TE Connectivity 58425 Series User manual

Other TE Connectivity Crimping Tools manuals

TE Connectivity

TE Connectivity AT-65 User manual

TE Connectivity

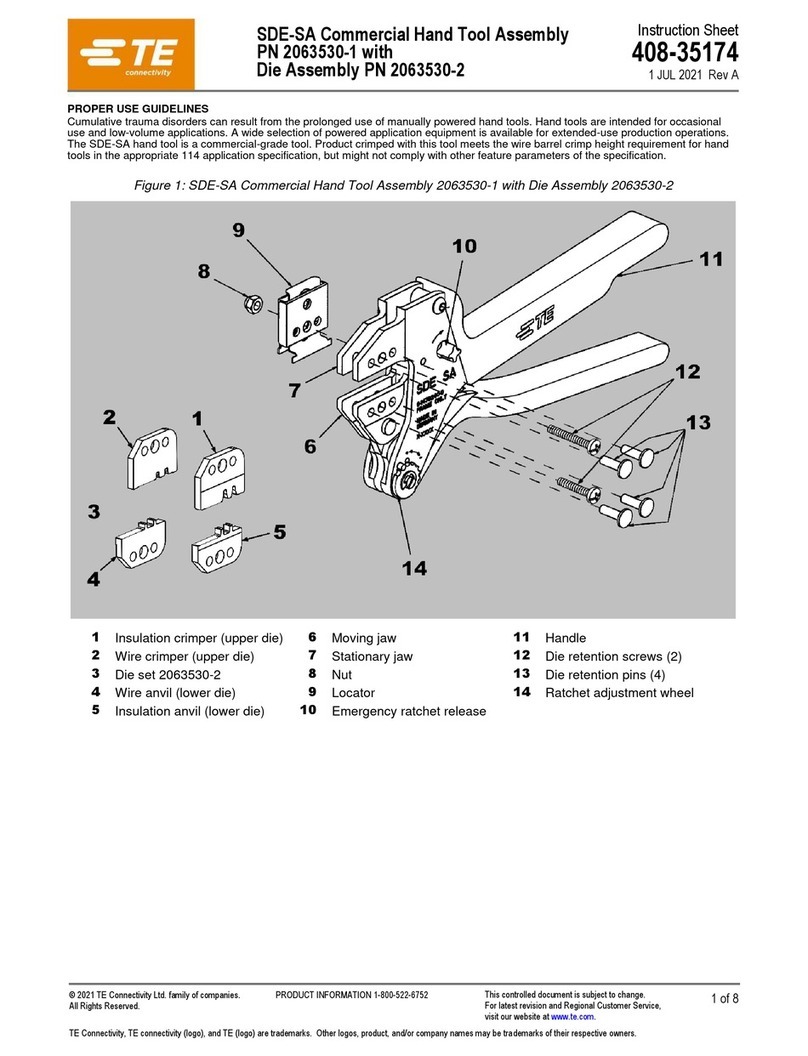

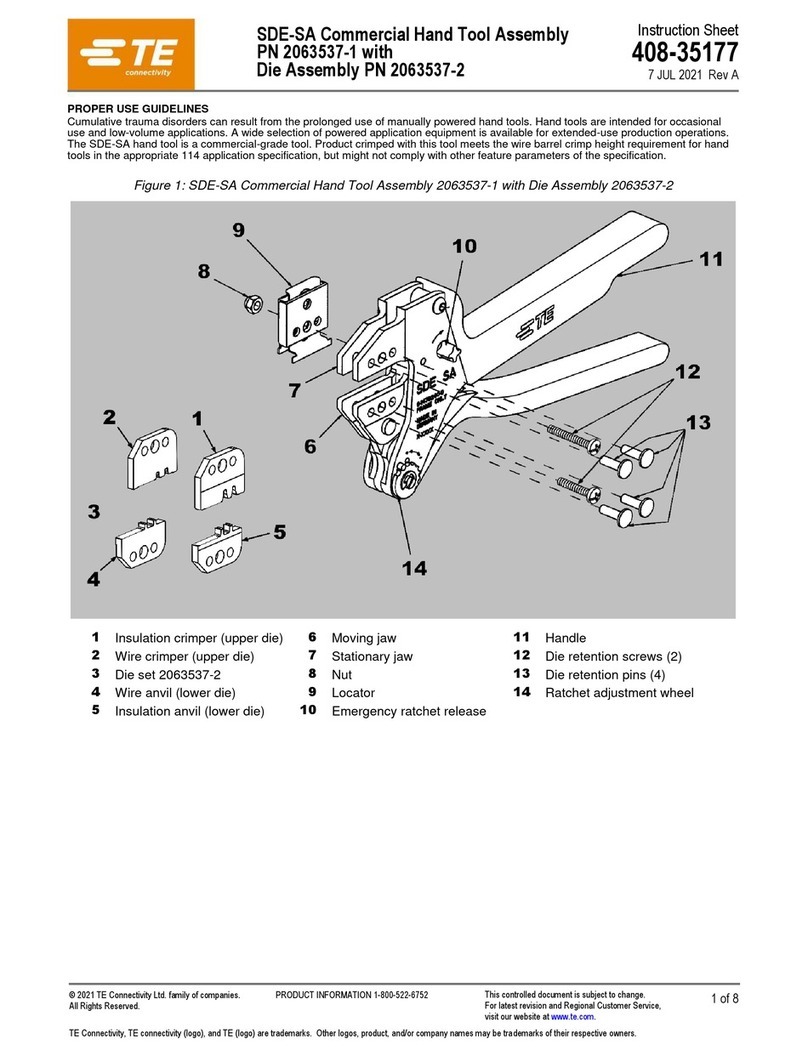

