TDW POLYSTOPP Manual

TDW France-22-E-03-09

1

POLYSTOPPfor PE PIPE

Bigsizes315-355mm

Operation and Maintenance Instructions*

*The present transitional version of the manual should be updated, upon the

launching of the new design valves.

TDW France-22-E-03-09

2

TDW France-22-E-03-09

3

© Copyright 2019

All rights reserved

T.D. Williamson France

NOTICE

Any operation involving work on pipe containing

liquids or gases under pressure is potentially

hazardous. It is necessary, therefore, that correct

procedures be followed in the use of this equipment to

maintain a safe working environment.

No person should use this equipment who is not fully

trained in the procedures stated in this manual, and

who is not fully aware of the potential hazards

connected with work on pipe containing liquids or

gases under pressure.

The purchaser of this equipment is responsible for the

manner in which this equipment is used and the

training and competence of the operators.

Should any difficulty arise at any time in the use of

this equipment, please contact TDW immediately.

T.D. Williamson (France) S.A.S.

11, rue de l’Atome – Z.I.

B.P. 50081

67802 BISCHHEIM cedex - France

Phone : +33 (0)3 88 19 72 38

Fax +33 (0)3 88 19 72 19

E-mail: tdw.commercial@tdwilliamson.com

Visit TDW’s Web Site at www.tdwilliamson.com

™ Trademark of T.D. Williamson, Inc. in the United States and foreign countries.

® Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries.

TDW France-22-E-03-09

4

Table of Contents

Paragraph

Title

Page

Section I: Introduction

1.0

Description

5

2.0

Scope of Applications

6

3.0

System Components

7

4.0

Safety

9

5.0

Equipment Orientation

9

Section II: Installation and operation of the TDW SHORTCUTT10 inch valve

1.0

Introduction

10

2.0

Operating instructions

11

Section III: Tapping 315 and 355 mm Lines with the T-203 Tapping Machine

1.0

Introduction

13

2.0

General Information

13

3.0

Preparations

13

4.0

Tapping the Line

18

Section IV: Plugging the Line

1.0

Introduction

20

2.0

Plugging the Main Line

20

Section V: Setting the Completion Plug with the POLYSTOPPCompletion Machine

1.0

Preparing the completion machine

30

2.0

Installing the plug

31

3.0

Removal of the valve

32

Section VI: Maintenance

1.0

Introduction

34

2.0

SHORTSTOPPII Plugging Machine

34

3.0

POLYSTOPPcompletion machine

37

4.0

SHORTCUTTvalve

37

Appendix

Parts Lists

39

TDW France-22-E-03-09

5

Section I: Introduction

1.0 Description

The POLYSTOPP®Tapping and Plugging

System is designed for use on 315 and 355 mm

polyethylene pipe.

The system is designed for use with TDW

Electrofusion Saddle Fittings. The fittings

permit access to a line to plug it while line work

is being performed.

