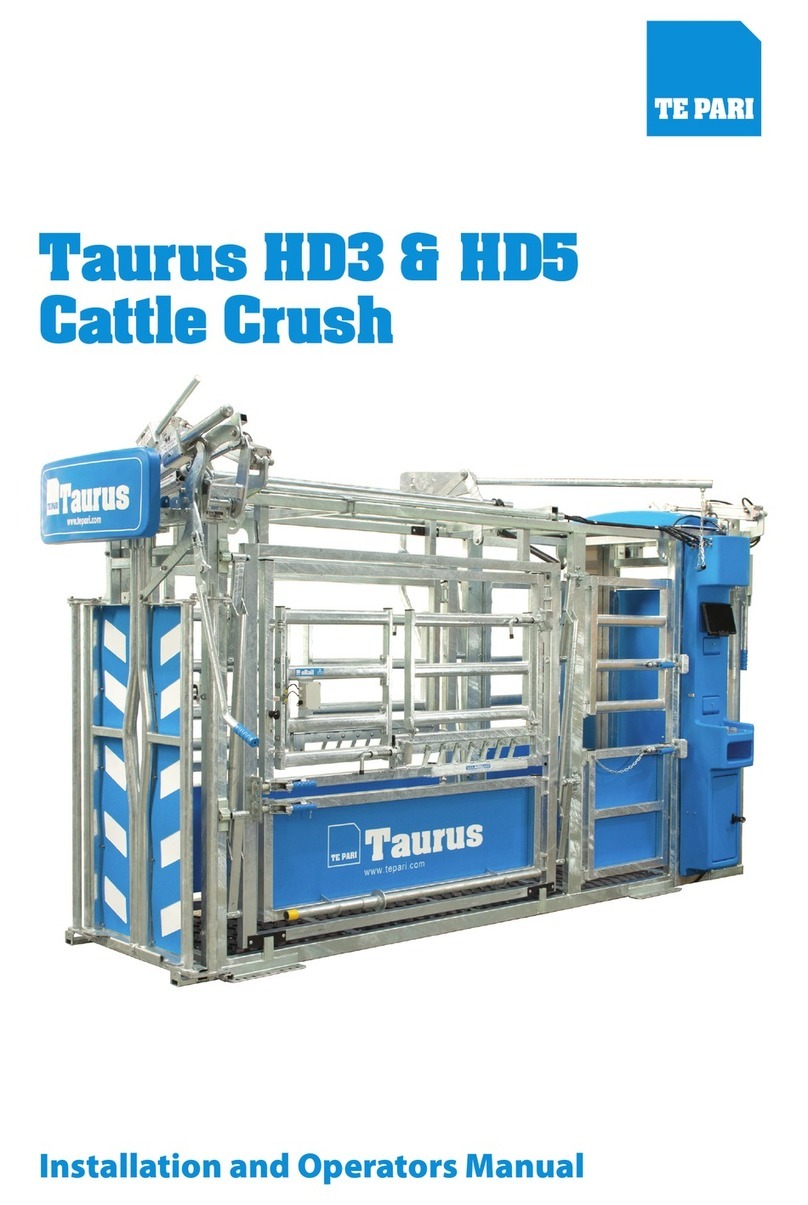

Te Pari Racewell HD3 User manual

Operators Manual

Racewell

HD3, HD4 & HD6

Sheep Handlers

2Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD3/HD4/HD6

Contents

Main components of your Racewell handler 3

Compressor 4

Attaching the air ttings and connecting the compressor 4

Power Supply 4

Remote Control 5

Dashboard controls 6–7

Positioning the sensors (eyes) 8

Anti backing hook 9

Adjusting the clamp and weigh area width 9

Adjusting the lead up race 9

Trouble shooting guide 10–13

Hazard Identication 14

EC Declaration of Conformity Machinery 15

Contact us Back

3Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

Main components of your Racewell handler

2

Draft Gates Entry GateClamp and Weigh Area Leadup Race

4Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

Compressor

The following specication is required for your Racewell Handler:

If your compressor lower capacity than these specication then the Racewell may work slowly.

Manufacturer installation and maintenance guidlines for the compressor should be followed.

This includes checking the oil and draining water from the tank.

Please note: when turning the compressor on or o use the switch on the compressor

and not the switch at the power source.

