408-6759

3of 4

Rev C

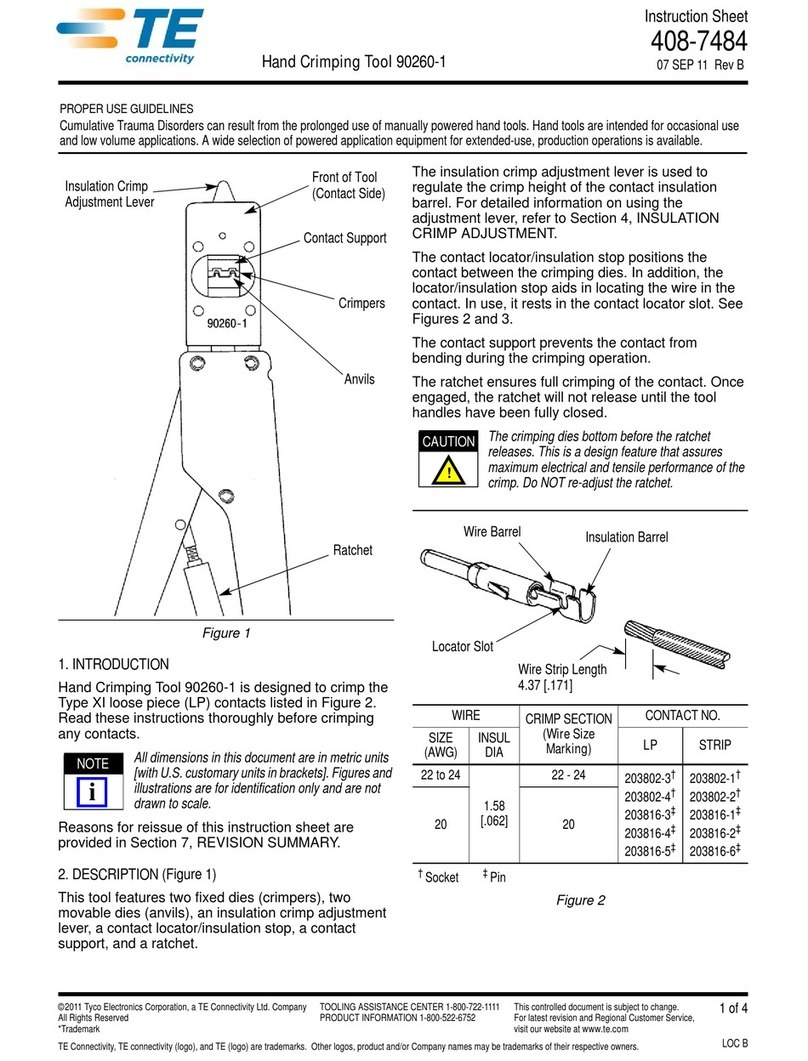

2. Insert crimped contact assembly into the

connector. Slide the ferrule forward over the braid

and support sleeve as described in the appropriate

instruction sheet packaged with the connector.