The entire system includes equipment for

tapping into the line, plugging the main, and

installingacompletion pluginthefittinginorder

to remove the tapping valve. Some components

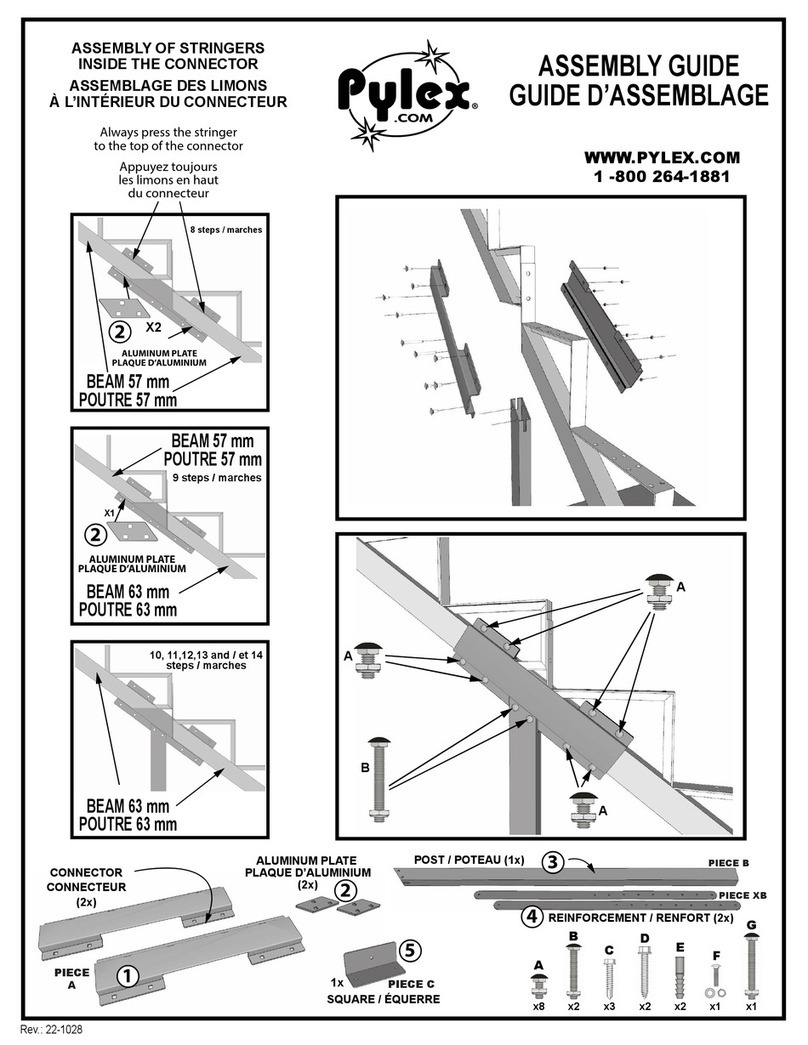

of the 315-355 mm system are shown in Figure

1.

Tapping

Plugging

Completion

Figure 1. POLYSTOPPSystem big sizes

for PE Pipe 315-355 mm

This manual describes the procedures for using

this tapping, pluggingand completion system to:

•plug the main line, keeping the line in

service.

•to complete the job by setting a

completion plug, enabling removal of

all tapping/plugging equipment.

TDW France-22-E-03-09

6

This manual is intended to aid the safe operation

and proper maintenance of POLYSTOPP® big

sizes 315-355 mm equipment. Read this

manual carefully before attempting to

operate the equipment. If any portion of this

manual is not clearly understood, or if any

questions arise concerning the equipment's use,

contact T.D. Williamson, S.A. or the nearest

factory representative.

WARNING: Do not attempt a plugging and

completion operation without

following the procedures

contained in this manual. A

departure from prescribed

procedures could present a

hazardous situation causing

injury to personnel and

damage to equipment.

Do not alter this equipment or

any of its component parts.

Use only replacement parts

manufactured or

recommended by TDW.

Any alteration of this

equipment, or use of parts not

manufactured or

recommended by TDW could

cause the machine to

malfunction, causing damage

to the equipment and/orinjury

to personnel.

Before taking this equipment to the field for an

actual plugging operation, conduct a tapping and

plugging exercise on a length of test pipe to

become familiar with the operational

characteristics of the equipment.

2.0 Scope of Applications

The POLYSTOPP® big sizes equipment can be

used on polyethylene pipe, for tapping and

plugging SDR 11 and SDR 17.6 pipe in sizes 315

and 355 mm for the following applications:

•To temporarily stop flow in the line (using

one plugging machine).

•To isolate a section of the line (using two

plugging machines).

•To set a completion plug in the TDW

polyethylene electrofusion saddle fitting.

A complete job will consist of the following

major steps:

•Installation and testing of the fitting(s).

•Tapping the line through the fitting (s).

•Plugging the main line.

•Setting the completion plug.

•Removing the equipment.

