408-7587

3of 4

Rev A

3. Actuate the machine a complete cycle. Check to

be sure the contact is properly crimped. The wire

must be visible through the inspection hole of the

contact.

4. INSPECTION

4.1. Daily Maintenance

The importance of daily maintenance cannot be over

emphasized, as this can easily and efficiently be

performed after each shift, ensuring satisfactory

performance and continuous production. TE

Connectivity recommends the following:

1. Remove dust, moisture, and other contaminants

with a clean brush or soft lint-free cloth. Do NOT

use objects that could damage the dies. If foreign

matter cannot be removed easily, or if the proper

replacement parts are not available, return the dies

to your supervisor.

2. Make sure the proper die holding screws are in

place and secured with the proper retaining rings.

3. Check die alignment and tighten die holding

screws at least twice daily. Make sure the dies are

protected with a THIN coat of any good S.A.E.

No. 20 motor oil. DO NOT OIL EXCESSIVELY.

4. When the dies are not in use, store them in a

clean, dry area.

4.2. Periodic Inspection

Regular inspections should be performed and

recorded by your Quality Control Department with a

record of scheduled inspections remaining with the

dies or supplied to supervisory personnel responsible

for the dies. TE recommends at least one inspection a

month, however, frequency of inspection will depend

on the amount of use, ambient working conditions,

operator training and skill, and your own established

standards. These inspections should be performed in

the following sequence.

A. Visual Inspection

1. Remove all lubrication and accumulated film by

immersing the dies in a suitable commercial de-

greaser that will not effect paint or plastic material.