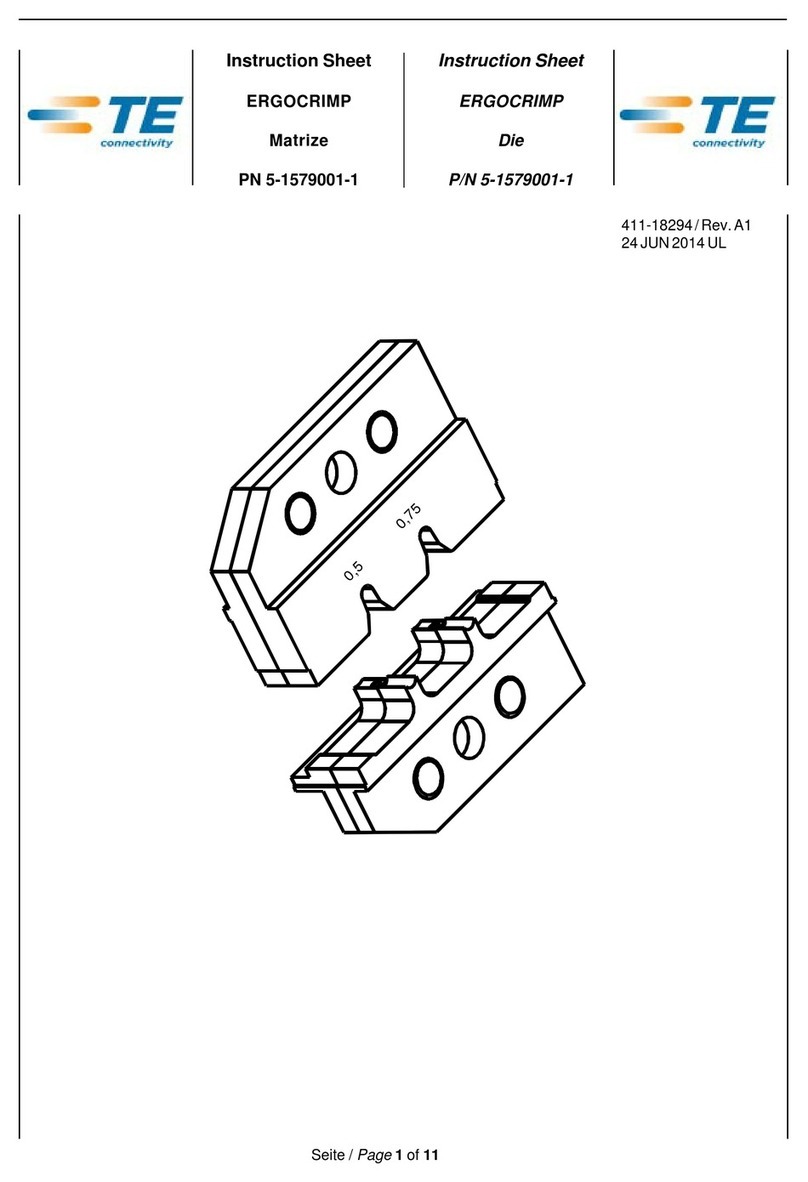

3. Insert connector ferrule into proper crimp area.

When using RG-178/U or RG-196/U cable, place

ferrule in crimp area B. For all other cable sizes,

use crimp area A.

4. Slide ferrule and contact through the crimp area

until the ferrule flange bottoms against the die to

prevent damage to the connector. Close tool

handles until the ratchet releases.

5. Open tool handles fully to remove crimped

connector assembly.