TE Connectivity SDE-SA User manual

TE Connectivity

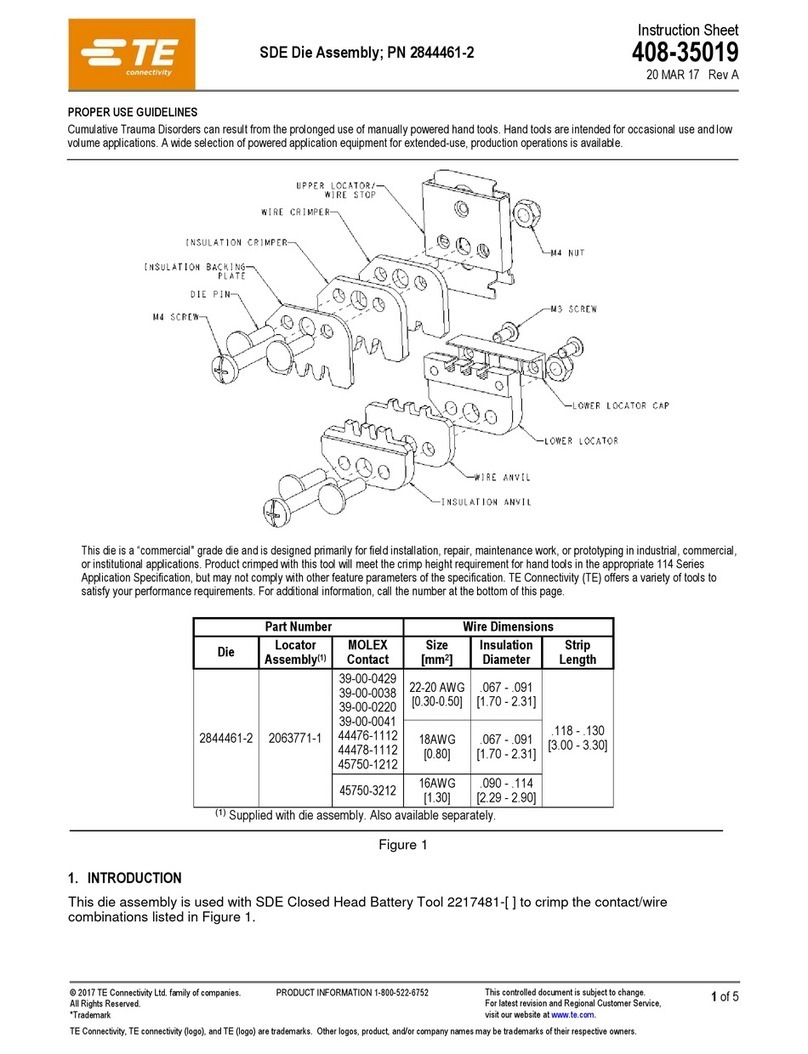

TE Connectivity 2844461-2 User manual

TE Connectivity

TE Connectivity 2378809-1 User manual

TE Connectivity

