TCF 3500pro3 User manual

Installation manual water-cooler

1 or multiple water cooled Opticlimates can be connected to 1 water cooler. The water cooler is a

super efficient way to recirculate water or a glycol-mix in a closed loop system. The fan(s) and the

circulation-pump are the only parts that consume energy. The water cooler makes it possible to

prepare water for the Opticlimates at outside temperatures over 40°C.*

Setting up the system starts with a good design of the system. Pump-size, piping diameter and

layout are the most important items when designing the system.

The pump:

The circulator pump must supply a pre defined flow at a given pressure. The flow is determined by

the energy that must be circulated (KW) and the pressure depends on the pressure-drop of the

complete system (Opticlimate(s) + piping + water-cooler) We always calculate the correct pump for

your setup. We suggest to place the pump indoor.

The piping:

We suggest to use PE-piping with quick connectors. Prevent knees or other fittings that reduce

water-flow. We supply all the fittings for PE piping in the package. Supplying the piping is also

possible.

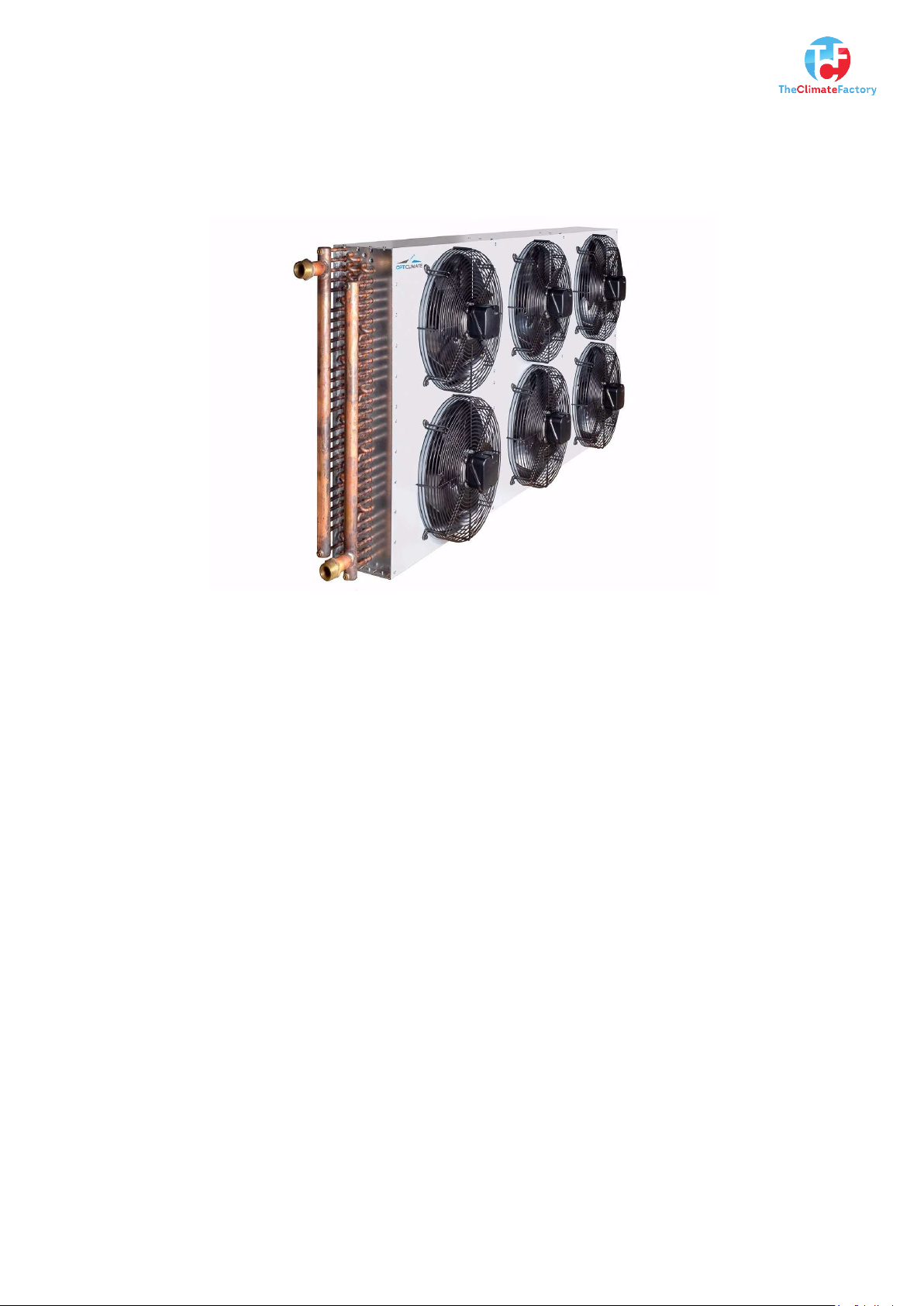

The water cooler:

The stock water coolers come as Industrial heavy duty and Ultra light /compact. The stock versions

are all vertical models (roof/floor or wall mount). Both models can also be ordered as a horizontal

model (roof /floor mount)

The fittings:

Supplied fittings are for PE piping applications. We supply automatic bleeders, air separators, ball

valves, treated fittings depending on your setup.

