical communication has been established and there

is Ethernet activity), "PWRA" and/or "PRWB" LEDs solidly lit.

On the Slave units: "MSTR/SLVE" LED Off on all Slave units. All other LEDs should behave

the same way as those on the Master unit.

Note:See chapter 4 for software configurations and system monitoring.

- 14 -

TC3720

User's Manual

Rev. 1.5

Chapter 4 - Software Configuration

Configuring the TC3720's

Software Configurations are done through the Management port (RJ-45 connector on the rear panel of the

switches).

Note: Software configurations will overwrite the current hardware settings. If changed, the hardware

settings will not reflect the current software settings.

In order to configure the TC3720's that is, set to default, the user needs to use a PC with a web browser

installed.Furthermore, the PC's IPaddress must besetwithin the rangeof192.168.254.1 to 192.168.254.99,

and with a Network Mask of 255.255.255.0. We recommend that you set your PC within these ranges to

avoid a potential conflict with the IP configuration of the TC3720's. If your PC does not have a compatible

IP Address and Network Mask, or you are not sure about the settings, refer to the "PC IP Configuration"

section on page 30 for more detail. You can also change the IP address of the TC3720 by matching it up with

that of your PC, refer to Console Port Settings on page 26.

To configure the TC3720, simply enter the default IP address of the TC3720 in the Web browser's address

box. For example, if the unit is set to Master by hardware settings, SHR ID=0, the default IP address should

be 192.168.254.100.

If, for example, the unit is set to be a Slave with SHR ID=4 (with rear panel DIP switch #3 to the down

position), then the default IP address should be 192.168.254.(100+4).

(Attention: Contact your network administrator if you are unsure about the settings. Improper settings may

result in disruption of the existing network.)

Once you enter the IP address and click enter, you will see a verification window, where you will be prompted

to enter a username and password:

Enter user under User Name and enter password under Password and click "OK."

You will then see a window as in figure 5.

Note: The username and password can be returned to the default username and password by using the reset

button(refer to rearpanel diagram on figure2). All settings willbe returned tothecurrent hardware settings.

If you would like to use the default IP addresses, see page 11 to do the configurations using the SHR ID

settings.

- 15 -

TC3720

User's Manual

Rev. 1.5

Login

Basic

Switch Name

Location

Contact

Description

Mac Address

Network

IP Address

Subnet Mask

Default Gateway

SHR Master

SHR Port

SHR ID

SHR Master ID

Port Settings

Copper Ports (1 - 6)

Port State

Speed Duplex

Ingress Limit

Egress Limit

Flow Control

Fiber Ports (F1 and F2)

Port State

Ingress Limit

Egress Limit

Flow Control

SHR Status

Login Settings (Username and Password)

SiteMap:The site map below can be used as a guide to navigate through the desired sections for software

configurations.

- 16 -

TC3720

User's Manual

Rev. 1.5

Software Configuration Continue

Configure Basic:

Use the links on the left side of the page to navigate to the desired section.

Clickthe"Basic"linkontheleft side of the page and you willseethewindowasinfigure5,andyou can begin

the configurations. You may change the values/names of the Switch Name, Location or Contact fields as

you like or you can leave as they appear.

The location field will be shown on the SHR error report to assist in locating the units with broken fiber optic

links (see figure 12 on page 23).

MAC Address (cannot be changed).

When done, click Apply to save the changes.

Figure 5. TC3720 Configure Basic Window

- 17 -

TC3720

User's Manual

Rev. 1.5

Figure 6. TC3720 IP Settings Window

Software Configuration Continue

Configure IP Settings:

To configure the IP settings, click the "IP Settings" link on the left side of the page. On the IP settings window,

enter in the related IP address, Subnet Mask and Default Gateway as shown on figure 6, below.

Note:All switches and monitoring systems should be on the same network ( Contact your network

administrator for valid n etwork settings).

SHR Master: Select either Master or Slave.

SHR Port:This is the UDP port used by the TC3720. It can be any number as long as it is not used for public

port such as 80, 23 and etc. We recommend to use the factory default UDP port.

Note:All SHR ports of the switches on the ring should be kept the same.

SHR ID: Any integer. All units in a ring must have a unique SHR ID.

SHR Master ID: All units in a ring must be set to the same SHR Master ID.