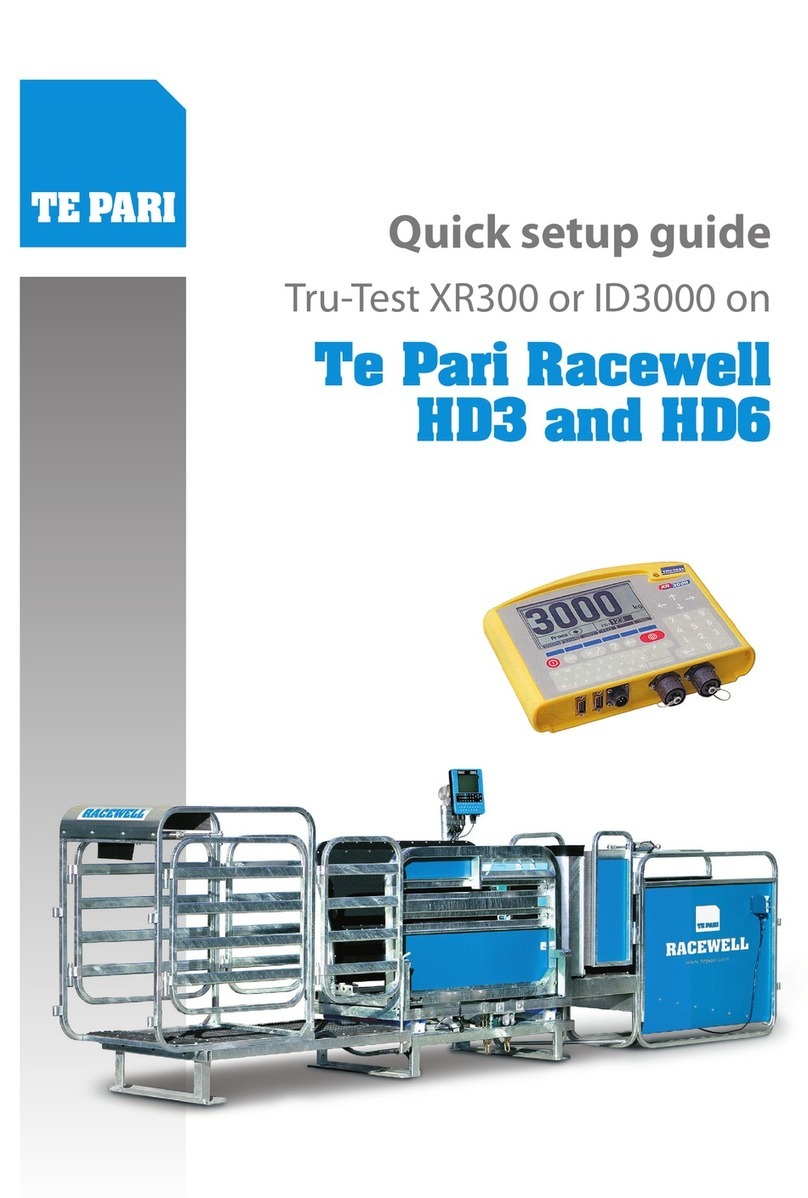

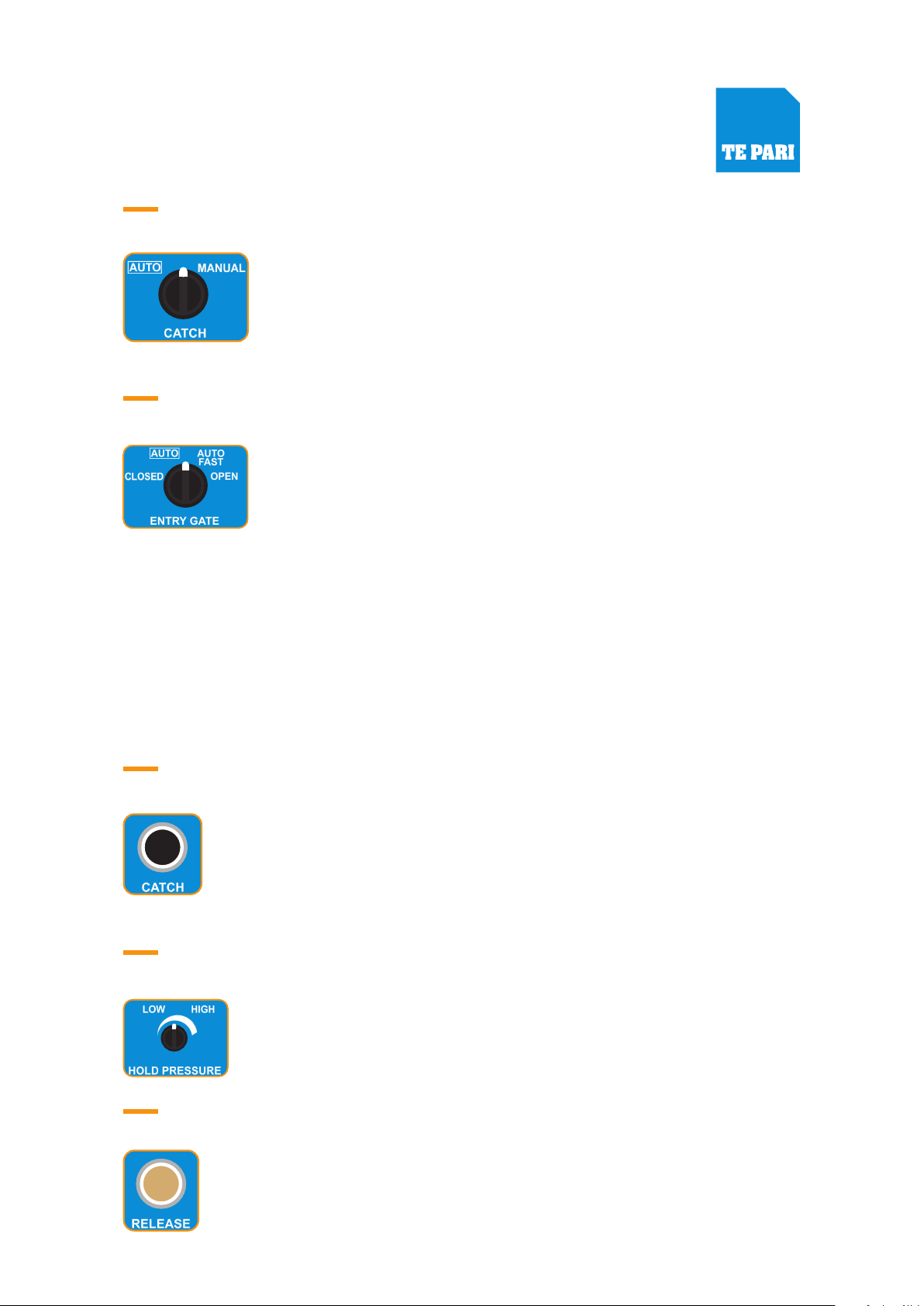

Attaching the air ttings and connecting the compressor

Connect the air line to the Racewell handler. The connection

is located underneath the Clamp and Weigh Area. If the

compressor is located some distance away from the racewell

handler it is recommended that you include a water trap on the

line to avoid condensation getting to the handler pneumatics.

The image above shows a design for a simple water trap.

Power Supply

Power can be supplied via

mains (110V AC to 240V AC)

or via the 12 Volt battery leads

supplied with the handler. The

internal system is all 12 Volt AC

power supply.

1 m / 3 feet

(approx)

From your Compressor

Ball or tap valve

To your Racewell

12 CFM capacity Minimum pressure of 90psi

5Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

Remote Control

All remotes have the following buttons:

The remote is powered by x2 AA batteries.

HD3 HD4 HD6

Tilt: Up / Down Clamp: Clamp/Release Draft gates

6Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

Dashboard controls

Your Racewell handler has a number of dierent operating modes. These are explained below.

(Starting from the Left button on the dashboard)

Power

When power is connected to the Racewell Handler it can then be powered on via the

dashboard power button. When the Racewell Handler is ON the button will glow green. It is

strongly recommended to turn the racewell Handler o when you have nished working.

Draft gates

The draft gate switch will move the postion of the Drafting gates to the left

or right. When Auto drafting the switch must be set to AUTO. The draft gate

direction can be changed at any time during weighing and drafting should you

wish to change the direction manually.

Release button

When set to AUTO the sheep will be automaticlly released from the Clamp and

weigh area when it has been weighed. If set to MANUAL then the operator will

have to press the release button for the sheep to be released.

Tilt

The tilt switch will move the Clamp and Weigh area up or down for access to the

sheep.

7Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

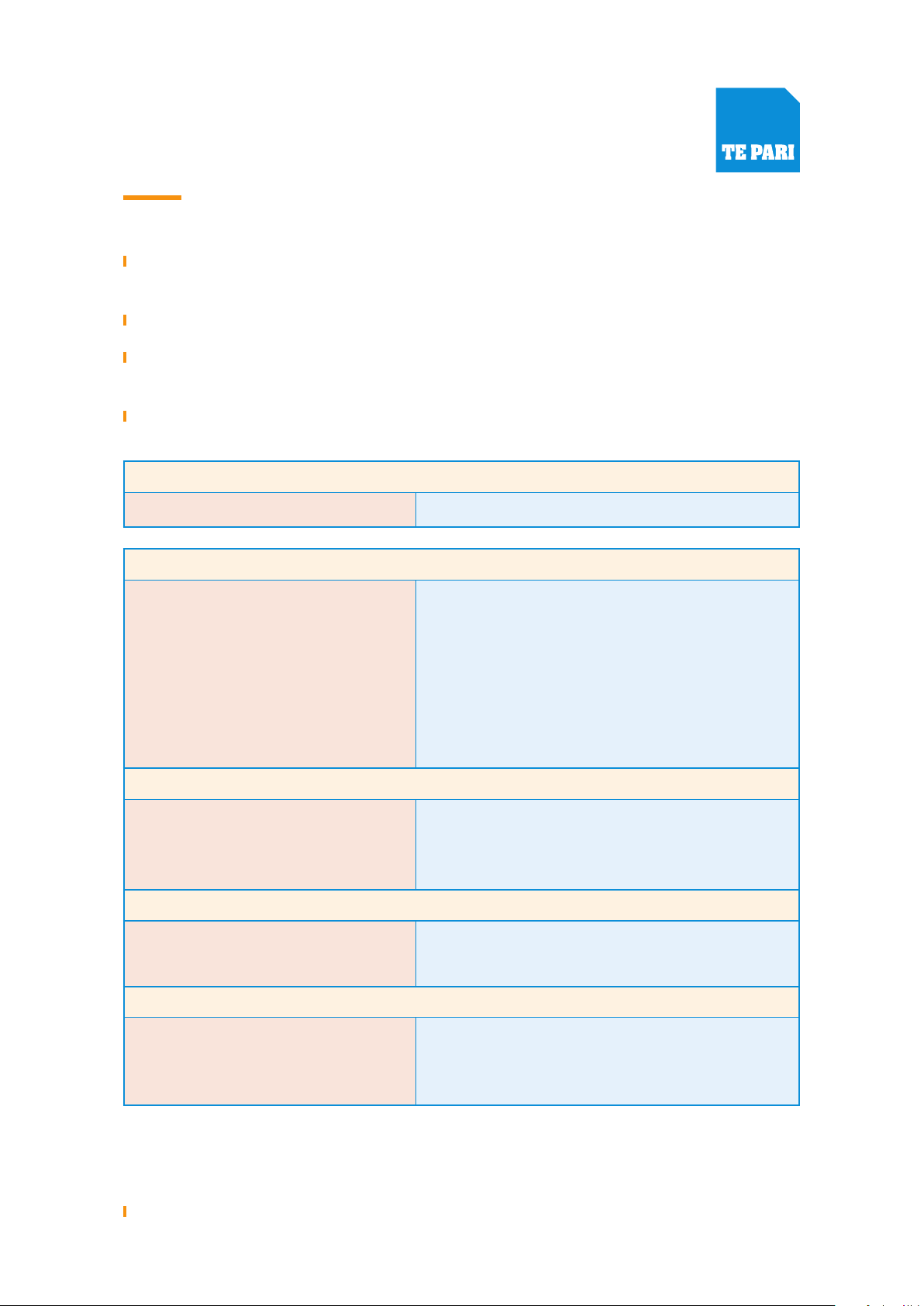

Catch (Auto/Manual)

The Catch switch is used if the operator wants to catch a sheep manually rather

than using the eyes on the side of the machine. For general use the switch should

be set to AUTO.

Safety Note: Please ensure the machine is turned o or this switch is set to manual

before adjusting the clamp wall width. Failure to do could result in the clamp being activated and personal injury

Entry

The entry gate has 4 modes:

Closed: The entry gate will remain closed regardless of the sensors on the side

of the Handler. This option is used when you may have sheep in the race and do

not want them to come through the handler.

Auto: The Entry gate will be closed when one of the Blue eyes on the side of the handler are activated.

