TE Connectivity PRO-CRIMPER III User manual

Other TE Connectivity Crimping Tools manuals

TE Connectivity

TE Connectivity ERGOCRIMP 539 685-2 User manual

TE Connectivity

TE Connectivity 46754-2 User manual

TE Connectivity

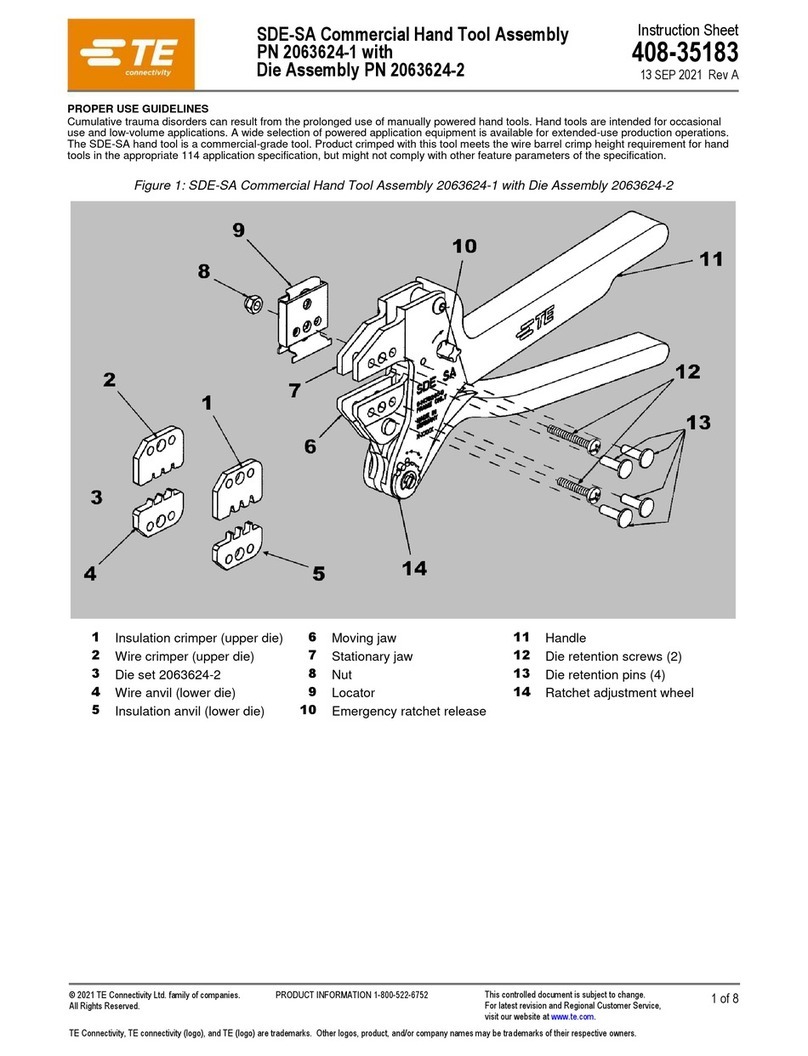

TE Connectivity 2063624-1 User manual

TE Connectivity

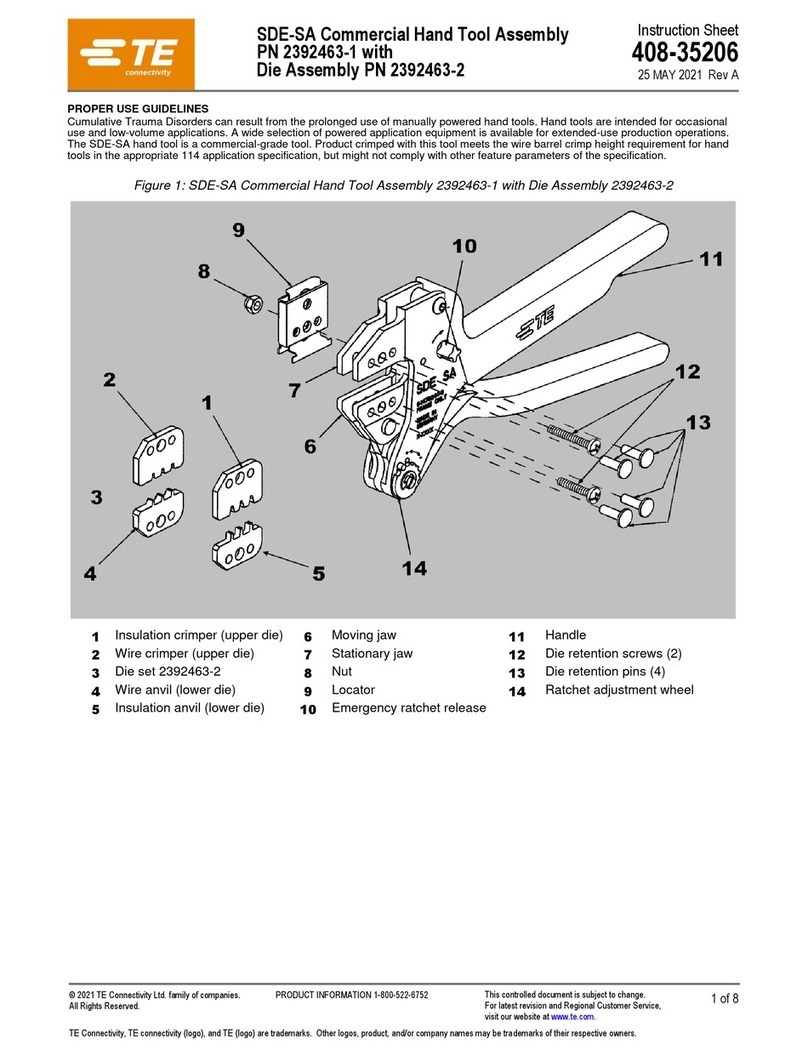