© TCF 2019© TCF 2019

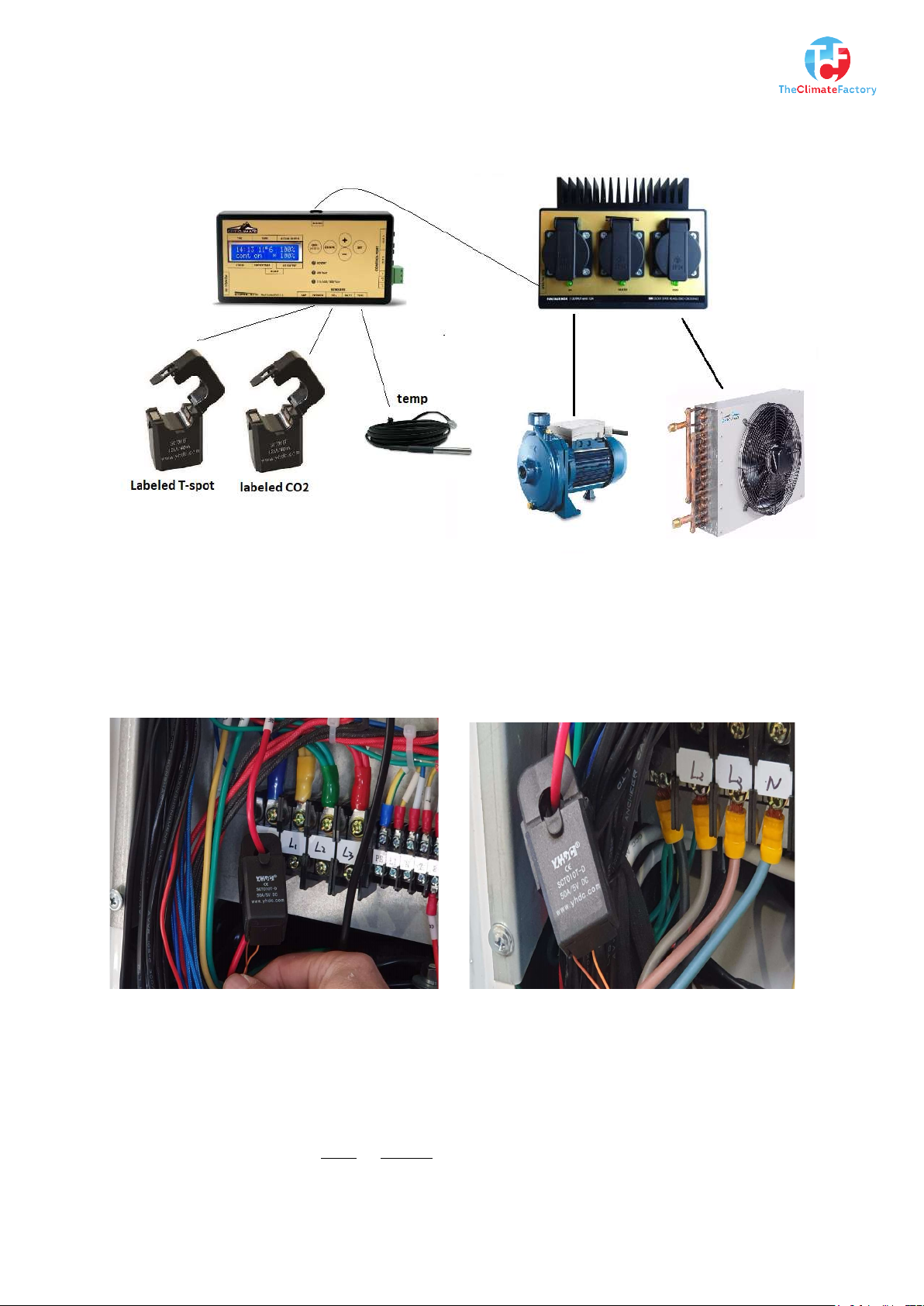

The Fan/pump control:

Fan and pump control are supplied as an option. The Fan/pump control comes as a set of different

parts.

-Temperature sensor for water temperature

-Startsensor (current clamp) to determent or compressor is on or off

-Fan/pump controller (the brain)

-Fan/pump box (connects to fan and pump)

The Fan/pump control makes the system even more efficient. The fan speed of the water cooler is

regulated depending on water temperature and the pump will only run when there is a need for

cooling. When the system is not in use, the pump will run a pre-defined cycle to prevent freezing in

colder climates. In cold climates a 20% or more glycol mix is recommended to prevent freezing.