TDW France-22-E-03-09

7

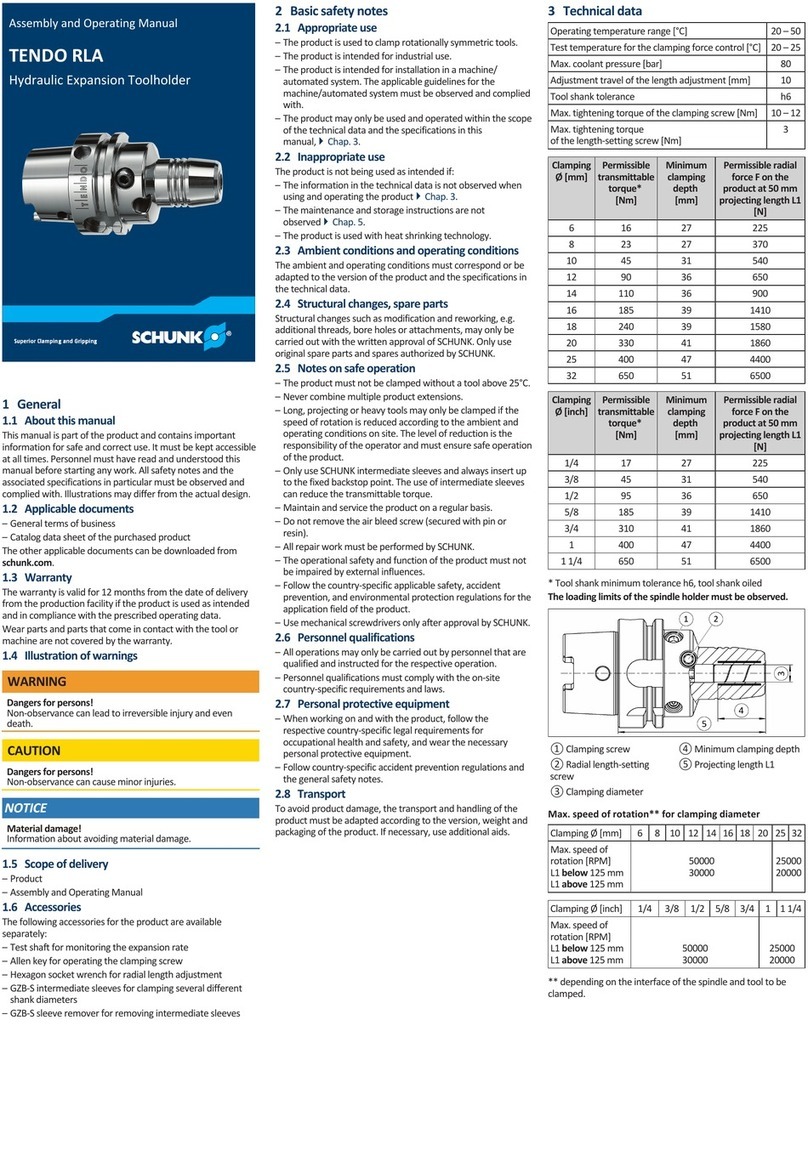

3.0 System Components

3.1 Primary System

A. The tapping machine used with this system

is the TDW T-203 tapping machine for both

315 and 355 mm pipe.

B. The T-203 tapping machine is an air or

hydraulic driven tapping machine used for

315 and 355 mm taps. See figure 2.

Figure 2. T-203 Tapping Machine

C. The SHORTSTOPP II 8x12 Folding Head

Plugging Machine is used with this system

to plug 315- and 355 mm lines. This

plugging machine consist of a control bar,

housing, a jacking mechanism for lowering

and raising the plugging head, and a folding

plugging head which opens into the line,

stopping flow. An example of a folding head

plugging machine is shown in figure 3.

Figure 3. SHORTSTOPPII Plugging Machine

TDW France-22-E-03-09

8

D. When tapping and plugging work is done, a

completion plug must be inserted into the

neck of the fitting using the POLYSTOPP

completion machine. The completion plug

is lowered through the valve and threaded

into position in the neck of the fitting. An

O-ring provides a seal. The completion

machine is shown in Figure 4.