TE Connectivity SDE-SA User manual

TE Connectivity

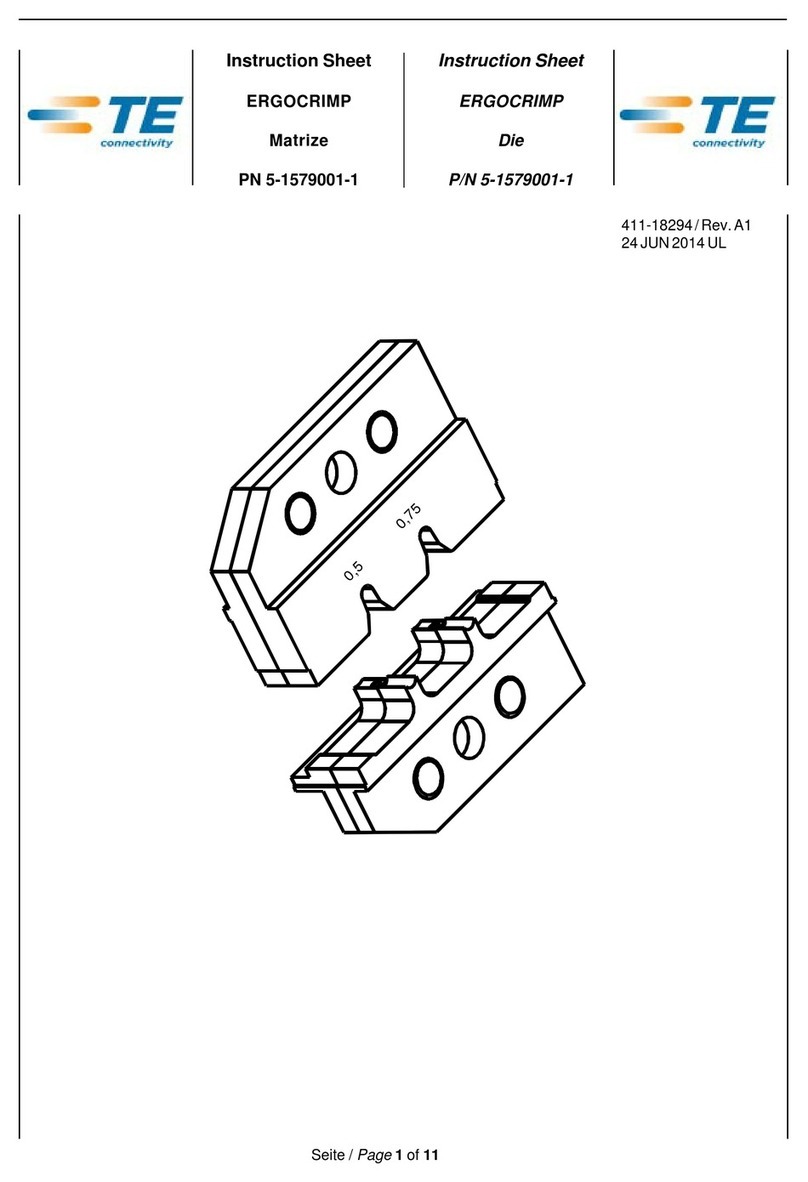

TE Connectivity ERGOCRIMP 5-1579001-1 User manual

TE Connectivity