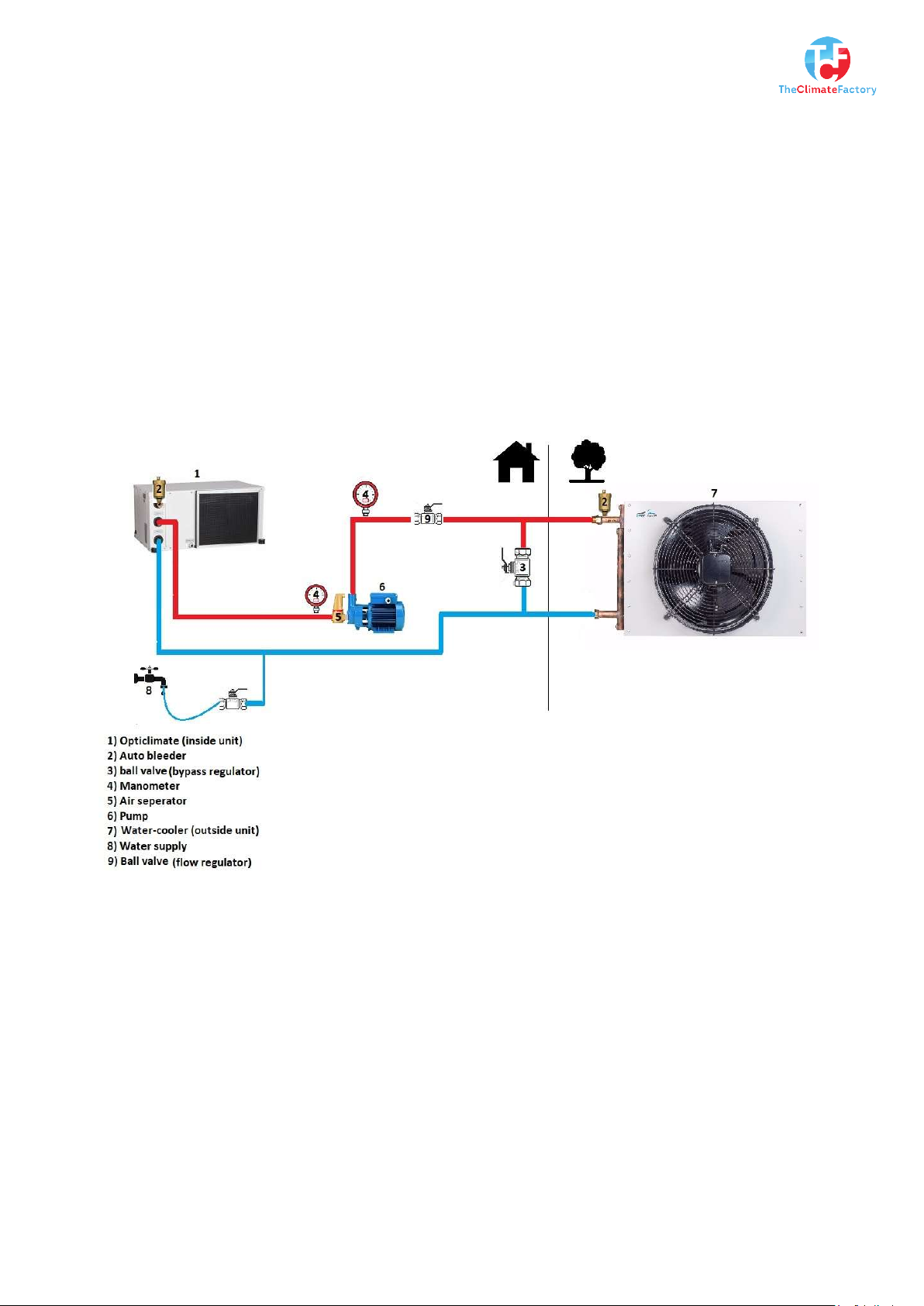

-Setting up 1 Opticlimate on 1 water-cooler

The system is filled with water or glycol mix. The water supply (8) must be located at the lowest

point of the system. Automatic bleeders (2) must be located at the highest point of the system. A

manometer (4) is positioned on the both the return and supply side of the pump. The air separator

(5)must be located at a location where the pressure in a running system is the lowest. (pump intake)

The set contains 2 ball valves, one to regulate flow (9) and one for the by-pass (3)

Air in the system reduces capacity and can damage pump or heat exchangers. Make sure air is

bleeded from the system after filling. Power the pump for a few seconds to bring air to the highest

point in the system. After bleeding, let the pump run full power, the air seperator will remove any

air bubbles that remain in the system. This can take a few minutes, hours or even days depending on

the layout of the piping.

