408-9535

2of 4

Rev C

If crimping head must be removed after being in

production, pressure must be released in the

hydraulic system before head is removed.

- If using Hydraulic Power Unit 69120-[ ],

DISCONNECT POWER UNIT FROM

POWER SUPPLY.

- If using Hydraulic Hand Pump 314979-1,

depress the pressure release.

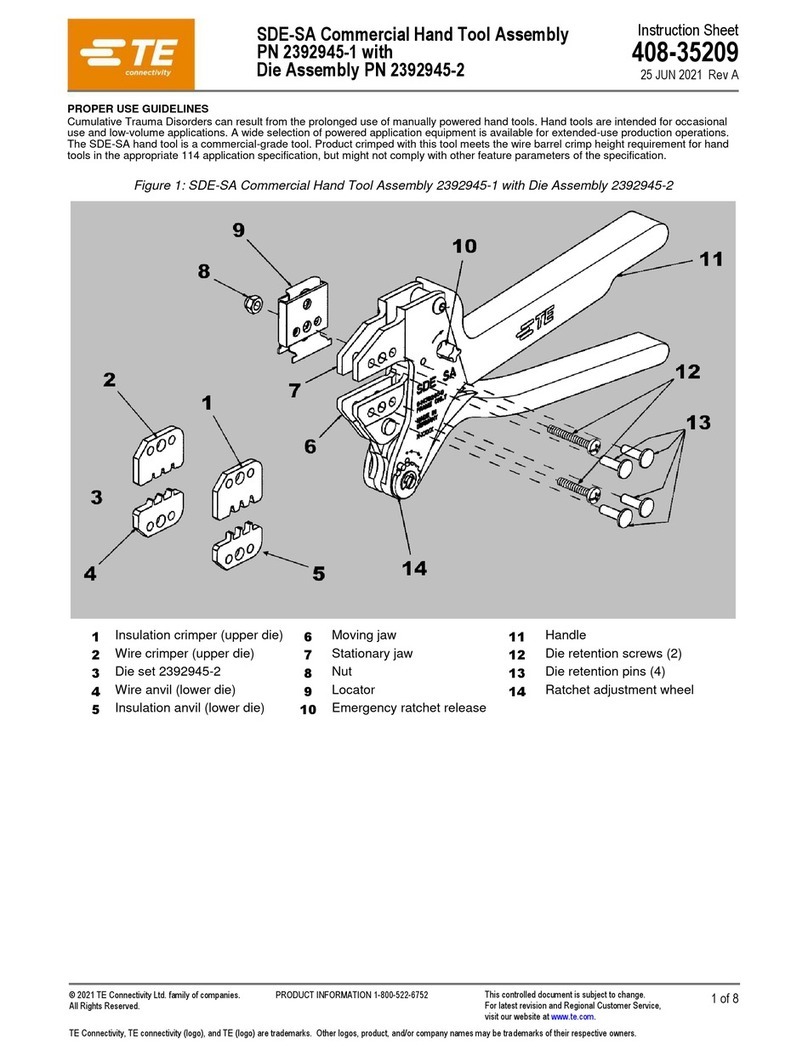

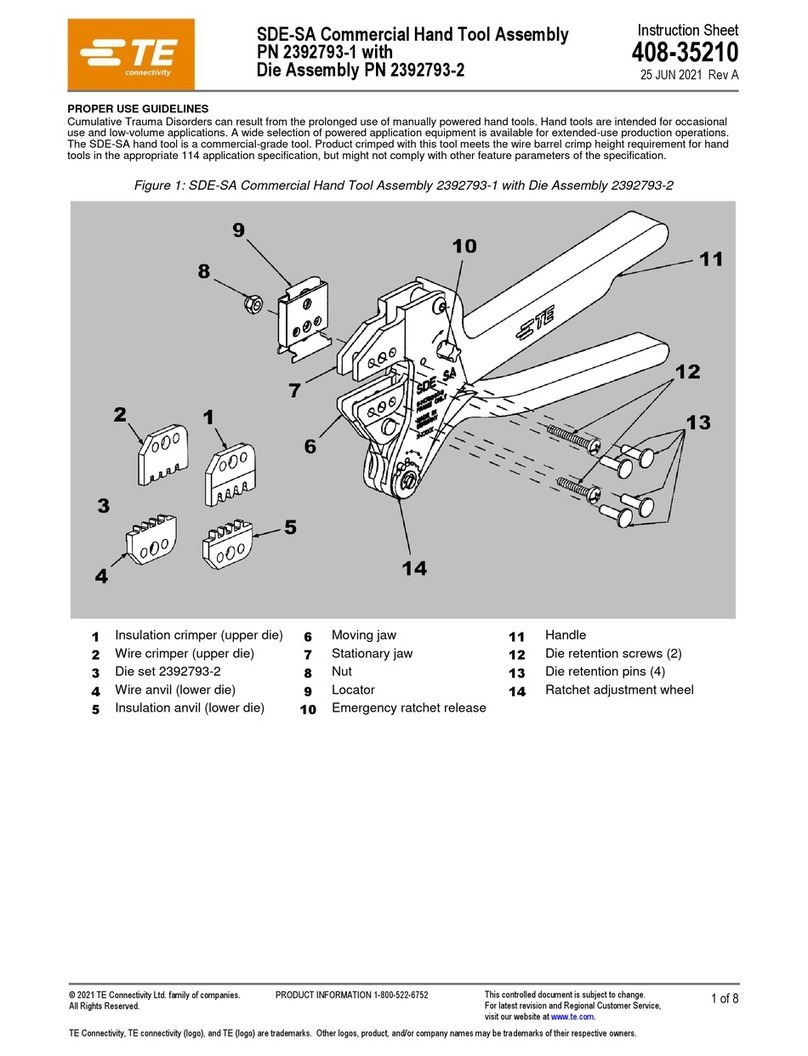

Yoke

Setscrew

Ram

Setscrew

Ram Advanced

Stationary / Upper Die

Moving / Lower Die

Latch Pin

Removed

Figure 2

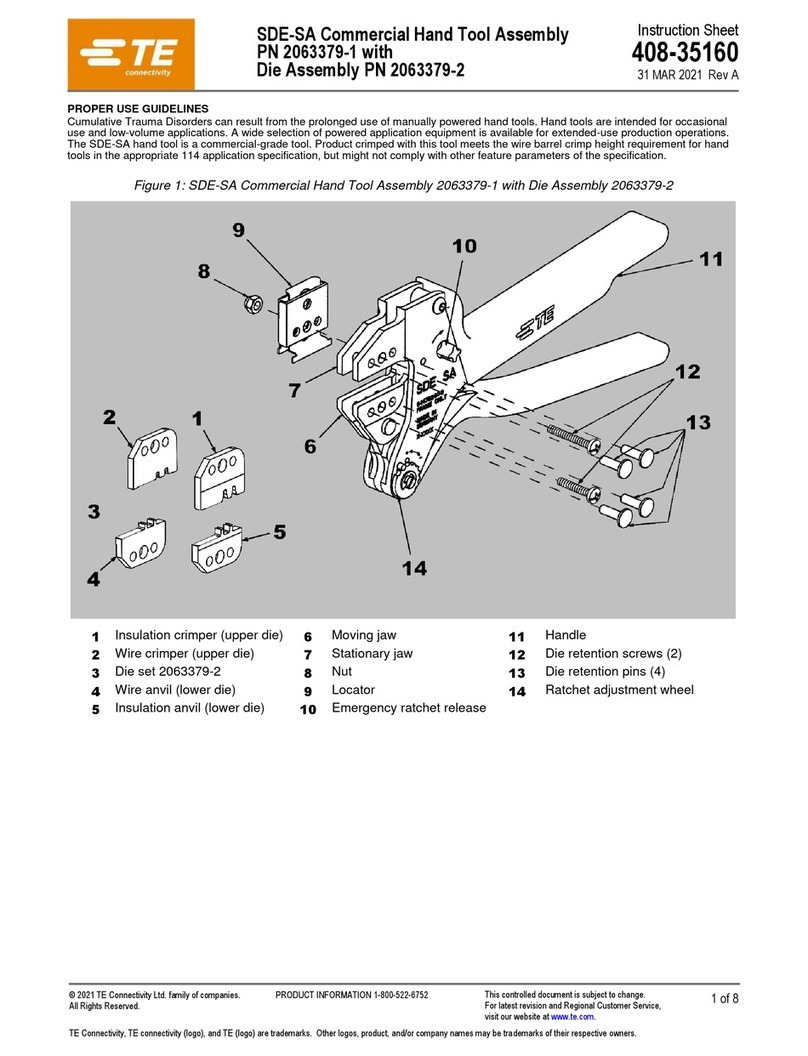

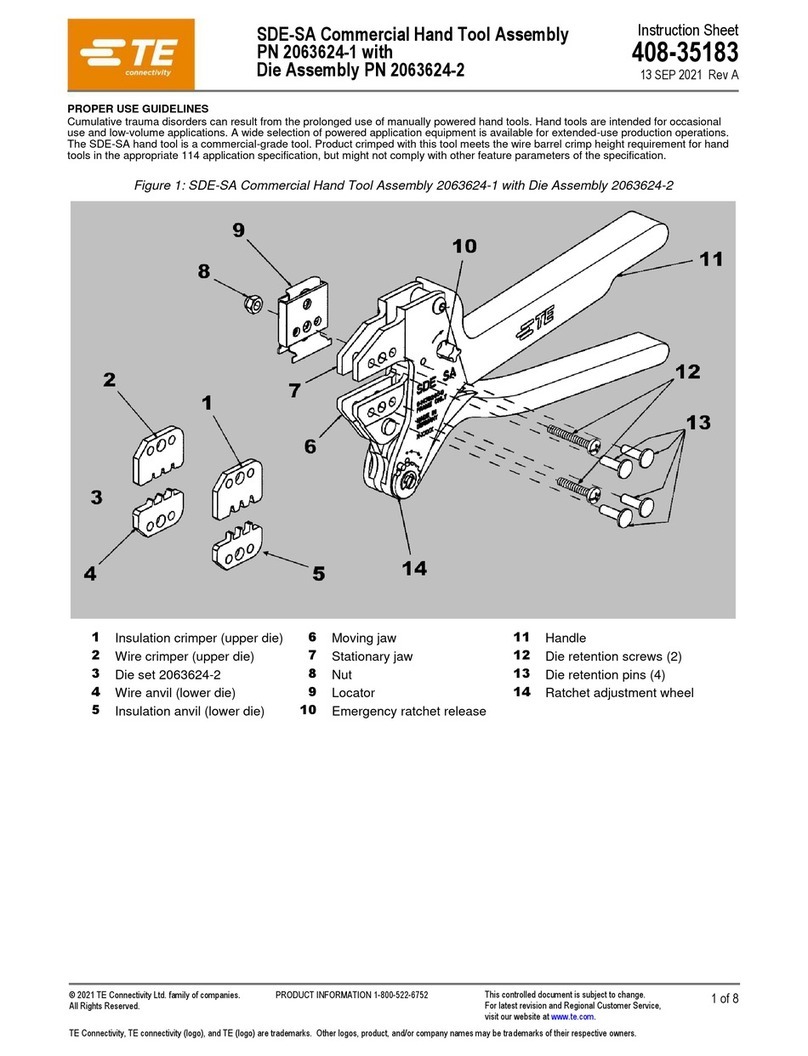

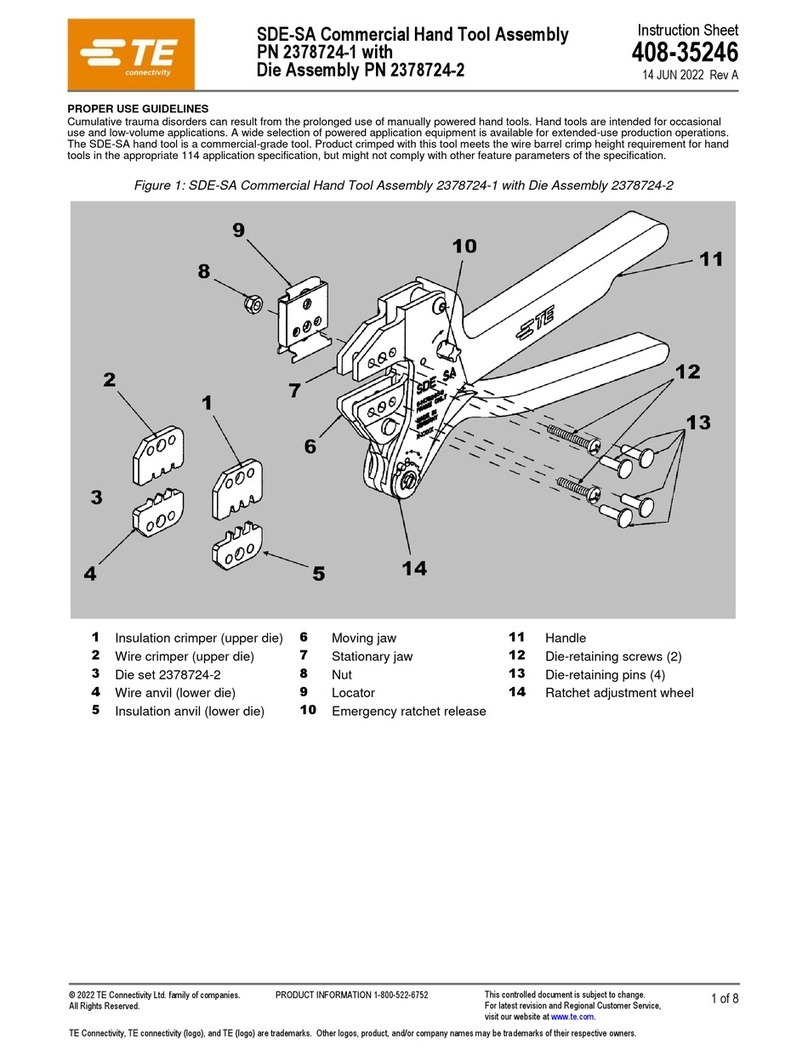

4. DIE INSERTION AND REMOVAL (Figure 2)

Avoidpersonal injury. When using power unit,

exercise caution to avoid accidently depressing

foot pedal or handle control when installing or

changing dies.

Make sure that matched die set, terminal, and wire

size are compatible. With crimping head properly

