TE Connectivity 91366- 1 User manual

Other TE Connectivity Crimping Tools manuals

TE Connectivity

TE Connectivity 2386892-1 User manual

TE Connectivity

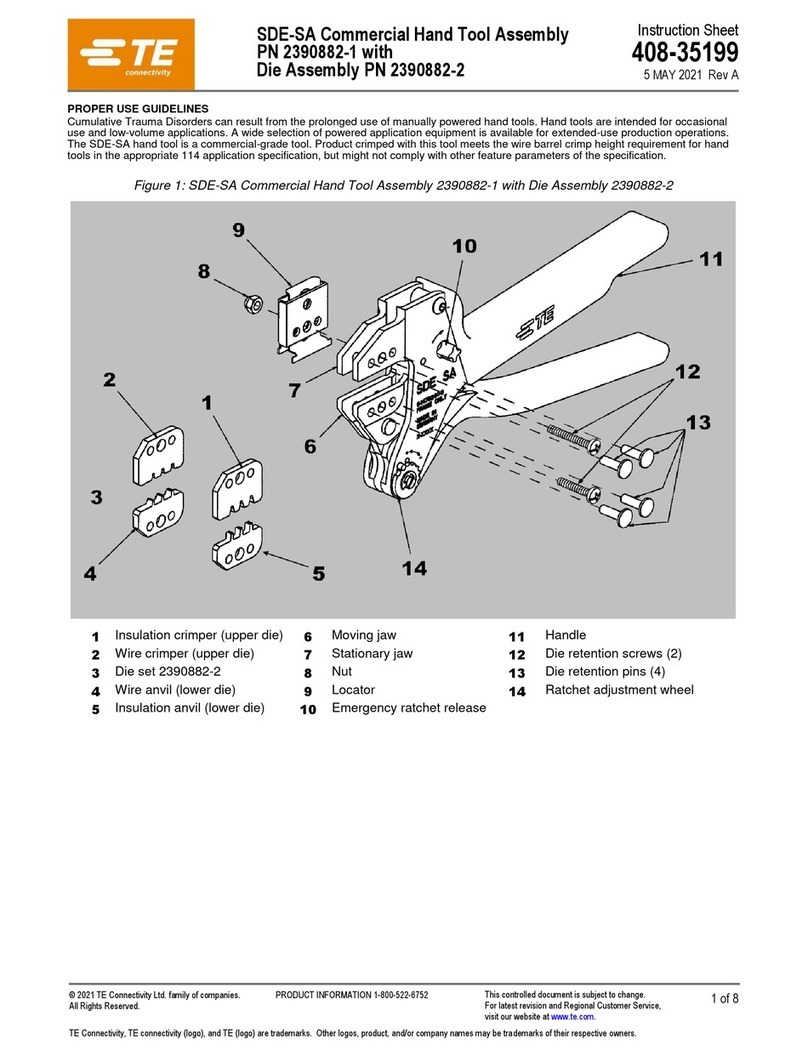

TE Connectivity 2390882-1 User manual

TE Connectivity

