Piezo Haptic Actuators - PowerHap Z63000Z2910Z1Z44

Application note for evaluation kit 60 V

Preliminary data

PPD PI AE/IE PD 2019-05-08

Please read Cautions and warnings and Page 2 of 28

Important notes at the end of this document.

1Introduction ...................................................................................................................................................... 4

1.1Ordering code .......................................................................................................................................... 4

1.2Features ................................................................................................................................................... 5

1.3Description ............................................................................................................................................... 5

2Quick start guide .............................................................................................................................................. 6

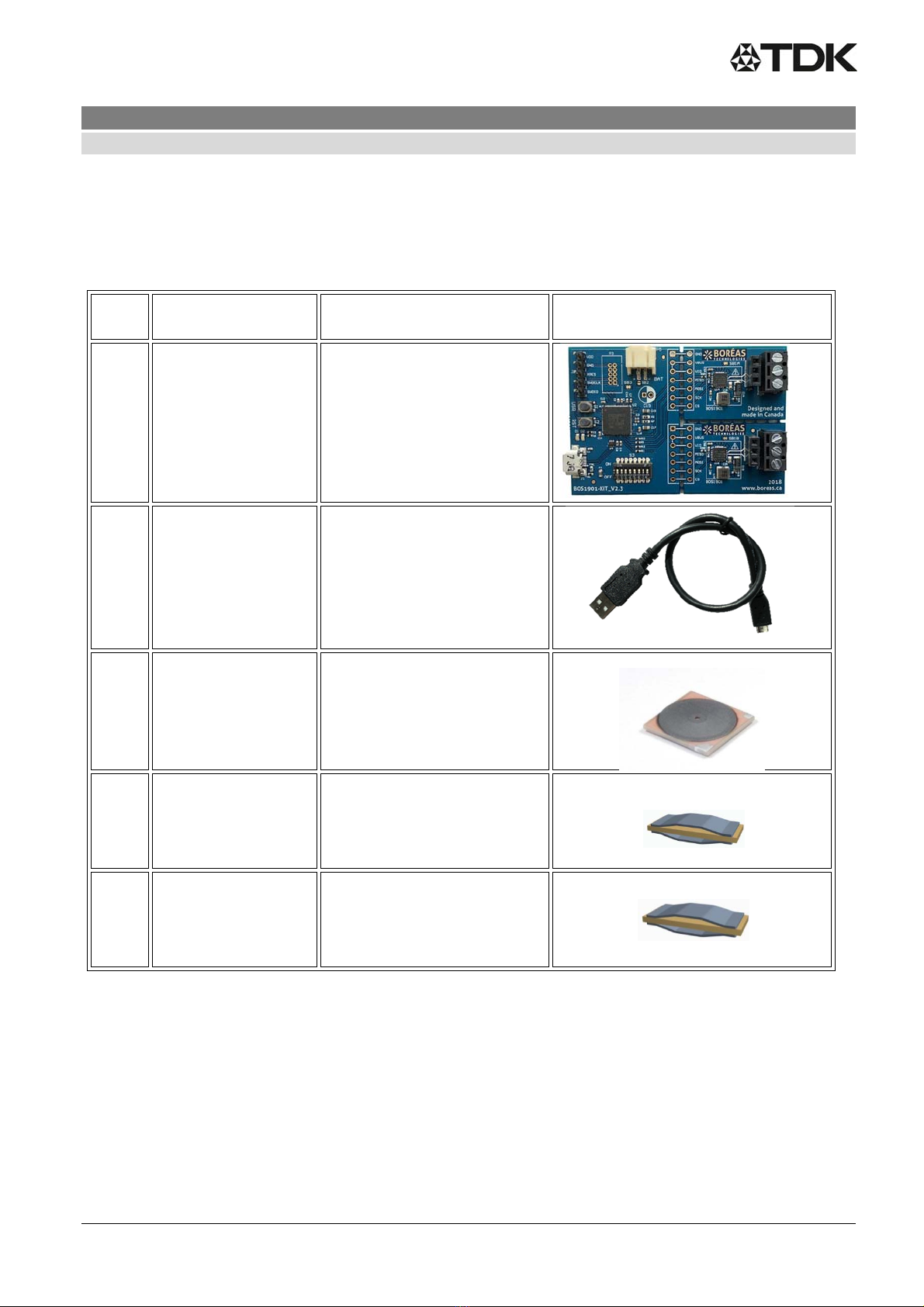

2.1What is in the box .................................................................................................................................... 6