installed, refer to die set instructions, and insert /

change die set as follows:

1. Remove latch pin and open yoke on

crimping head.

2. Loosen setscrew in yoke. Refer to die set

instructions and insert stationary (upper) die which

includes the nest area into well of yoke. Tighten

setscrew.

3. Activate power unit to advance ram until setscrew

is visible (about 12.7 mm [.50 in.]). Loosen

setscrew.

4. Insert moving (lower) die, which serves as the

indenter, into ram well, making sure that moving die

is properly oriented to mate with stationary die.

Tighten setscrew.

5. Close yoke and secure with latch pin.

6. Slowly close dies to ensure proper alignment.

7. Complete the cycle and return the ram to the

DOWN position.

Always ensure that latch pin is fully inserted or

damage may occur to yoke, dies, or latch pin.

5. CRIMPING PROCEDURE

Avoid personal injury. When operating power unit,

exercisecautionwhileholding terminals,splices,or

wire near crimping area.

The following crimping procedure provides general

information. Refer to instructions packaged with

individual die sets for specific products, wire sizes,

strip dimensions, positioning of terminals and splices

in the dies, and crimping procedures.

Never operate the power unit without having a

crimping head attached to the handle control or

crimping head coupling.

1. Insert terminal or splice in the stationary (upper)

die according to instructions packaged with the

dies. Make sure the latch pin is secure before

activating the power unit.

2. Slowly advance moving (lower) die with short,

quick strokes until terminal or splice is secure.

3. Insert the stripped wire.

4. Cycle tool to complete crimp. Remove crimped

terminal or splice.

If the splice or terminal sticks in the die after

crimping, apply a rocking action to remove it from

the die.

6. INSPECTION / MAINTENANCE

Make sure hydraulic pressure is released and

power supply is disconnected before following

inspection and maintenance procedures, unless

otherwise specified in the procedure.

Each crimping head is assembled and inspected

before shipment. TE Connectivity recommends that

the crimping head be inspected immediately upon its

arrival at your facility, and at regularly scheduled

intervals, to ensure that the crimping head has not

been damaged during handling. Frequency of

inspection depends upon the following: care, amount

of use, and handling of the head; type and size of

products crimped; degree of operator skill; and

environmental conditions.

6.1. Cleaning

Remove accumulations of dirt and grease on the

crimping head, especially in areas where dies are

installed and terminals are crimped. Clean the entire

head frequently with a clean, lint-free cloth.