Figure 4. POLYSTOPPCompletion Machine

3.2 Accessory Equipment

A. The POLYSTOPP10" Valve is used with

the POLYSTOPP Big Sizes Plugging

System. See figure 5.

Figure 5. POLYSTOPP10" Valve (valve design will

be changed after September 2019)

B. Tapping and plug setting machine adapters

are used to connect various equipment

components to the POLYSTOPP10"

valve. They are flanged on the lower end to

match the valve and threaded on the upper

end to match related equipment. Two such

adapters are shown in Figure 6.

Completion machine Adapter in 2

parts

T-203 Adapter

Figure 6. Machine Adapters

C. Another adapter is a spool used to adapt the

8" SHORTSTOPP® II plugging machine to

the POLYSTOPP10" Valve. It is shown in

Figure 7.

Figure 7. SHORTSTOPP® II plugging machine to

POLYSTOPP10" Valve adapter

D. Cutters are designed to cut through the pipe,

and retain the coupon and chips, minimizing

the amount of chips left in the pipe. Cutter

holder, cutter and pilot are shown in Figure

8.

Figure 8. Cutter holder, cutter and pilot drill

TDW France-22-E-03-09

9

E. Fittings are designed to plug the main line.

The plugging fitting top half is bolted to the

lower half and electrofused to the line. The

top half of the fittings has a completion plug

that is installed into the neck after work is

completed and a blind flange is installed.

This seals the fitting. Fitting is shown in

Figure 9.

Figure 9 : Plugging Fitting

3.3 Related Publications

TDWFrance-22-E-03-09 user manual provides

procedures for preparation of the pipe and

installation of the fitting by the electrofusion

process. Other publications of interest include:

•00-3795-0115 : T-203b Tapping

Machine

4.0 Safety

4.1 Protective Clothing

Protective clothing is recommended whenever

working around machinery. Suggestions

include use of a hard hat, gloves, safety glasses,

safety shoes, garments to cover exposed areas

of skin, and breathing apparatus when toxic

atmosphere exists.

4.2 WARNINGS and Cautions

The purpose of WARNINGS and Cautions in

this manual is to call the operator's attention to

the possible danger of injury to personnel and

damage to equipment and deserves careful

attention and understanding.

A. WARNING: A Warning indicates a

potentially hazardous situation which, if

not avoided, could result in death or serious

injury and damage to equipment.

B. Caution: A Caution indicates a potentially

hazardous situation which, if not avoided,

may result in minor to moderate injury and

damage to equipment. It may also be used

to alert against unsafe practices.

4.3 Proper Grounding

Polyethylene pipe often has internal and external

electrostatic charges that can be hazardous to

personnel and equipment. Develop and use

procedures that provide a grounding system to

eliminate this hazard. The following can be used

as a guideline.

A. Minimize the external charge by wet-

wrapping (or equivalent method) the pipe

outside before installing the SHORTSTOPP

II System.

B. Ground the equipment as follows:

1. Before making the tap, attach the

TDW provided ground strap assembly

from ground to the valve-support.

2. When using the plugging machine for

plugging or completion plug setting,

attach the ground strap assembly to the

valve-support.

WARNING: Before tapping, plugging or

setting a completion plug,

properly ground equipment to

eliminate any static electricity.

Electrostatic charges can be

hazardous to personnel and

equipment.

4.4 Pipe Support

It is mandatory to provide blocks under the pipe

to support the weight of the equipment.

5.0 Equipment Orientation

Use of directional words such as "up," "down,"

"raise," and "lower" throughout this manual

assumes the fitting and valve are mounted on top

of the line and the tap is made vertically through

the top of the pipe. If the valve is installed and

the tap is made in any other orientation,

substitution of appropriate directional words will

be required.

TDW France-22-E-03-09

10

Section II: Installation and operation

of the POLYSTOPP10" Valve

1.0 Introduction

The POLYSTOPP 10" Valve is a full-opening temporary valve used with TDW drilling or tapping machines and

SHORTSTOPP® II plugging equipment. It is recoverable after the tap is complete and a completion plug is set in

the TDW SHORTSTOPP® or POLYSTOPP® fitting.

