408-2363

3of 4

Rev J

3. Make certain all pins, pivot points, and bearing

surfaces are protected with a THIN coat of any good

SAE 20 motor oil. DO NOT oil excessively.

4. When the tool is not in use, keep the handles

closed to prevent objects from becoming lodged in

the crimping dies. Store the tool in a clean, dry area.

4.2. Periodic Inspection

Regular inspections should be performed by quality

control personnel. A record of scheduled inspections

should remain with the tool and be supplied to

personnel responsible for the tool. Though

recommendations call for at least one inspection a

month, the inspection frequency should be based on

the amount of use, ambient working conditions,

operator training and skill, and established company

standards. These inspections should be performed in

the following sequence:

A. A.Visual Inspection

1. Remove all lubrication and accumulated film by

immersing the tool (handles partially closed) in a

suitable commercial degreaser that will not affect

paint or plastic material.

2. Make certain all retaining pins are in place and

secured with retaining rings. If replacements are

necessary, refer to Section 5, REPLACEMENT

AND REPAIR.

3. Close the tool handles until the ratchet releases,

then allow handles to open freely. If they do not

open quickly and fully, the spring is defective and

must be replaced. See Section 5, REPLACEMENT

AND REPAIR.

DO NOT CONTINUE TO SQUEEZE THE TOOL

HANDLES AFTER THE RATCHET RELEASES.

Damagewill occur tothe tool if theratchet is forced

against the stop pin.

4. Inspect the head assembly, with special

emphasis on checking for worn, cracked, or broken

jaws. If damage to any part of the head assembly is

evident, the tool must be evaluated and repaired.

See Section 5, REPLACEMENT AND REPAIR.