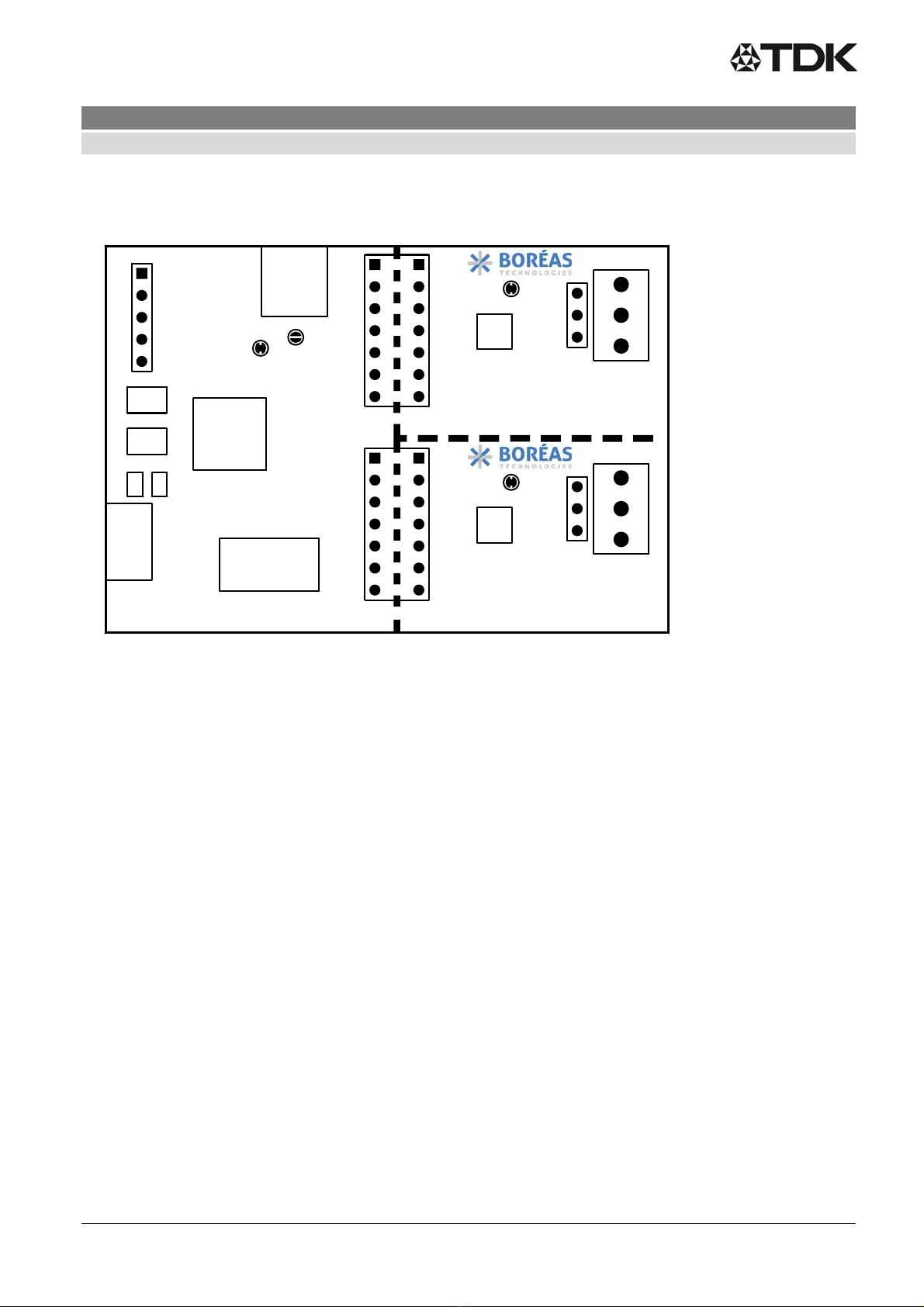

2.2PCB overview .......................................................................................................................................... 7

2.3Quick start procedure .............................................................................................................................. 7

3Hardware ......................................................................................................................................................... 8