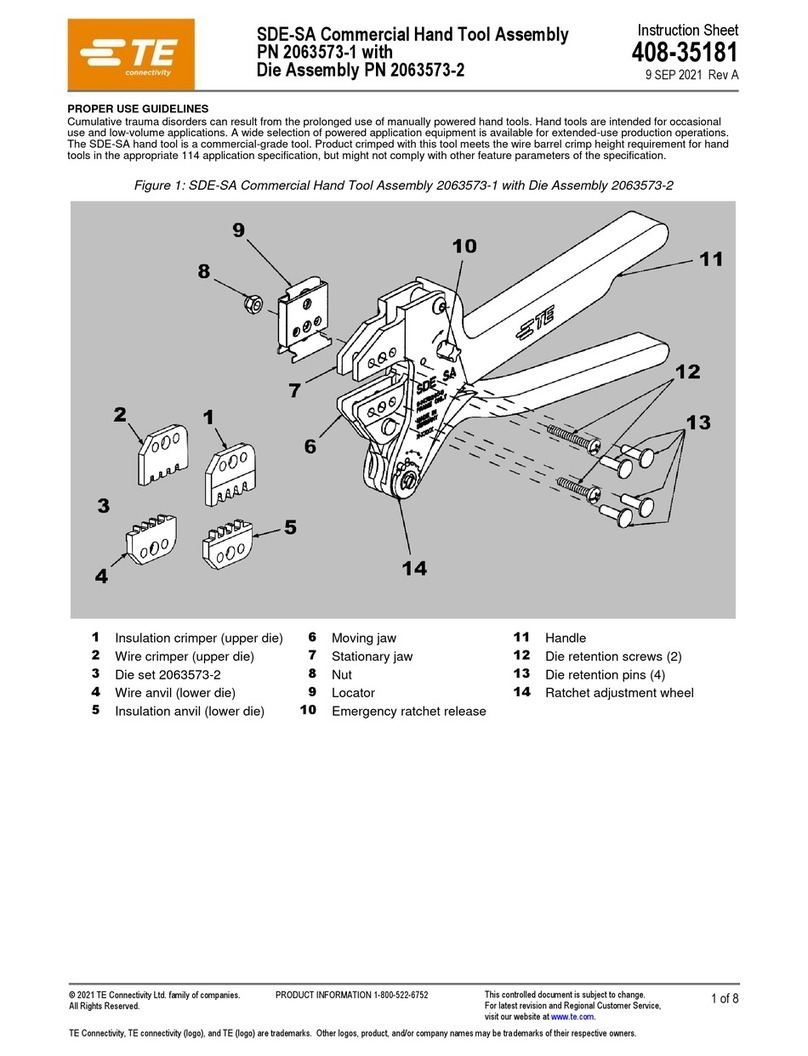

5. MAINTENANCE AND INSPECTION

5.1. Daily Maintenance

1. Remove dust, moisture, and other contaminants

with a clean, soft brush, or a clean, soft, lint-free

cloth. Do NOT use any objects that could damage

the dies or tool.

2. Make sure that the proper die retaining screws

are properly secured.

3. When the dies are not in use, store them in a

clean, dry area. When the tool is not in use, store it

with the handles closed to prevent objects from

becoming lodged within the jaws.

5.2. Visual Inspection

1. Remove all lubrication and accumulated film from

the dies by immersing the dies in a suitable

commercial degreaser.

2. Make certain that all die retaining screws and die

components are properly secured.

3. Inspect the crimping surfaces for flattened,

chipped, worn, or cracked areas. If damage is

evident, the dies must be replaced. Refer to Section

6, REPLACEMENT.

