3 │

Regulus BIO 55 MIX-BP G75 1F - www.regulus.eu

A. SAFETY INSTRUCTIONS

●

The hydraulic connection of the load unit must be carried out by a person

qualiedaccordingtotheapplicablestandardsandregulations.

●Anyinterventions in the electrical installation must be carried out by a person

qualiedaccordingtotheapplicablestandardsandregulations.

●The BIO 55 MIX-BP G75 1F load unit is in no way a replacement for the safety

components of the heating system, hot water system and boiler. These safety

elements must always be installed in accordance with the applicable standards and

regulations. The diagrams published in this manual represent wiring examples and

may not be complete. Carry out the actual installation according to the heating

designandensurethatallprescribedsafetyfeaturesaretted.

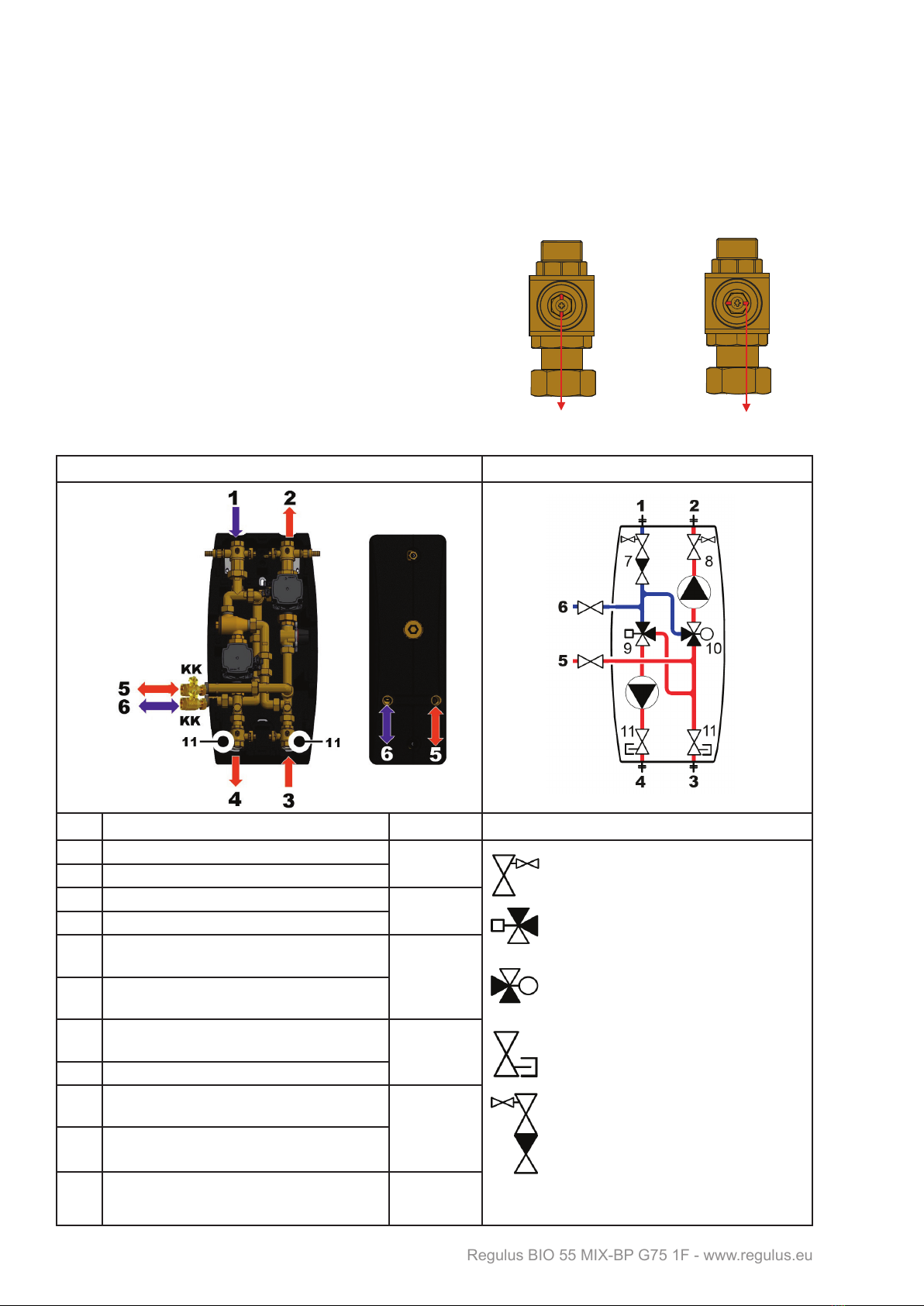

B. INTRODUCTION, DESCRIPTION

BIO 55 MIX-BP G75 1F Load Unit includes a complete hydraulic connections for the

installation of a heating system with a solid fuel boiler. All you need to do is connect

a suitable controller, boiler, safety elements, one heating system and a thermal

store, then set the desired parameters in the external controller.