1.1 Site Preparation

The POLYSTOPP 10" Valve matches ANSI Class 150 bolt patterns.

The compact design of the POLYSTOPP 10" Valve minimizes drilling machine boring bar length required to

complete the tap.

TDW France-22-E-03-09

2.0 Operating instructions

2.1 Installation

A. The POLYSTOPP10" Valve (valve design will be changed after September 2019) can be installed on a

TDW POLYSTOPP® PE or SHORTSTOPP® fitting 315 and 355 mm.

B. Put the support plate on the lower face of the valve with specific nuts

C. Put the centering device onto the plug of the fitting.

D. Put the Plug + centering device onto the fitting.

E. Put the reinforcement tool around the outlet of the fitting.

F. Install the valve onto the fitting. The centering device will guide the valve. Squeeze the nuts in cross,

respecting the torque in minimum 3 turns The torque applies on the nuts is more and less 47 N.m.

G. Put the 2 pipe supports on the pipe and screw on hand be in contact with the support plate

TDW France-22-E-03-09

H. Remove the centering device with the completion machine. With the effort to remove the plug is too

important, unscrew a little the lower nuts of the valve.

I. The operating handle is used for both opening and closing the valve seat.

2.2 Operation

A. When the valve is installed, and before tapping the pipe, open and close the valve disc. The index indicates

the operating disk is in position fully open.

CAUTION: do not use force to open or close a POLYSTOPP

10" Valve. If a valve will not seal with normal

force, foreign material may be in the path of the valve disc travel, or an O-ring, damaged by failure to

equalize pressure properly, can cause leakage. In these cases, excessive force will not cause a valve to

seal and can damage the valve, possibly resulting in personal injury.

Do not use any tool other than the handle provided to operate the valve.

B. The POLYSTOPP10" Valve must not be opened against differential pressure. The pressure must be

equalized on both sides of the disc. An internal bypass, shown in Figure 10, is used for pressure equalization

as well as purging air from the housing above through a bleeder valve.

Fig 10. Internal bypass on POLYSTOPP® 10" valve (valve design will be changed after September 2019)

C. When opening the internal bypass, do not force the bypass valve. The internal by-pass valve must remain

open so that pressure is equalized on both sides of the valve disc before opening the valve.

D. Additional information on operating the POLYSTOPP10" Valve in tapping or plugging operations can be

found in the appropriate tapping or plugging machine manual. Make sure to apply the CAUTION remarks

provided in paragraph 2.2A above.

TDW France-22-E-03-09

Section III: Tapping 315 and 355 mm Lines

w/the T-203 Tapping Machine

1.0 Introduction

When tapping a 315 or 355 line, the T-203

Tapping machine is used to make the tap.

It is important that the entire operation be planned

carefully in advance to make sure that all

equipment and fittings necessary to do the job are

readily available.

2.0 General Information

2.1 Procedures

If the line is to be temporarily plugged after

tapping, it should be tapped with product flowing

so that the tapping chips will disperse. If the chips

have been dispersed, a better seal is likely when

the line is plugged off.

2.3 Keeping Line in Service

If a section of line is to be isolated and repaired,

and it is desired to keep the line in service, as

many as six taps of varying sizes could be

required.

A. Two to isolate the section of line.

B. Two to connect a bypass around the isolated

section.

C. One of two connections for blow-down of the

isolated section and equalization of pressure.

D. After the scope of the work has been defined,

the equipment must be selected, assembled,

and inspected to ensure proper working order.

3.0 Preparation

3.1 Fitting

Attach fitting to pipeline following fitting

installation instructions.

3.2 Valve

A. For installing the valve, see the paragraph

2.1 above.

3.3 Tapping Machine

A. Install the tapping machine adapter on tapping

machine. Sealing gland on bottomof machine

assures proper cutter alignment in the adapter

when attached. See Figure 12.