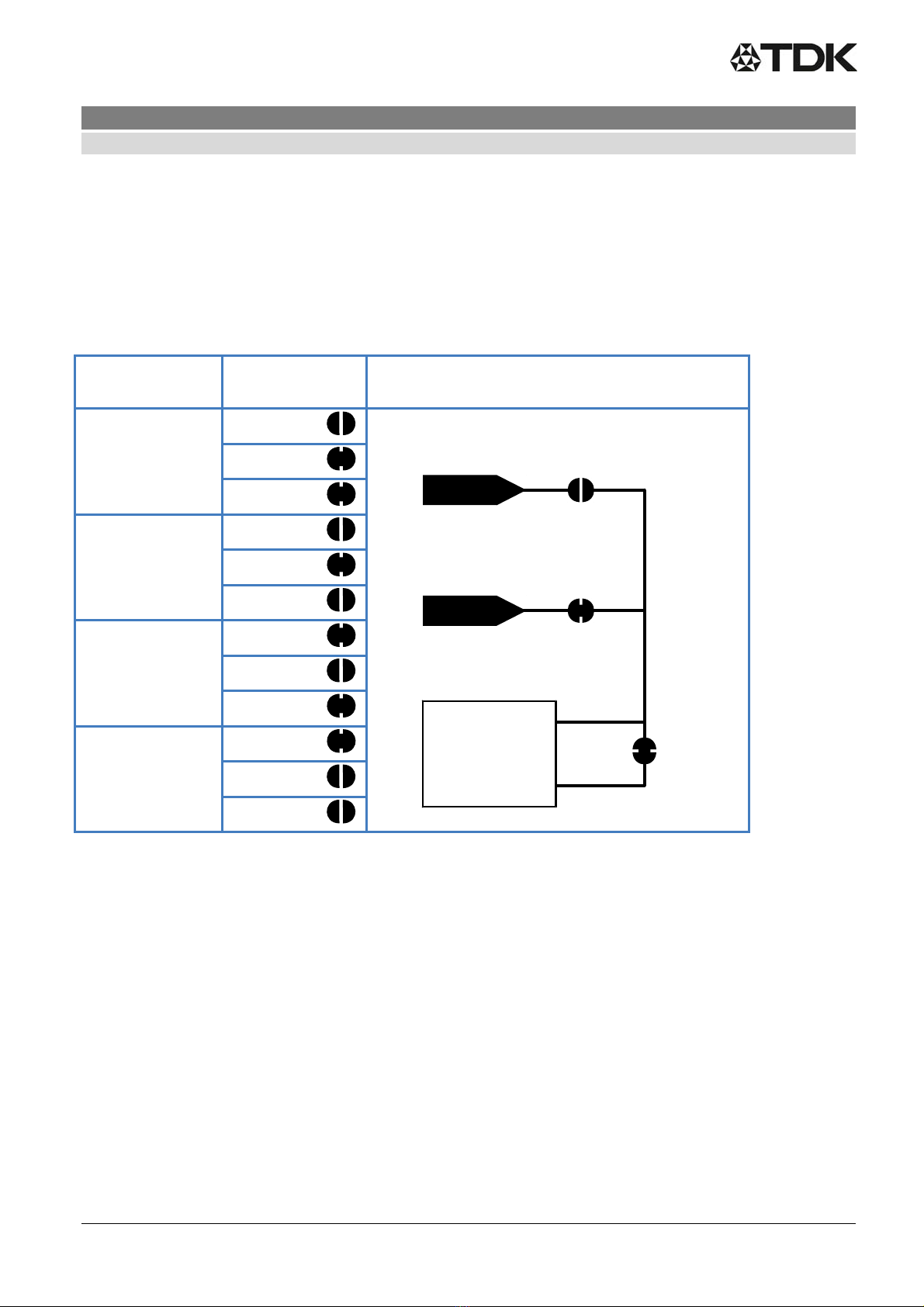

3.1Jumper options ........................................................................................................................................ 8

3.1.1Use BAT power (external power supply connection) .......................................................................... 8

3.1.2Use UPI feature ................................................................................................................................... 9

3.2Piezo actuators ........................................................................................................................................ 9

3.3DIP switch settings ................................................................................................................................ 10

3.4Output configuration options .................................................................................................................. 12

3.4.1Differential output configuration ......................................................................................................... 12

3.4.2Single ended output configuration ..................................................................................................... 12

3.5Breakable units ...................................................................................................................................... 13

4Software ......................................................................................................................................................... 13

4.1Software installation procedure ............................................................................................................. 13

4.2Software operation ................................................................................................................................. 13

5Firmware ........................................................................................................................................................ 14

5.1Identifying the firmware revision number ............................................................................................... 14

5.2Firmware installation / update procedure .............................................................................................. 15

5.3Firmware modification – using PSoC® CreatorTM ................................................................................. 16

5.4Adjusting sensing feedback parameters ................................................................................................ 17

5.4.1Sensing feedback amplitude .............................................................................................................. 17

5.4.2Sensing feedback frequency ............................................................................................................. 17

5.4.3Sensing threshold .............................................................................................................................. 17

5.4.4Response type ................................................................................................................................... 18

6Design reference ........................................................................................................................................... 19

6.1Schematics ............................................................................................................................................ 19

6.2PCB Layout ............................................................................................................................................ 21

6.3Bill of materials ...................................................................................................................................... 23

7FAQ and troubleshooting ............................................................................................................................... 24

8Notes and warnings ....................................................................................................................................... 24