TDK-Lambada HWS?HWS User manual

HWSSeries

AC-DCSwitchingPowerSupply

HWS・HWS/ME・HWS/HD・HWS-P

Environmental-friendly

User-friendly

Safety

●Green power line

●Complies with RoHS Directive

●Energy Saving

●Miniature package

●Unified style

●Extensive product line

●High reliability design

●Safety-oriented design

●Safe to operate

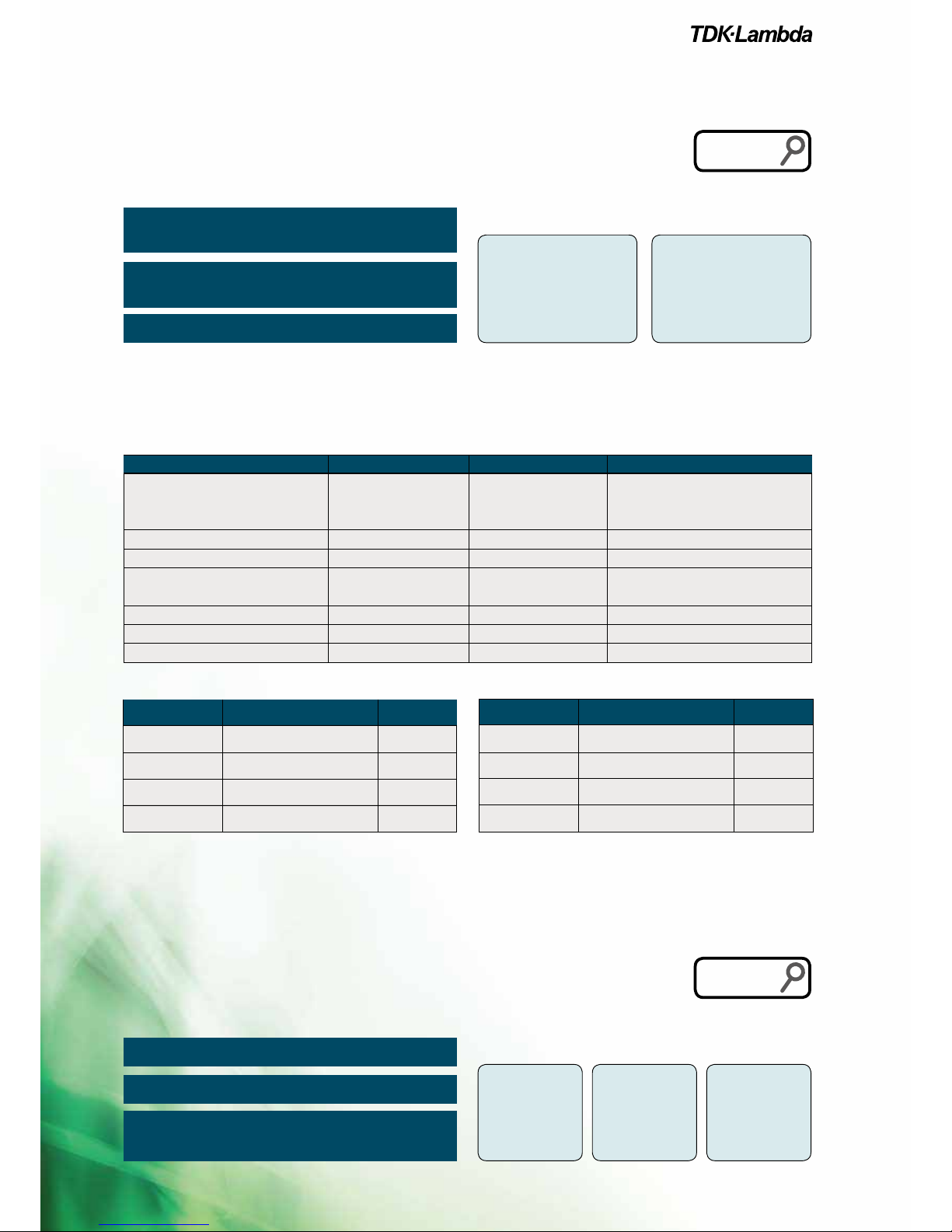

HWS Series Line Up

■HWS Series Model Name

HWS *** - ** **

Output power

Output voltage

Option code

● Output power

In addition to 11 models for 15W 〜1800W, there are 2 models

for peak power models which bring the total of 13 models.

● Output voltage

Wide variety of line up from 3.3V to 48V. 60V is also available for 1000W and above models.

● Option code

・

HWSGeneral industrial

・

HWS/MEMedical standard (IEC60601) compliance

・

HWS/HDSuitable for harsh environment/Heavy duty equipment

・

HWS-PPeak power load

HWS

HWS Series put together the concept of

"Environment-friendly", "User-friendly", and

"Safety" as its foundation to offer wide range

of product.

Code Contents

ME EN/UL60601 Approved, low leakage current for medical application

HD Double-sided coating and -40℃start up, suitable for harsh environment

A Cover for additional safety operation

R Remote ON/OFF by external voltage

ADIN DIN Reel type

PV External voltage adjustment

FG Low leakage current type

*Not all models are available for above option and longer delivery might be needed for option models. Please contact our sales for more information

HWSSeries

WIDE SELECTION OF LINE UP RANGE FROM

GENERAL INDUSTRIAL, MEDICAL, HEAVY DUTY

TO POWER SUPPLY WITH PEAK OUTPUT

WIDE SELECTION OF LINE UP RANGE FROM

GENERAL INDUSTRIAL, MEDICAL, HEAVY DUTY

TO POWER SUPPLY WITH PEAK OUTPUT

Exhaust type forced air cooling using built-in fans

installed at the rear of the unit (300W - 1800W )

No space is required at the

side between power supplies

when multiple units are used.

Built-in automated speed

control fan contribute to low

acoustic noise during normal

temperature operation.

Unified style

Unified style of 82mm height make it more

convenient in design when multiple units

are used. All models can be embedded in

19-inch 2U rack mount

90

85

80

75

70

65

60

3.3 5 12

HWS150

Previous model of 150W

15

Output voltage

24 48

Efficiency (%)

Long Life

105° long life elec. capacitors are

used and design to operate for

24 hours/365 days continously

using guranteed life time from

component manufacturers.

High efficiency design

Synchronous rectification circuit

is used in 3.3V/5V output to sup-

port lower voltage higher current.

These products achieved more

than 80% efficiency

Warranty: 5 years

Reliability design

Safety terminal

User-friendly

Safety

HWSAC/DC Switching Power Supply

Environment-friendly

Complies to RoHS Directives

Energy saving

●Reducing power loss during operation through high efficient

design.

●Fan will stop during output "OFF" initiated by remote ON/OFF.

Designed to meet worldwide safety regula-

tion. It also meet the requirement for CE

marking, which is a safety standard in Euro-

pean Union.

150W

126.5±1

Previous

model

Previous

model

150 0W

42±1

Miniaturization of over 50%

UL60950-1/CSA C22.2

No.60950-1

CEマーキング

(低電圧指令適合)

UL508/CSA C22.2 No.14-M95

EN50178

Safety design

Previous

model

HWS

150W

Saves

19W

Line up

P7

Previously, cover was required to

ensure safety in the terminal. With

safety terminal, life areas are cov-

ered by terminal block and direct

contact with finger can be prevented (finger protection).

With integral construction between screw and terminal, it will

prevent the screw from dropping off into the unit (300W -

1800W type are using input terminal)

times[ms]

Voltagesags(%)

0

-10

-20

-30

-40

-50

-60

-80

-100

50 200 500 1000

SEMIF47-0200range

The momentary voltage drop (voltage sag) power supply fault that

may occur due to certain natural disaster or lightning is a critical issue

for semiconductor factories and semiconductor manufacturing equip-

ment. The supply voltage sag (voltage drop) and duration is stipulated

by the SEMIF47-0200, " Specification For Semiconductor Processing

Equipment Voltage Sag Immunity" standard which is a US semicondu-

tor equipment standard and can be met when 200VAC input is used.

Safe operation

While swicthing power supply

provide stable DC power, there

are environmental condition

requirement that unique to the

different fields in which equip-

ment is used.

HWS1000 - 1800 featured red

marking on the + side and black

marking on the - of the output

terminal. This reduce the pos-

sibility of incorrect connection

Live area, terminal screw are covered.

Safety terminal does not require terminal cover

Terminal structure with integrated screw

inserting round crimp terminal

Terminal are tightened with screwdriver.

Screw cannot fall out or loss

safety is assured even without terminal

cover

HWSSeries

H82mm

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

nn

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

9

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

i

n

n

n

nn

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

h

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

UU

U

U

U

UUU

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

U

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

r

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

c

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

k

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

m

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

u

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

n

tt

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

tt

t

t

t

t

t

t

t

t

t

t

t

t

t

t

Fit in 19-inch 2U rack mount

Miniature Package

By increasing efficiency

and optimization of compo-

nets and circuit design, we

achieved over 50% miniatur-

ization.

HWS/ME

HWS/HD Line up

P31

Line up

P51

●Immunity (All models)

Attention:

Please read the instruction manual carefully before using this product. On top of the following condition, please refer to to "HWS Series" standard instruction manual (p25-).

