1Safety.........................................................................................................................................4

1.1 Residual risks....................................................................................................................................4

1.2 Information and obligations for the operator.....................................................................................6

1.3 Impermissible operating conditions...................................................................................................6

1.4 Emissions..........................................................................................................................................6

2Description of device................................................................................................................7

2.1 Intended use .....................................................................................................................................7

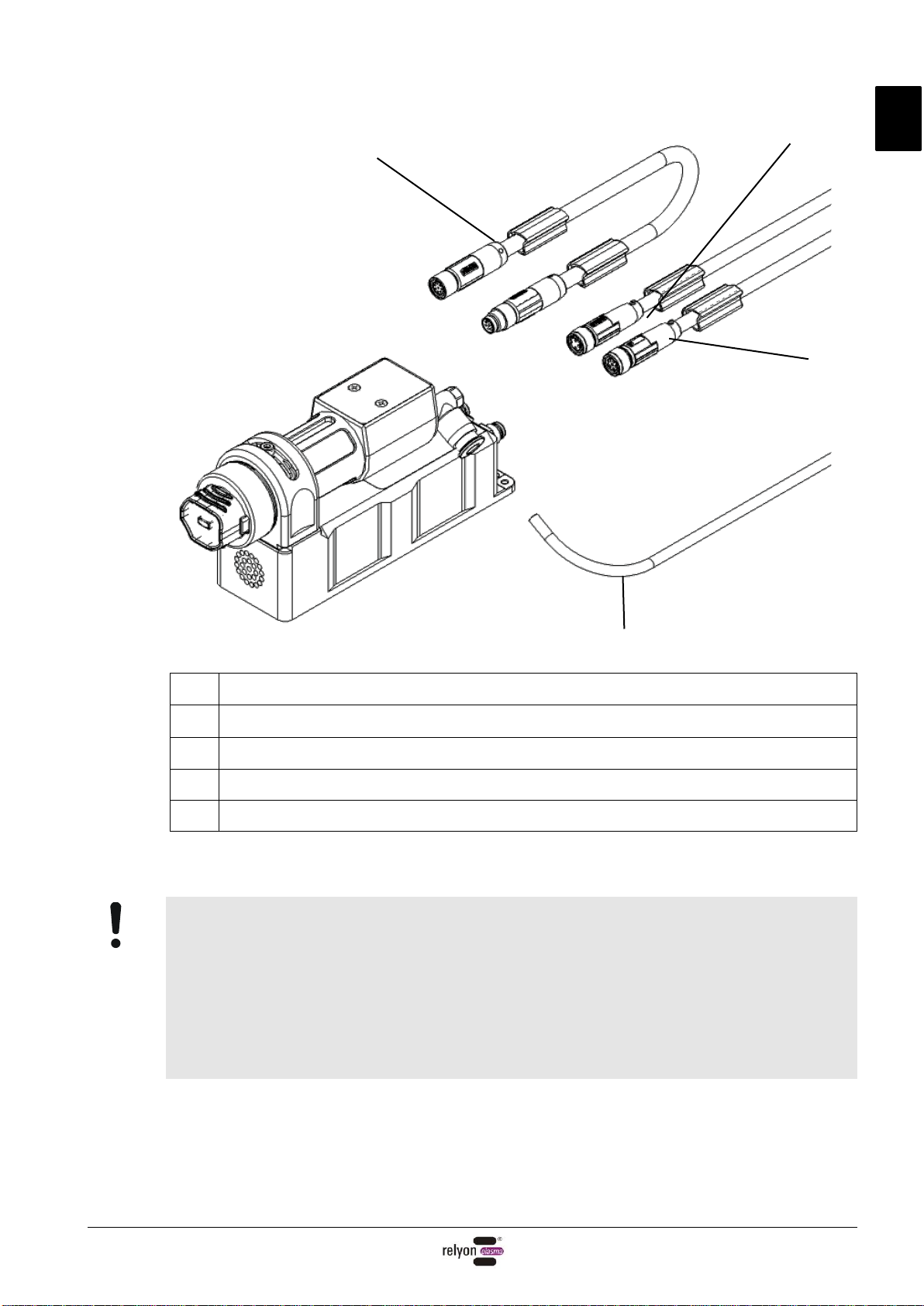

2.2 Scope of delivery...............................................................................................................................7

2.3 Description of device.........................................................................................................................8

2.4 Connecting lead assignment.............................................................................................................9

3Technical data.........................................................................................................................11

4Transport / storage .................................................................................................................11

5Installation...............................................................................................................................12

5.1 Unpacking .......................................................................................................................................12

5.2 Installation requirements.................................................................................................................12

5.3 Positioning the components............................................................................................................12

5.4 Mounting the components...............................................................................................................14

5.5 Connecting the gas supply..............................................................................................................15

5.6 Connecting the connection cable Digital I/O...................................................................................15

5.7 Adjusting the module carrier ...........................................................................................................16

6Special note on the operation of the plasma process..........................................................18

6.1 General description.........................................................................................................................18

6.2 Carrying out surface treatment .......................................................................................................19

6.3 Measures to take after the surface treatment.................................................................................19

7Operation.................................................................................................................................20

7.1 LED indicator on driver unit.............................................................................................................20

7.2 Switching signals.............................................................................................................................20

7.3 Error acknowledgement..................................................................................................................20

7.4 Inserting / removing the module......................................................................................................21

7.5 Commissioning a device with digital I/O communication................................................................22

7.6 Working with module “Standard”.....................................................................................................23

7.7 Working with module “Nearfield”.....................................................................................................23

7.8 Working with other modules............................................................................................................23

8Taking out of service ..............................................................................................................24

9Maintenance............................................................................................................................24

9.1 Cleaning..........................................................................................................................................24

9.2 Replacing a module ........................................................................................................................24

10 Troubleshooting .....................................................................................................................25

11 Environment............................................................................................................................26

11.1 Disposal ..........................................................................................................................................26

12 Conformity / standards...........................................................................................................26

12.1 CE ...................................................................................................................................................26

12.2 FCC.................................................................................................................................................26

12.3 Product standards...........................................................................................................................27

13 Spare parts..............................................................................................................................27