2. Make sure all holding screws, retaining rings, and

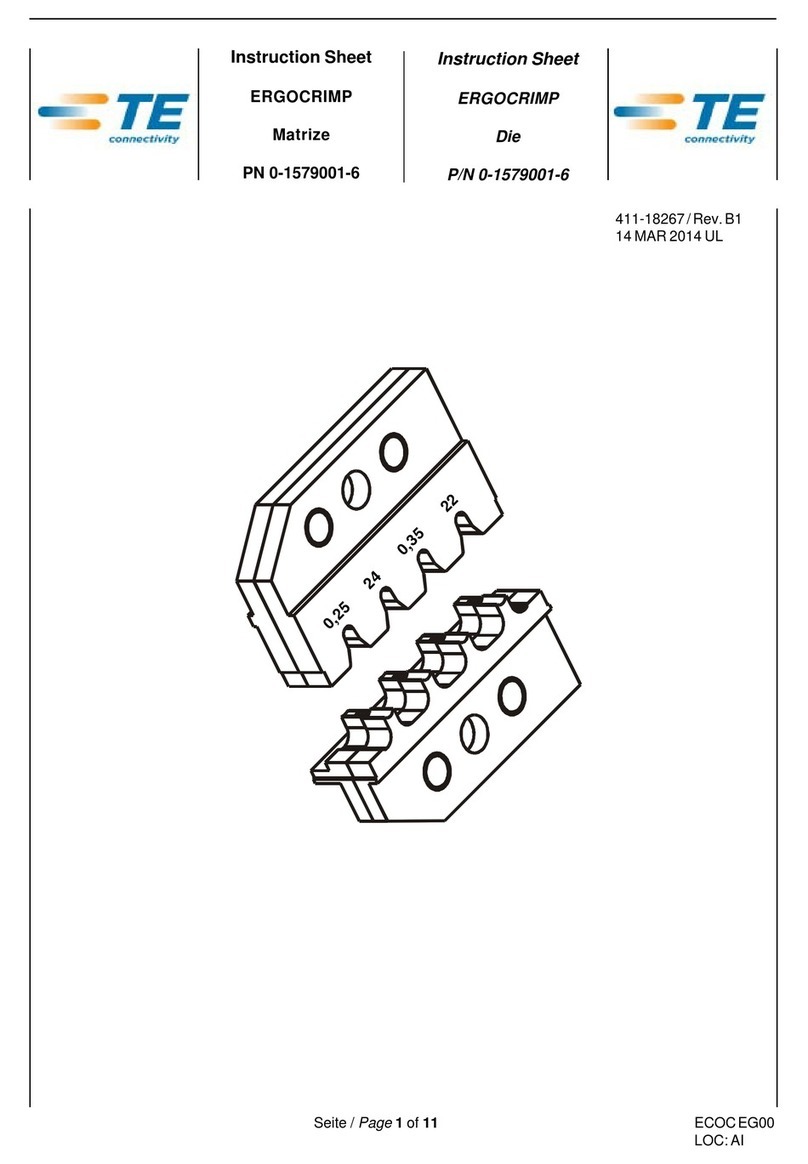

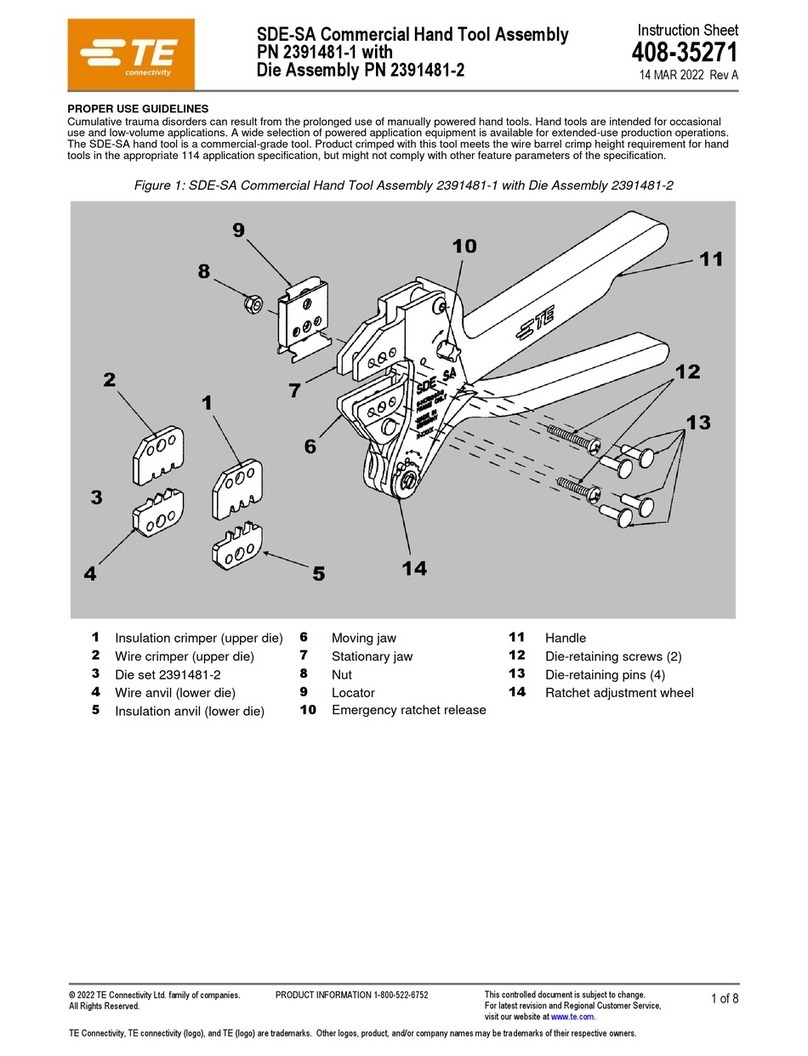

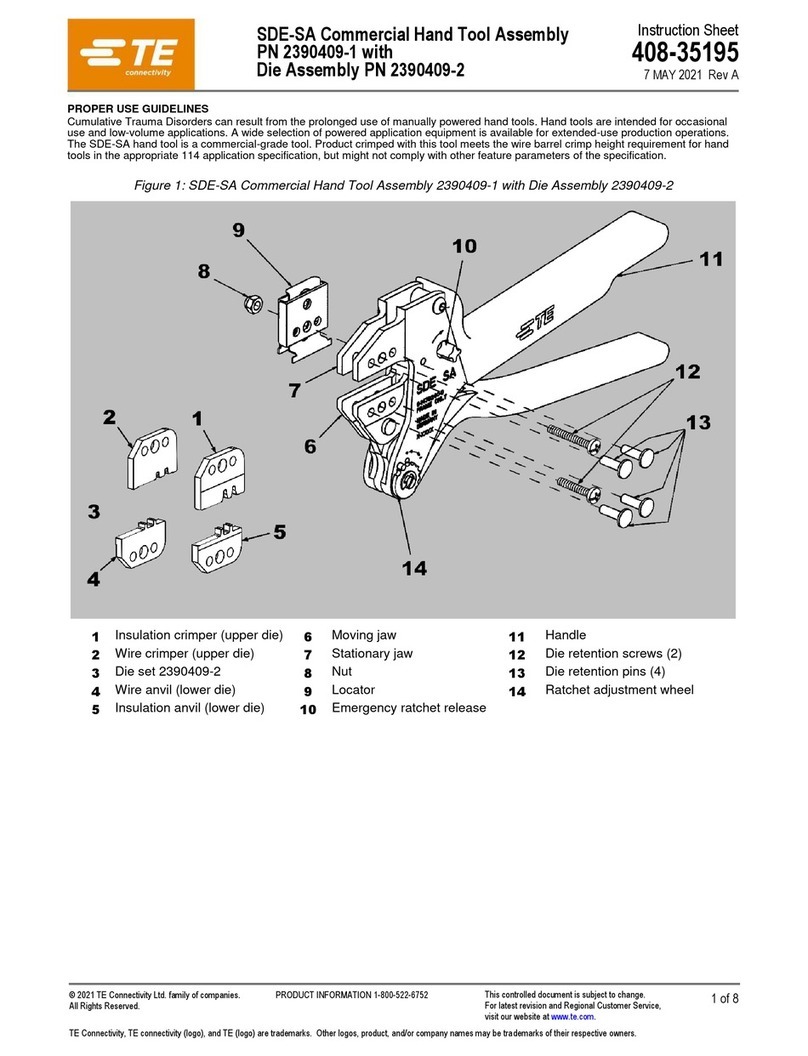

die components are in place. Refer to the parts

listed in Figure 4 if replacements are necessary.

3. Check all bearing surfaces for wear. Remove and

replace worn components.

4. Inspect the crimp area for flattened, chipped,

cracked, worn, or broken areas. Make sure the

holding screws and the depressions on the

stationary die are properly color-coded. Refer to

Section 2, DESCRIPTION. If damage is evident, the

dies must be repaired before returning to service.

Refer to Section 5, REPAIR AND REPLACEMENT.