Please confirm whether there is insulation materials used inside the equipment (whether there is patient direct contact or indirect contact with the equipment). All models are

approved for basic insulation, therefore additional insulation circuit may be needed in the equipment.

●Emission (HWS30,50,100,150,300/ME) ●Emission (HWS 600,1500/ME)

Medical safety standard (EN60601/UL60601)

compliance

7 models with 42 line ups

Contribute to shortened the time needed in develop-

ing medical equipment and reduce its cost

Designed to meet MIL-STD-810F

(shock and vibration)

PCB coating

-40℃Start up

Era where standard power supply used in medical application

Harsh environment applications

AC/DC Standard switching power supply

for rugged and heavy duty

Items

Electrostatic

Radiated susceptibility

Electrical fast transient/burst

Surge

Conducted susceptibility

Power frequency magnetic field

Voltage dips. Short interuption

Standard

lEC61000-4-2

lEC61000-4-3

lEC61000-4-4

lEC61000-4-5

lEC61000-4-6

lEC61000-4-8

lEC61000-4-11

Compliance Level

Level3

(Level 2,3 for

300W, 600W)

Level 3

Level 3

Level 3,4

Level 3

Level 4

Complied

Notes

Aerial discharge: 8kV

Contact discharge:6kV

(4kV for 1500W)

10V/m

2kV

Common: 4.0kV

Differential mode: 2.0kV

10V

30A/m

Test items

Radiated electric field

Conducted emissions

Conducted harmonics

Flicker

Standard

EN55022/EN55011,FCC,VCCI

EN55022/EN55011,FCC,VCCI

IEC61000-3-2

IEC61000-3-3

Notes

Class B Compliance

Class B Compliance

Conformed

Conformed

Test items

Radiated electric field

Conducted emissions

Conducted harmonics

Flicker

Standard

EN55022/EN55011,FCC,VCCI

EN55022/EN55011,FCC,VCCI

IEC61000-3-2

IEC61000-3-3

Notes

Class A Compliance

Class A Compliance

Conformed

Conformed

Medical lasers,

X-Ray,

Microwave thera-

phy equipment

Diagnosis equip-

ments,

Analysis/testing

devices

Main applications

Leakage current: max. 0.5mA

100VAC(Typ):0.2mA/30〜150W、0.15mA/300W、0.12mA/600W、0.2mA/1000〜1500W

230VAC(Typ):0.4mA/30〜150W、0.39mA/300W、0.34mA/600W、0.4mA/1000〜1500W

EMC

HWSSeries

AC/DC Switching power supply for

medical application

Main applications

LED display

Device

Process

control

Factory

machinery

4

HWS-P

Support drive load with 3 times of peak power

AC/DC Switching power supply

with peak power capability

Factory

machiney

Textile

machinery,

Cash dispenser

Main applications

Line up

P69

Low acoustic noise with automated speed control fan

High power in compact size

Up to 3 times of peak current

High Reliability and User Friendly Power Supply for

Drive Load Application

The growth of motor and printer head applications, the center of

multifunction and high speed machineries, have been increased

from year to year. HWS-P is superior to provide function to sup-

port instant current in typical drive load with up to 3 times peak

current in compact size.

By taking into consideration on the demand of high reliability in-

dustrial equipment, elec. capacitor is expected to have 7 year of

life (Ta=40°)

. Also, 5 year warranty is provided.

The design include OCP circuit with shut off function, OVP circuit,

temperature sensor for automatic speed control fan as well as

built-in OTP circuit. All of these functions give a better safety and

ease to the users.

Mode

Output Voltage

HWS300P HWS600P

Ave. output

current

Peak current Ave. output

current

Peak current

100V input 200V input 100V input 200V input

24V 12.5A 21.0A 42.0A 25.0A 40.5A 83.0A

36V 8.4A 14.0A 28.0A 16.7A 27.0A 55.5A

48V 6.3A 10.5A 21.0A 12.5A 20.0A 41.5A

HWSSeries

Up to 3 times peak current to give powerful

support to motor and printer head application

Up to 3 times peak current to give powerful

support to motor and printer head application

Semiconductor

testing device

HWS 7

Specifications

HWS15 8

HWS30 10

HWS50 12

HWS80 14

HWS100 16

HWS150 18

HWS300 20

HWS600 22

HWS1000 24

HWS1500 26

HWS1800T 28

HWS/HD 31

Specifications

HWS30/HD 32

HWS50/HD 34

HWS100/HD 36

HWS150/HD 38

HWS300/HD 40

HWS600/HD 42

HWS1000/HD 44

HWS1500/HD 46

HWS1800T/HD 48

HWS/ME 51

Specifications

HWS30/ME 52

HWS50/ME 54

HWS100/ME 56

HWS150/ME 58

HWS300/ME 60

HWS600/ME 62

HWS1000/ME 64

HWS1500/ME 66

HWS-P 69

Specifications

HWS300P 70

HWS600P 72

HWS Series All 74

Block Diagram

HWS15, 30, 50, 80, 100, 150 74

HWS300, 600, 1000 75

HWS1500, 1800T 76

Sequence Time Chart

HWS300, 600, 1000 77

HWS1500, 1800T 78

Instruction Manual

HWS15, 30, 50, 80, 100, 150 79

HWS300, 600 85

HWS1000 93

HWS1500 104

HWS1800T 113

HWS300P, 600P 124

Contents

Instruction Manual

HWS HWS HD HWS ME HWS-P

■Applications

■Features

HWS

■ProductLineup

SingleOutput15W-1800W

Y

E

A

R

S

warranty

5

■Features

〔HWS15-150〕

HWS50−5/□□

■

ConformitytoRoHSDirective

■Modelnamingmethod

〔HWS300-1800〕

HWS300−5/□□

Instruction Manual

HWS HWS HD HWS ME HWS-P

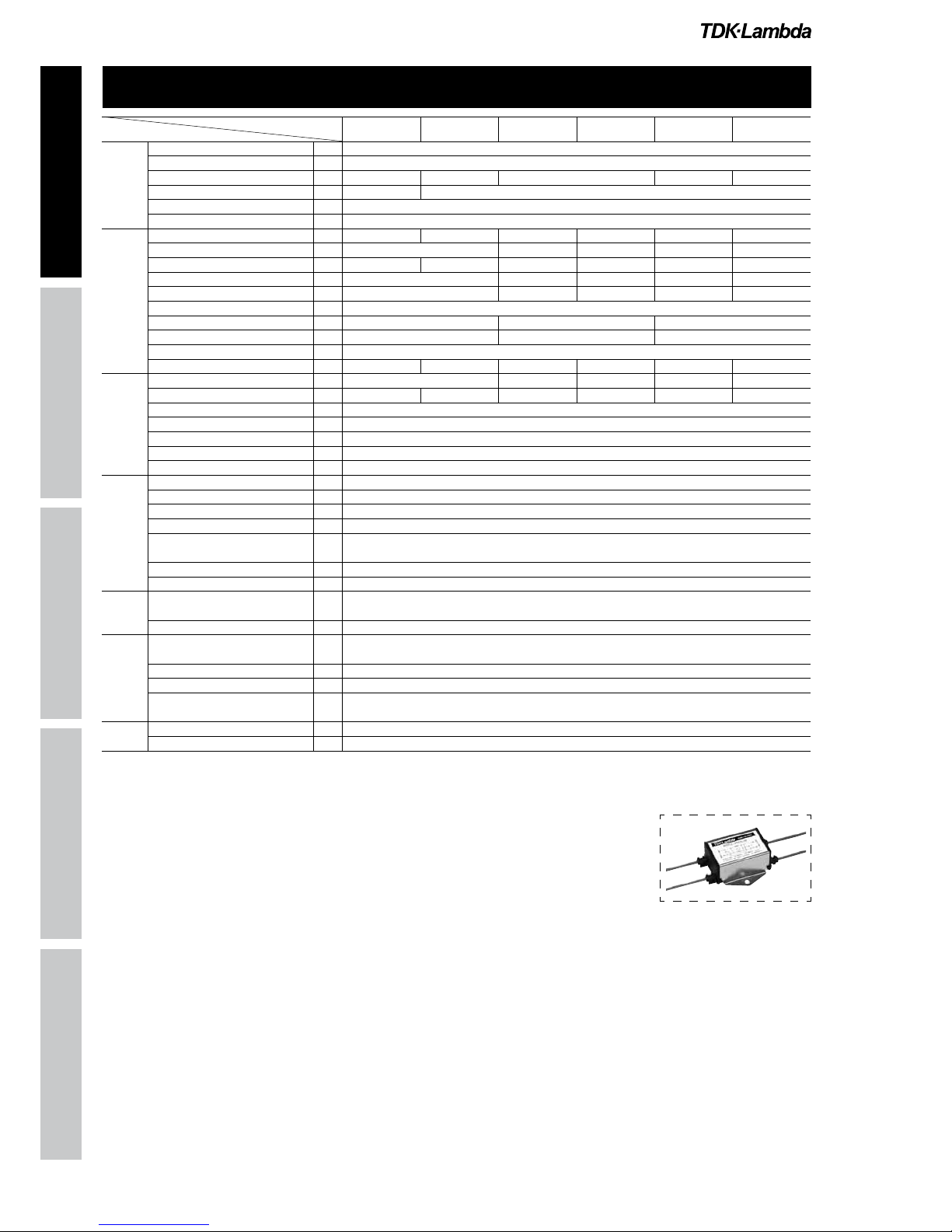

ITEMS/UNITS MODEL HWS15-3 HWS15-5 HWS15-12 HWS15-15 HWS15-24 HWS15-48

Input

Voltage Range (*2) V AC85 - 265 or DC120 - 370

Frequency (*2) Hz 47 - 63

Efficiency (100/200VAC)(typ) (*1) 68 / 71 77 / 79 80 / 81 82 / 83 80 / 80

Current (100/200VAC)(typ) (*1) A 0.3 / 0.15 0.4 / 0.2

Inrush Current (100/200VAC)(typ) (*3)