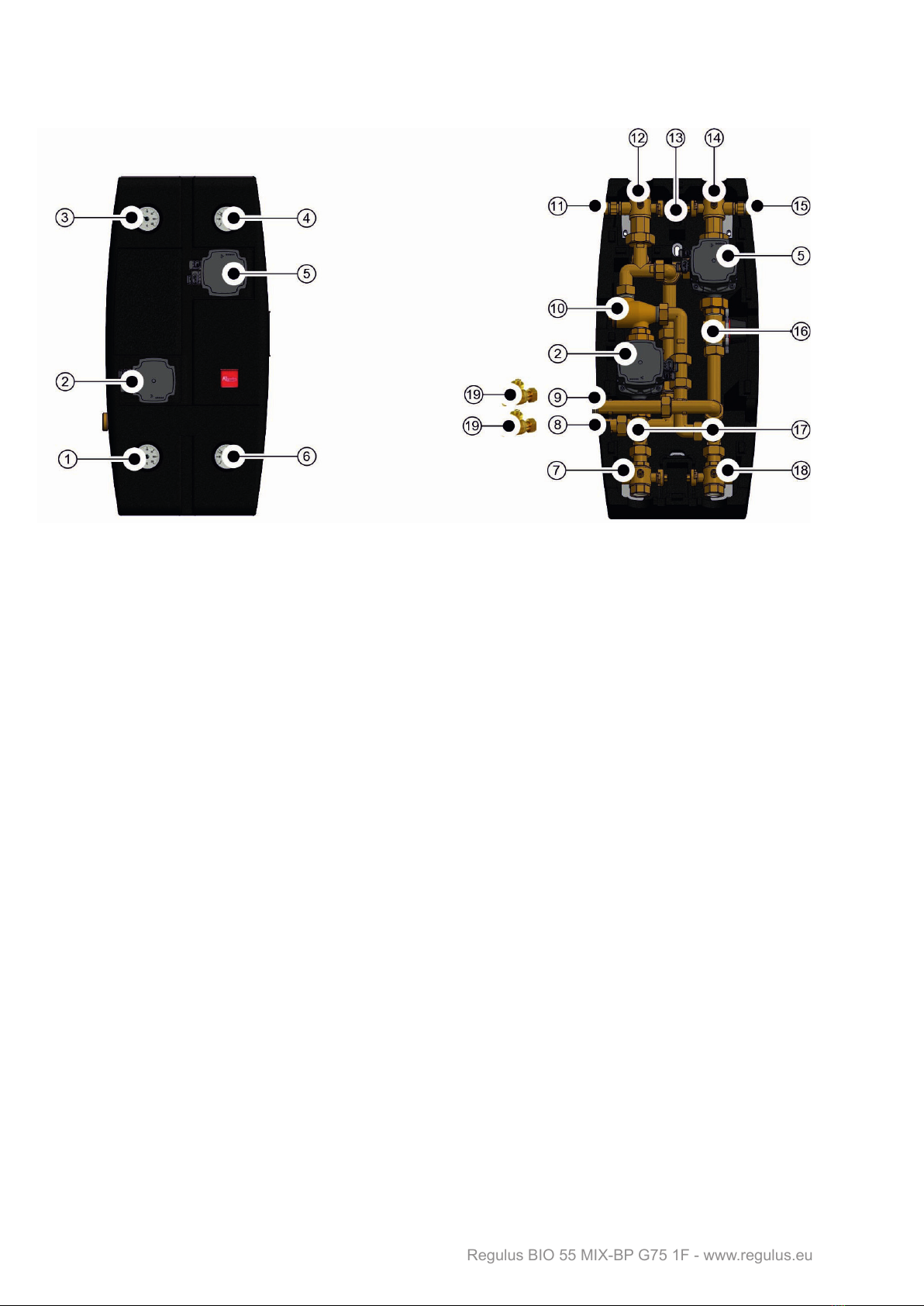

The Load Unit involves

●twoGrundfosUPM3FlexAS25-75circulationpumps(enablingcontroleitherby

PWM signal or by selecting a pump performance curve)

●TSV3BMloadvalvewithautomaticbypassbalancing

●3-waymixingwayformaintainingthedesiredtemperatureintheheatingcircuit*

●twoballvalveswithdrainvalvesforshuttingoffanddrainingtheheatingsystem

●

check valve integrated in the ball valve body located at the return line from the

heating system

●twoballvalvestoshutofftheboilercircuitu

●twodrainvalvestodraintheloadunit

●twoballvalvespermittingtoshutoffthethermalstorecircuit(enclosedinsupply)

●handleforballvalves

●fourthermometers

●

outets for connecting a (combination) thermal store and alternative outlets for

connecting optional accessories

* Mixing valve actuator is not included in supply and shall be ordered separately.

The Load Unit delivery includes a package containing:

Mounting kit:

●2screws,5x50,panhead

●2washers6.4instainlesssteelDIN9021/A2

●2wallplugs,8mm,TX

Others:

●2ballvalvewithunionnut,G1“FuxG1“F