Contents

1 Legal Information.........................................................................................................4

2 About this Document..................................................................................................5

2.1 Objective and Target Group..............................................................................5

2.2 Explanation of Symbols....................................................................................5

2.2.1 Typographic Conventions................................................................. 5

2.2.2 Symbols Used.................................................................................... 5

2.3 Figures................................................................................................................6

2.4 Downloading Manuals...................................................................................... 6

3 Safety............................................................................................................................7

3.1 Intended Use......................................................................................................7

3.2 General Safety Instructions.............................................................................. 7

3.3 Organizational Measures.................................................................................. 7

3.3.1 User Manual....................................................................................... 7

3.3.2 General Personnel Qualification.......................................................7

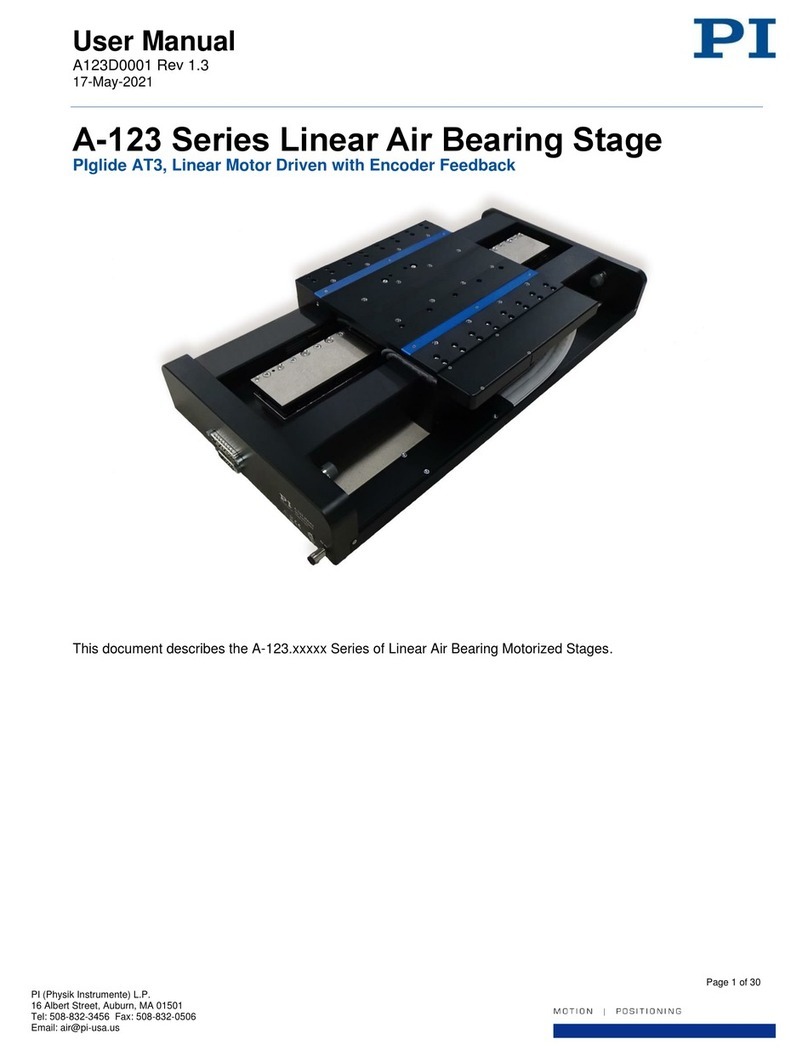

4 Product Description..................................................................................................... 8