A 14 / 28, Ta=25, cold start

Leakage Current (*10) mA Less than 0.5. (0.2 (typ) at 100VAC / 0.4 (typ) at 230VAC)

Output

Nominal Voltage VDC 3.3 5 12 15 24 48

Maximum Current A 3 1.3 1 0.65 0.33

Maximum Power W 10 15 15.6 15 15.6 15.8

Maximum Line Regulation (*5) mV 20 48 60 96 192

Maximum Load Regulation (*6) mV 40 96 120 192 384

Temperature Coefficient Less than 0.02% /

Maximum Ripple & Noise (0<Ta<70) (*4)

mVp-p

120 150 200

Maximum Ripple & Noise (10<Ta<0) (*4)

mVp-p

160 180 240

Hold-up Time (typ) (*9) ms 20

Voltage Adjustable Range VDC 2.97 - 3.96 4.0 - 6.0 9.6 - 14.4 12.0 - 18.0 19.2 - 28.8 38.4 - 52.8

Function

Over Current Protection (*7) A >3.15 >1.36 >1.05 >0.68 >0.34

Over Voltage Protection (*8) VDC 4.13 - 4.95 6.25 - 7.25 15.0 - 17.4 18.8 - 21.8 30.0 - 34.8 55.2 - 64.8

Remote Sensing -

Remote ON/OFF Control -

Parallel Operation -

Series Operation Possible

Line DIP Built to meet SEMI-F47 (200VAC Line only)

Environment

Operating Temperature (*11) -10 to +70 (-10 to +50: 100%, +60: 60%, +70: 20%)

Storage Temperature -30 to +85

Operating Humidity RH 30 - 90 (No dewdrop)

Storage Humidity RH 10 - 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1min)

19.6m/s² constant, X, Y, Z 1hour each.

Shock (In package) Less than 196.1m/s²

Cooling Convection cooling

Isolation Withstand Voltage Input - FG : 2kVAC (20mA), Input - Output : 3kVAC (20mA)

Output - FG : 500VAC (100mA) for 1min

Isolation Resistance More than 100Mat 25and 70%RH Output - FG : 500VDC

Standards

Safety Standards (*12) Approved by UL60950-1, CSA C22.2 No.60950-1, EN60950-1, EN50178 UL508 (with cover models only),

CSA C22.2 No.14-M95 (with cover models only) Built to meet UL508, DENAN

PFHC Built to meet IEC61000-3-2

EMI Built to meet EN55011/EN55022-B, FCC-B, VCCI-B

Immunity Built to meet IEC61000-4-2(Level 2,3), -3(Level 3), -4(Level 3),

-5(Level 3,4), -6(Level 3), -8(Level 4), -11

Mechanical

Weight (typ) g 180

Size (W x H x D) mm 26.5 x 82 x 80 (Refer to outline drawing)

(*1) At 100/200VAC, Ta=25and maximum output power.

(*2) For cases where conformance to various safety specs (UL, CSA, EN) are required, to be described as 100 - 240VAC (50/60Hz).

(*3) Not applicable for the in-rush current to noise filter for less than 0.2ms.

(*4) Measure with JEITA RC-9131A probe, bandwidth of scope :100MHz.

For start up at low ambient temperature and low input voltage, output ripple noise might not meet specification.

However, there is no overshoot at start up and output ripple noise specification can be met after one second.

(*5) 85 - 265VAC, constant load.

(*6) No load-Full load, constant input voltage.

(*7) Foldback current limit with automatic recovery. Not operate at over load or dead short

condition for more than 30 seconds.

(*8) OVP circuit will shutdown output, manual reset (Re power on).

(*9) At 100/200VAC, Ta=25, nominal output voltage and maximum output current.

(*10) Measured by the each measuring method of UL, CSA, EN and DENAN (at 60Hz).

(*11) Ratings - Derating at standard mounting.

- Load (%) is percent of maximum output power or maximum output current, whichever is greater.

- As for other mountings, refer to derating curve.

(*12) As for DENAN, built to meet at 100VAC.

Pleasereferto"TDK-Lambda

EMCFilters"catalog.

●

RecommendedEMCFilter

HWS15 Specifications(Read instruction manual carefully, before using the power supply unit.)

HWS 15

Instruction Manual

HWS HWS HD HWS ME HWS-P

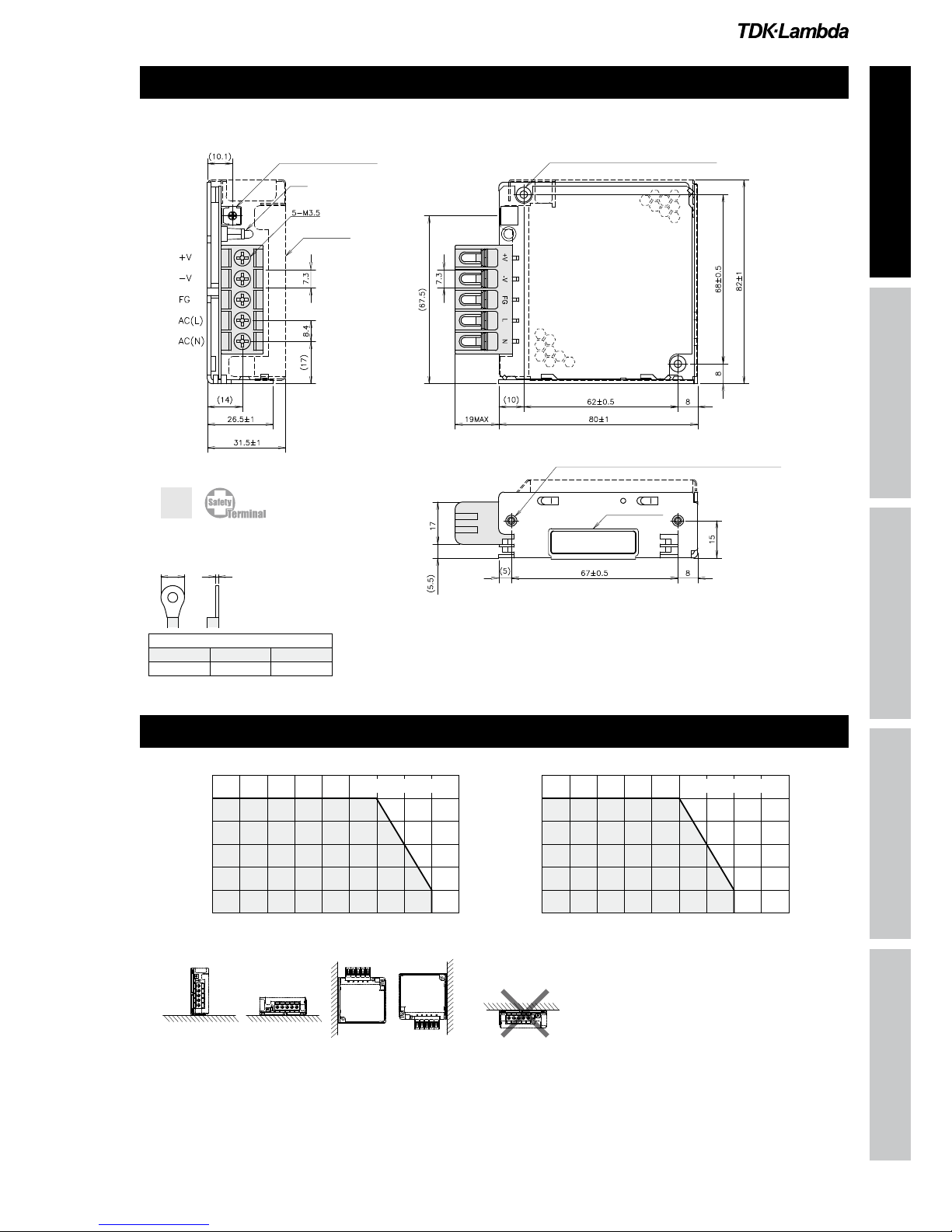

【HWS15】

D(max)t(max) Qty(max)

6.8mm 0.8mm 2pcs

Dt

VOLTAGEADJUSTMENT

COVER

(OPTION)

(WITHOUTCOVER)

(WITHCOVER)

NAMEPLATE

2-M3EMBOSSED,TAPPEDANDCOUNTERSUCKHOLES

SCREWPENETRATIONDEPTHMAX.6mm

2-M3TAPPEDHOLES

LED

unit:mm

RecommendedSolderlessTerminal

SCREWPENETRATIONDEPTHMAX.6mm

0

20

40

60

80

100

120

-10 0 10203040506070 80

MOUNTINGA,B,C,D

0

20

40

60

80

100

120

-10 0 10203040506070 80

Ta(°C)

MOUNTINGA,B,C,D

LOAD(%)

Ta(°C)

LOAD(%)

MOUNTINGA

(STANDARDMOUNTING)

MOUNTINGB MOUNTINGC MOUNTINGD DON'TUSE

HWS 15

Output Derating

Outline Drawing

Instruction Manual

HWS HWS HD HWS ME HWS-P

Pleasereferto"TDK-Lambda

EMCFilters"catalog.