For example:The "SHR Master ID" and "SHR ID" for the Master should always be the same (by

default they should be zero "0"). The "SHR Master ID" value should also be set to zero

on all Slave units in the ring to match that of the Master. If this value is changed in the

Master unit, it should also be changed to the same value on all Slave units in the ring.

When done, click Apply to save the changes.

Note:A window as in figure 14, page 25 will pop-up asking you to reset the new settings. After you click

"reset" all the changes will be saved. Then you will see a window asking you to refresh your browser

or enter a new IP (only when you change the IP address) to continue the software configurations.

- 18 -

TC3720

User's Manual

Rev. 1.5

Figure 7. TC3720 Port Settings Window

Software Configuration Continue

Configure Port Settings

Click the "Port Settings" link on the left side of the page to configure either the "RJ-45 Ports" 1 through 6

orthe"Fiber Ports"F1orF2settings.After clickingthe"PortSettings"link,you willseethefollowingwindow

shown on figure 7, below. It shows the information of all ports.

For example, click on the copper Port 5 and you will see a window as in figure 8, next page.

- 19 -

TC3720

User's Manual

Rev. 1.5

Software Configuration Continue

Port State:Enable or disable the port state.

Speed/Duplex:The speed and duplex on the fiber port is fixed to 100M/Full. You can select the speed

and duplex mode of the RJ-45 ports as follows:

Auto-Negotiating, 100Mbps/Full Duplex, 100Mbps/Half Duplex, 10Mbps/Full Duplex,

or 10Mbps/Half Duplex.

Ingress Limit:Rate limiting for inbound traffic (data going into the TC3720 port). The default

value of the rate limit is None (no limit on the inbound traffic). The rate limit can

be set to 128K, 256K, 512K, 1M, 2M, 4M, 8M, 16M, 32M, or 64M. (bps).

Egress Limit:Rate limiting for outbound traffic (data going out from the TC3720 port). The default

value of the rate limit is None ( no limit on the outbound traffic). The rate limit can be

set to 128K, 256K, 512K, 1M, 2M, 4M, or 8M. (bps).

Flow Control:Enable or disable the flow control. (Keep it in the default setting - "Disabled.")

Figure 8. TC3720 Port Settings Dialog Box

- 20 -

TC3720

User's Manual

Rev. 1.5

Software Configuration Continue

Figure 9. TC3720 Port Settings Dialog Box

Ingress Limit: Rate limiting for inbound traffic.