It will open again when eye is cleared

Auto fast: The Entry gate will be closed when one of the Blue eyes on the side of the handler are activated

however it will open at the same time as the clamp releases allowing for faster ow into the machine

Open: The entry gate will remain open regardless of the sensors on the side of the Handler. This option

is very useful when doing tasks such as treatments and the animals are not being weighed as it provides

continuous ow

Recommended postion is AUTO

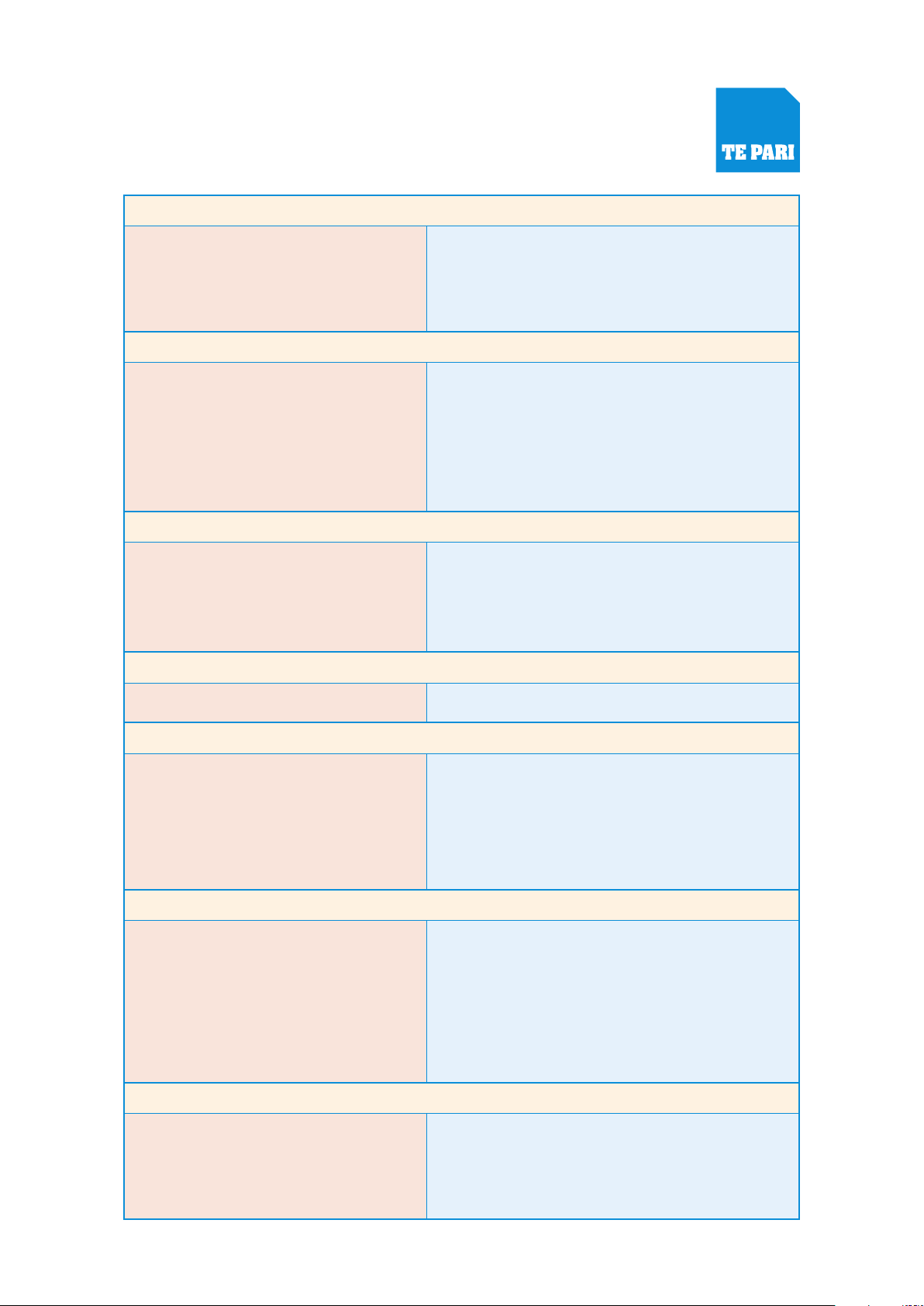

Catch

The catch button will activate the clamp. This button is used for catching a sheep

manually. If a sheep is caught in the clamp and the button is pressed again, more air

will ow to the cylinder and increase the pressure on the sheep. If the catch switch is

set to AUTO and you press the CATCH button. It will overide the auto function and the

sheep will not be released automatically.

Hold pressure

The Hold pressure knob increases or decreases the pressure of the clamp wall. The

recommended setting is at about ⁄ if your compressor is running at reommended

pressure of 90100 psi. If set to the lowest pressure the clamp wall will not move at all.

It is important not to have the pressure to high for animal welfare.

Release

The release button will release the clamp. This button is used for releasing a sheep

manually.

8Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

SENSOR EYE POSITION GUIDE FOR DAGGING SMALLER SHEEP

SENSOR EYE POSITION GUIDE

FOR WEIGHING SMALLER LAMBS

SENSOR EYE POSITION GUIDE FOR

WEIGHING LARGER LAMBS OR SHEEP

Please Note: Wool dust or debris covering any of the four eyes can aect operation.