●

RecommendedEMCFilter

(*1) At 100/200VAC, Ta=25and maximum output power.

(*2) For cases where conformance to various safety specs (UL, CSA, EN) are required, to be described as 100 - 240VAC (50/60Hz).

(*3) Not applicable for the in-rush current to noise filter for less than 0.2ms.

(*4) Measure with JEITA RC-9131A probe, bandwidth of scope :100MHz.

For start up at low ambient temperature and low input voltage, output ripple noise might not meet specification.

However, there is no overshoot at start up and output ripple noise specification can be met after one second.

(*5) 85 - 265VAC, constant load.

(*6) No load-Full load, constant input voltage.

(*7) Foldback current limit with automatic recovery. Not operate at over load or

dead short condition for more than 30 seconds.

(*8) OVP circuit will shutdown output, manual reset (re power on).

(*9) At 100/200VAC, Ta=25, nominal output voltage and maximum output current.

(*10) Measured by the each measuring method of UL, CSA, EN and DENAN (at 60Hz).

(*11) Ratings - Derating at standard mounting.

- Load (%) is percent of maximum output power or maximum output current, whichever is greater.

- As for other mountings, refer to derating curve.

(*12) As for DENAN, built to meet at 100VAC.

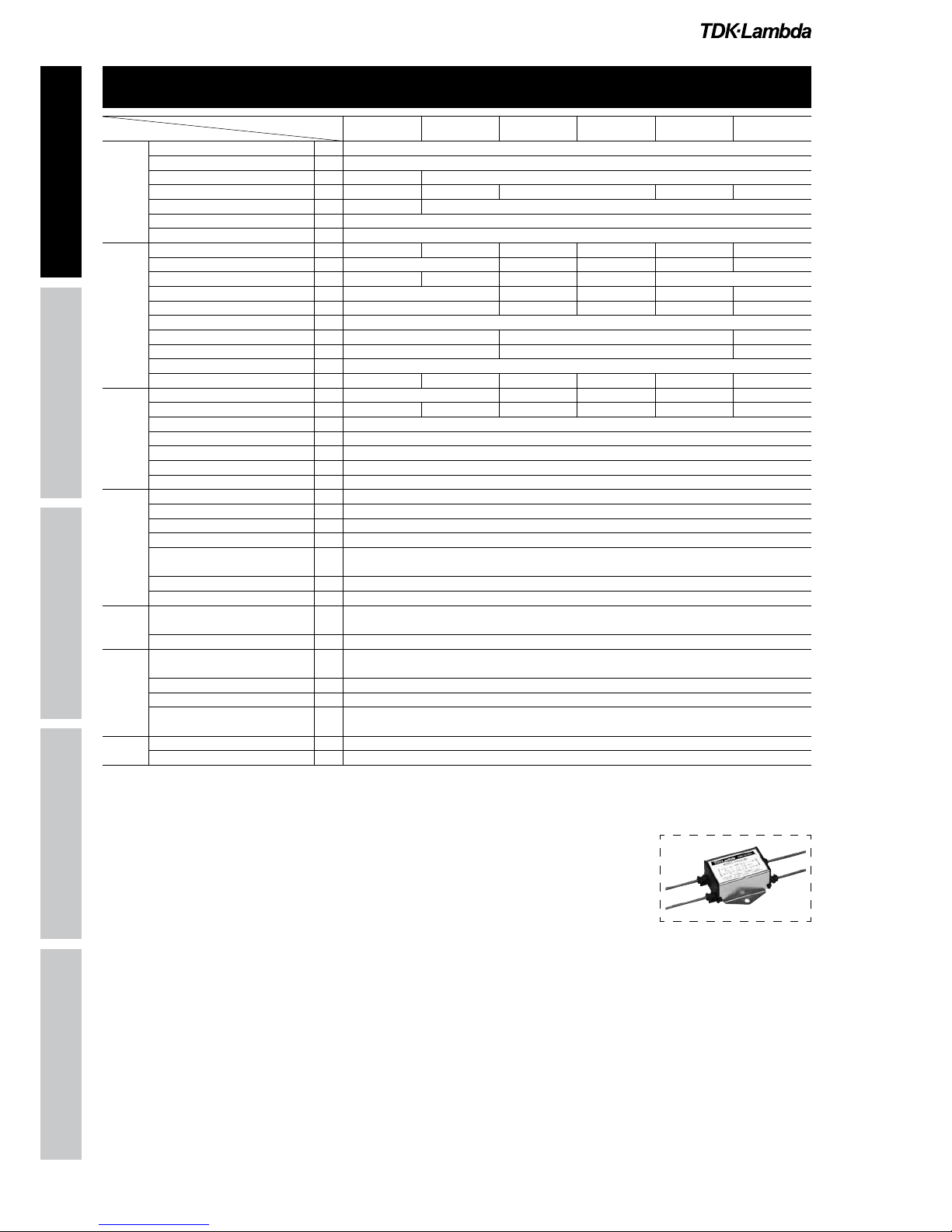

ITEMS/UNITS MODEL HWS30-3 HWS30-5 HWS30-12 HWS30-15 HWS30-24 HWS30-48

Input

Voltage Range (*2) V AC85 - 265 or DC120 - 370

Frequency (*2) Hz 47 - 63

Efficiency (100/200VAC)(typ) (*1) 70 / 73 77 / 80 81 / 83 83 / 86 82 / 83

Current (100/200VAC)(typ) (*1) A 0.6 / 0.3 0.8 / 0.4

Inrush Current (100/200VAC)(typ)(*3)

A 14 / 28, Ta=25, cold start

Leakage Current (*10) mA Less than 0.5. (0.2 (typ) at 100VAC / 0.4 (typ) at 230VAC)

Output

Nominal Voltage VDC 3.3 5 12 15 24 48

Maximum Current A 6 2.5 2 1.3 0.65

Maximum Power W 20 30 31.2

Maximum Line Regulation (*5) mV 20 48 60 96 192

Maximum Load Regulation (*6) mV 40 96 120 192 384

Temperature Coefficient Less than 0.02% /

Maximum Ripple & Noise (0≤Ta≤70) (*4)

mVp-p

120 150 200

Maximum Ripple & Noise (10≤Ta< 0) (*4)

mVp-p

160 180 240

Hold-up Time (typ) (*9) ms 20

Voltage Adjustable Range VDC 2.97 - 3.96 4.0 - 6.0 9.6 - 14.4 12.0 - 18.0 19.2 - 28.8 38.4 - 52.8

Function

Over Current Protection (*7) A >6.3 >2.62 >2.1 >1.36 >0.68

Over Voltage Protection (*8) VDC 4.13 - 4.95 6.25 - 7.25 15.0 - 17.4 18.8 - 21.8 30.0 - 34.8 55.2 - 64.8

Remote Sensing -

Remote ON/OFF Control -

Parallel Operation -

Series Operation Possible

Line DIP Built to meet SEMI-F47 (200VAC Line only)

Environment

Operating Temperature (*11) -10 to +70 (-10 to +50: 100%, +60: 60%, +70: 20%)

Storage Temperature -30 to +85

Operating Humidity RH 30 - 90 (No dewdrop)

Storage Humidity RH 10 - 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1min)

19.6m/s² constant, X, Y, Z 1hour each.

Shock (In package) Less than 196.1m/s²

Cooling Convection cooling

Isolation Withstand Voltage Input - FG : 2kVAC (20mA), Input - Output : 3kVAC (20mA)

Output - FG : 500VAC (100mA) for 1min

Isolation Resistance More than 100Mat 25and 70%RH Output - FG : 500VDC

Standards

Safety Standards (*12) Approved by UL60950-1, CSA C22.2 No.60950-1, EN60950-1, EN50178 UL508 (with cover models only),

CSA C22.2 No.14-M95 (with cover models only) Built to meet DENAN

PFHC Built to meet IEC61000-3-2

EMI Built to meet EN55011/EN55022-B, FCC-B, VCCI-B

Immunity Built to meet IEC61000-4-2(Level 2,3), -3(Level 3), -4(Level 3),

-5(Level 3,4), -6(Level 3), -8(Level 4), -11

Mechanical

Weight (typ) g 220

Size (W x H x D) mm 26.5 x 82 x 95 (Refer to outline drawing)

HWS30 Specifications(Read instruction manual carefully, before using the power supply unit.)