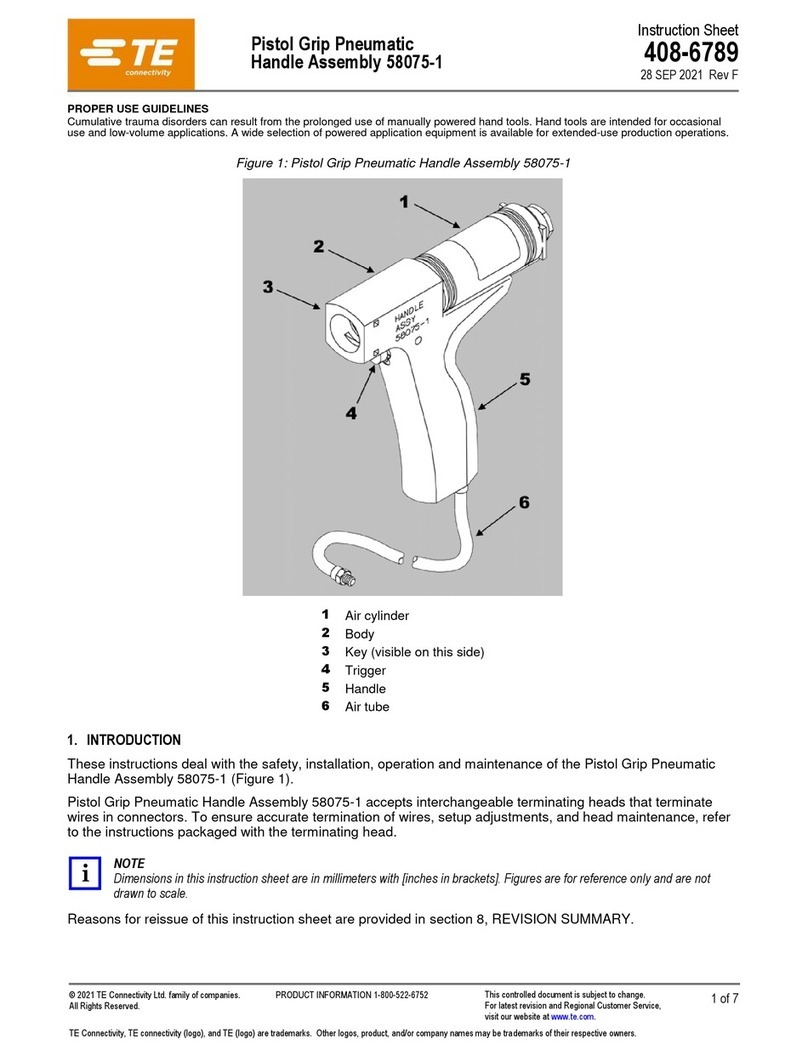

TE Connectivity 58075-1 User manual

TE Connectivity

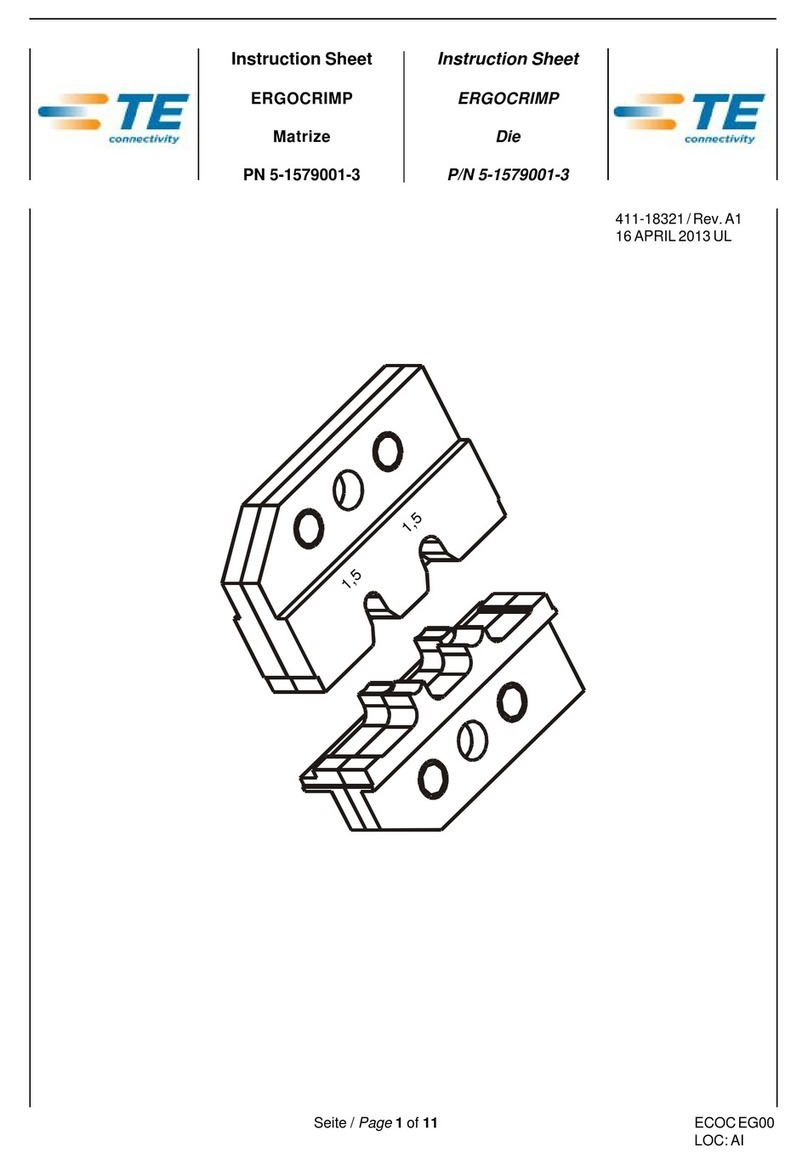

TE Connectivity ERGOCRIMP 5-1579001-3 User manual

TE Connectivity