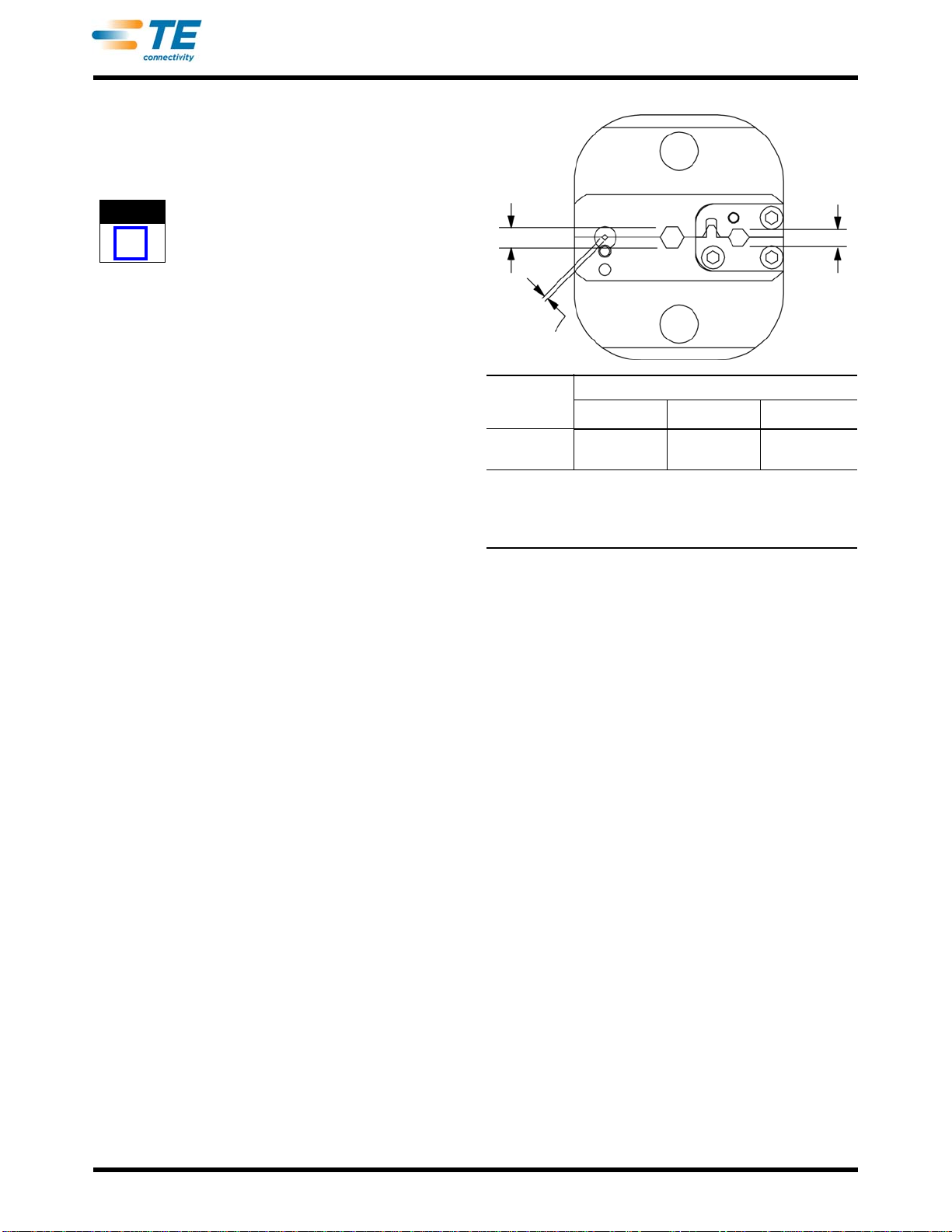

5.3. Measuring Die Opening

The die assembly will perform correctly as long as:

(1) the product specified is correct for the application,

(2) the specific die assembly is used, (3) the die

assembly has been measured to ensure that the

openings are correct, and (4) the die assembly

bottoms.

Figure 5 provides information on die opening sizes.

For specific applications where wire stiffness, material,

or insulation may give different than standard

performance, it may be necessary to measure the

crimped ferrule, rather than to verify the size of the die

opening.