TE Connectivity ERGOCRIMP 1-1579001-3 User manual

TE Connectivity

TE Connectivity 2390275-1 User manual

TE Connectivity

TE Connectivity 2844594-1 User manual

TE Connectivity

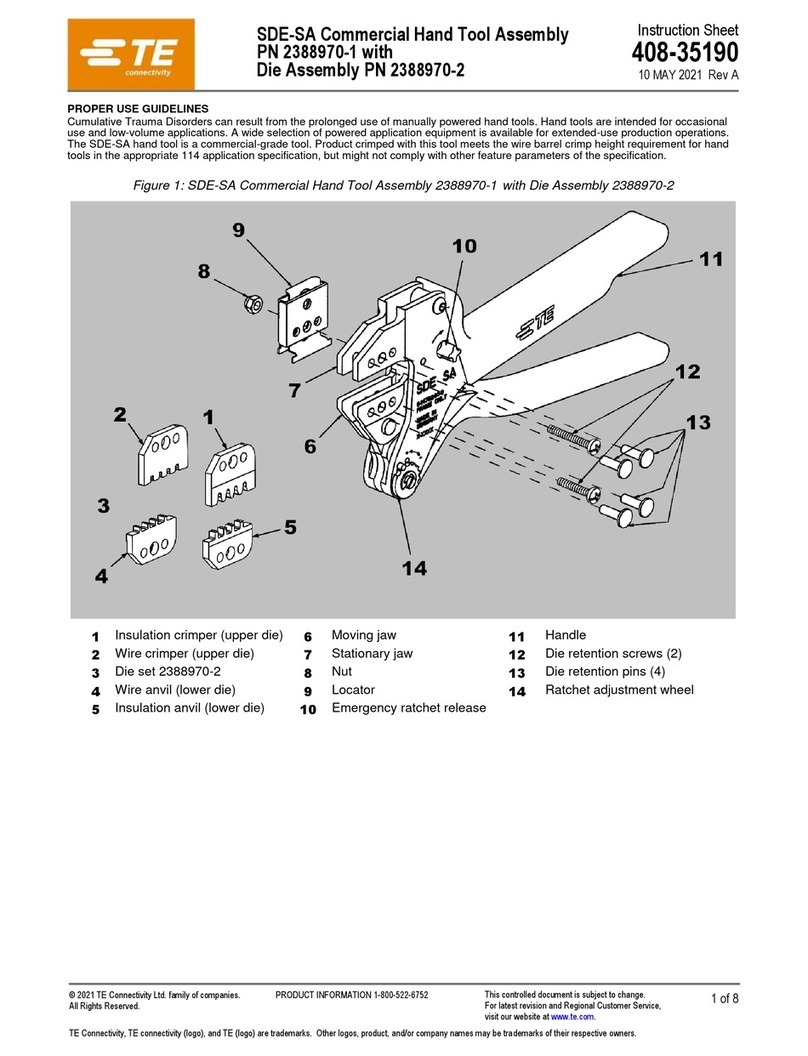

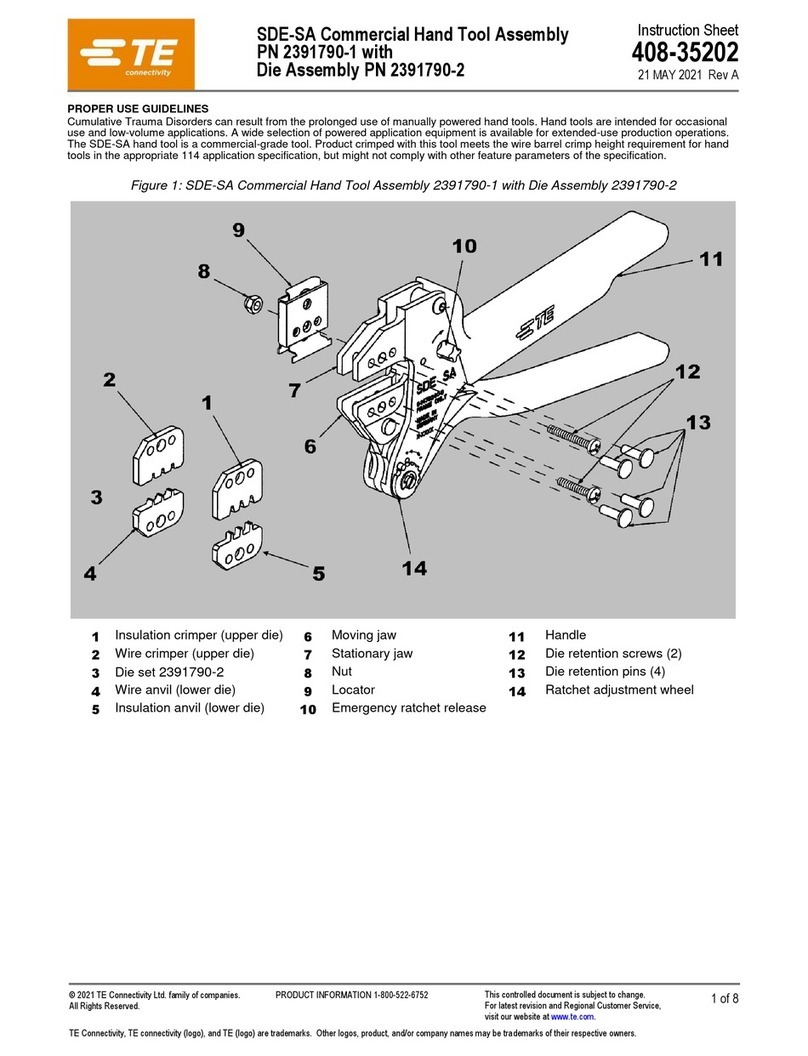