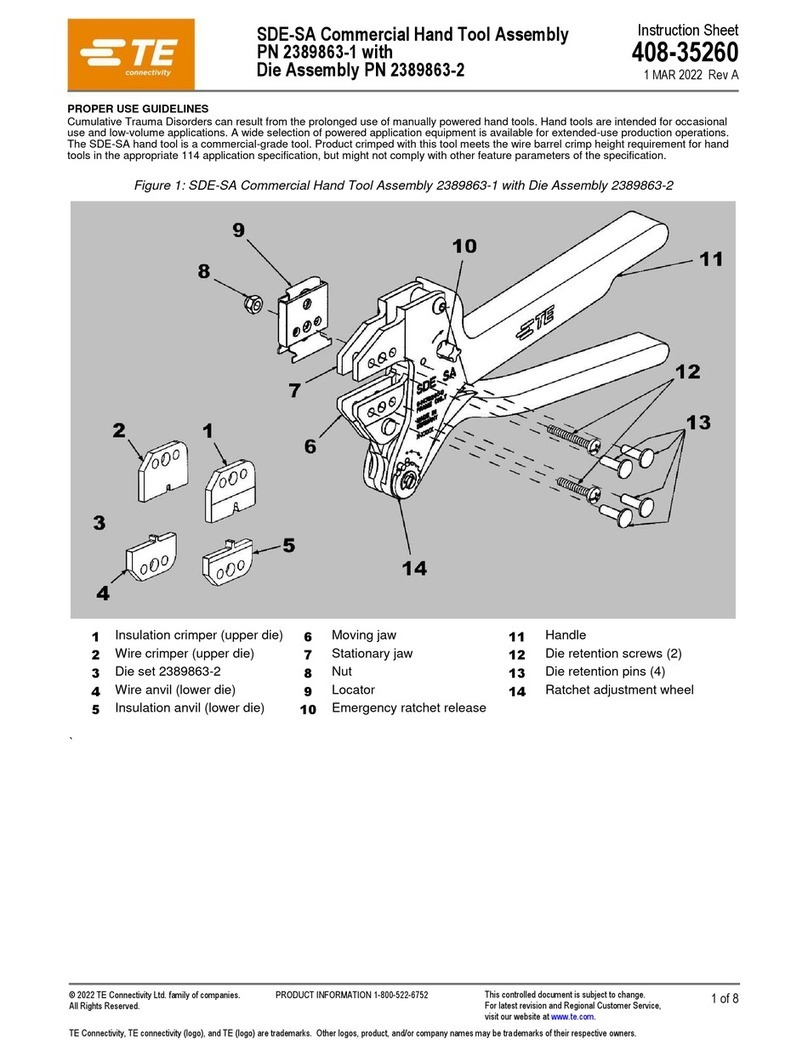

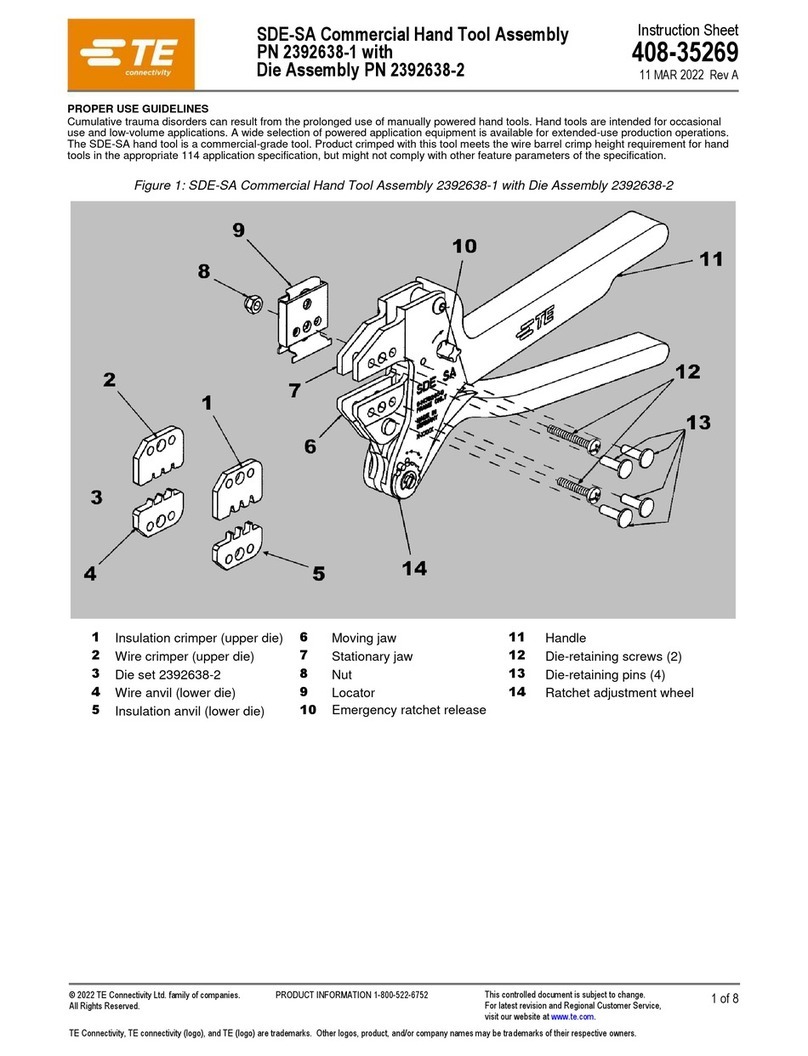

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity CERTI-CRIMP 90066-7 User manual