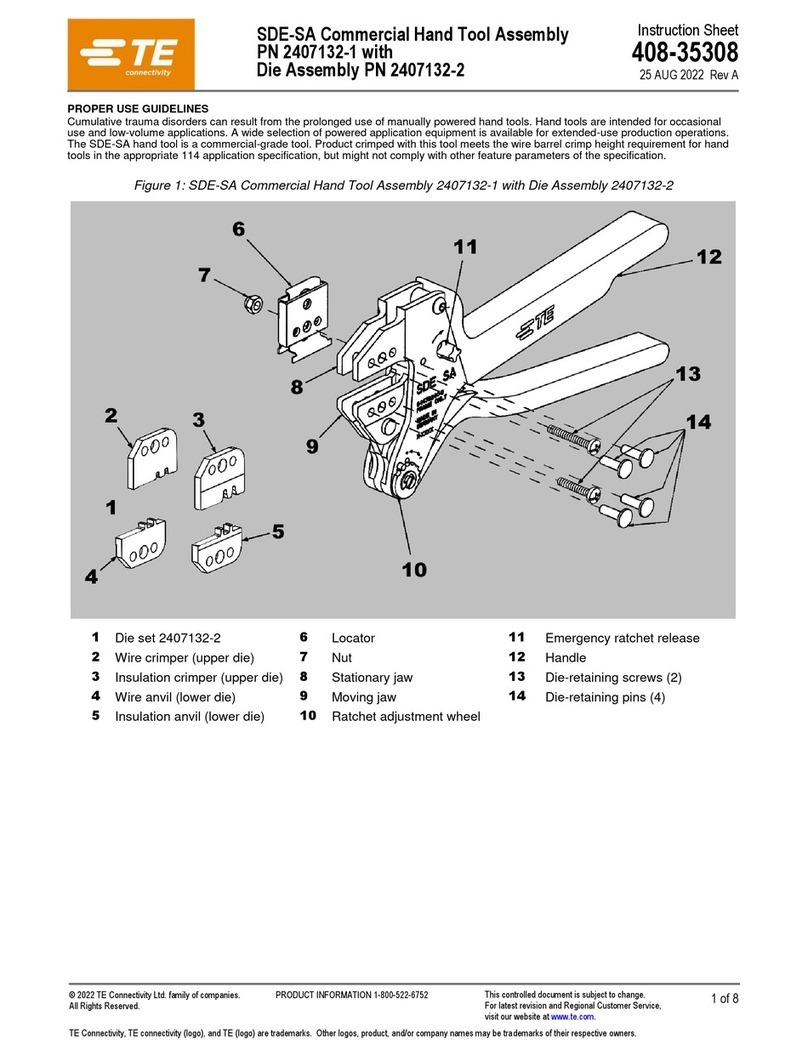

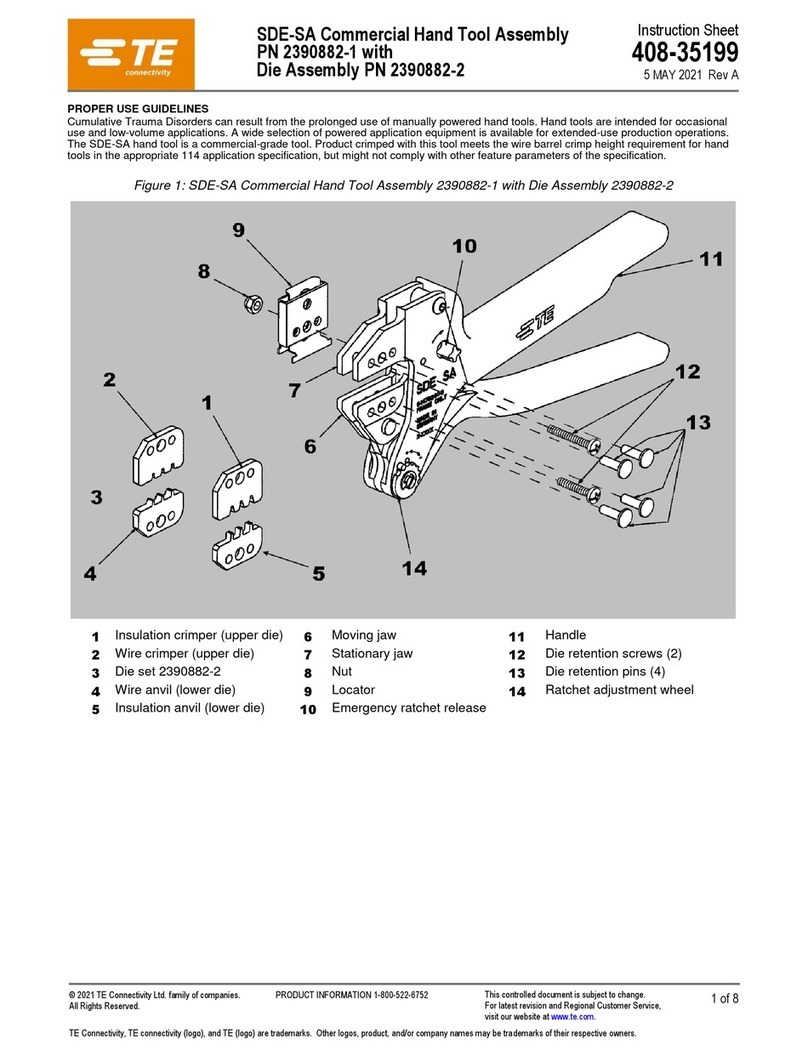

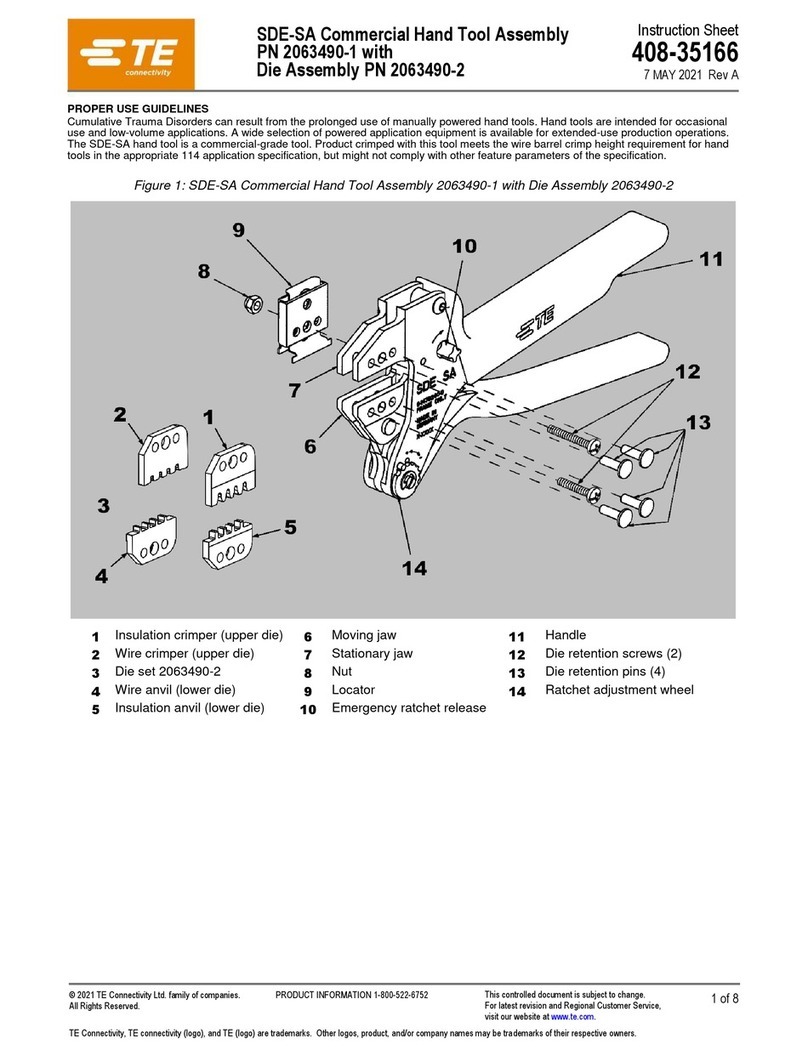

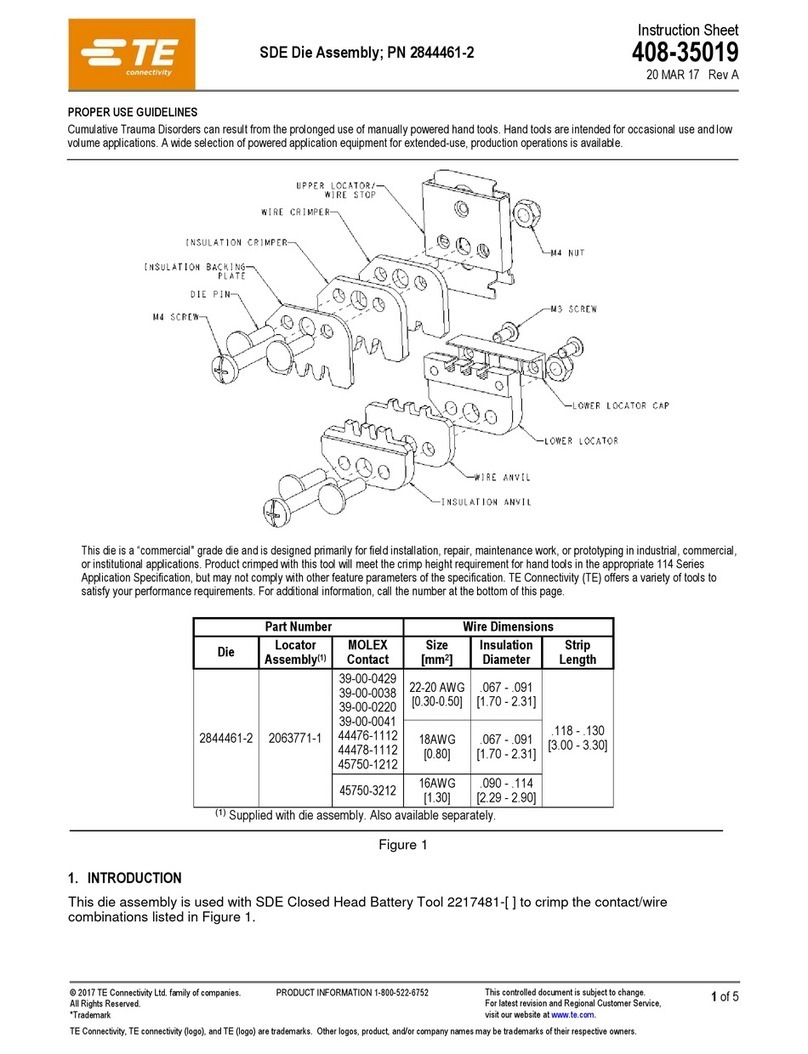

DIE

ASSEMBLY DIE OPENING (mm [in.])

A B C†

58046-1 3.00 ±0.08

[.118 ±.003] 2.39 ±0.10

[.094 ±.004] 0.610 - 0.673

[.0240 - .0265]

† NOTE: Alternate method to check “C” dimension is to crimp a

#20AWGsolidwire,andmeasurethecrimpheight.Onesidemay

be 0.051 [.0020] out of tolerance, as long as the average

measurements of both sides are within the dimension specified.

Figure 5

Crimp height inspection is performed through the

use of a micrometer with a modified anvil,

commonly referred to as a crimp height comparator.

TE does not market crimp height comparators.

Refer to Instruction Sheet 408-7424 for detailed

information on obtaining and using a crimp height

comparator.