TE Connectivity SDE-SA 2391790-1 User manual

TE Connectivity

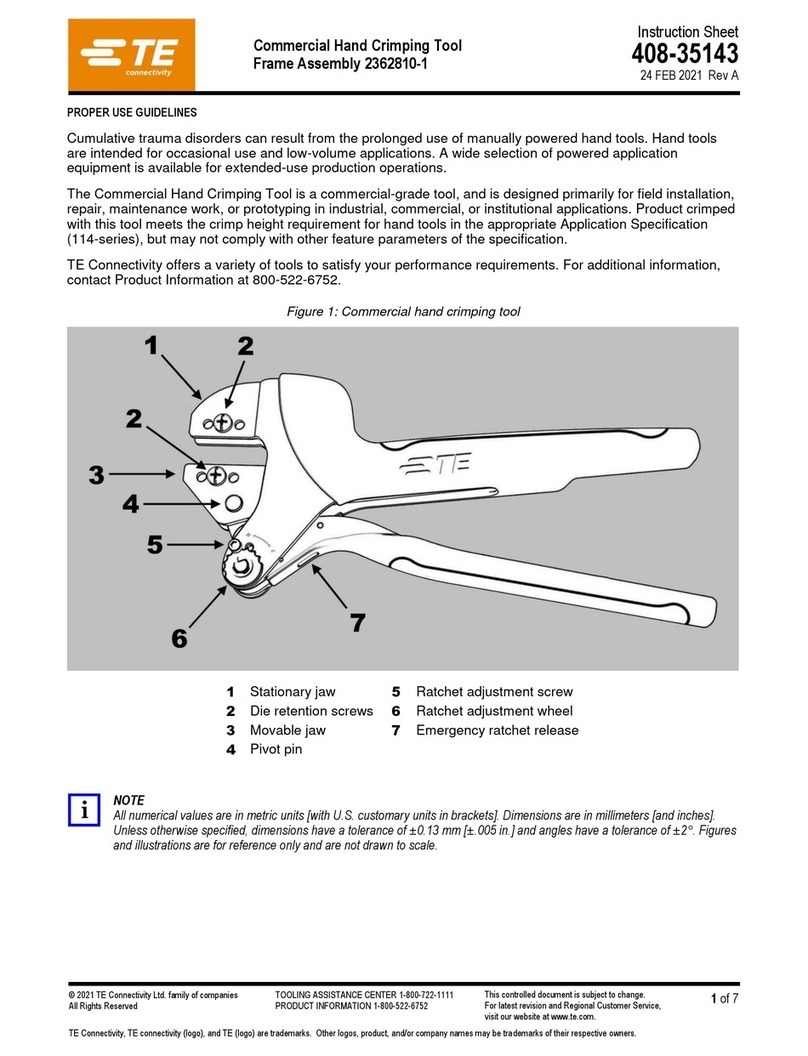

TE Connectivity 2362810-1 User manual

TE Connectivity

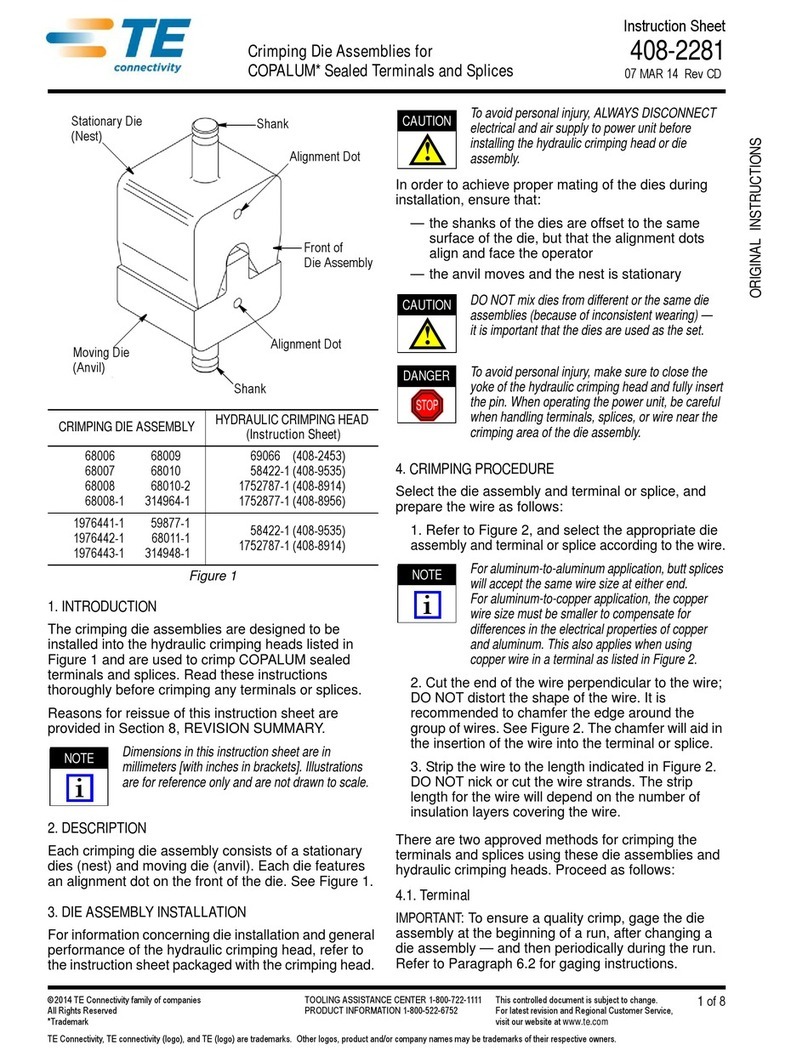

TE Connectivity COPALUM 408-2281 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