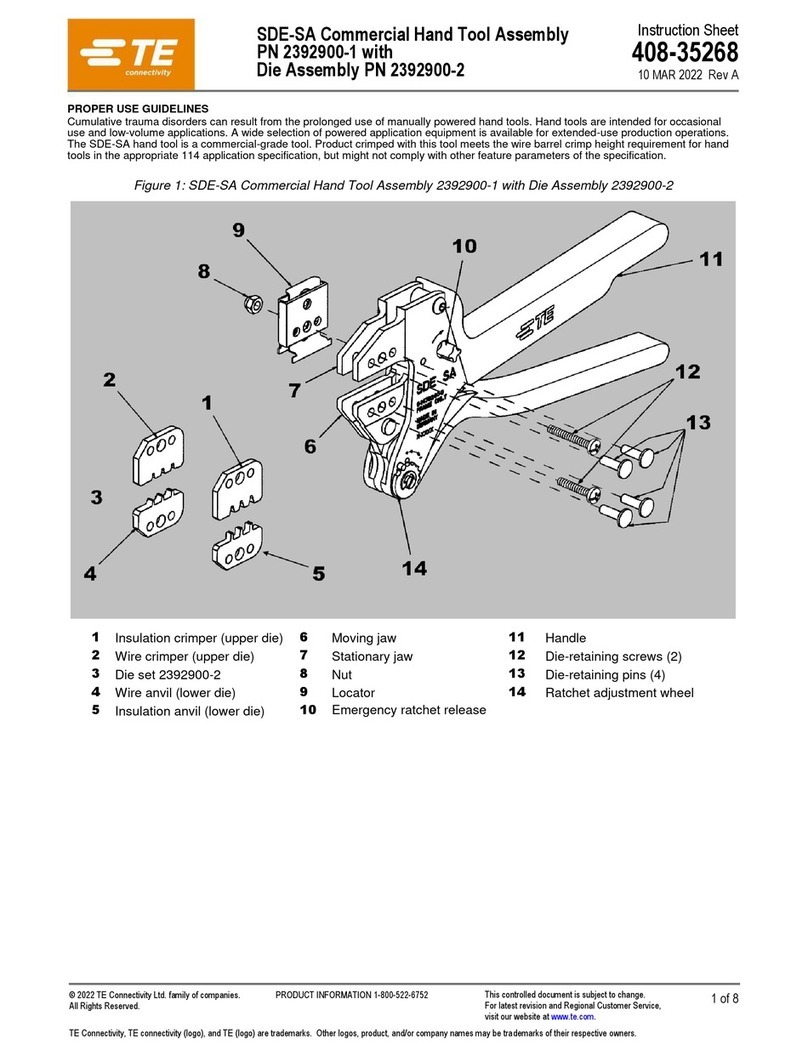

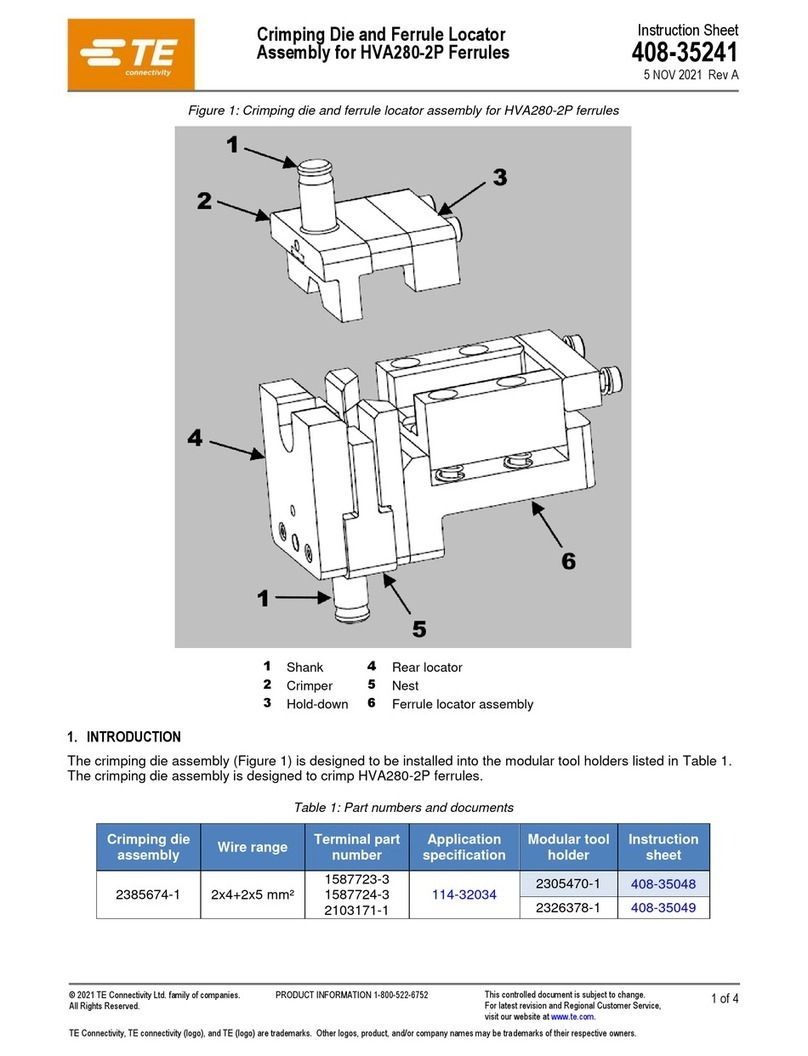

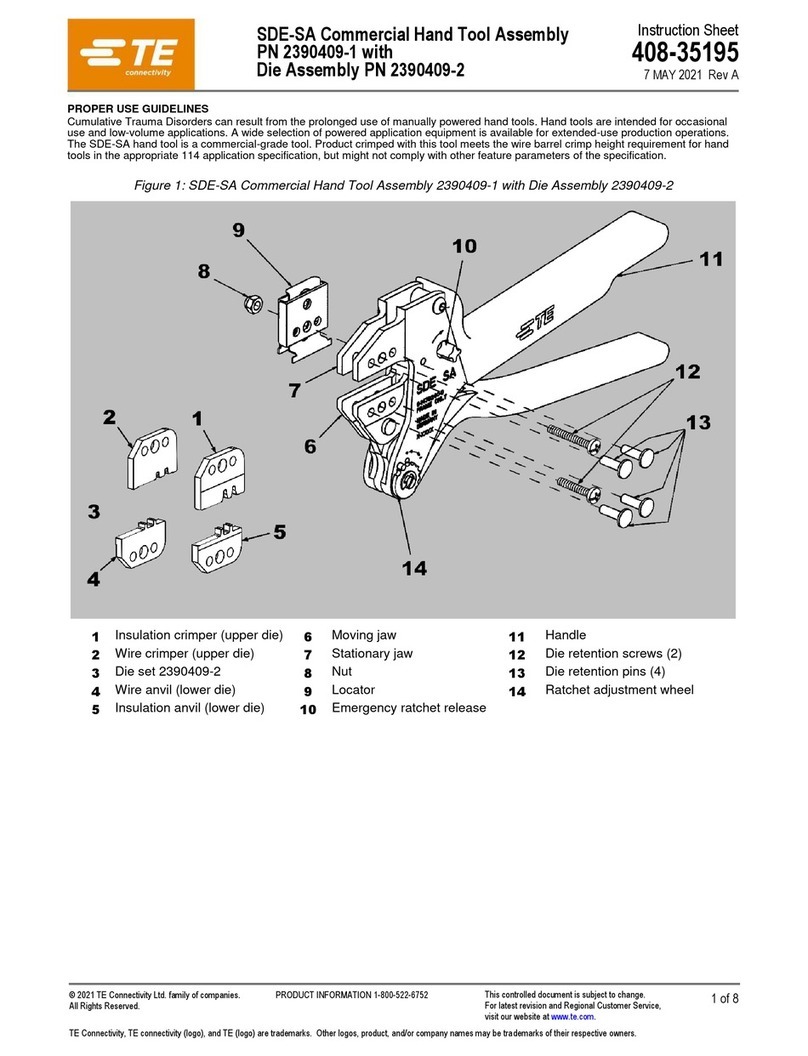

B. Jaw Closure Inspection

This inspection requires the use of a plug gage

conforming to the dimensions in Figure 5. Proceed as

follows:

1. Knock out the roll pins securing dies to jaws, then

remove dies.

2. Close the tool handles to the last notch on the

ratchet (the handles will automatically open if they

are closed beyond this point).

3. Align the GO element with the tool jaws. Push the

GO element straight into the jaw closure without

using force. The GO element must pass completely

through the jaw closure as shown in Figure 5.

4. Align the NO-GO element with the jaw closure

and try to insert it into the jaw closure. The NO-GO

element may start entry but must not pass

completely through the jaw closure as shown in

Figure 5.

5. Re-install the dies and secure them with the roll

pins.

If the jaw closure conforms to the gage inspection, the

tool is considered dimensionally correct and should be

lubricated with a THIN coat of any good SAE 20 motor

oil. If not, the tool must be repaired before returning it

to service (see Section 5, REPLACEMENT AND

REPAIR).

C. Ratchet Inspection

This inspection requires the use of a plug gage

conforming to the dimensions in Figure 5. Proceed as

follows:

1. Knock out the roll pins securing dies to jaws,

remove dies, then insert the NO-GO element

between tool jaws.

Figure 5

PLUG GAGE DIMENSION

GO ELEMENT NO-GO ELEMENT

6.680-6.688 [.2630-.2633] 7.059-7.061 [.2779-.2780]

Suggested Plug Gage Design

76.2 [3.00]

4.8 x 4.8 [.19 x .19]

(45° Ref)

4.8 [.19]

NO-GO

Dim. GO

Dim.

Gaging the Jaw Closure

Jaw

Closure

Jaw

Closure

GO Element NO-GO Element

GO element must pass

completely through jaw

closure.

NO-GO element may enter

partially, but must not pass

completely through jaw closure.

Radius

NO-GO GO