Figure 12. Install Tapping Adapter

B. Extend boring bar until the end is accessible.

C. Assemble pilot drill. Insert pilot drill through

flange and secure with cap screw. The socket

head cap screw goes through the pilot drill

shaft.

D. Install pilot drill and flange assembly through

cutter and align four bolt holes.

CAUTION: Cutter teeth are extremely sharp.

Wear gloves when handling cutter.

B. Install cutter holder over pilot drill shaft and

align the four bolt holes. Insert bolts into the

holes and thread into cutter shell. Use a flat

TDW France-22-E-03-09

washer on each bolt. Tighten bolts wrench-

tight.

Figure 13. Cutter Holder, Cutter & Pilot drill

Assembly

F. Slide cutter holder/cutter assembly onto

tapping machine boring bar, and align bolt

hole through boring bar. Be extremely careful

of cutter teeth and pilot drill tip.

Figure 14. Cutter holder

G. Install bolt through cutter holder and boring

bar. Install and tighten nut to secure cutter

assembly, as shown in Figure 15.

Figure 15. Install bolt and Nut

H. Retract cutter fully into housing. Zero will

show in one of the four tapping machine sight

windows. The boring bar may require turning

slightly to align zero. See Figure 16.

Figure 16. Zero in Window

3.4 Required Measurements

Tapping Measurements. The following

measurements must be taken prior to tapping to

determine the boring bar travel distance required

to complete the tap: Figure 17 shows the

measurements necessary to complete the tap.

TDW France-22-E-03-09

Figure 17. Measurements

A. Take and record measurement A. This is the

distance from the face of the tapping machine

adapter flange to the tip of the pilot drill. See

Figures 17 and 18.

Figure 18. Take and Record Measurement A

B. Take and record measurement B. This is the

distance from the top face of the tapping

valve, including gasket, to the top of the pipe

to be tapped. See Figures 17 and 19.

Figure 19. Take and record Measurement B

C. Add Measurement A to Measurement B to

determine the lower-in distance.

D. Measurement C is the distance from the top

of the pipe to the point where the coupon is

free and the cutter has “cleaned up” the

tapped hole. See Figure 20. This distance is

dependent on the size of cutter and size of

pipe, SDR of the pipe.

TDW France-22-E-03-09

Figure 20. Measurement C

E. The sum of distance C and the lower-in

distance (B+A) is the total boring bar travel

required to complete the tap. This number

will be visible in the travel indication port

when the tap is completed.

F. If a completion plug is to be set after the

tapping operation, take and record

measurement H for later use. See Figures 17

and 21. This is the distance from the valve

face, including gasket, to the bottom of the

grove in the neck of the fitting.

Figure 21. Measurement H

3.5 Install Machine

A. Open and close tapping valve to make sure

that it operates freely. Count and record turns

required to open and close the valve. Leave

valve closed.

B. Install T-203 machine on tapping valve and

secure. See Figure 22.

TDW France-22-E-03-09

Figure 22. Install T-203 Tapping Machine (valve design

will be changed after September 2019)

C. Install bleeder valve. See figure 23.

Figure 23. Install Bleeder Valve

3.6 Conduct Pressure Test

A. Using the bleeder valve for access, conduct

pressure test on tapping

machine/adapter/valve/fitting installation.

Make sure tapping valve is open for test. Test

to pipeline pressure.

CAUTION: Do not exceed pipe pressure when

conducting pressure test. Exceeding the

piping system internal pressure may

cause damage to the carrier pipe making

it difficult or impossible to complete the

tapping and/or line plugging operation.

B. After test is completed, leave tapping valve

and bleeder valve open.

3.7 Selecting Power Unit

A. If using air motor drive:

1. Prepare air motor. Minimum air supply

must be 105 cfm (2,9736 cubic meter per

minute) at 90 psi (6 bar).

2. Be sure air supply hose is blown clear of

dirt and moisture. Compressor should

have baffled receiver to keep liquid out

of supply line.