Table of contents

Other TC Communications Switch manuals

Popular Switch manuals by other brands

Moxa Technologies

Moxa Technologies EDS-316 Series Quick installation guide

NewTek

NewTek Tricaster TCXD850 user guide

Krom Schroder

Krom Schroder DG**H series operating instructions

Bosch

Bosch Rexroth HED 8 Series manual

Eneo

Eneo IAR-7SE2024MMA user manual

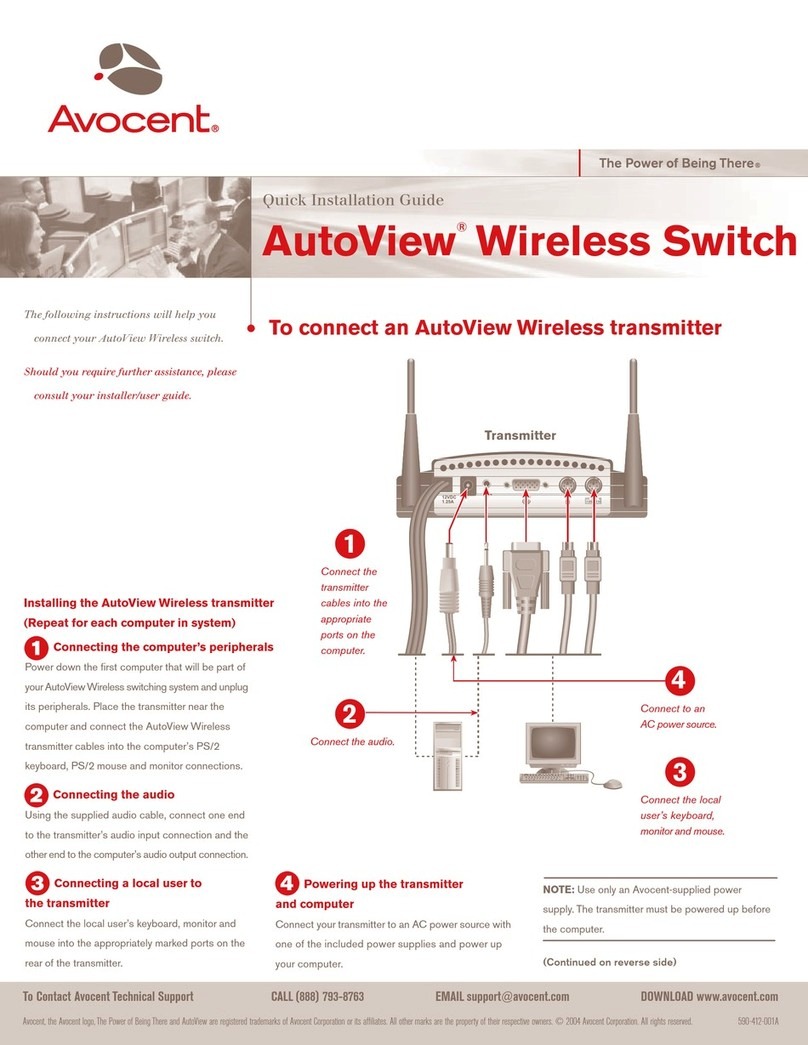

Avocent

Avocent AutoView 1400 Quick installation guide

Lindy