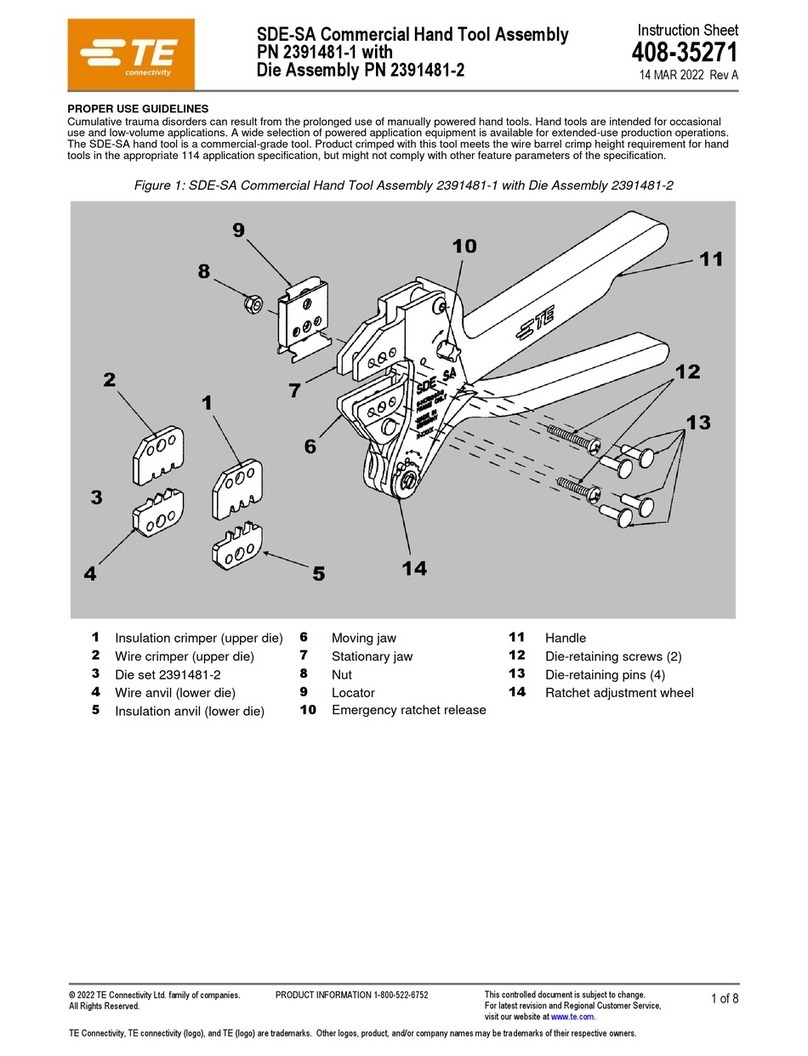

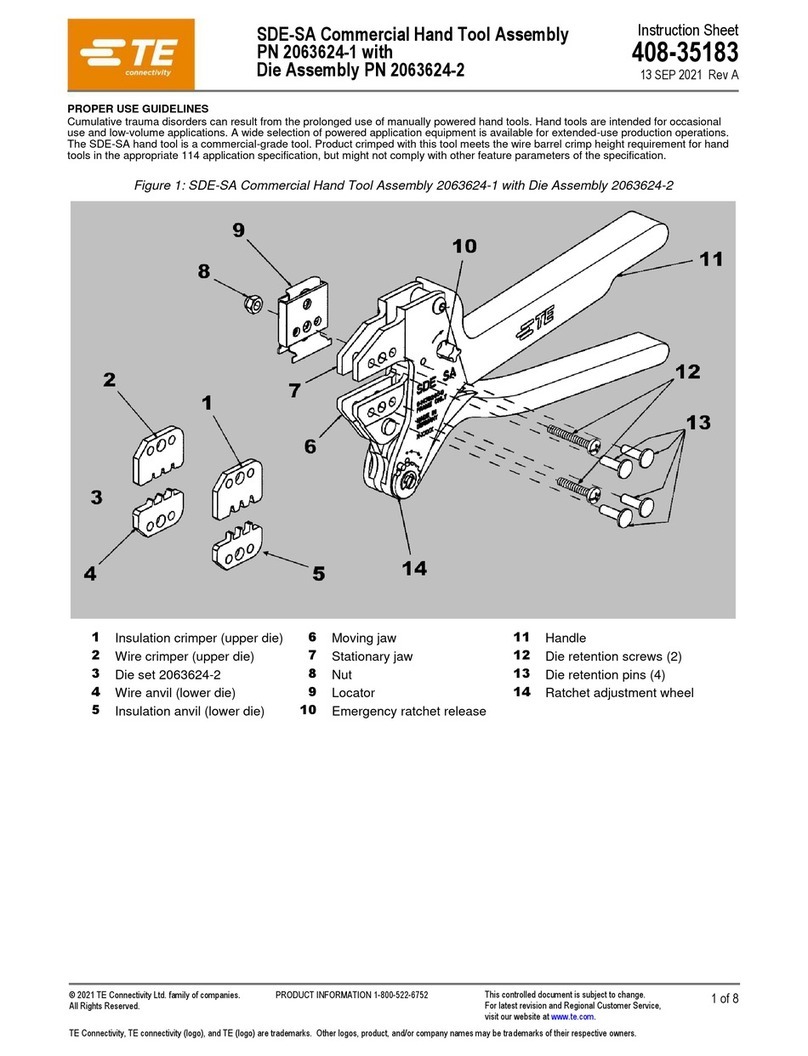

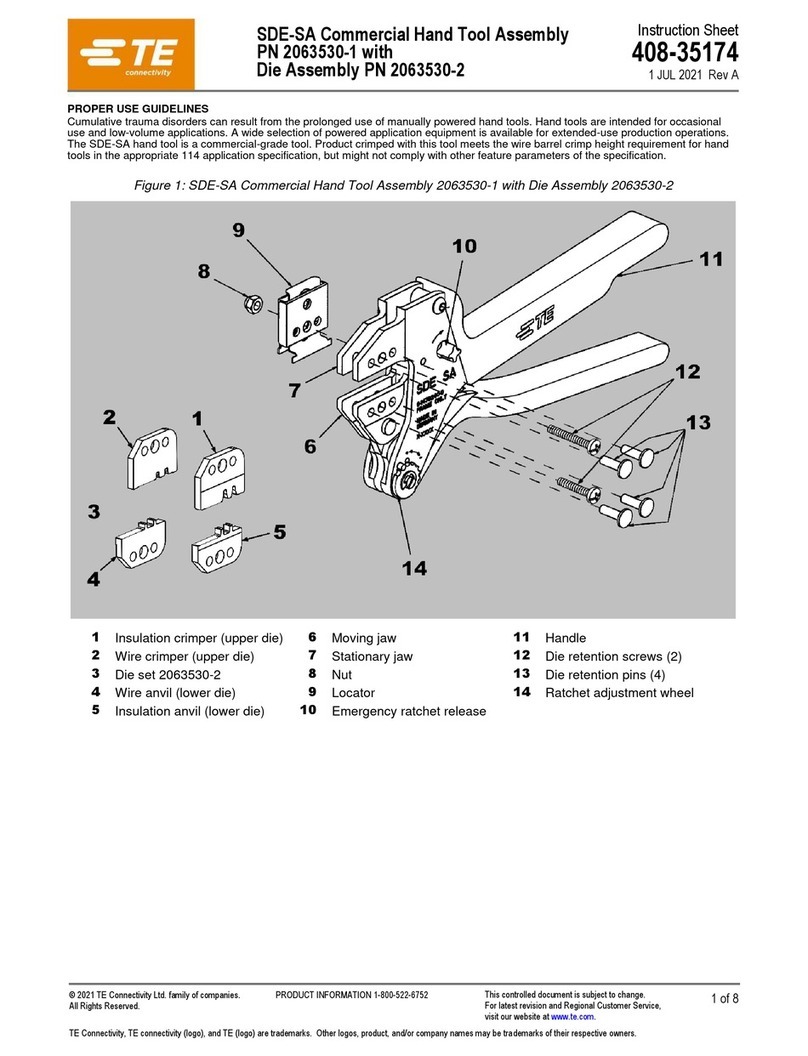

5.4. Ratchet Adjustment (Figure 6)

The tool frame assembly ratchet mechanism features

an adjustment wheel with numbered settings. If the

crimp height is not acceptable, adjust the ratchet as

follows:

1. Remove the lockscrew from the ratchet

adjustment wheel.

2. With a screwdriver, adjust the ratchet wheel from

the opposite side of the tool.

3. Observe the ratchet adjustment wheel. If a tighter

crimp is required, rotate the adjustment wheel

COUNTERCLOCKWISE to a higher-numbered

setting. If a looser crimp is required, rotate the

adjustment wheel CLOCKWISE to a lower-

numbered setting.

4. Replace the lockscrew.

5. Make a sample crimp and measure the crimp

height. If the crimp height is acceptable, secure the

lockscrew. If the dimension is unacceptable, remove

lockscrew and continue to adjust the ratchet, and

again measure a sample crimp