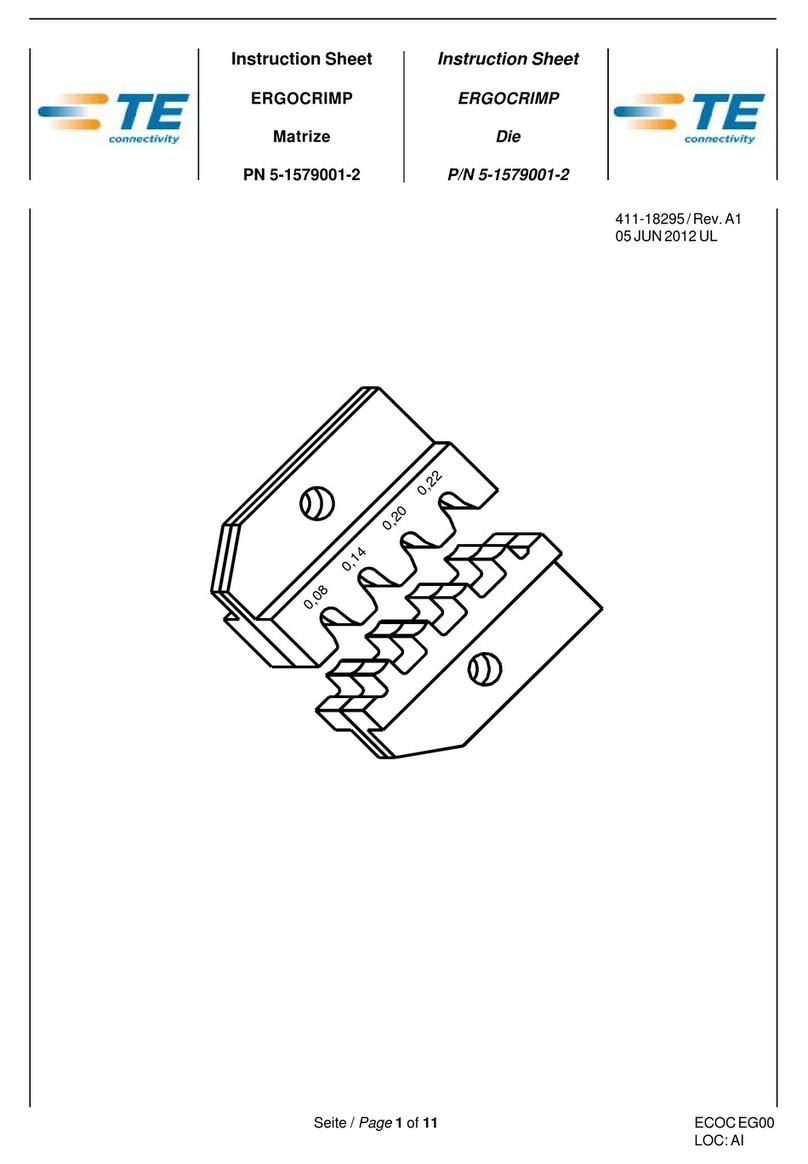

TE Connectivity ERGOCRIMP 5-1579001-2 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

TE Connectivity CERTI- CRIMP Series User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III 58521-1 User manual