Make sure that the lenses of the eyes are clean at all times.

Positioning the sensors (eyes)

Blue Eyes These activate the closing of the entry gate to stop the next sheep coming in while

there is one being weighed. The backing hook in the lead up race is also activated

by these eyes.

Black eyes When one of the blue eyes is covered and one of the black eyes is covered the clamp

will activate and a sheep will be caught and weighed. It is important that the eyes are

positioned correct and that a sheep can not get inbetween the Blue and black eyes.

The eyes are on magnets to allow ease of adjustment to suit the size of animals you are working

with or the task your wanting to achieve in the handler.

9Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

Anti backing hook

This works with the auto gate, and ensures that the animal

can't walk backwards the handler.

The anti backing hook is activated by the blue eyes and

prevents the sheep moving backwards when it is released. It

is recommended the hook is disabled when doing tasks such

as crutching where the sheep is caught towards the back of

the clamp and weigh area. The hook can be deactivated by shifting the pin position.

Adjusting the clamp and weigh area width

At the bottom of the clamp wall, there are adjustment holes.

Safety Note: Please ensure the machine is turned o or this switch is set to manual before adjusting

the clamp wall width. Failure to do so could result in the clamp being activated and personal injury. It

is also possible to remove the air hoses on the cylinder to make adjustment easier

The width of the clamp and weigh area can be adjusted to suit dierent size animals. Ideal

adjustment will catch the sheep with the clamp wall parellel with the other side and minimise

movment of the clamp wall to catch a sheep.

Size can also be adjusted dierently from front to back if required.

The length of the squeeze clamp wall ram can also be adjusted. In the middle of the moving wall

there are four adjustments for ram length. Adjust the ram so that the clamp wall movement is

minimal to catch a sheep. Ideally the wall is vertical when a sheep is clamped

Adjust this pin so the wall cannot touch the opposite side. This is a safety feature so that hands

and ngers cannot be caught in the empty unit accidentally.

Safety Note: when adjusting for large sheep the wall may be able to touch the opposite side. Be

careful not to activate the clamp without a sheep in the clamp area

Adjusting the lead up race

The lead up race can be adjusted for width at

the top and bottom. A slight V conguration is

best to prevent smaller animals turning around.

Shift pin position

10 Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

Trouble shooting guide

Please check this trouble shooting guide before contacting customer support, as often

something quite simple could be the problem.

A service charge will be made for call outs if the fault is not covered by your warranty.

When testing the unit without sheep ensure at least one blue an one black eye are covered,

covering either of the blue eyes on their own will only close the auto gate.

For your safety, and that of others, never leave the unit operational when not attended.

SYMPTOM

POSSIBLE CAUSES POSSIBLE SOLUTIONS

NO POWER AT UNIT AND IT WON’T GO

12v adaptor not getting power

Faulty extension cords to 12V adaptor

Faultly 12v Adaptor

Faulty On/O switch

Wire loose/o in autobox

No air to unit

Check the12v adaptor cord is rmly connected

Check all extension cords

Check for external damage to the adaptor and using a

multimeter check the adaptor output is at least 11 volts

Check the On/O switch and wiring to it

Check wiring generally for breaks or chew marks

Check the air lines and compressor

SHEEP UNIT DOING UNUSUAL THINGS

Fluctuating power supply

Faulty Catch/Release switch

Faulty compressor

Check power, compressor and test unit for a stable weight

Check air lines and wiring

Check compressor is operating correctly

AUTO GATE MOVING UNEXPECTEDLY

Sensors (eyes) obscured by dust or wool Check the sensors (eyes) for dust on the lenses