Lindy 43154 user manual

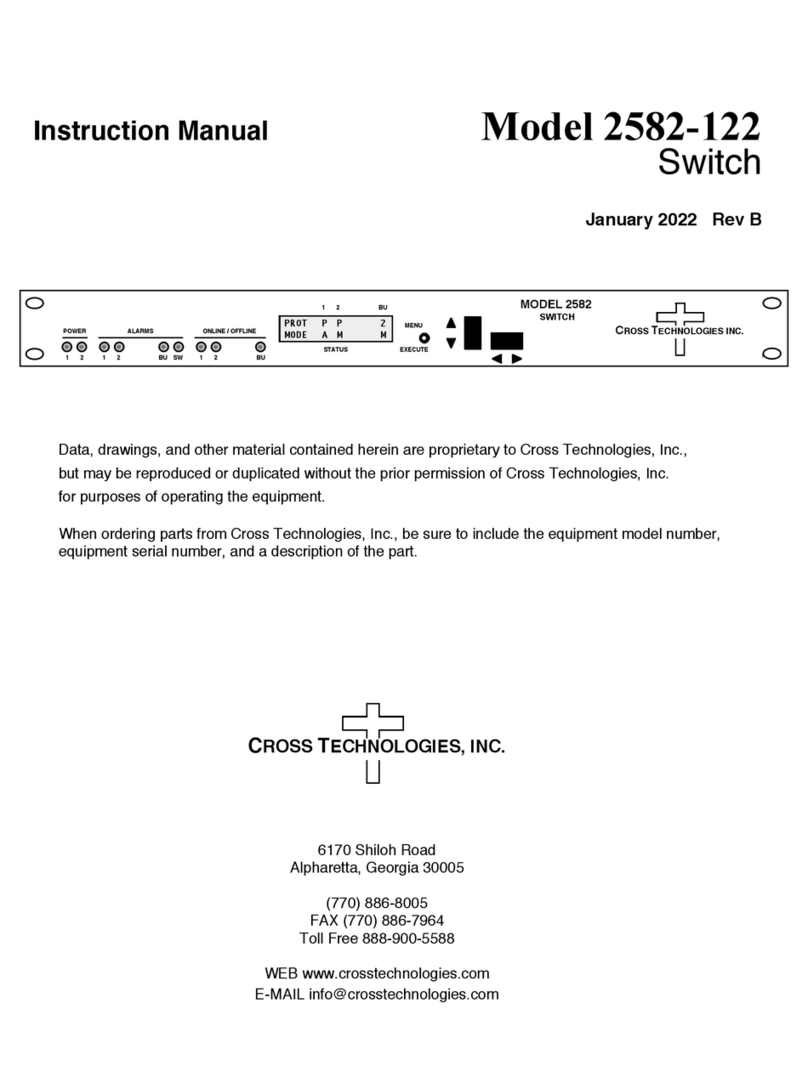

Cross Technologies

Cross Technologies 2582-122 instruction manual

Alcatel-Lucent

Alcatel-Lucent LambdaUnite 1675 Installation and System Turn-Up Guide

Belkin

Belkin F1DF102P Quick installation guide

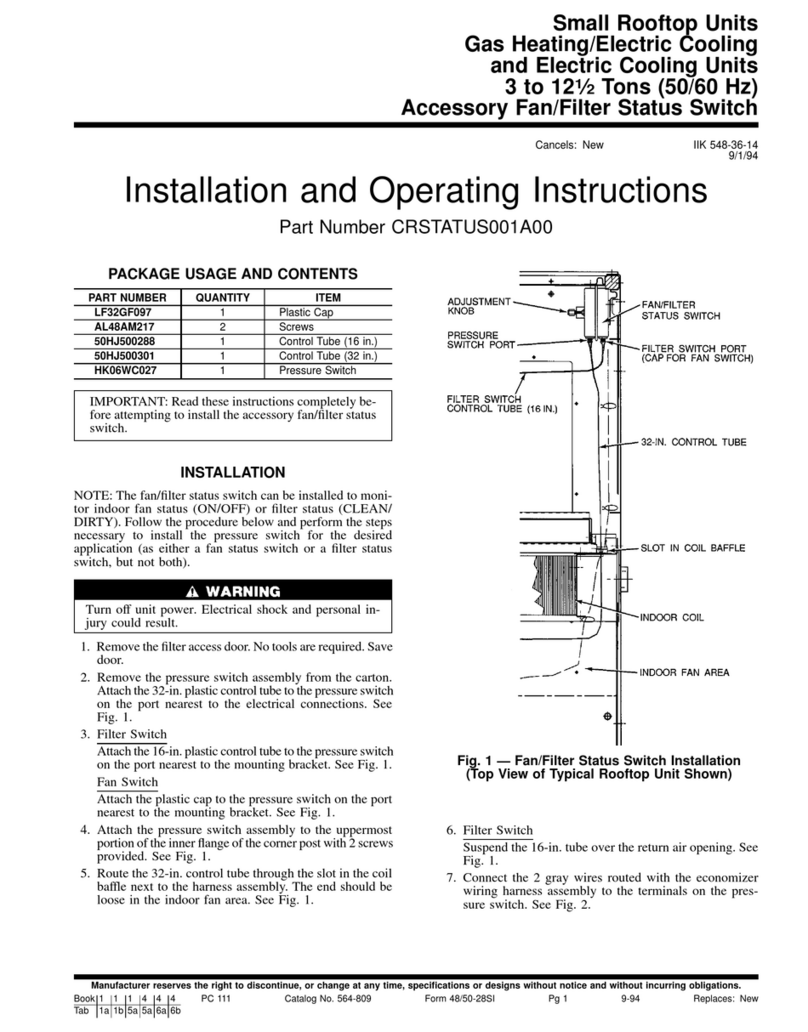

Carrier

Carrier CRSTATUS001A00 Installation and operating instructions

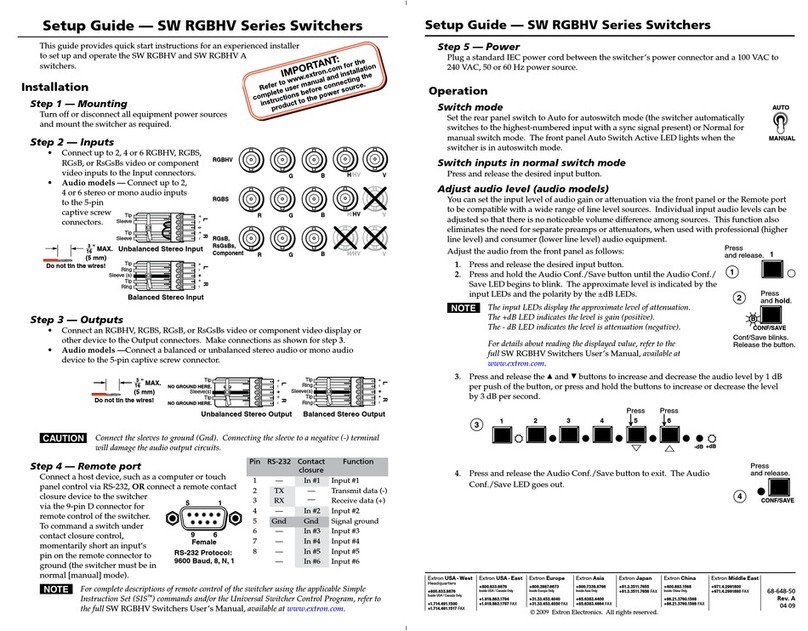

Extron electronics

Extron electronics SW RGBHV Series Setup guide