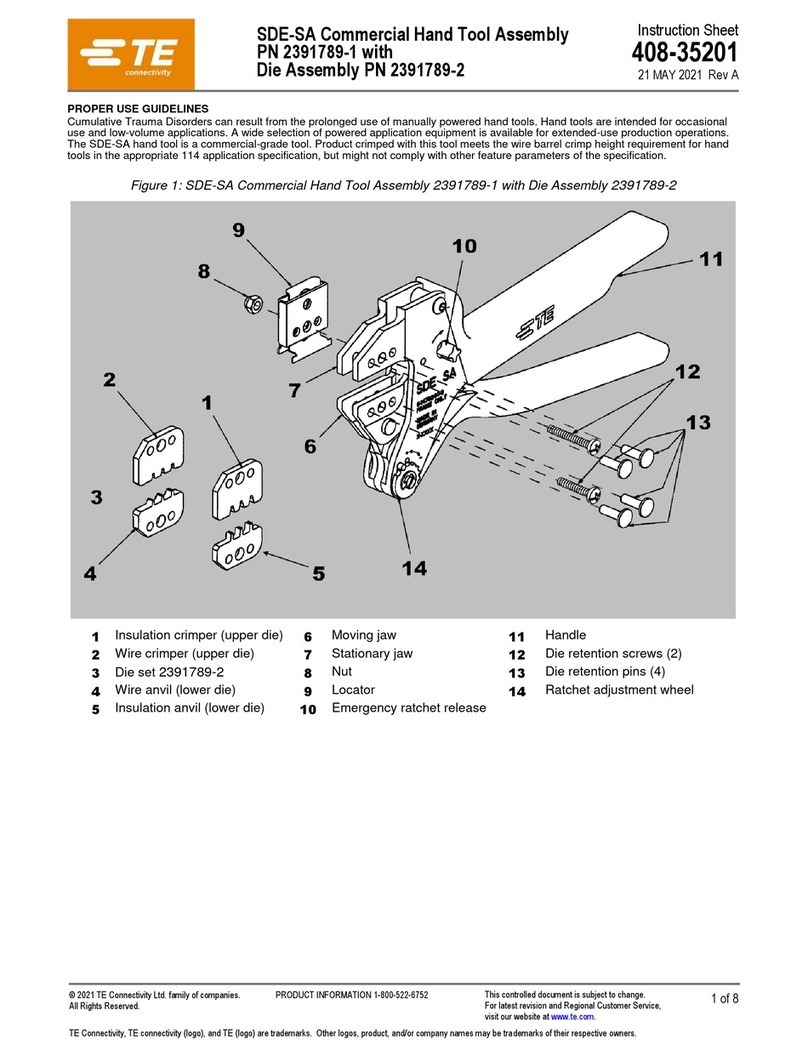

TE Connectivity 2391789-1 User manual

TE Connectivity

TE Connectivity 2392637-1 User manual

TE Connectivity

TE Connectivity 528050-3 User manual

TE Connectivity

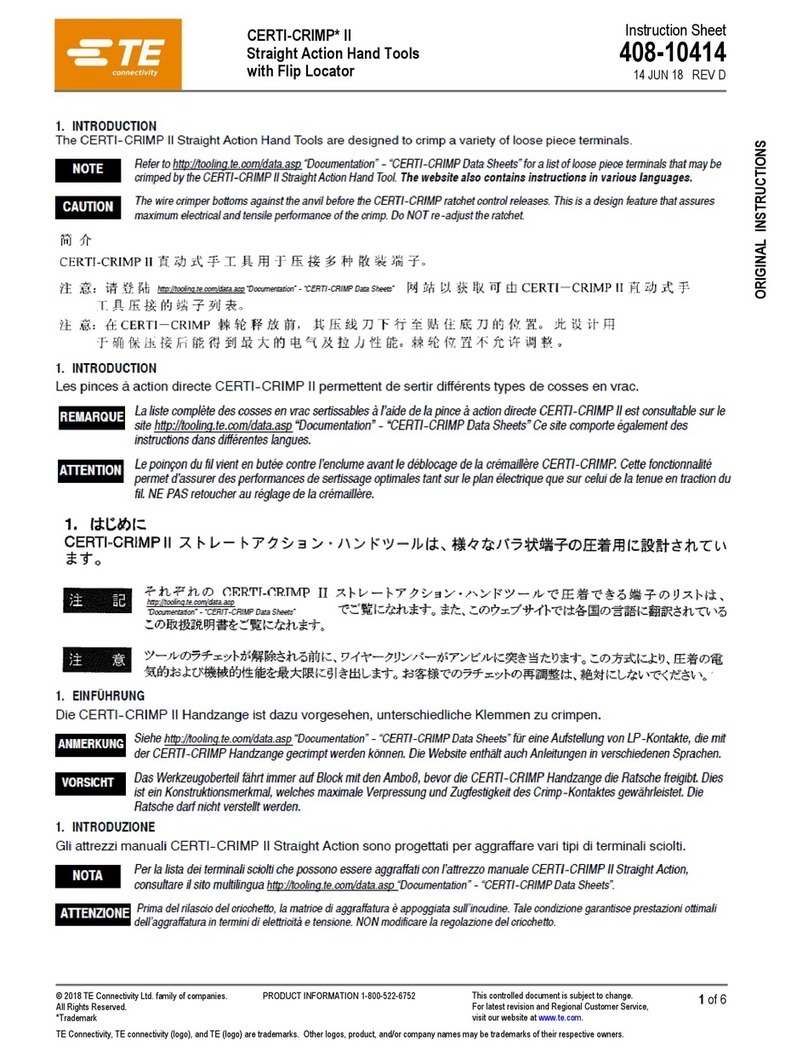

TE Connectivity CERTI-CRIMP II 2381707-1 User manual