HWS 30

Instruction Manual

HWS HWS HD HWS ME HWS-P

【HWS30】

VOLTAGEADJUSTMENT

LED

NAMEPLATE

SEENOTEA

unit

COVER

(OPTION)

(WITHOUTCOVER)

(WITHCOVER)

RecommendedSolderlessTerminal

Qty(max)

2pcs

2-M3EMBOSSED,TAPPEDANDCOUNTERSUCKHOLES

SCREWPENETRATIONDEPTHMAX.6mm

2-M3TAPPEDHOLES

SCREWPENETRATIONDEPTHMAX.6mm

0

20

40

60

80

100

120

-10 0 10203040506070 80

0

20

40

60

80

100

120

-10 0 10203040506070 80

MOUNTINGA,B,C,D

Ta(°C)

MOUNTINGA,B,C,D

LOAD(%)

Ta(°C)

LOAD(%)

MOUNTINGA

(STANDARDMOUNTING)

MOUNTINGB MOUNTINGC MOUNTINGD DON'TUSE

Output Derating

Outline Drawing

HWS 30

Instruction Manual

HWS HWS HD HWS ME HWS-P

(*1) At 100/200VAC, Ta=25and maximum output power.

(*2) For cases where conformance to various safety specs (UL, CSA, EN) are required, to be described as 100 - 240VAC (50/60Hz).

(*3) Not applicable for the in-rush current to noise filter for less than 0.2ms.

(*4) Measure with JEITA RC-9131A probe, bandwidth of scope : 100MHz.

(*5) 85 - 265VAC, constant load.

(*6) No load-full load, constant input voltage.

(*7) Constant current limit and hiccup with automatic recovery. Not operate at over load

or dead short condition for more than 30 seconds.

(*8) OVP circuit will shutdown output, manual reset (re power on).

(*9) At 100/200VAC, nominal output voltage and maximum output current.

(*10) Measured by the each measuring method of UL, CSA, EN and DENAN (at 60Hz).

(*11) Ratings - Derating at standard mounting.

- Load (%) is percent of maximum output power or maximum output current, whichever is greater.

- As for other mountings, refer to derating curve.

(*12) As for DENAN, built to meet at 100VAC.

Pleasereferto"TDK-Lambda

EMCFilters"catalog.

●

RecommendedEMCFilter

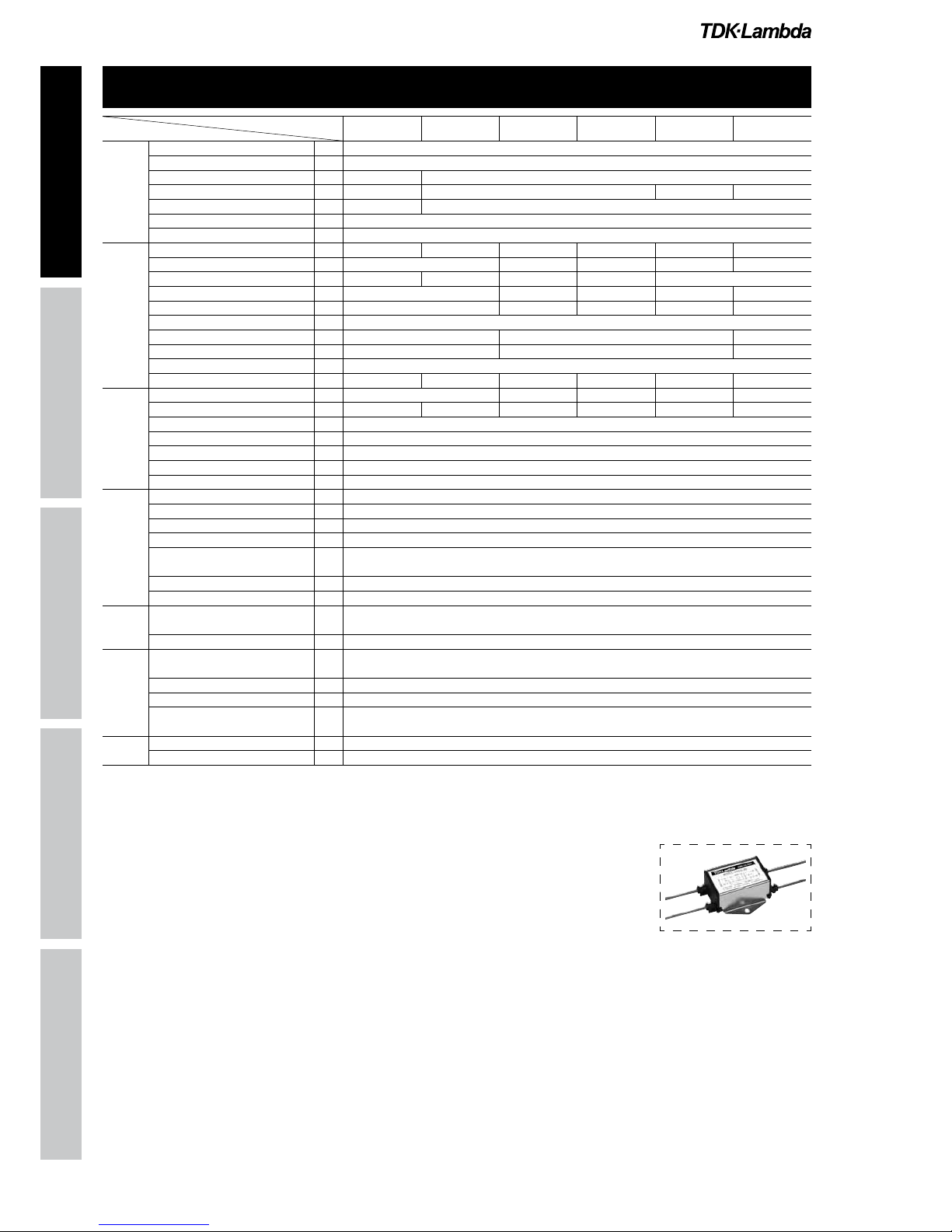

ITEMS/UNITS MODEL HWS50-3 HWS50-5 HWS50-12 HWS50-15 HWS50-24 HWS50-48

Input

Voltage Range (*2) V AC85 - 265 or DC120 - 370

Frequency (*2) Hz 47 - 63

Power Factor (100/200VAC)(typ) (*1)

0.98 / 0.90 0.99 / 0.95

Efficiency (100/200VAC)(typ) (*1) 76 / 78 82 / 84 81 / 83 82 / 84 83 / 85

Current (100/200VAC)(typ) (*1) A 0.5 / 0.25 0.7 / 0.35

Inrush Current (100/200VAC)(typ)

(*3) A 14 / 28, Ta=25, cold start

Leakage Current (*10) mA Less than 0.5. (0.2 (typ) at 100VAC / 0.4 (typ) at 230VAC)

Output

Nominal Voltage V 3.3 5 12 15 24 48

Maximum Current A 10 4.3 3.5 2.2 1.1

Maximum Power W 33 50 51.6 52.5 52.8

Maximum Line Regulation (*5) mV 20 48 60 96 192

Maximum Load Regulation (*6) mV 40 96 120 192 384

Temperature Coefficient Less than 0.02% /

Maximum Ripple & Noise

(0

≤

Ta

≤

70) (*4)

mVp-p

120 150 200

Maximum Ripple & Noise (

10

≤

Ta< 0) (*4)

mVp-p

160 180 240

Hold-up Time (typ) (*9) ms 20

Voltage Adjustable Range VDC 2.97 - 3.96 4.0 - 6.0 9.6 - 14.4 12.0 - 18.0 19.2 - 28.8 38.4 - 52.8

Function

Over Current Protection (*7) A >10.5 >4.51 >3.67 >2.31 >1.15

Over Voltage Protection (*8) V 4.13 - 4.95 6.25 - 7.25 15.0 - 17.4 18.8 - 21.8 30.0 - 34.8 55.2 - 64.8

Remote Sensing -

Remote ON/OFF Control Possible (/R Option)

Parallel Operation -

Series Operation Possible

Line DIP Built to meet SEMI-F47 (200VAC Line only)

Environment

Operating Temperature (*11) -10 to +70 (-10 to +50: 100%, +60: 60%, +70: 20%)

Storage Temperature -30 to +85

Operating Humidity RH 30 - 90 (No dewdrop)

Storage Humidity RH 10 - 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1min) 19.6m/s² constant,

X, Y, Z 1hour each.

Shock (In package) Less than 196.1m/s²

Cooling Convection cooling

Isolation Withstand Voltage Input - FG : 2kVAC (20mA), Input - Output : 3kVAC (20mA)

Output - FG : 500VAC (100mA) for 1min

Isolation Resistance More than 100Mat 25and 70%RH Output - FG : 500VDC

Standards

Safety Standards (*12) Approved by UL60950-1, CSA C22.2 No.60950-1, EN60950-1, EN50178 UL508 (with cover models only),

CSA C22.2 No.14-M95 (with cover models only) Built to meet DENAN

PFHC Built to meet IEC61000-3-2

EMI Built to meet EN55011/EN55022-B, FCC-B, VCCI-B

Immunity Built to meet IEC61000-4-2(Level 2,3), -3(Level 3), -4(Level 3), -

5(Level 3,4), -6(Level 3), -8(Level 4), -11

Mechanical

Weight (typ) g 280

Size (W x H x D) mm 26.5 x 82 x 120 (Refer to outline drawing)

HWS50 Specifications(Read instruction manual carefully, before using the power supply unit.)