© TCF 2019

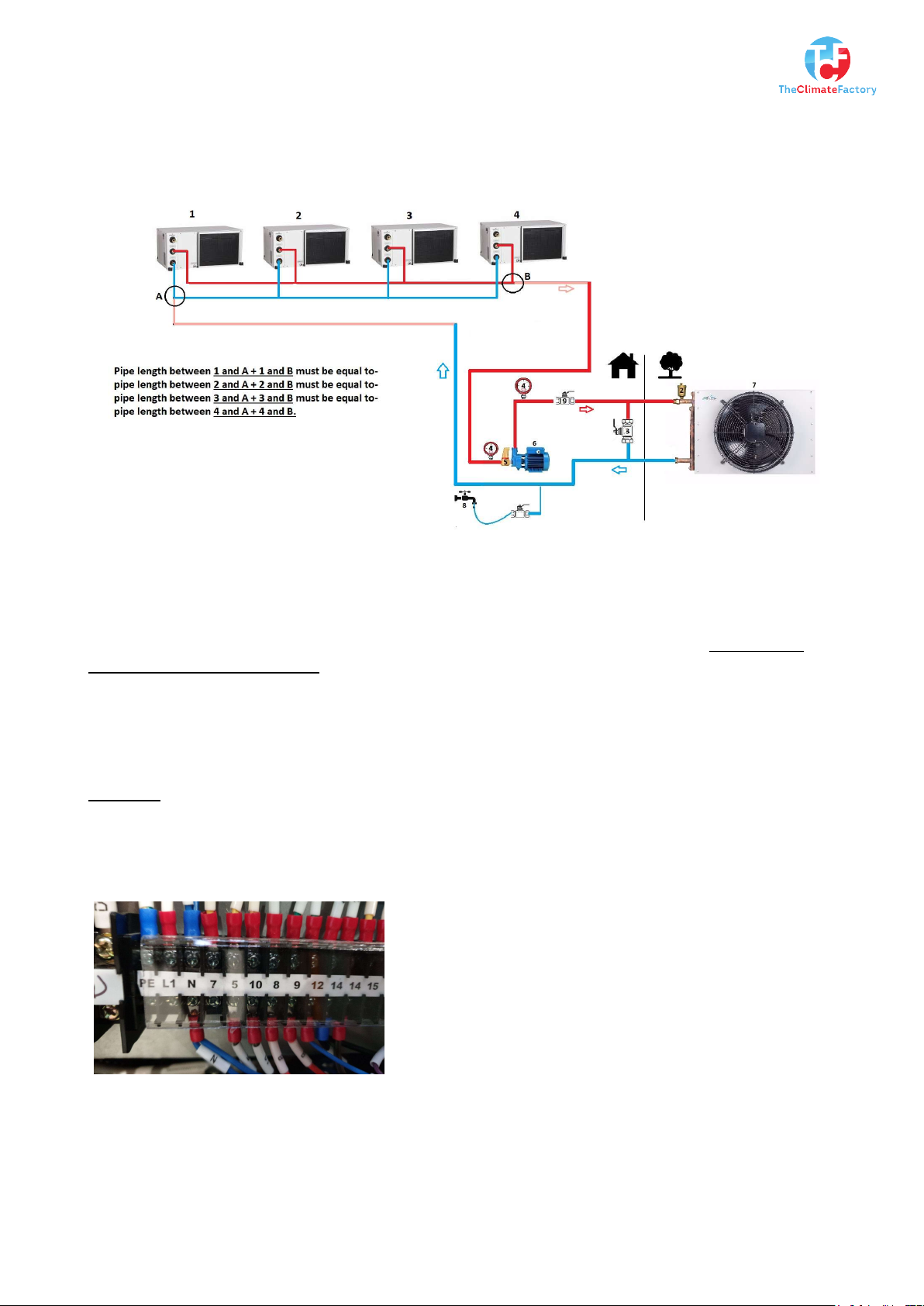

-Setting up multiple Opticlimates on 1 water-cooler

When connecting more than one Opticlimate to 1 water cooler, it's important that pipe resistance

(return and supply) for each Opticlimate is the same to prevent uneven water distribution between

the Opticlimates.

The setup of the water cooler and pump etc. is the same as described in the chapter Setting up 1

Opticlimate on 1 water-cooler.

The layout of the piping from and to the Opticlimates must be well designed. It's best to consult us

using a drawing or sketch of the situation on the Design sheet below.

-Setting up manual Fan/pump control

Tekening

The most simple and cheap way of fan and pump control is to power the pump always and

connecting the fan of the water cooler to connection N and 7 inside the electric compartment of the

Opticlimate.

The flow in this setup must be manualy adjusted with a valve in the piping between pump and water

cooler. The flow needs a periodic adjustment depending on outside temperatures. ΔT between

water-in and water-out of the Opticlimate needs to be 5K. More flow loweres ΔT, less flow

increases ΔT.

© TCF 2019

-Setting up fully automatic controlled Fan/pump control

A maxi-controller evo in combination with a fan-aux-box is used to control pump on/off and

fanspeed. The controller recieves 2 signals from 2 sensors: temperature sensor to determen water

temperature in the system and a current transformer to determen or the compressor inside the

opticlimate is on or off.