TE Connectivity

TE Connectivity 69339 User manual

TE Connectivity

TE Connectivity 2378809-1 User manual

TE Connectivity

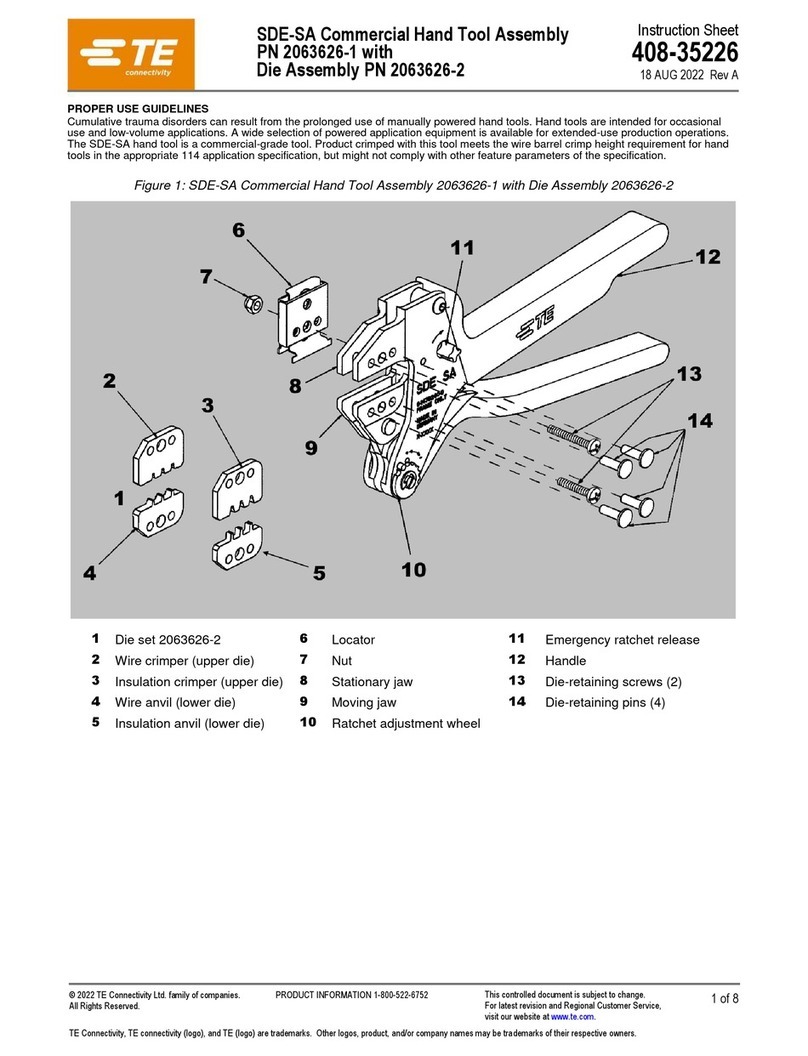

TE Connectivity SDE-SA PN 2063626-1 User manual

TE Connectivity

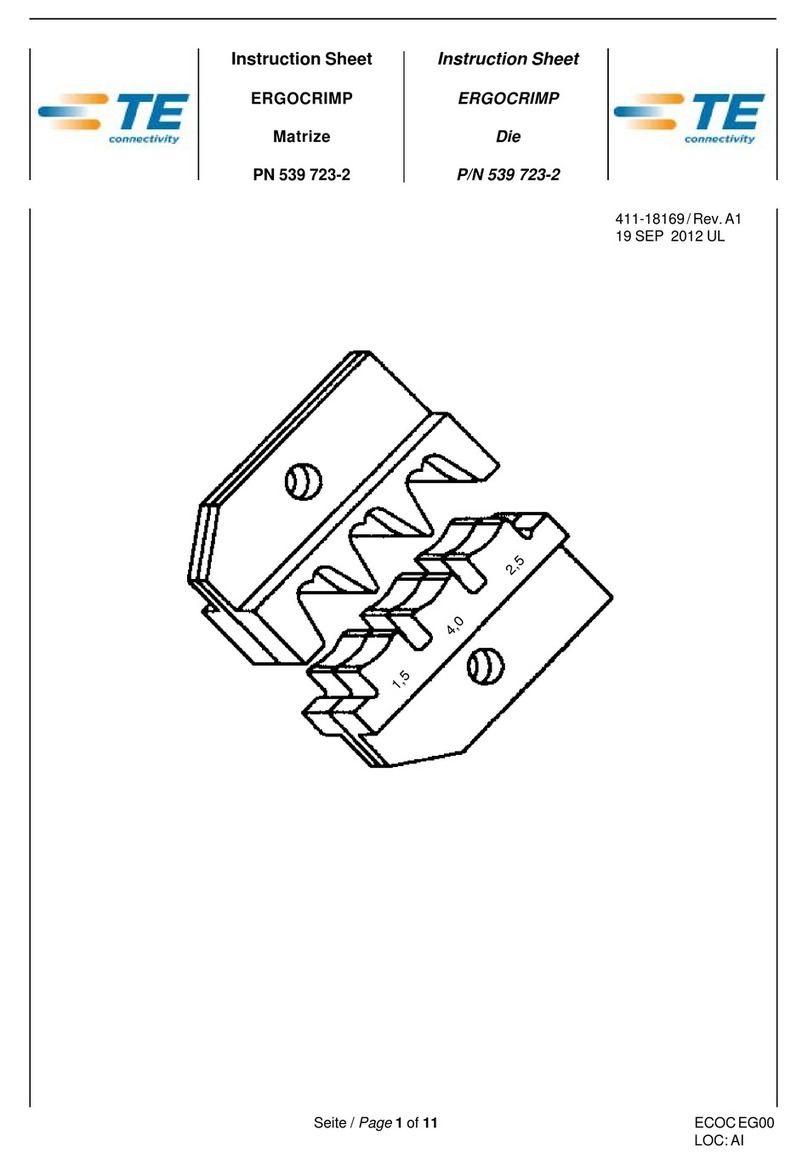

TE Connectivity ERGOCRIMP 539 723-2 User manual