TE Connectivity

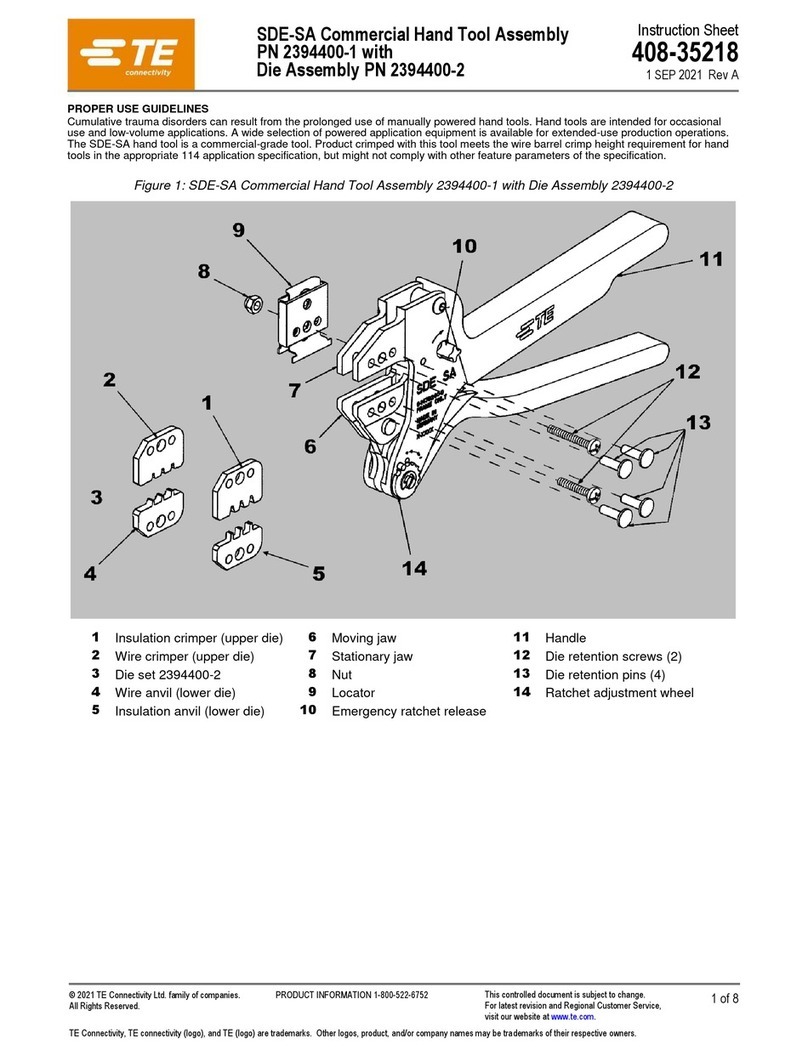

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity PRO- CRIMPER III User manual

TE Connectivity

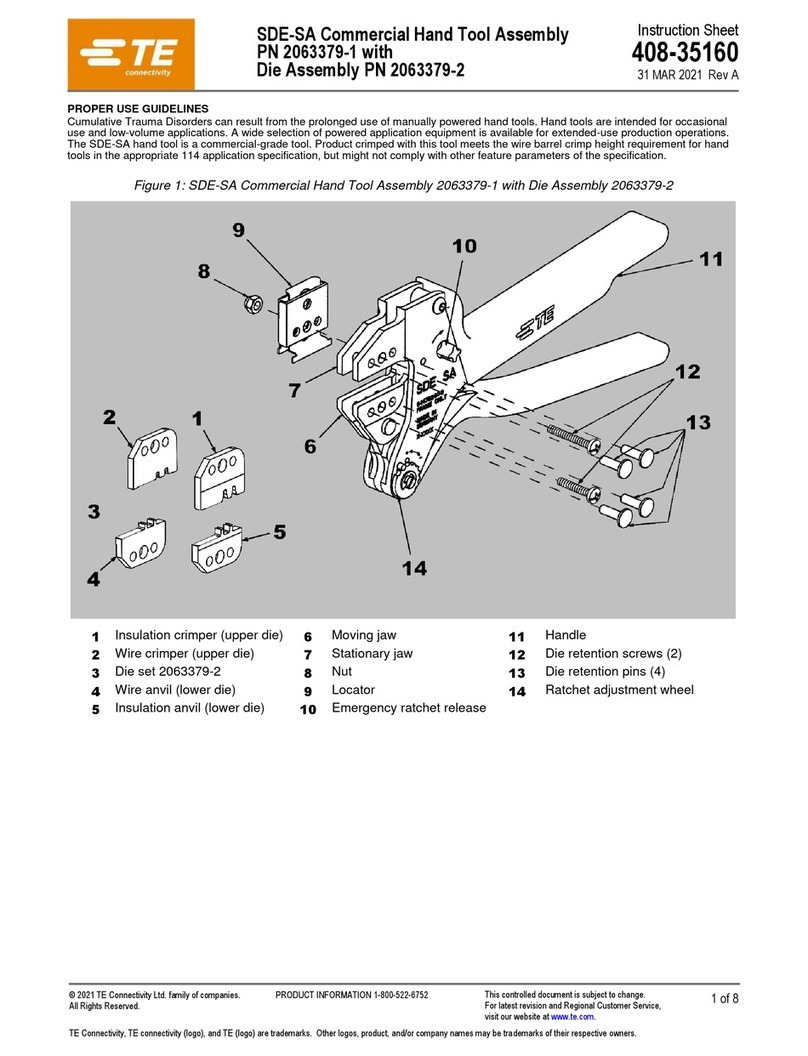

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity 220015 Series User manual