HWS 50

Instruction Manual

HWS HWS HD HWS ME HWS-P

【HWS50】

VOLTAGEADJUSTMENT

LED

COVER

(OPTION)

REMOTEON/OFFCONTROLCONNECTOR(SEENOTEA)

2-M3TAPPEDHOLES

SCREWPENETRATIONDEPTHMAX.6mm

2-M3EMBOSSED,TAPPEDANDCOUNTERSUNKHOLES

NAMEPLATE

UNIT:mm

(WITHOUTCOVER)

(WITHCOVER)

RecommendedSolderlessTerminal

Qty(max)

2pcs

0

20

40

60

80

100

120

-10 0 10203040506070 80

MOUNTINGA,B

MOUNTINGC,D

0

20

40

60

80

100

120

-10 0 10203040506070 80

Ta(℃)

MOUNTINGA,B

MOUNTINGC,D

LOAD(%)

LOAD(%)

Ta(℃)

MOUNTINGA

(STANDARDMOUNTING)

MOUNTINGB

MOUNTINGC MOUNTINGD

DONTUSE

HWS 50

Output Derating

Outline Drawing

Instruction Manual

HWS HWS HD HWS ME HWS-P

HWS80 Specifications(Read instruction manual carefully, before using the power supply unit.)

ITEMS/UNITS MODEL HWS80-3 HWS80-5 HWS80-12 HWS80-15 HWS80-24 HWS80-48

Input

Voltage Range (*2) V AC85 - 265 or DC120 - 370

Frequency (*2) Hz 47 - 63

Power Factor (100/200VAC)(typ) (*1)

0.98 / 0.90 0.99 / 0.95

Efficiency (100/200VAC)(typ) (*1) 77 / 79 82 / 85 83 / 85 84 / 86

Current (100/200VAC)(typ) (*1) A 0.72 / 0.36 1.04 / 0.52

Inrush Current (100/200VAC)(typ) (*3)

A 14 / 28, Ta=25, cold start

Leakage Current (*10) mA Less than 0.5. (0.2 (typ) at 100VAC / 0.4 (typ) at 230VAC)

Output

Nominal Voltage VDC 3.3 5 12 15 24 48

Maximum Current A 16 6.7 5.4 3.4 1.7

Maximum Power W 52.8 80 80.4 81 81.6

Maximum Line Regulation (*5) mV 20 48 60 96 192

Maximum Load Regulation (*6) mV 40 96 120 192 384

Temperature Coefficient Less than 0.02% /

Maximum Ripple & Noise (0≤Ta≤70) (*4)

mVp-p

120 150 200

Maximum Ripple & Noise (10

≤

Ta< 0) (*4)

mVp-p

160 180 240

Hold-up Time (typ) (*9) ms 20ms

Voltage Adjustable Range VDC 2.97 - 3.96 4.0 - 6.0 9.6 - 14.4 12.0 - 18.0 19.2 - 28.8 38.4 - 52.8

Function

Over Current Protection (*7) A >16.8 >7.04 >5.67 >3.57 >1.79

Over Voltage Protection (*8) VDC 4.13 - 4.95 6.25 - 7.25 15.0 - 17.4 18.8 - 21.8 30.0 - 34.8 55.2 - 64.8

Remote Sensing Possible

Remote ON/OFF Control Possible (/R Option)

Parallel Operation -

Series Operation Possible

Line DIP Built to meet SEMI-F47 (200VAC Line only)

Environment

Operating Temperature (*11) -10 to +70 (-10 to +50: 100%, +60: 60%, +70: 20%)

Storage Temperature -30 to +85

Operating Humidity RH 30 - 90 (No dewdrop)

Storage Humidity RH 10 - 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1min)

19.6m/s² constant, X, Y, Z 1hour each.

Shock (In package) Less than 196.1m/s²

Cooling Convection cooling

Isolation Withstand Voltage Input - FG : 2kVAC (20mA), Input - Output : 3kVAC (20mA)

Output - FG : 500VAC (100mA) for 1min

Isolation Resistance More than 100Mat 25and 70%RH Output - FG : 500VDC

Standards

Safety Standards (*12) Approved by UL60950-1, CSA C22.2 No.60950-1, EN60950-1, EN50178 UL508 (with cover models only),

CSA C22.2 No.14-M95 (with cover models only) Built to meet DENAN

PFHC Built to meet IEC61000-3-2

EMI Built to meet EN55011/EN55022-B, FCC-B, VCCI-B

Immunity Built to meet IEC61000-4-2(Level 2,3), -3(Level 3), -4(Level 3),

-5(Level 3,4), -6(Level 3), -8(Level 4), -11

Mechanical

Weight (typ) g 450

Size (W x H x D) mm 28 x 82 x 160 (Refer to outline drawing)

(*1) At 100/200VAC, Ta=25and maximum output power.

(*2) For cases where conformance to various safety specs (UL, CSA, EN) are required, to be described as 100 - 240VAC (50/60Hz).

(*3) Not applicable for the in-rush current to noise filter for less than 0.2ms.

(*4) Measure with JEITA RC-9131A probe, bandwidth of scope : 100MHz.

(*5) 85 - 265VAC , constant load.

(*6) No load-full load, constant input voltage.

(*7) Constant current limit and hiccup with automatic recovery. Not operate at over load or

dead short condition for more than 30 seconds.

(*8) OVP circuit will shutdown output, manual reset (re power on).

(*9) At 100/200VAC, nominal output voltage and maximum output current.

(*10) Measured by the each measuring method of UL, CSA, EN and DENAN (at 60Hz).

(*11) Ratings - Derating at standard mounting.

- Load (%) is percent of maximum output power or maximum output current, whichever is greater.

- As for other mountings, refer to derating curve.

(*12) As for DENAN, built to meet at 100VAC.

Pleasereferto"TDK-Lambda

EMCFilters"catalog.

●

RecommendedEMCFilter

HWS 80

Instruction Manual

HWS HWS HD HWS ME HWS-P

【HWS80】

NAMEPLATE

SCREWPENETRATIONDEPTHMAX.6mm

unit:mm

VOLTAGEADJUSTMENT

LED

COVER

(OPTION)

(WITHCOVER)

(WITHOUTCOVER)

RecommendedSolderlessTerminal

Qty(max)

2pcs

1pc

2pcs

Others

Terminal

REMOTEON/OFFCONTROLCONNECTOR(SEENOTEA)

2-M3TAPPEDHOLES

SCREWPENETRATIONDEPTHMAX.6mm

2-M3EMBOSSED,TAPPEDANDCOUNTERSUNKHOLES

0

20

40

60

80

100

120

-10 0 10203040506070 80

Ta(℃)

MOUNTINGA

MOUNTINGB,C,D

LOAD(%)

MOUNTINGA

(STANDARDMOUNTING)

MOUNTINGB

MOUNTINGC MOUNTINGD

DONTUSE

0

20

40

60

80

100

120

-10 0 10203040506070 80

Ta(℃)

MOUNTINGA

MOUNTINGB,C,D

LOAD(%)

HWS 80

Outline Drawing

Output Derating

Instruction Manual

HWS HWS HD HWS ME HWS-P

ITEMS/UNITS MODEL HWS100-3 HWS100-5 HWS100-12 HWS100-15 HWS100-24 HWS100-48

Input

Voltage Range (*2) V AC85 - 265 or DC120 - 370

Frequency (*2) Hz 47 - 63

Power Factor (100/200VAC)(typ) (*1)

0.98 / 0.90 0.99 / 0.95

Efficiency (100/200VAC)(typ) (*1) 78 / 81 83 / 86 84 / 87

Current (100/200VAC)(typ) (*1) A 0.9 / 0.45 1.3 / 0.65

Inrush Current (100/200VAC)(typ) (*3)

A 14 / 28, Ta=25, cold start

Leakage Current (*10) mA Less than 0.5. (0.2 (typ) at 100VAC / 0.4 (typ) at 230VAC)

Output

Nominal Voltage VDC 3.3 5 12 15 24 48

Maximum Current A 20 8.5 7 4.5 2.1

Maximum Power W 66 100 102 105 108 100.8

Maximum Line Regulation (*5) mV 20 48 60 96 192

Maximum Load Regulation (*6) mV 40 96 120 192 384

Temperature Coefficient Less than 0.02% /

Maximum Ripple & Noise (0≤Ta≤70)(*4)

mVp-p

120 150 200

Maximum Ripple & Noise (10≤Ta< 0)(*4)

mVp-p

160 180 240

Hold-up Time (typ) (*9) ms 20

Voltage Adjustable Range VDC 2.97 - 3.96 4.0 - 6.0 9.6 - 14.4 12.0 - 18.0 19.2 - 28.8 38.4 - 52.8

Function

Over Current Protection (*7) A >21.0 >8.92 >7.35 >4.72 >2.20

Over Voltage Protection (*8) VDC 4.13 - 4.95 6.25 - 7.25 15.0 - 17.4 18.8 - 21.8 30.0 - 34.8 55.2 - 64.8

Remote Sensing Possible

Remote ON/OFF Control Possible (/R Option)

Parallel Operation -

Series Operation Possible

Line DIP Built to meet SEMI-F47 (200VAC Line only)

Environment

Operating Temperature (*11) -10 to +70 (-10 to +50: 100%, +60: 60%, +70: 20%)

Storage Temperature -30 to +85

Operating Humidity RH 30 - 90 (No dewdrop)

Storage Humidity RH 10 - 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1min) 19.6m/s² constant,

X, Y, Z 1hour each.