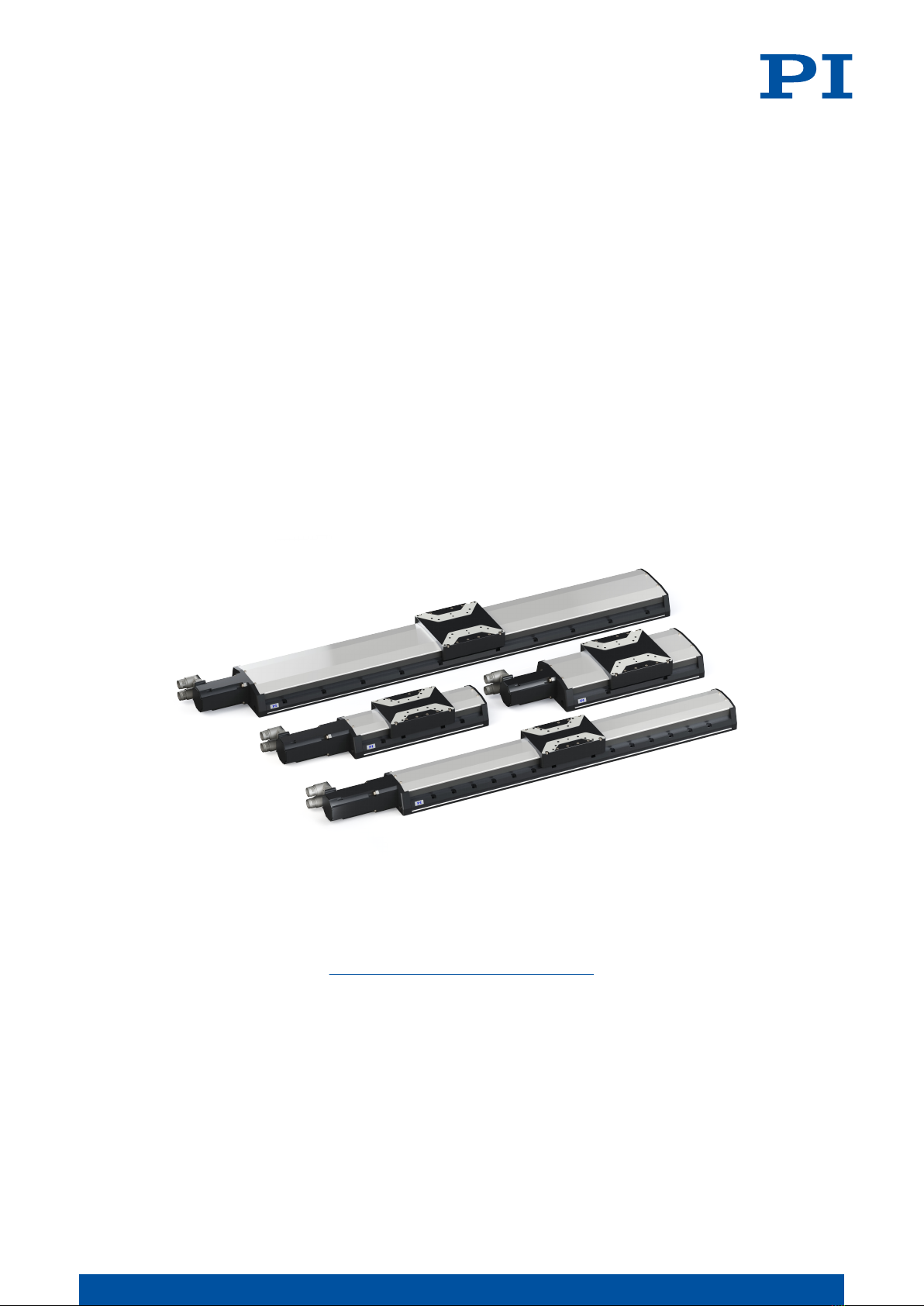

4.1 Model Overview.................................................................................................8

4.2 Product Labeling................................................................................................8

4.2.1 Type Plate........................................................................................... 9