TE Connectivity

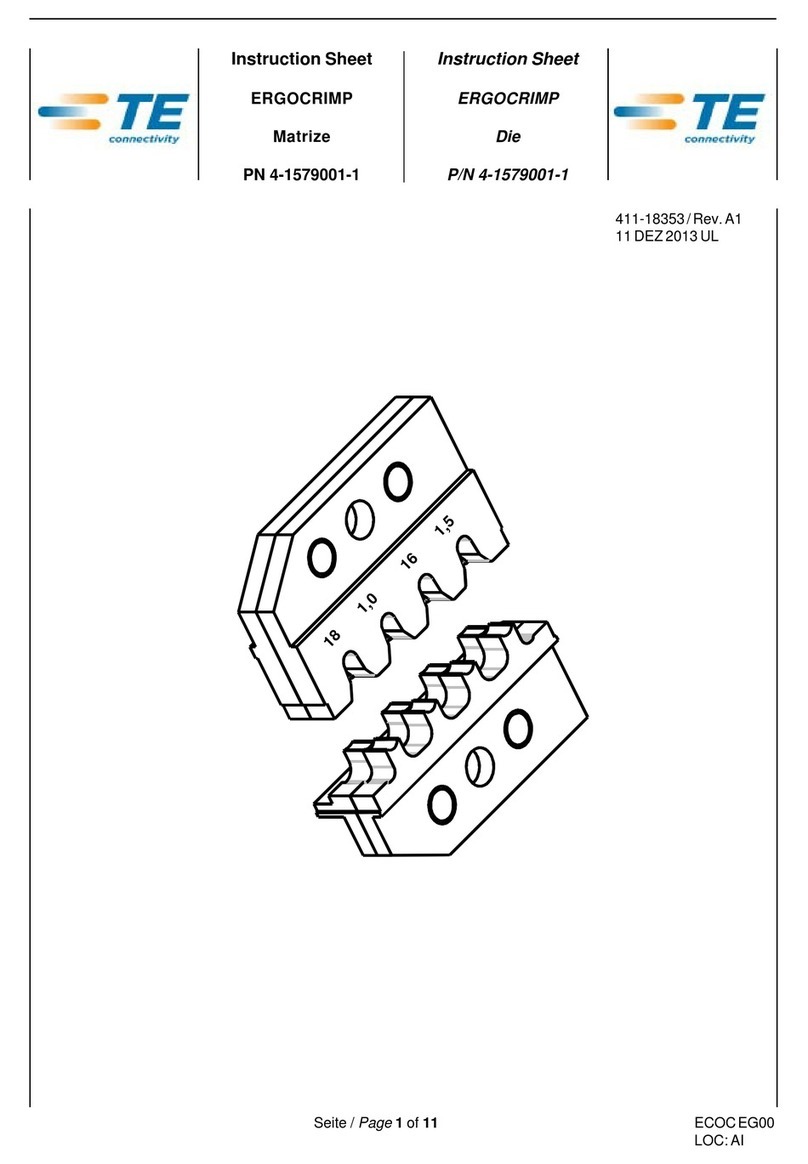

TE Connectivity ERGOCRIMP 4-1579001-1 User manual

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 User manual

TE Connectivity

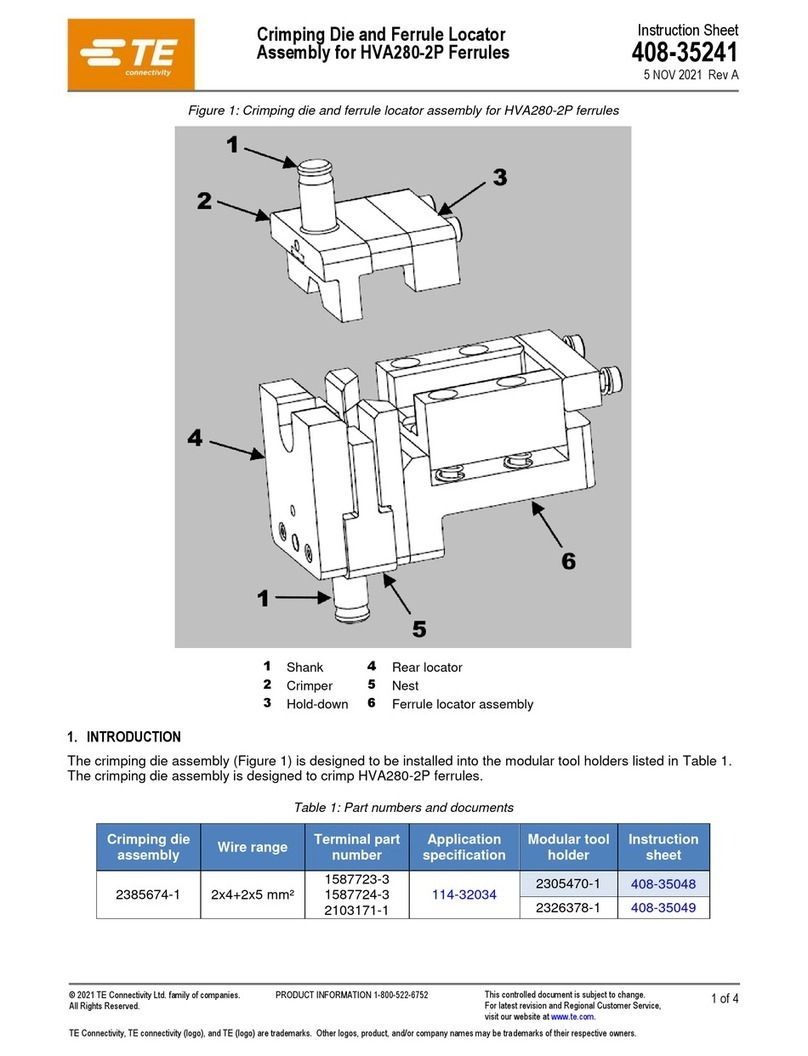

TE Connectivity HVA280-2P User manual

TE Connectivity

TE Connectivity CERTI-CRIMP 90165-1 User manual

TE Connectivity

TE Connectivity SDE-SA User manual

TE Connectivity