Shock (In package) Less than 196.1m/s²

Cooling Convection cooling

Isolation Withstand Voltage Input - FG : 2kVAC (20mA), Input - Output : 3kVAC (20mA)

Output - FG : 500VAC (100mA) for 1min

Isolation Resistance More than 100Mat 25and 70%RH Output - FG : 500VDC

Standards

Safety Standards (*12) Approved by UL60950-1, CSA C22.2 No.60950-1, EN60950-1, EN50178 UL508 (with cover models only),

CSA C22.2 No.14-M95 (with cover models only) Built to meet, DENAN

PFHC Built to meet IEC61000-3-2

EMI Built to meet EN55011/EN55022-B, FCC-B, VCCI-B

Immunity Built to meet IEC61000-4-2(Level 2,3), -3(Level 3), -4(Level 3),

-5(Level 3,4), -6(Level 3), -8(Level 4), -11

Mechanical

Weight (typ) g 450

Size (W x H x D) mm 28 x 82 x 160 (Refer to outline drawing)

(*1) At 100/200VAC, Ta=25and maximum output power.

(*2) For cases where conformance to various safety specs (UL, CSA, EN) are required, to be described as 100 - 240VAC (50/60Hz).

(*3) Not applicable for the in-rush current to noise filter for less than 0.2ms.

(*4) Measure with JEITA RC-9131A probe, bandwidth of scope :100MHz.

(*5) 85 - 265VAC, constant load.

(*6) No load-Full load, constant input voltage.

(*7) Constant current limit and hiccup with automatic recovery.

Not operate at over load or dead short condition for more than 30 seconds.

(*8) OVP circuit will shutdown output, manual reset (re power on).

(*9) At 100/200VAC, nominal output voltage and maximum output current.

(*10) Measured by the each measuring method of UL, CSA, EN and DENAN (at 60Hz).

(*11) Ratings - Derating at standard mounting.

- Load (%) is percent of maximum output power or maximum output current, whichever is greater.

- As for other mountings, refer to derating curve

(*12) As for DENAN, built to meet at 100VAC.

●

RecommendedEMCFilter

Pleasereferto"TDK-Lambda

EMCFilters"catalog.

HWS 100

HWS100 Specifications(Read instruction manual carefully, before using the power supply unit.)

Instruction Manual

HWS HWS HD HWS ME HWS-P

【HWS100】

VOLTAGEADJUSTMENT

COVER

(OPTION)

LED

(WITHOUTCOVER)

(WITHCOVER)

NAMEPLATE

unit

RecommendedSolderlessTerminal

Qty(max)

2pcs

1pc

2pcs

Others

Terminal

SCREWPENETRATIONDEPTHMAX.6mm

REMOTEON/OFFCONTROLCONNECTOR(SEENOTEA)

2-M3TAPPEDHOLES

SCREWPENETRATIONDEPTHMAX.6mm

2-M3EMBOSSED,TAPPEDANDCOUNTERSUNKHOLES

0

20

40

60

80

100

120

-10 0 10203040506070 80

Ta(℃)

MOUNTINGA

MOUNTINGB,C,D

LORD(%)

MOUNTINGA

(STANDARDMOUNTING)

MOUNTINGB

MOUNTINGC MOUNTINGD

DONTUSE

0

20

40

60

80

100

120

-10 0 10203040506070 80

Ta(℃)

MOUNTINGA

MOUNTINGB,C,D

LORD(%)

HWS 100

Outline Drawing

Output Derating

Instruction Manual

HWS HWS HD HWS ME HWS-P

(*1) At 100/200VAC, Ta=25and maximum output power.

(*2) For cases where conformance to various safety specs (UL, CSA, EN) are required, to be described as 100 - 240VAC (50/60Hz).

(*3) Not applicable for the in-rush current to noise filter for less than 0.2ms.

(*4) Measure with JEITA RC-9131A probe, bandwidth of scope : 100MHz.

(*5) 85 - 265VAC, constant load.

(*6) No load-full load, constant input voltage.

(*7) Constant current limit and hiccup with automatic recovery.

Not operate at over load or dead short condition for more than 30 seconds.

(*8) OVP circuit will shutdown output, manual reset (re power on).

(*9) At 100/200VAC, nominal output voltage and maximum output current.

(*10) Measured by the each measuring method of UL, CSA, EN and DENAN (at 60Hz).

(*11) Ratings - Derating at standard mounting.

- Load (%) is percent of maximum output power or maximum output current, whichever is greater.

- As for other mountings, refer to derating curve.

(*12) As for DENAN, built to meet at 100VAC.

Pleasereferto"TDK-Lambda

EMCFilters"catalog.

●

RecommendedEMCFilter

ITEMS/UNITS MODEL HWS150-3 HWS150-5 HWS150-12 HWS150-15 HWS150-24 HWS150-48

Input

Voltage Range (*2) V AC85 - 265 or DC120 - 370

Frequency (*2) Hz 47 - 63

Power Factor (100/200VAC)(typ) (*1)

0.98 / 0.90 0.99 / 0.95

Efficiency (100/200VAC)(typ) (*1) 78 / 81 83 / 86 85 / 88

Current (100/200VAC)(typ) (*1) A 1.3 / 0.65 1.9 / 0.95

Inrush Current (100/200VAC)(typ) (*3)

A 14 / 28, Ta=25, cold start

Leakage Current (*10) mA Less than 0.5. (0.2 (typ) at 100VAC / 0.4 (typ) at 230VAC)

Output

Nominal Voltage V 3.3 5 12 15 24 48

Maximum Current A 30 13 10 6.5 3.3

Maximum Power W 99 150 156 150 156 158.4

Maximum Line Regulation (*5) mV 20 48 60 96 192

Maximum Load Regulation (*6) mV 40 96 120 192 384

Temperature Coefficient Less than 0.02% /

Maximum Ripple & Noise (0≤Ta≤70) (*4)

mVp-p

120 150 200

Maximum Ripple & Noise (10≤Ta< 0) (*4)

mVp-p

160 180 240

Hold-up Time (typ) (*9) ms 20

Voltage Adjustable Range VDC 2.97 - 3.96 4.0 - 6.0 9.6 - 14.4 12.0 - 18.0 19.2 - 28.8 38.4 - 52.8

Function

Over Current Protection (*7) A >31.5 >13.6 >10.5 >6.82 >3.46

Over Voltage Protection (*8) V 4.13 - 4.95 6.25 - 7.25 15.0 - 17.4 18.8 - 21.8 30.0 - 34.8 55.2 - 64.8

Remote Sensing (*8) Possible

Remote ON/OFF Control Possible (/R Option)

Parallel Operation -

Series Operation Possible

Line DIP Built to meet SEMI-F47 (200VAC Line only)

Environment

Operating Temperature (*11) -10 to +70 (-10 to +50: 100%, +60: 60%, +70: 20%)

Storage Temperature -30 to +85

Operating Humidity RH 30 - 90 (No dewdrop)

Storage Humidity RH 10 - 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1min) 19.6m/s² constant,

X, Y, Z 1hour each.

Shock (In package) Less than 196.1m/s²

Cooling Convection cooling

Isolation Withstand Voltage Input - FG : 2kVAC (20mA), Input - Output : 3kVAC (20mA)

Output - FG : 500VAC (100mA) for 1min

Isolation Resistance More than 100Mat 25and 70%RH Output - FG : 500VDC

Standards

Safety Standards (*12) Approved by UL60950-1, CSA C22.2 No.60950-1, EN60950-1, EN50178 UL508 (with cover models only),

CSA C22.2 No.14-M95 (with cover models only)Built to meet DENAN

PFHC Built to meet IEC61000-3-2

EMI Built to meet EN55011/EN55022-B, FCC-B, VCCI-B

Immunity Built to meet IEC61000-4-2(Level 2,3), -3(Level 3), -4(Level 3),

-5(Level 3,4), -6(Level 3), -8(Level 4), -11

Mechanical

Weight (typ) g 500

Size (W x H x D) mm 37 x 82 x 160 (Refer to outline drawing)

HWS 150

HWS150 Specifications(Read instruction manual carefully, before using the power supply unit.)