Also check they have no loose wool in front of them

SHEEP ARE NOT BEING DRAFTED/SORTED

Draft switch Communication cable may not be connected or scale

congured correctly

Check cable for damage

Racewell HD SHEEP HANDLING SYSTEMS

DRAFTING THE WRONG WAY FOR PRESET WEIGHTS

Ensure the manual draft switch is in the auto position

Turn power o and on again on the Handler. This will

force a communication handshake between the scales

and handler

EVERYTHING WORKS APART FROM THE DRAFTER

Indicator not talking to drafter Check comms cable between indicator and autobox

for damage

Turn power o and on again on the Handler. This will

force a communication handshake between the scales

and handler

Ensure autodrafting option on your indicator is selected

PARTS OF THE UNIT ARE WORKING SLOWLY

Constricted, broken or punctured air lines Check the airlines for cracks & leaks

Remove hoses from the cylinder and test. This will

help identify if the issue is a air issue or a cylinder issue

Ensure the compressor is resting upon the airlines

CRUSH WALL IS NOT OPERATING QUICKLY ENOUGH

Low air pressure Check the compressor–require 90--120psi

TILT GOING BACK OR CREEPING OVER

Faulty switch

Faulty solenoid

Air leak

Repair or replace the switch

Replace solenoid

Check joints and lines and remedy as required

Remove air line and see if there is air ow leaking

through the valve. If so contact support

UNIT IS NOT CATCHING PROPERLY

Low air pressure

Eye not working

Dirty Sensor (eye)

Incorrect eye positions

Check compressor output is above 90 psi at all times

Check sensor (eye) and cables for damage

Remove wool and/or dust from the sensor (eye) lenses

Adjust positions so 1x blue and 1x black eye get covered

Remove air line and see if there is air ow leaking

through the valve. If so contact support

WALL PRESSURE IS HIGH ALL THE TIME

Faulty potentiometer Check and adjust or replace as required

Remove hoses from ram and activate catch and see

if air keeps coming out should only do a short burst,

possible the valve needs service as its stuck open

Racewell HD SHEEP HANDLING SYSTEMS

UNIT SLOWLY RELEASES AFTER SHEEP ARE CLAMPED

Air may be leaking

Catch solenoid may be faulty

Damage to cylinder piston

Check for air leaks

Check solenoid

Check piston

Remove air line and see if there is air ow leaking

through the valve. If so contact support

THE UNIT IS NOT HOLDING THE SHEEP

The unit is designed to operate at 90-120psi Check the ram adjustment on the moving walls

allows the ram to apply pressure to the wall

Check the potentiometer(increase/decrease knob)

on the dashboard is turned up enough

Ensure any regulator on the compressor is set to

correct pressure

SHEEP SLIPPING OUT OF CLAMP

Potentiometer (increase/decrease knob)

Wall position

Air leak

Adjust upwards to increase pressure

Ensure position is correct for animal size, when a

sheep is held the top at of the crush wall should be

about vertical

Check for air leaks to ram and replace hosing

SHEEP ARE GETTING TOO FAR THROUGH THE UNIT

Wall not adjusted for animal size

Eye lengths are too short

Potentiometer (increase/decrease knob)

Compressor

Air leak

Adjust the wall

Adjust the black eyes closer to the blue ones so the

sheep is caught further back

Adjust upwards to increase pressure

Check pressure is 90 psi cut in and 120-130psi cut out

Check if crush cylinder needs lubricating

MACHINE IS CLOSING WITHOUT ANY SHEEP

Dirty eyes

Eye length is too long

Clean eyes and ensure they are free from dust, wool etc.

Use allen key to remove grub screw so the sensor can

be removed from the plastic eye holder, on the back

of the sensor is a small at head screw which can be

adjusted to increase or decrease the read range

REDUCTION IN AIR PRESSURE

Water trap lters Should be checked visually every 3 months and

replaced as required

Please ensure there is no air pressure from compressor

into the handler

Racewell HD SHEEP HANDLING SYSTEMS

REMOTE CONTROL IS NOT WORKING PROPERLY OR AT ALL

Flat remote control battery

Remote is not programmed to your unit

Check and replace as required

Program remote to your unit by turning on the unit then:

Remote

EYES ARE NOT WORKING

Faulty eye switch

Dirty or broken eye

Eye cables broken or frayed

Check power supply. low power will aect eye

performance

Swap the eyes from each cable to elimate cable or

eye issues

Check eye cables are not damaged

INDICATOR READOUT IS FLUCTUATING OR NOT ZEROING

Plugs not completely connected

Plugs are damp

Battery is not adequately charged

Unit is damp

Electrical interference

Check loadbar cables are rmly in place, don’t over

tighten

Check for moisture

Check there is nothing touching the clamp and weigh

area including build up of dirt or muck underneath

Check battery is in a charged state

Check indicator to unit cord

Electrical interference from a short can aect your

indicator

Battery and unit charges must be kept dry

NOT AUTOMATICALLY DRAFTING OR RELEASING

Comms cable fault

Incorrect indicator settings

Communication cable from indicator to unit is damaged

or has dirty terminals – clean terminals with CRC

Communications cable is in the wrong comm port

Check your indicator settings are correct

TRU-TEST INDICATOR DISPLAYS WAIT FOR TRIGGER

Clean eyes

Ensure communication cable connected turn handler

o and on, ensure the scale does not require

information like a trait before it will record

Check the Yand Communications cables and the

cables pins for damage, replace if required

INDICATOR NOT ZEROING

Tension in loadbars Refer to the scale manual

Loosen 4 top bolts on loadbars, if they settle they

may require a washer in one corner

Loadbars may require servicing

14 Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

Hazard Identication

The Racewell Drafter has moving gates positioned at both the front and rear of the unit. Keep

hands clear to avoid the risk of a crush injury when the machine is operational.