TE Connectivity

TE Connectivity PRO-CRIMPER III User manual

TE Connectivity

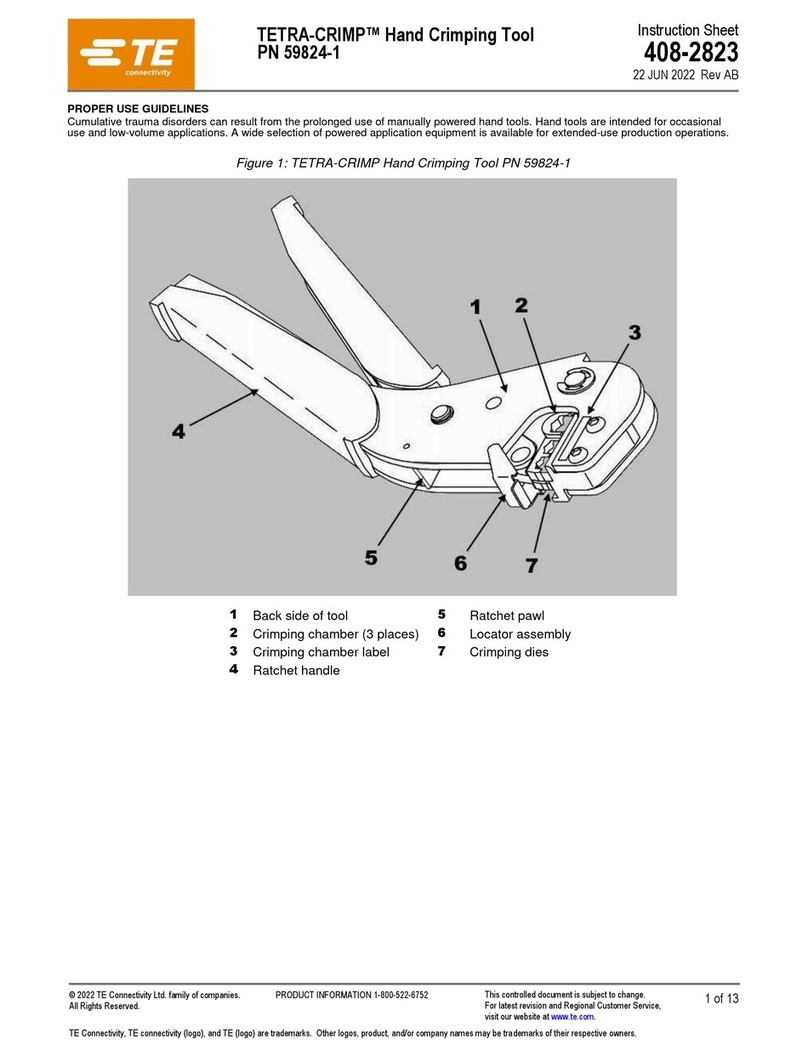

TE Connectivity TETRA-CRIMP 59824-1 User manual

TE Connectivity

TE Connectivity PRO- CRIMPER III User manual

Popular Crimping Tools manuals by other brands

Emerson

Emerson Klauke ES 20RMCCFB manual

Continental Refrigerator

Continental Refrigerator PC150HD quick start guide

Tyco Electronics

Tyco Electronics CERTI-CRIMP 90418-1 instruction sheet

Emerson

Emerson Klauke ES 105CFB manual

molex

molex 207129 Series Specification sheet

molex

molex 207129 Series Specification sheet