Instruction Manual

HWS HWS HD HWS ME HWS-P

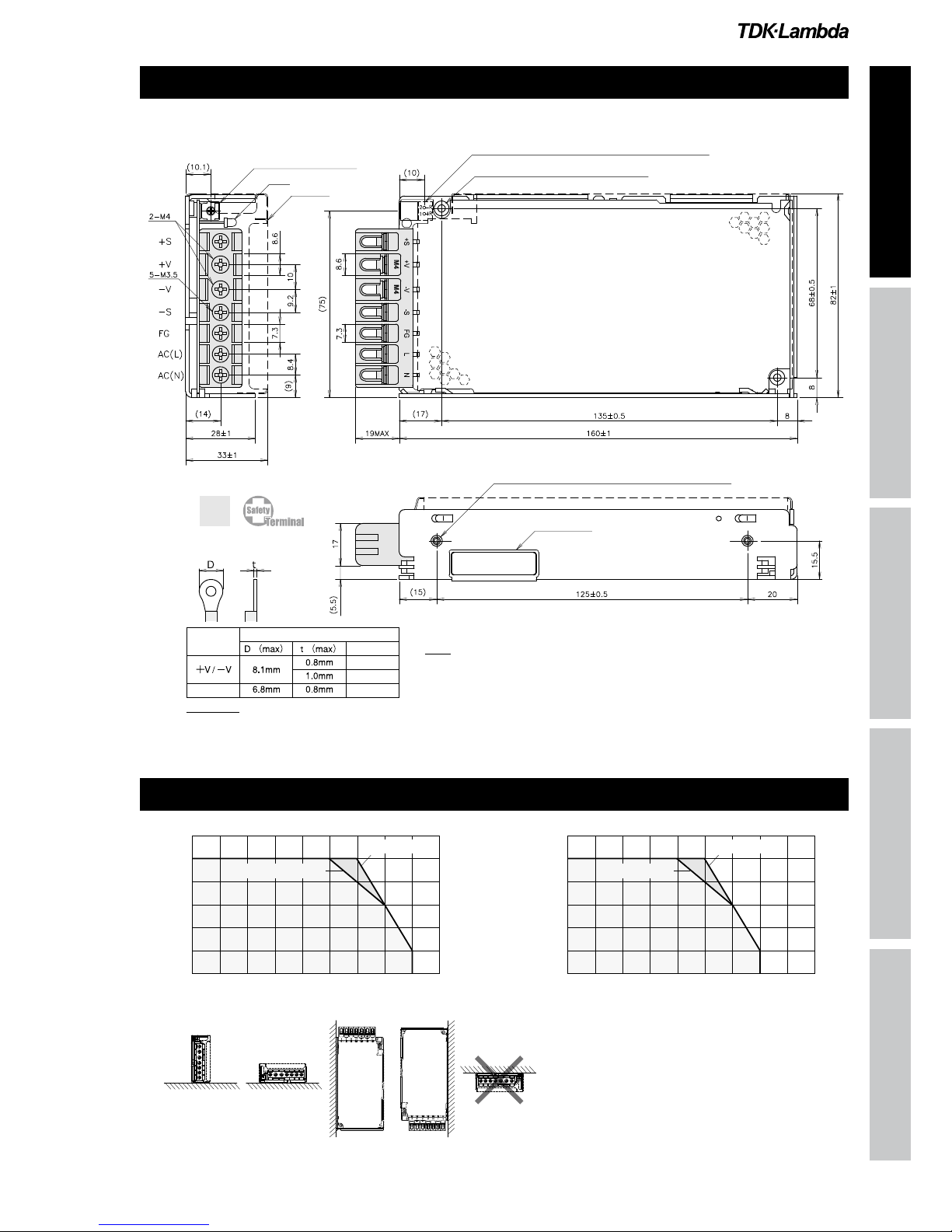

【HWS150】

Terminal

D(max)t(max) Qty(max)

+V/−V8.1mm 0.8mm 2pcs

1.0mm 1pc

Others 6.8mm 0.8mm 2pcs

Dt

VOLTAGEADJUSTMENT

LED

COVER

(OPTION)

NAMEPLATE

unit:mm

(WITHOUTCOVER)

(WITHCOVER)

RecommendedSolderlessTerminal

SCREWPENETRATIONDEPTHMAX.6mm

REMOTEON/OFFCONTROLCONNECTOR(SEENOTEA)

2-M3TAPPEDHOLES

SCREWPENETRATIONDEPTHMAX.6mm

2-M3EMBOSSED,TAPPEDANDCOUNTERSUNKHOLES

0

20

40

60

80

100

120

-10 0 10203040506070 80

MOUNTINGB

MOUNTINGA

MOUNTINGC,D

Ta(°C)

LOAD(%)

MOUNTINGA

(STANDARDMOUNTING)

MOUNTINGB

MOUNTINGC MOUNTINGD

DON'TUSE

0

20

40

60

80

100

120

-10 0 10 20 25 30 40 50 60 70 80

MOUNTINGA

Ta(°C)

LOAD(%)

MOUNTINGB,C,D

HWS 150

Output Derating

Outline Drawing

Instruction Manual

HWS HWS HD HWS ME HWS-P

ITEMS/UNITS MODEL HWS300-3 HWS300-5 HWS300-12 HWS300-15 HWS300-24 HWS300-48

Input

Voltage Range (*2) V AC85 - 265 or DC120 - 330

Frequency (*2) Hz 47 - 63

Power Factor (100/200VAC)(typ) (*1)

0.99 / 0.95

Efficiency (100/200VAC)(typ) (*1) 74 / 77 79 / 82 80 / 83 82 / 85

Current (100/200VAC)(typ) (*1) A 2.7 / 1.4 3.8 / 1.9 4.1 / 2.1

Inrush Current (100/200VAC)(typ) (*3)

A 20 / 40

Leakage Current (*10) mA Less than 0.75. (0.2 (typ) at 100VAC / 0.44 (typ) at 230VAC)

Output

Nominal Voltage VDC 3.3 5 12 15 24 48

Maximum Current (*13) A 60 27 22 14 (16.5) 7

Maximum Power W 198 300 324 330 336

Maximum Line Regulation (*5) mV 20 48 60 96 192

Maximum Load Regulation (*6) mV 30 72 90 144 288

Temperature Coefficient Less than 0.02% /

Maximum Ripple & Noise (0≤Ta≤70) (*4)

mVp-p

120 150 350

Maximum Ripple & Noise (10≤Ta< 0) (*4)

mVp-p

180 200 400

Hold-up Time (typ) (*9) ms 20

Voltage Adjustable Range VDC 2.64 - 3.96 4.0 - 6.0 9.6 - 14.4 12.0 - 18.0 19.2 - 28.8 38.4 - 52.8

Function

Over Current Protection (*7) A >63 > 28.4 >23.1 >16.7 >7.4

Over Voltage Protection (*8) V 4.13 - 4.95 6.25 - 7.25 15.0 - 17.4 18.8 - 21.8 30.0 - 34.8 55.2 - 64.8

Remote Sensing Possible

Remote ON/OFF Control Possible

Parallel Operation Possible

Series Operation Possible

Monitoring Signal PF (Open collector output)

Line DIP Designed to meet SEMI-F47 (200VAC Line only)

Environment

Operating Temperature (*11) -10 to +70 (-10 to +50: 100%, +70: 50%)

Storage Temperature -30 to +85

Operating Humidity RH 10 - 90 (No dewdrop)

Storage Humidity RH 10 - 95 (No dewdrop)

Vibration At no operating, 10 - 55Hz (sweep for 1min) 19.6m/s² constant,

X, Y, Z 1hour each.

Shock (In package) Less than 196.1m/s²

Cooling Forced air by blower fan

Isolation

Withstand Voltage Input - FG : 2.5kVAC (20mA), Input - Output : 3kVAC (20mA)

Output - FG: 500VAC (100mA), Output-CNT: 100VAC(100mA) for 1min

Isolation Resistance More than 100MOutput - FG : 500VDC

More than 10MOutput -CNT : 100VDC at 25and 70%RH

Standards

Safety Standards (*12) Approved by UL60950-1, UL508 (24V model only), CSA C22.2 No.60950-1,

CSA C22.2 No.14-M95 (24V model only), EN60950-1, EN50178 Designed to meet DENAN

PFHC Designed to meet IEC61000-3-2

EMI Designed to meet EN55011/EN55022-B, FCC-B, VCCI-B

Immunity Designed to meet IEC61000-4-2(Level 2,3), -3(Level 3), -4(Level3),

-5(Level 3,4), -6(Level 3), -8(Level 4), -11

Mechanical

Weight (typ) g 1000

Size (W x H x D) mm 61 x 82 x 165 (Refer to outline drawing)

(*1) At 100/200VAC, Ta=25and maximum output power.

(*2) For cases where conformance to various safety specs (UL, CSA, EN) are required, to be described as 100-240VAC (50/60Hz).

(*3) Not applicable for the inrush current to noise filter for less than 0.2ms.

(*4) Measure with JEITA RC-9131A probe, bandwidth of scope :100MHz.

(*5) 85 - 265VAC, constant load.

(*6) No load-full load, constant input voltage.

(*7) 3.3, 5V model: Constant current limit and hiccup with automatic recovery.

12 - 48V model: Constant current limit with automatic recovery.

Avoid to operate at over load or short circuit condition for more than 30 seconds.

(*8) OVP circuit will shut the output down, manual reset (CNT reset or Re power on).

(*9) At 100/200VAC, nominal output voltage and maximum output current.

(*10) Measured by the each measuring method of UL, CSA, EN and DENAN (at 60Hz), Ta=25.

(*11) Ratings - Derating at standard mounting. Refer to output derating curve.

- Load (%) is percent of maximum output power or maximum output current, whichever is greater.

(*12) As for DENAN, designed to meet at 100VAC.

(*13) ( ): Peak output current at 200VAC. Operaing time at peak output is less than 10 sec, duty is less than 35%.

Pleasereferto"TDK-Lambda

EMCFilters"catalog.

●

RecommendedEMCFilter

HWS 300

HWS300 Specifications(Read instruction manual carefully, before using the power supply unit.)

This manual suits for next models

37

Table of contents

Other TDK-Lambada Power Supply manuals

Popular Power Supply manuals by other brands

Altronix

Altronix AL624ET installation instructions

Allen-Bradley

Allen-Bradley Series B installation instructions

Siemens

Siemens 4AV2306-2EB00-0A operating instructions

Shell

Shell SPS-500-01 manual

Rockwell Automation

Rockwell Automation 1606-XLE960 instruction manual

Puls

Puls QS10.481-C1 installation manual