Crush hazard

WARNING

! !

Entry gate The entry gate will move when switch position is changed on the dashboard or the

blue sensor is covered. Be sure to keep your limbs, head and body out of the area of

movement area

All above hazards can be activated be the double foot pedals. unplug when not in use

Clamp wall The clamp wall will move quickly and with force when the catch or release button

on dashboard or button on remote is pressed. It is also activated when one of the

blue and one of the black eyes are covered. It can also be activated if the foot pedal

is connected to the clamp / release plug on the underside of the handler. Depending

o the adjustment of the wall it is possible for the wall to come in contact with the

opposite side of the clamp and weigh area. This is a potential crush hazard. Be sure to

keep your limbs, head and body out of the area of movement area. Please ensure the

machine is turned o or this switch is set to manual before adjusting the clamp wall

width. Failure to do so could result in the clamp being activated and personal injury.

It is also possible to remove the air hoses on the cylinder to make adjustment easier

Tilt If the handler is tted with a tilt option–The tilt will move when the tilt switch position

is changed on the dashboard or button on remote is pressed. It can also be activated

if the foot pedal is connected to the Hoist Up/Down plug on the underside of the

handler. Ensure the entry gate is closed before tilting. This is a potential crush hazard.

Be sure to keep your limbs, head and body out of the area of movement area

Tilt Service position. If the tilt is up to allow access to the control box under the oor be sure

that the power is disconnected to the machine and that a chock is put in place to prevent

the tilt from coming down while working on the handler. This is a potential crush hazard.

Be sure to keep your limbs, head and body out of the area of movement area

Draft gates The draft gates will move when the switch position is changed on the dashboard or

gate buttons pressed on the remote. Be sure to keep your limbs, head and body out

of the area of movement area. Draft gates may activate from signals received from the

scale causing unexpected movement

All the above hazards are applicable during manual or automatic operation.

15 Te Pari Racewell HD3, HD4 & HD6 Operators Manual

Racewell HD SHEEP HANDLING SYSTEMS

EC DECLARATION OF CONFORMITY MACHINERY

(according to Annex II.1.A of the Machinery Directive)

Te Pari Products Ltd hereby declares as manufacturer that the Racewell Sheep

Handler with specications:

Meets the provisions of the following Directives:

Machinery Directive (2006/42/EG)

And furthermore declares that (parts of) the following harmonized standards have

been applied:

Machine :

Type :

Serial :

Year :

Manufacturer : Te Pari Products Ltd

Address : 9 Endeavour Crescent, Oamaru, Otago 9494

Country : New Zealand

Responsible : Patrick Blampied

ISO 14120: Safety of machinery - Guards - General requirements for the design and

construction of xed and movable guards

IEC 60204-1: 2006 Safety of machinery - Electrical equipment of machines

Part 1: General requirements

ISO 13849-1: Safety of machinery - Safety-related parts of control systems

Part 1: General principles for design

IEC 61310-1: 2008 Safety of machinery. Indication, marking and actuation.

Part 1: Requirements for visual, auditory and tactile signals

IEC 61310-2: 2008 Safety of machinery. Indication, marking and actuation.

Part 2: Requirements for marking

ISO 4414 : 2010 Pneumatic uid power - General rules and safety requirements for

systems and their components

NEW ZEALAND HEAD OFFICE

PO Box 25, 9 Endeavour Crescent

Oamaru, 9444, New Zealand

FREEPHONE NZ: 0800 837 274

REST OF WORLD: + 64 3 433 0077

EMAIL

AUSTRALIA OFFICE

44 Ricky Way, Epping

Melbourne, 3076 VIC

PHONE: 1800 650 682

EMAIL

accounts : [email protected]om

Thank you for your purchase, enjoy your new Te Pari Racewell HD Sheep Handlers

from the Te Pari team

Warranty Claims and Returns Form

https://www.tepari.com/contact-us/warranty-claim/

Other manuals for Racewell HD3

2

This manual suits for next models

2

Table of contents

Other Te Pari Farm Equipment manuals