TE Connectivity

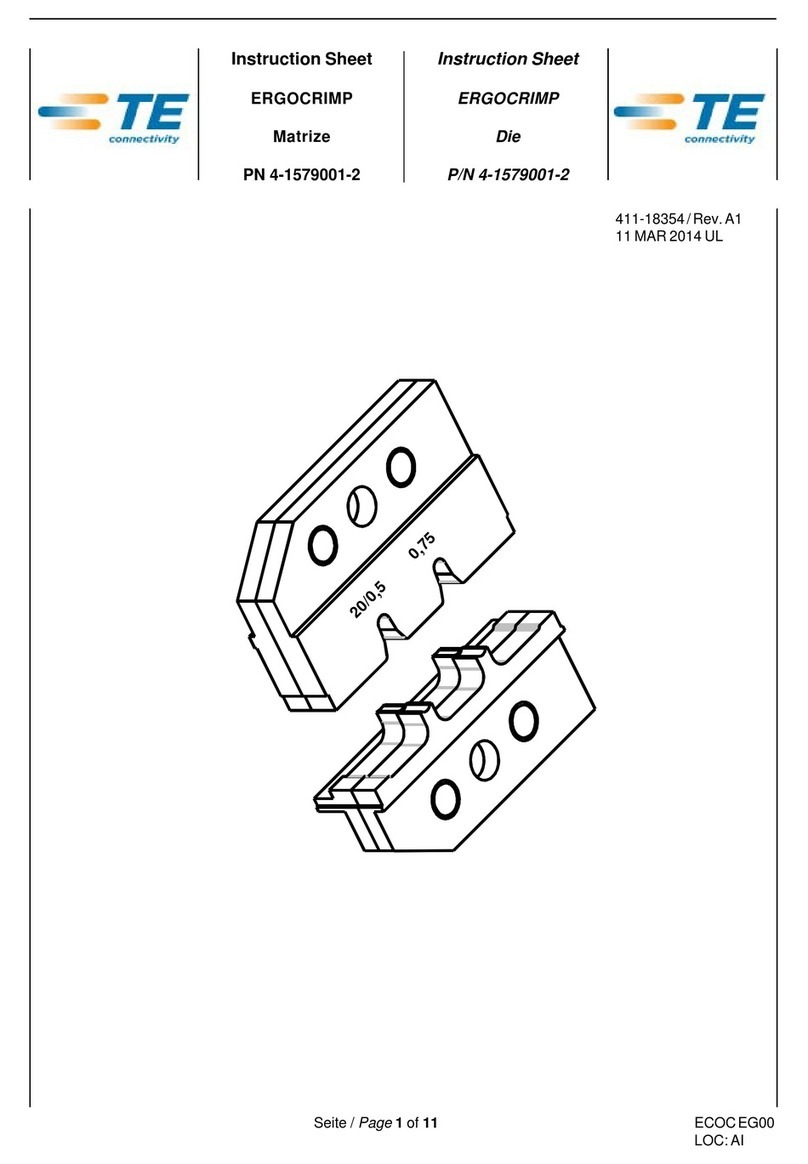

TE Connectivity 4-1579001-2 User manual

TE Connectivity

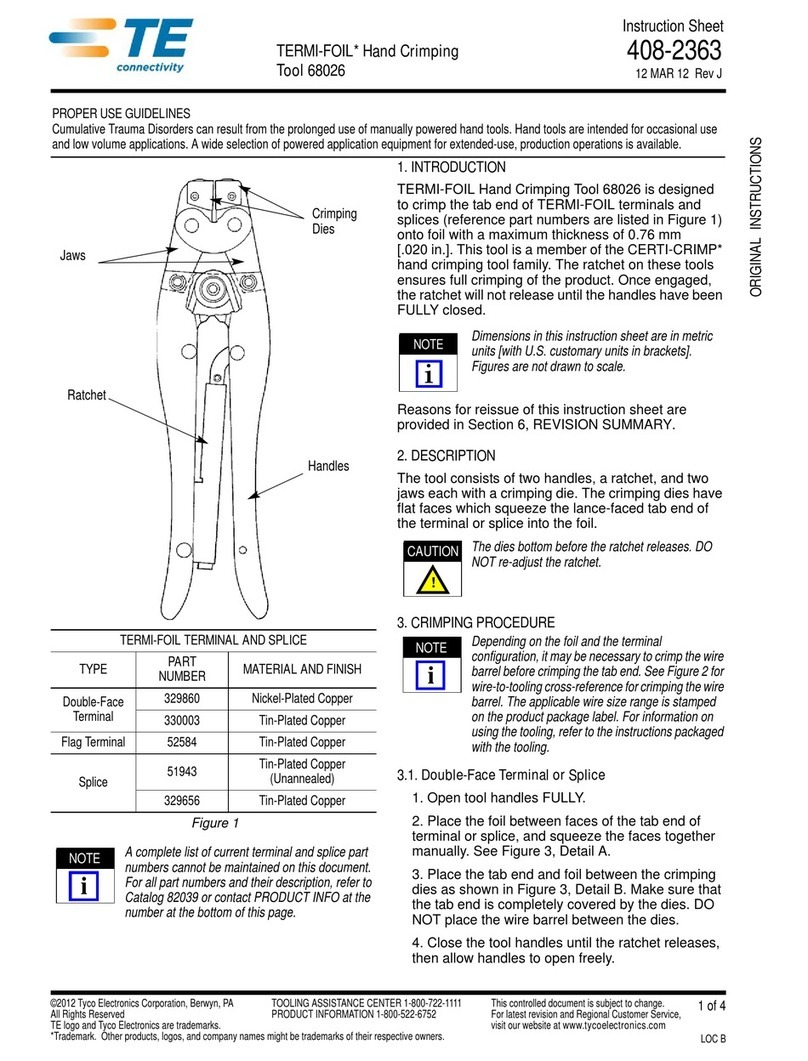

TE Connectivity TERMI-FOIL 68026 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

TE Connectivity SOLISTRAND 69097 User manual

TE Connectivity

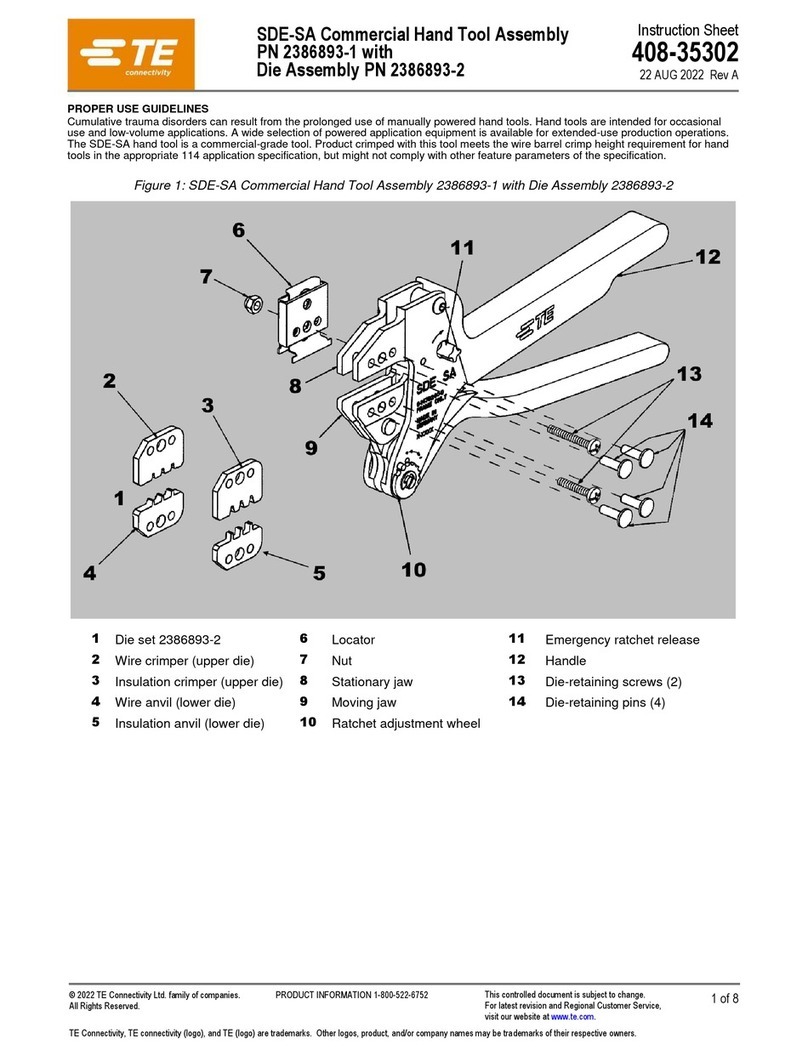

TE Connectivity 2386893-1 User manual

TE Connectivity

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity 539 726-2 User manual

TE Connectivity

TE Connectivity 2063379-1 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

molex

molex 207129 Series Specification sheet

molex

molex 207129 Series Specification sheet