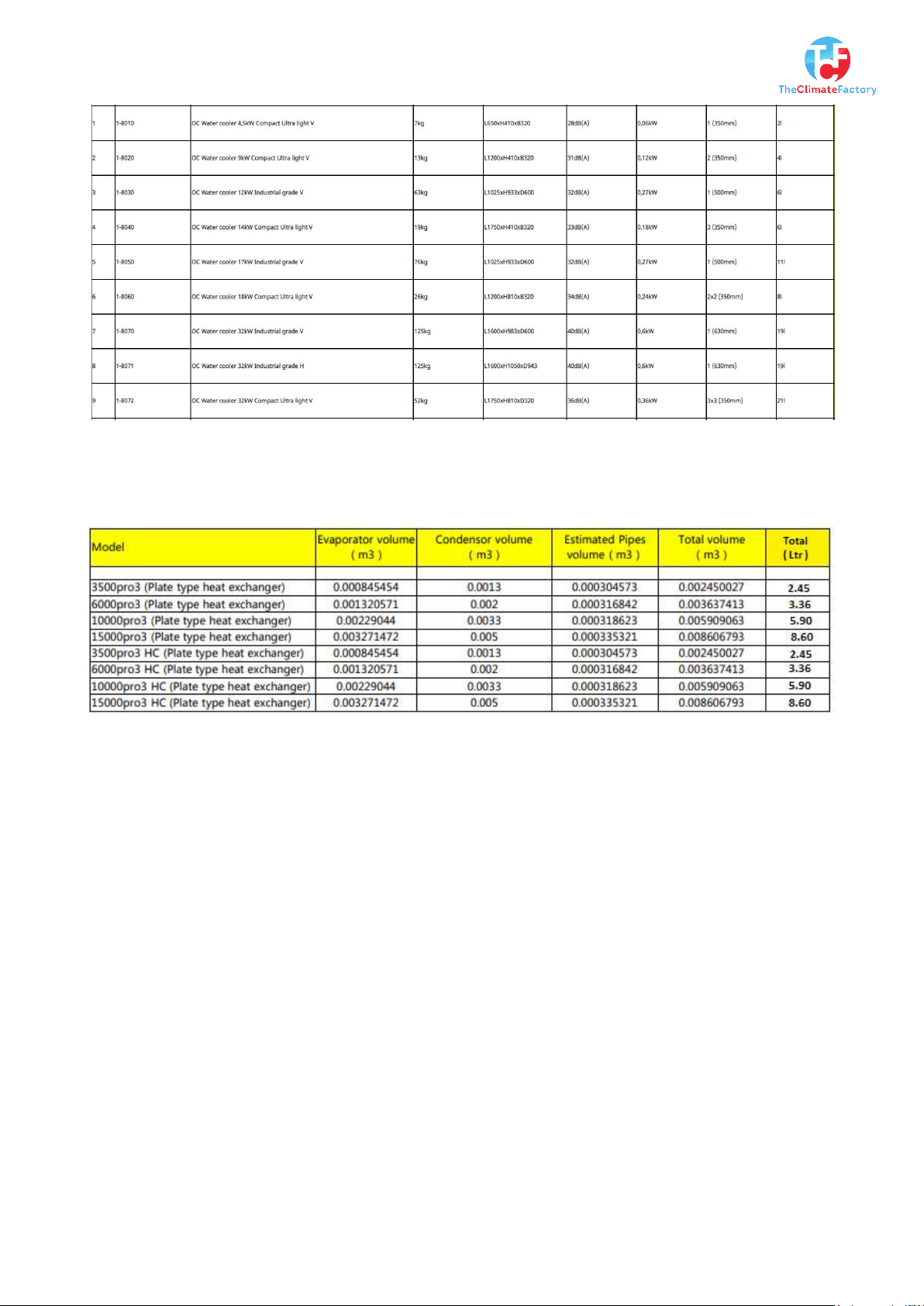

Connecting the current transformer:

On/off model Opticlimate Inverter model Opticlimate

When using an on/off model Opticlimate, find the cable that powers the compressor coming from

relays KM1. Cable code U,V or W.

When using an inverter model Opticlimate, find the cable that powers the inverter PCB or

compressor. The current clamp can be opened to clamp around the cable. Plug the other end into the

controller. The cable is labeled CO2 or T-spot. A current transformer labeled CO2 must be

connected to the controller CO2 port. A current transformer labeled T-spot must be connected to the

INFRARED port of the controller.

© TCF 2019

Connecting the water temperature sensor:

Move isolation back as far as possible Place sensor on copper pipe

Move the isolation sleeve back to cover the sensor and route the cable to the controller.

Plug the cable into the controller on the TEMP port.

Connecting the fan-aux-box:

Use the supplied communication-cable to connect the controllers AUX connection on top with the

fan-aux-box AUX-IN connection on the left side. The power outlet marked FAN on the fan-aux-box

must be connected to the fan of the water cooler and the pump must be connected to the outlet

marked RH. The settings on the controller are pre-set. Do not change them without consultation.

Power both the controller and fan-aux-box. The fan and pump go on for a few seconds, this is

normal at first startup.

© TCF 2019

-deter-men ΔT and adjusting

The design ΔT of the the system is 5K. This means that the temperature difference between the

water-inlet and outlet of the Opticlimate must be maintained at 5K. To deter-men this value press

the S-key short on the remote of the Opticlimate. In the display appears C-01 and a temperature.

Using the up-and down keys you can scroll from C-01 up to C-06.

To determent ΔT subtract the temperature value C02 from C03.

C02 – Water-out temperature (supply to water cooler)

C03 - Water-in temperature (return from water cooler)

Example: C02= 45°C

C03= 39°C -

ΔT= 6°K

-Balancing with manual or auto by-pass

-Adding glycol to the system

In an environment where glycol (antifreeze) in case of a leak could come in contact with food,

chemicals or in a pharmaceutical or agriculture plant, propylene glycol must be used. We

recommend to use a 20% glycol / water mix. (antifreeze protection -10°C) or more depending on

outside conditions.