TE Connectivity SDE-SA 2379968-1 User manual

TE Connectivity

TE Connectivity 528008-4 User manual

TE Connectivity

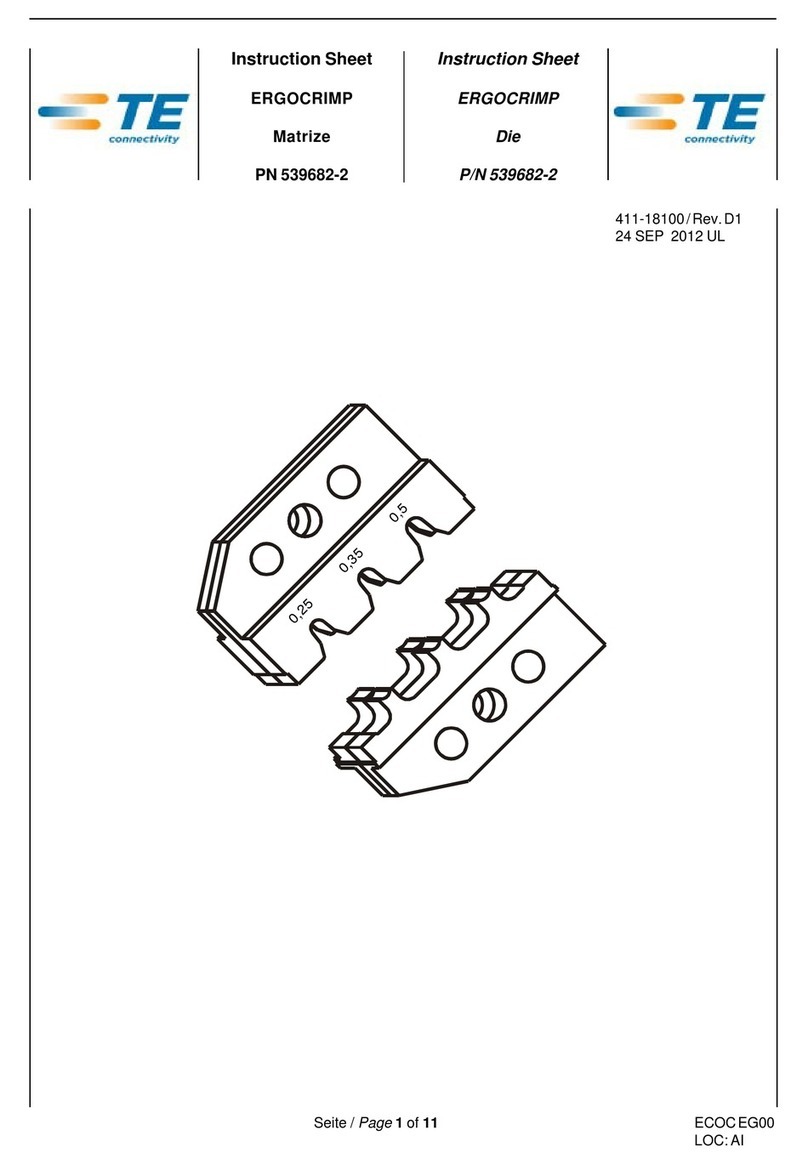

TE Connectivity 539682-2 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

TE Connectivity 58422-1 User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

molex

molex 207129 Series Specification sheet

molex

molex 207129 Series Specification sheet