4.3 Scope of Delivery...............................................................................................9

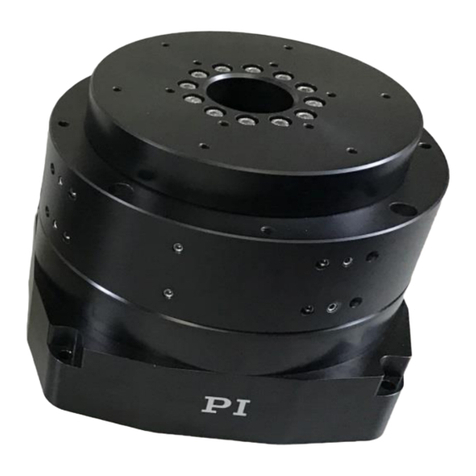

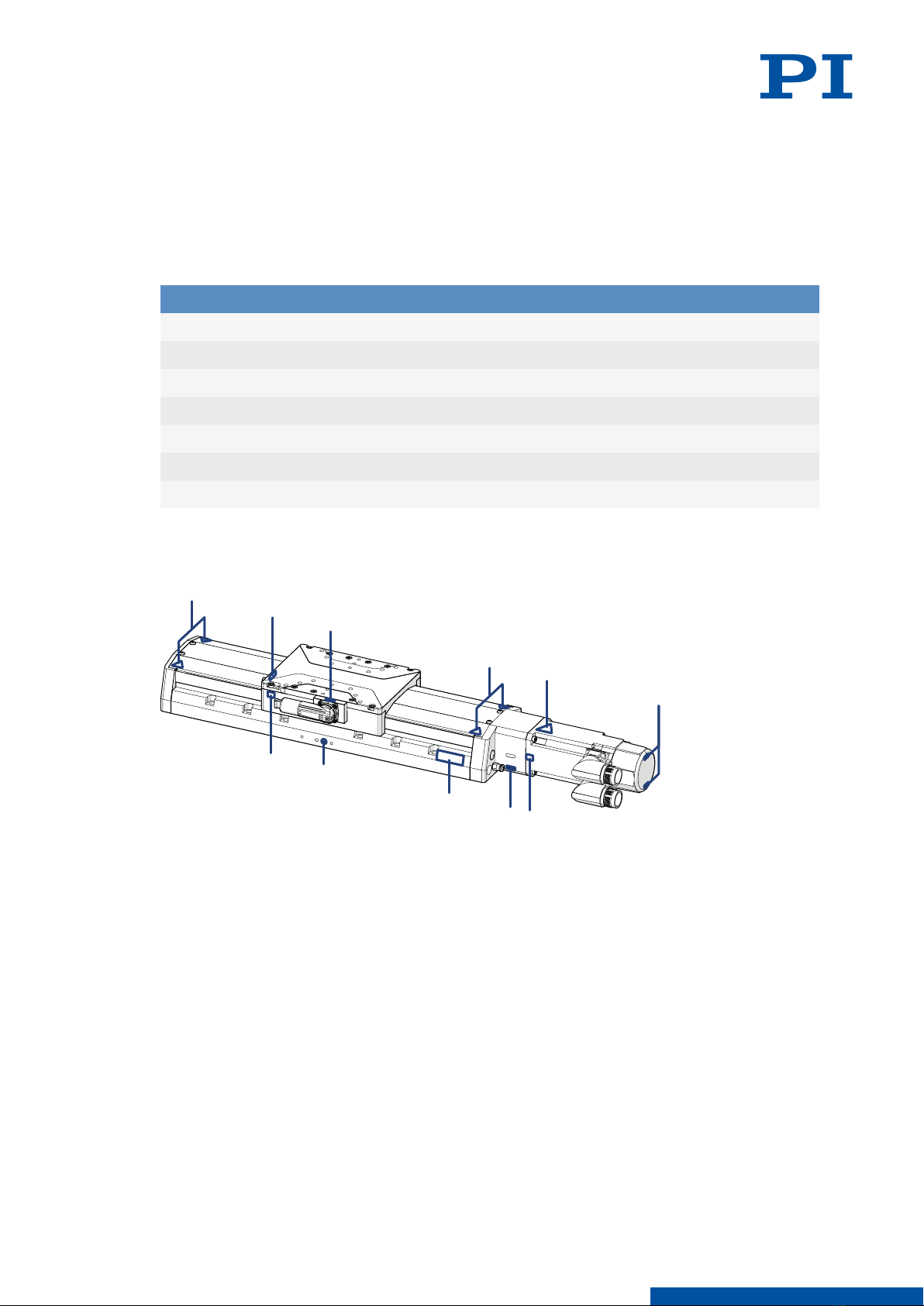

4.4 Overview.......................................................................................................... 10