3. Attach air hose. See Figure 24.

Figure 24. Connect Air Supply

4. Adjust lubricator to supply approximately

10 drops of oil per minute. A good grade

of SAE 10W engine oil is recommended.

5. Check operation of motor by opening and

closing control valve.

TDW France-22-E-03-09

4.0 Tapping the Line

4.1 Making the Tap

A. Turn feed screw adjusting cap

counterclockwise to relieve spring tension.

See Figure 25.

Figure 25. Turn Feed Screw Adjusting Cap

B. Install lower-in crank in top of machine and

turn counterclockwise, lowering boring bar

until pilot drill touches top of pipe. The

computed lower-in distance (measurements

A and B) should appear in the travel indicator

port. Retract boring bar one revolution and

remove hand crank.

Note: One revolution of the hand crank will lower

the boring bar 1/8 inch. If, for example, the

lower-in distance was 20 inches, it would

require 160 revolutions of the hand crank to

lower the boring bar to this point.

CAUTION: Do not use the air motor or

hydraulic motor to lower the boring bar.

Damage to the cutter and pilot may

occur.

C. Open air control valve (Figure 26) to start

rotation of boring bar. Adjust filter regulator

knob until desired rpm is obtained. The

recommended RPM is between 15 & 20

RPM.

Figure 26. Open Air Control Valve

Note: RPM can be checked easily by observing

the numbers as they come around in the travel

indication port. Count for 15 seconds and

multiply by four to determine rpm.

CAUTION: Speeds higher than 37 rpm may

cause damage and premature wear to

the air motor.

E. Turn feed adjusting cap clockwise to feed pilot

into pipe. Stop adjustment when air motor

begins to load up.

F. As the pilot drill penetrates the pipe wall,

allow line pressure to completely fill valve

and fittings. Blow line liquid or gas through

bleeder valve a few seconds to purge all air.

Close bleeder valve tightly. The machine can

continue tapping during the air purging

process.

WARNING: Vent pressure bleed valve away

from work area and personnel.

Stand clear of vent when

bleeder valve is opened,

otherwise personal injury can

result from blowing material.

G. If the machine stalls, stop and retract cutter a

few turns of the hand crank and resume

tapping.

H. When tap is complete, check number on

boring bar in travel indication port to make

sure computed travel distance has been

reached.

I. Turn off air control valve or close hydraulic

valve to stop boring bar rotation.

J. Turn feed adjusting cap fully counter-

clockwise to stop feed.

K Place hand crank on top of machine and turn

clockwise, fully retracting cutter into tapping

TDW France-22-E-03-09

machine adapter. Zero should appear in the

travel indication port. Remember that it takes

eight turns to retract boring bar 1 inch.

L. Close tapping valve.

M. Open bleeder valve to bleed off pressure in

adapter.

WARNING: Vent pressure bleed valve away

from work area and personnel.

Stand clear of vent when

bleeder valve is opened,

otherwise personal injury can

result from blowing material.

4.2 Remove Tapping Machine

A. Remove bleeder valve

Figure 27. Remove Chips & coupon

CAUTION: Cutter teeth are very sharp. Wear

gloves and handle cutter with extreme

care when removing chips.

B. After tapping has been completed, take off

the tapping machine.

C. Extend the boring bar.

D. Disassemble the pilot drill and the cutter.

E. Remove the cutter from the cutter holder.

F. Remove the cutter holder.

G. Remove the coupon from the cutter and also

the chips. PE cutters are designed to capture

all but a spoon-full of the chips. In most cases,

chip removal is not necessary.

H. If needed, chips can be removed from the

line by using the POLYSTOPP cleaning

machine.

TDW France-22-E-03-09

Section IV: Plugging the Line

1.0 Introduction

This section provides procedures for temporarily plugging 315-355 mm line while work is being performed.

The line may be kept in service during plugging operations by plugging it at two locations to isolate the line

section in between and running a bypass around the isolated area.