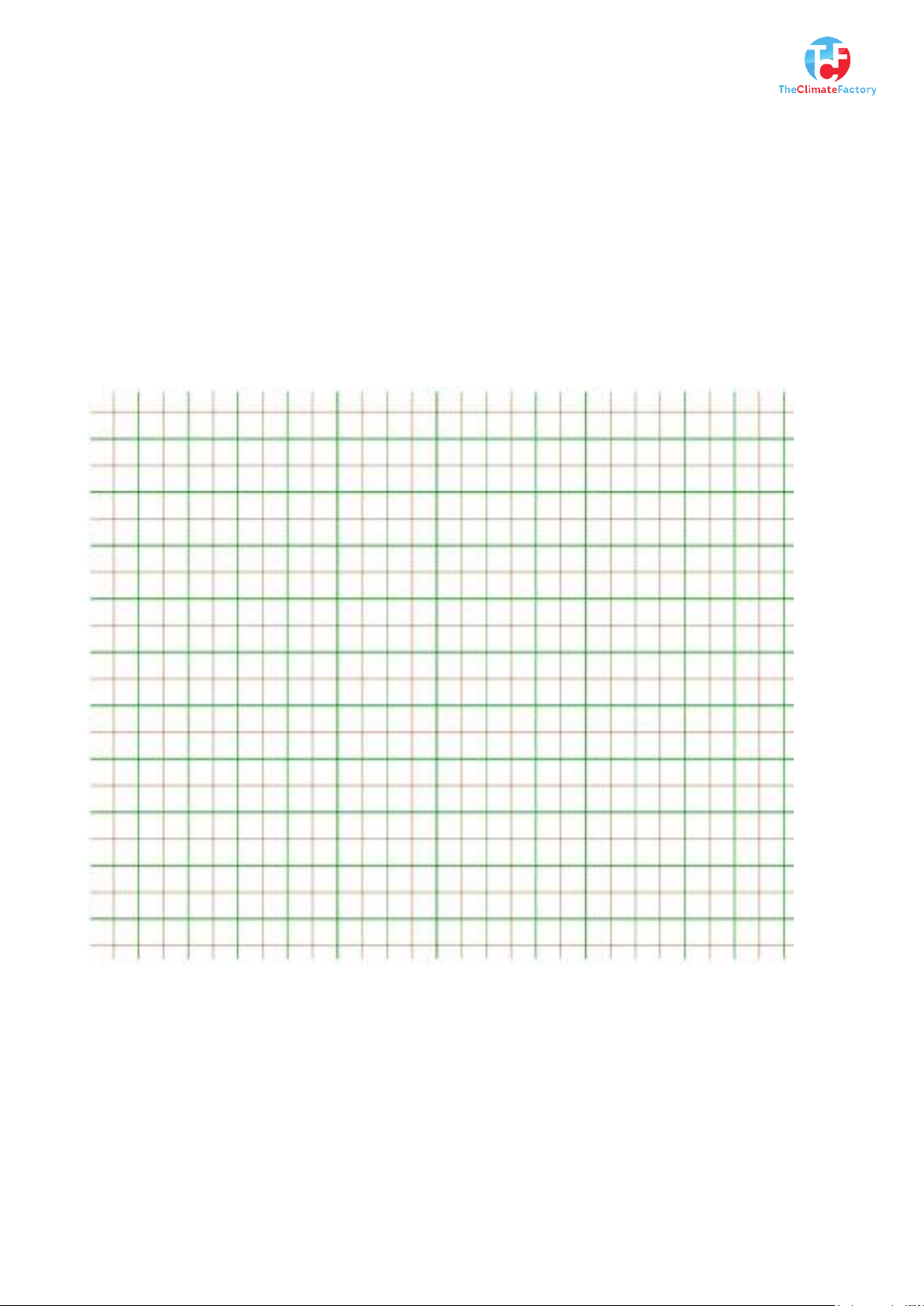

To determen how much glycol must be added, you need to know the total volume of water in the

system. The specification sheets below help to determen how much volume your system contains.

© TCF 2019

Order nr. Model Weight Dimensions Sound level Cooling power Fan Volume

1 meter of 25mm PE piping has a volume of 0,35ltr

1 meter of 32mm PE piping has a volume of 0,60ltr

Example:

A 15000pro3 high capacity (HC) on 1 x 17KW and a total pipe length of 100mtr x 32mm =

8.6 ltr + 11ltr + (100x 0.6ltr=60ltr) = 79.6ltr total volume. You need 16ltr of glycol to make a 20%

glycol/water mix.

When adding glycol to an empty system, use a pump to add the calculated amount of glycol, then

top-up the system with water until the static pressure is 1.5bar.

When adding glycol to system that is already pressurised and full with water, remove more water

than the amount of glycol you want to add, add the calculated amount of glycol and top-up with

water until the static pressure of the system is 1.5bar.