B. Mechanical Inspection

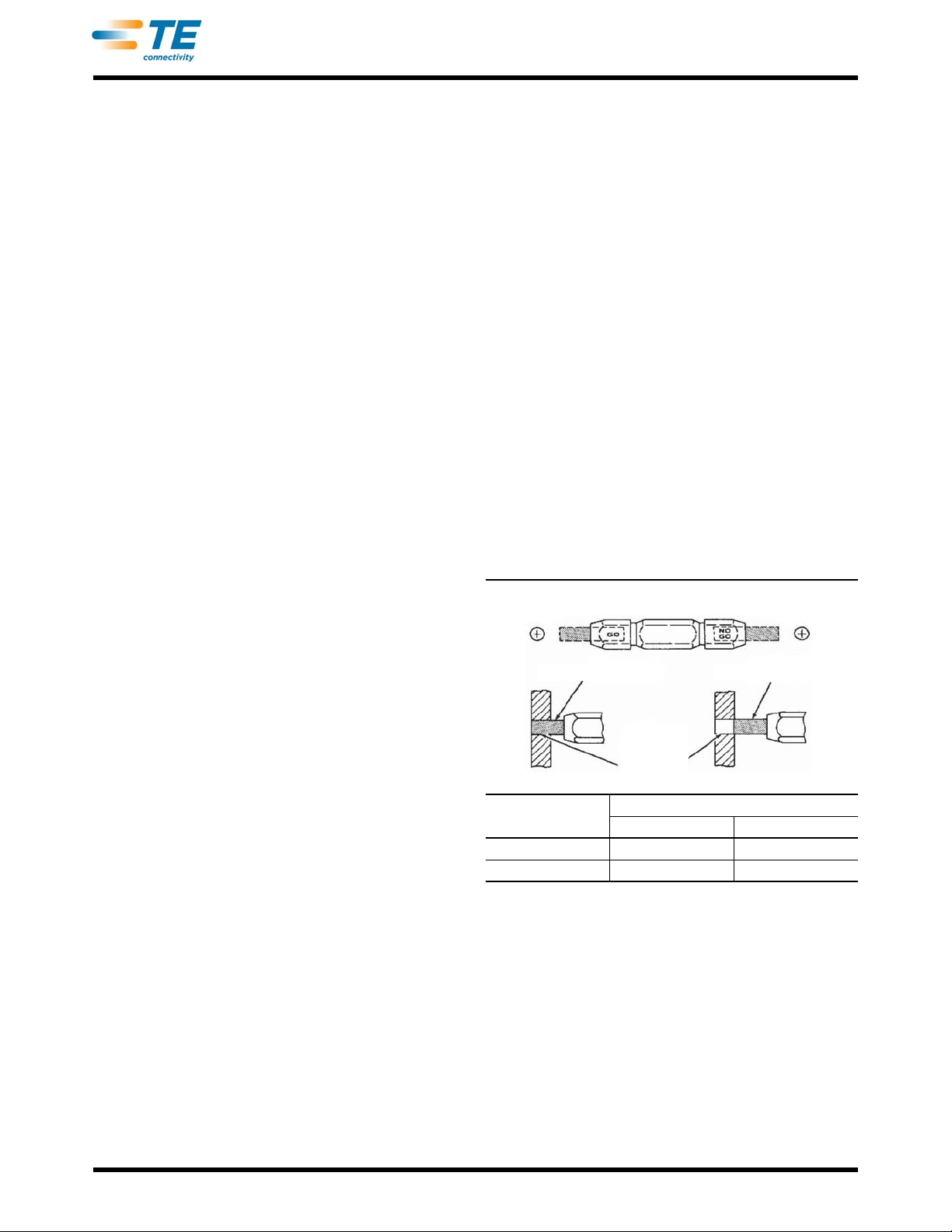

This inspection utilizes a GO / NO-GO gage

conforming to the dimensions in Figure 3. TE does not

manufacture or market these gages. Refer to

Instruction Sheet 408-7424.

Proceed as follows:

1. Mate the dies until it is evident that they have

bottomed. Hold the dies in this position with

approximately 69 kPa [10 psi].

2. Align the GO element with the wire barrel

crimping area and push it straight into the crimping

chamber without using force. The GO element must

pass completely through the crimping chamber as

shown in Figure 3.

3. Now align the NO-GO element and try to insert it

straight into the same crimping chamber. The

NO-GO element may start entry but must not pass

completely through as shown in Figure 3.

If the crimping chambers conform to the gage

inspection, the dies are considered dimensionally

correct and should be lubricated with a THIN coat of

oil. If not, the dies must be repaired before returning

them to service. Refer to Section 5, REPAIR AND

REPLACEMENT.

Figure 3

5. REPAIR AND REPLACEMENT

The parts listed in Figure 4 are customer replaceable

parts. A complete inventory can be stocked and

controlled to prevent lost time when replacement of

parts is necessary. The dies can also be returned to

TE for evaluation and repair. Send the dies and a

written description of the problem to:

CUSTOMER SERVICE (038-035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105-3608

CRIMPING DIE

NUMBER GAGE DIMENSION

GO (DIA) NO-TO (DIA)

90080-2 1.54 [.0605] 1.613 [.0635]

90103 1.003 [.0395] 1.080 [.0425]

Suggested Plug Gage Design

End View End View

GO Element NO-GO Element

WireBarrel

Crimping

Chamber