2.0 Plugging the Main Line

All parts that makeup the plugging head assembly must be clean and in good condition. Remove all dirt and

any rust scale from all mating surfaces and bolt holes. All internal threads should be inspected for wear, and

a light coating of lubricating oil applied to reduce friction.

If using a plugging machine with a jack, check the drag on the jacking mechanism following the instructions

in Section VI, Maintenance. Make sure this test is done without the sealing element attached.

2.1 Install the Plugging Head

A. Extend the control bar through the plugging head housing and insert the control bar handles in the

handle connectors. Twist the upper handle to disengage the locking pin. Turn the control bar handles

to align the keyways on the lower end of the external and internal bars, as shown in Figure 28.

Figure 28. Align Control Bar Keyways

B. Plugging head halves are shown in Figure 29.

Table of contents

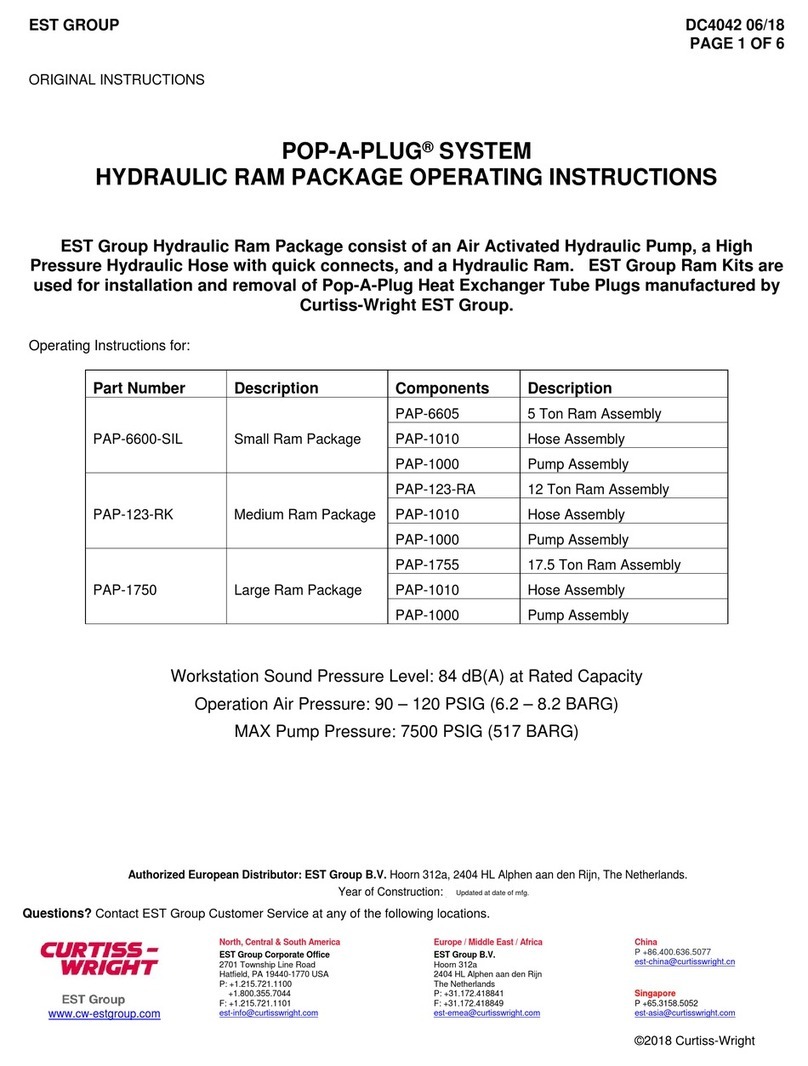

Other TDW Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

ABB

ABB HT562797 Operation manual

technotrans

technotrans manroland beta.d 40 Original instruction manual

SCHUNK

SCHUNK TENDO RLA Assembly and operating manual

Curtiss-Wright

Curtiss-Wright POP-A-PLUG SYSTEM operating instructions

Regulus

Regulus BIO 55 MIX-BP G75 1F Installation and operation manual

ABB

ABB HT847245 Operation manual