Note: -

-Pure water cools better than a glycol/water mix

-A water glycol mix prevents corrosion

-Use an automotive antifreeze tester and a sample of the glycol/water mix to check the freezing-

point of the mix. Make sure the mix is correct for weather conditions in your area.

© TCF 2019

Design sheet

Number of Opticlimates on 1 water cooler_______________________________________

Opticlimate model (s)___________________________________________________pro3/pro4

Distance between Opticlimates and water cooler_________________________________mtr

Heat load Opticlimates (KW)_________________________________________________KW

Max. outside temperature ____________________________________________________°C

Min. outside temperature ____________________________________________________°C

Sketch of the situation

© TCF 2019

This manual suits for next models

7

Table of contents

Popular Water Dispenser manuals by other brands

Omnifilter

Omnifilter OB1 installation instructions

Halsey Taylor

Halsey Taylor Contour Series owner's manual

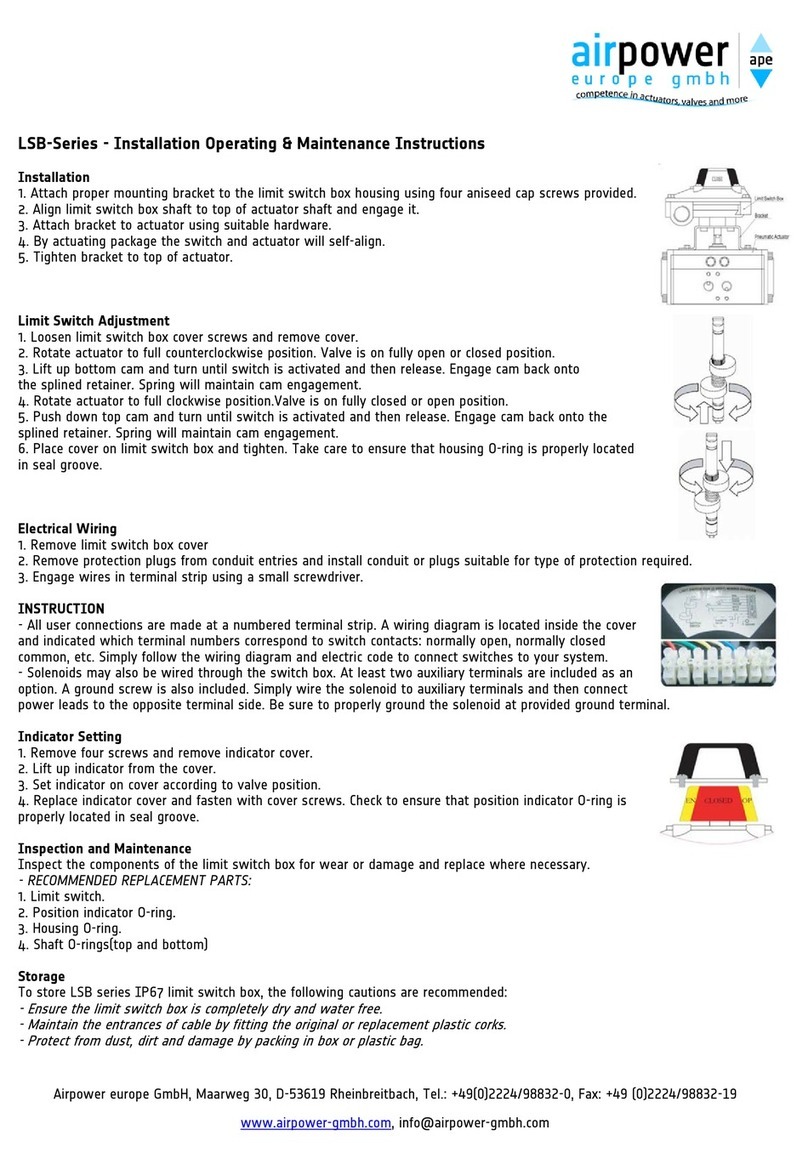

AirPower

AirPower LSB Series Installation, operating, & maintenance instructions

JCLASS

JCLASS SUPER HOT Installation, use and maintenance handbook

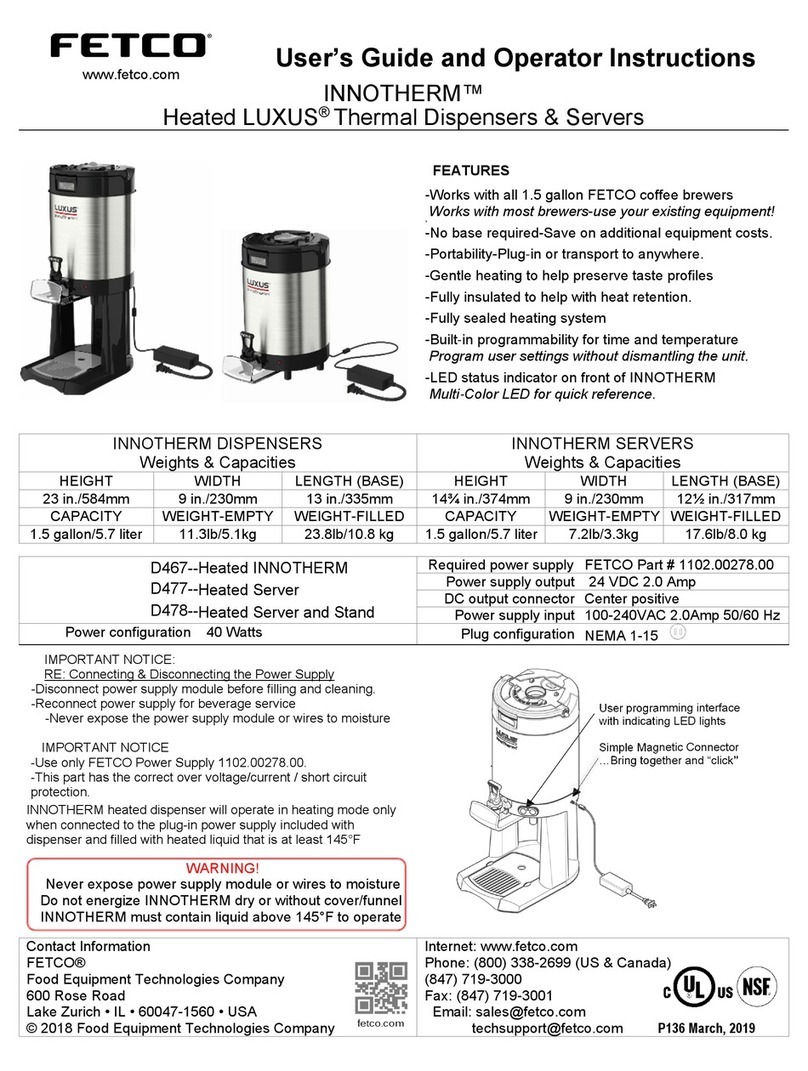

Fetco

Fetco INNOTHERM L4-HD15 Users guide and operator instructions

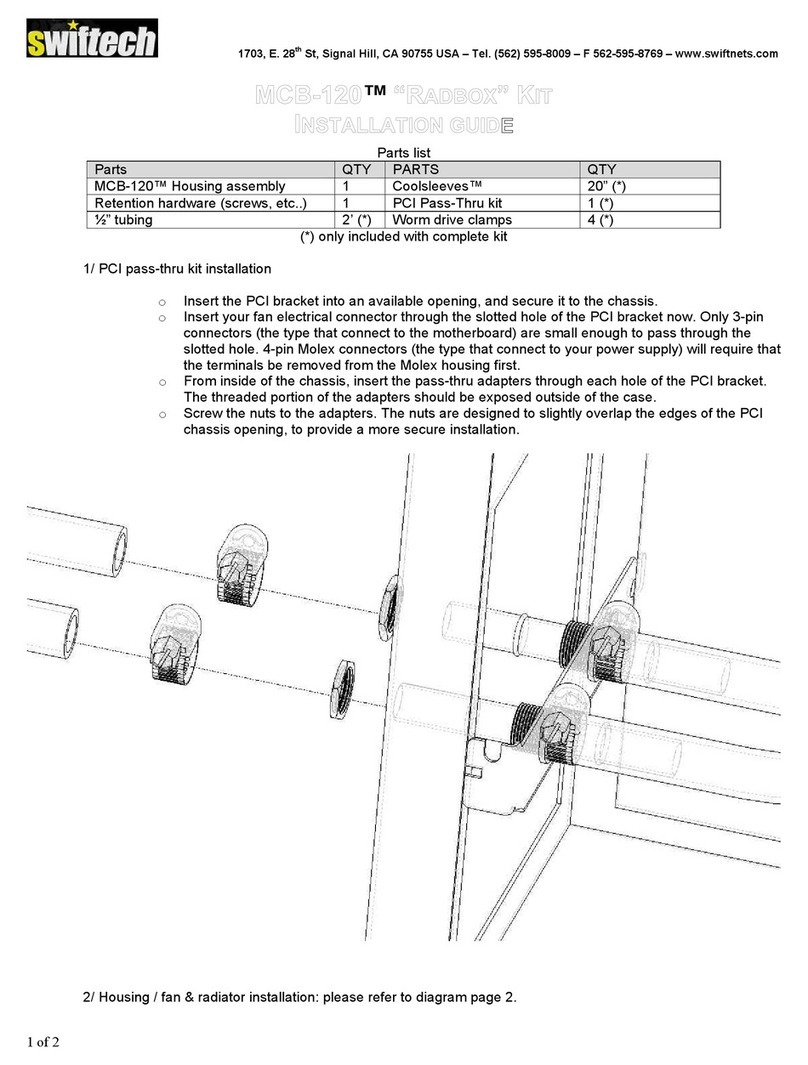

swiftech

swiftech MCB-120 installation guide

ClearWave

ClearWave CW-125 instructions

Everpure

Everpure Water Filter and Cartridge QL2-OW200L Specification sheet

Hellenbrand

Hellenbrand FM Series Brochure & specs

Atmospheric Water Systems

Atmospheric Water Systems dewpoint DH9 owner's manual

Addie Water Systems

Addie Water Systems 6700 Service manual

BRIO

BRIO CLPOU320UVF3 Setup manual