4.4.1 Base Body......................................................................................... 10

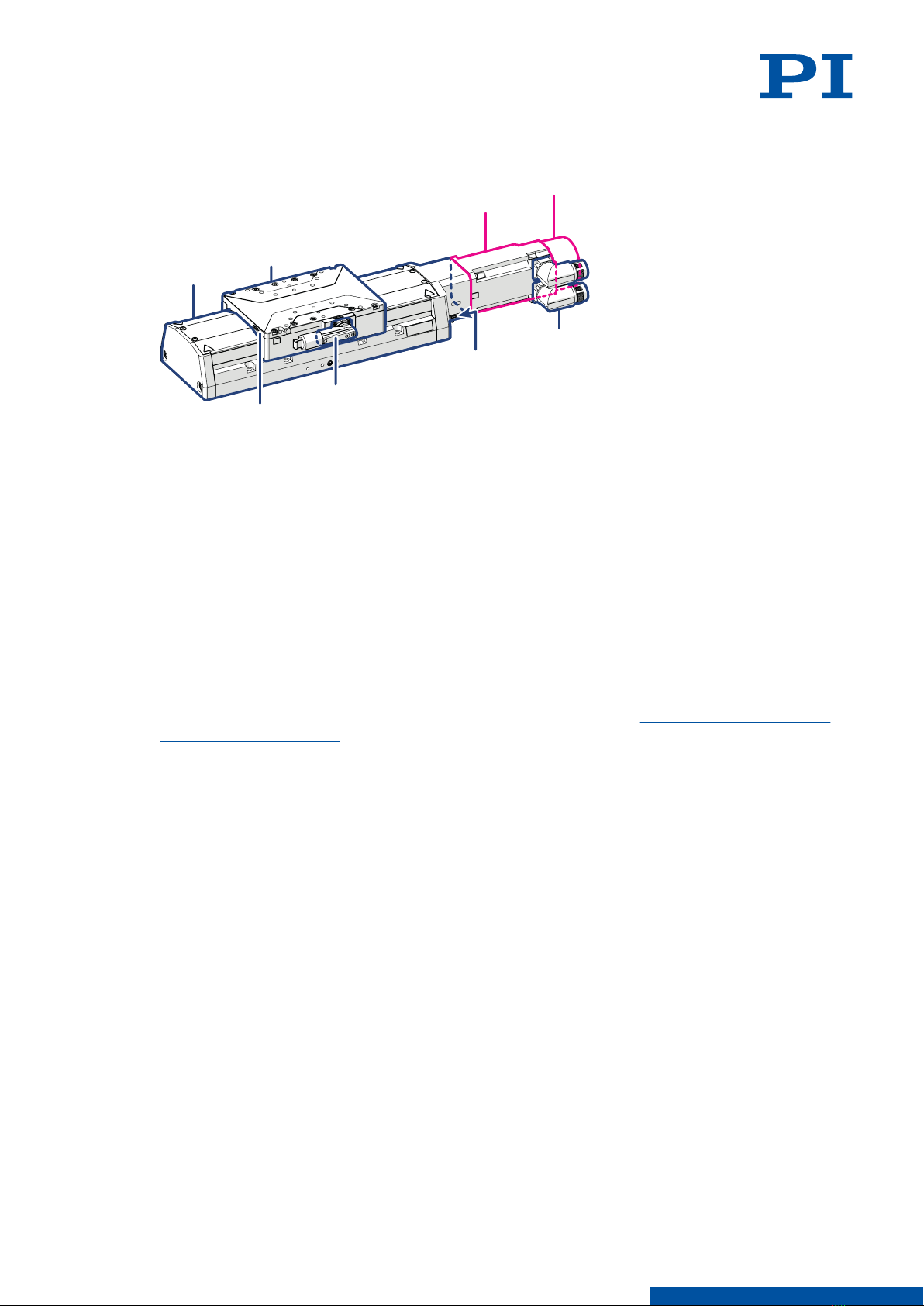

4.4.2 Drive.................................................................................................. 11

4.4.3 Holding brake................................................................................... 11

4.4.4 Linear Encoder Connector............................................................... 11

4.4.5 Purge Air System..............................................................................11

4.5 Direction of Motion..........................................................................................13

4.6 Suitable Electronics......................................................................................... 13

5 Unpacking.................................................................................................................. 14

6 Installation................................................................................................................. 15

6.1 Mounting the L-417.xx9211E0B........................................................................15

6.2 Connecting the L-417.xx9211E0B to the Protective Earth Conductor........... 16

6.3 Mounting the Load onto the L-417.xx9211E0B............................................... 18

6.4 Connecting the L-417.xx9211E0B..................................................................... 19

7 Startup / Operation................................................................................................... 21

7.1 Starting and Operating the L-417.xx9211E0B................................................. 21

CONTENTS L417M0015EN ‒ 9/10/2019

2MOTION | POSITIONING