Safety

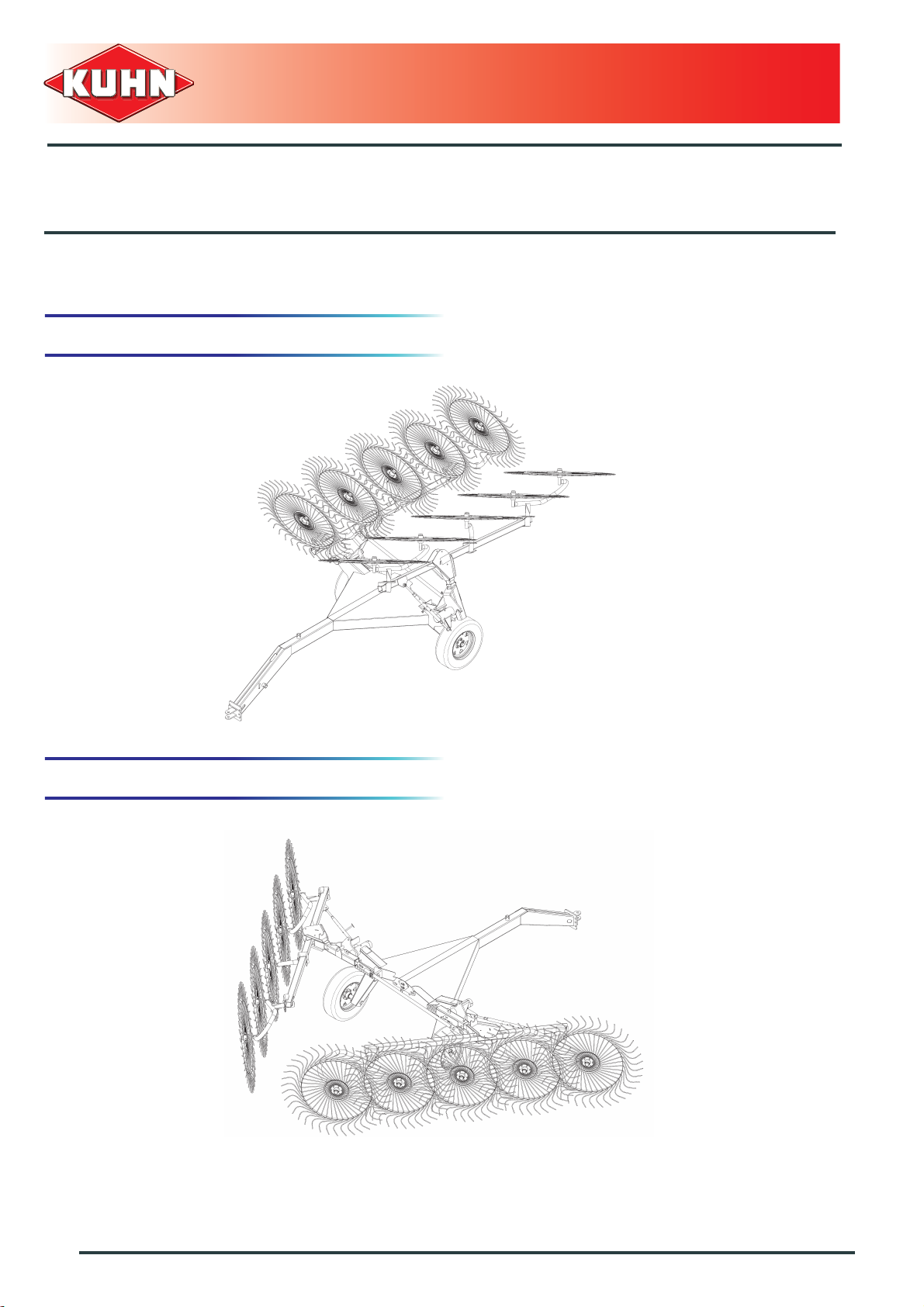

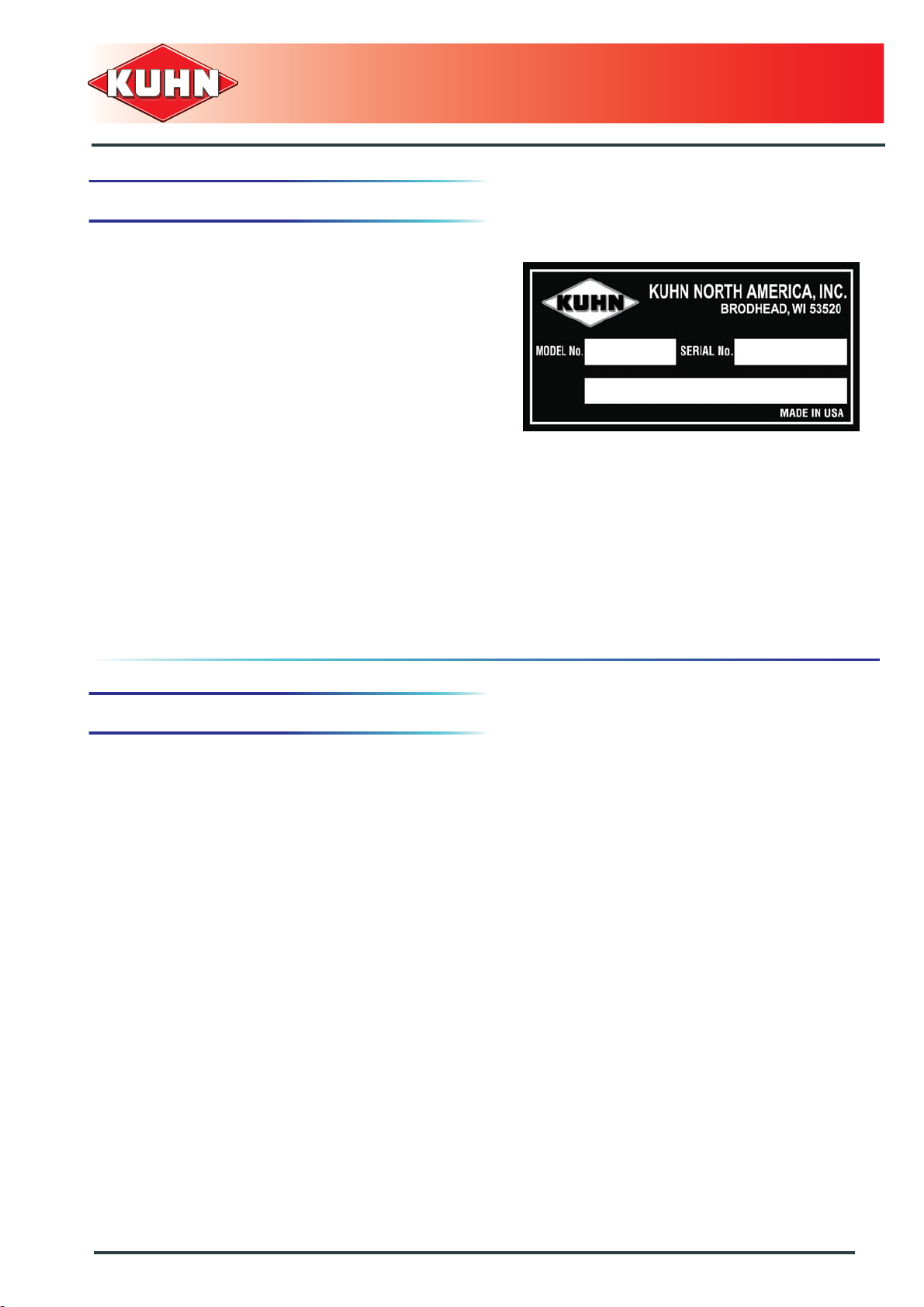

SpeedRake

SR108 SR110 SR112

7

2. Safety instructions

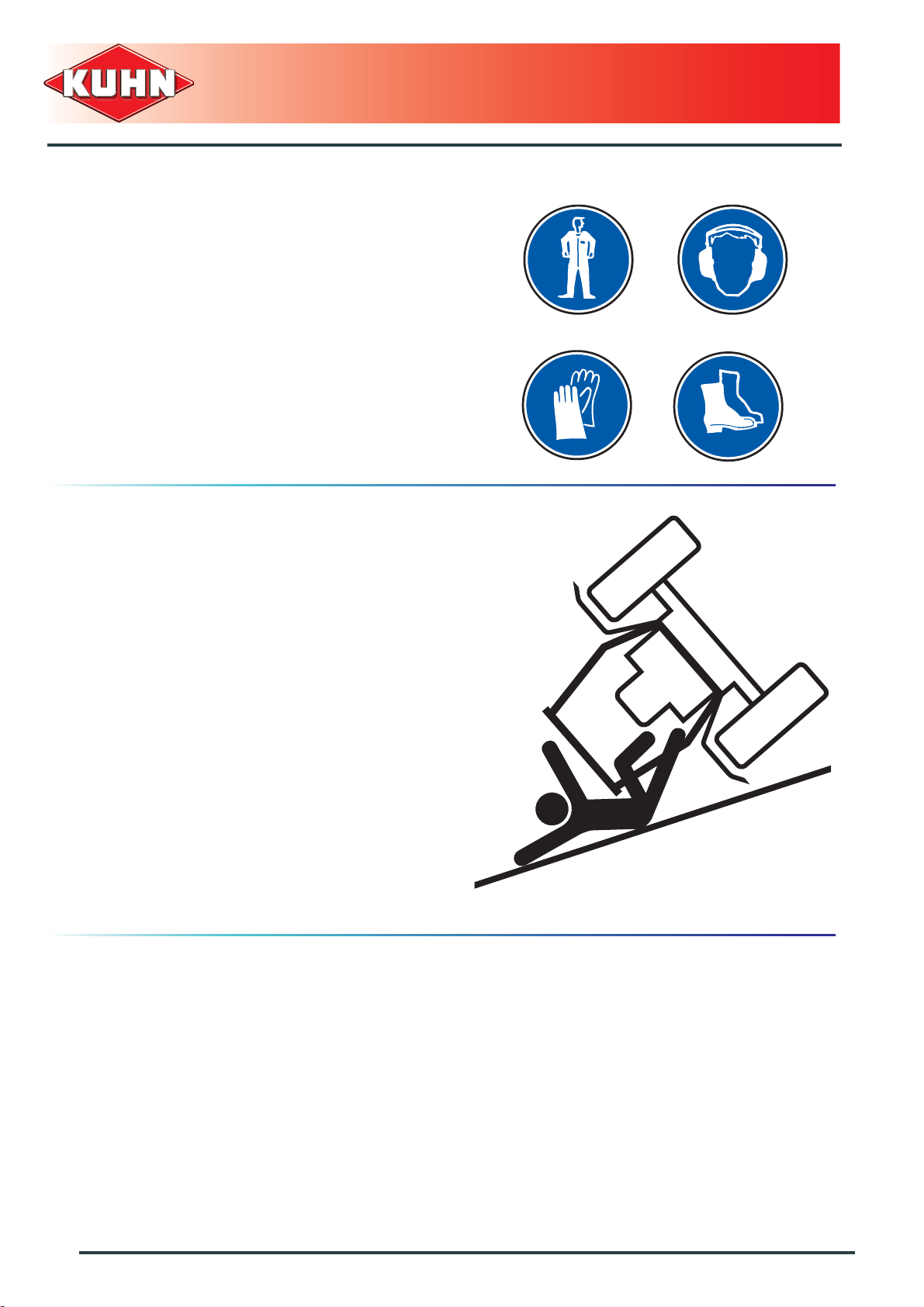

Read and follow the safety instructions

Before using the machine, carefully read all the safety

instructions in this manual and the warnings placed on

the machine. Failure to follow the instructions contained

in this manual could result in product or property

damage, severe personal injury, or death. All applicable

safety procedures, codes and requirements of any

federal, provincial, state and local agencies, as well as

safe working practices and good judgment, must be

used by personnel when assembling, servicing,

adjusting or operating this equipment.

Before starting work, the operator must be familiar with

all machine controls, handling devices and their

functions. It is too late to learn once work has been

started!

Never let anyone operate the machine who is not trained

to do so.

Should you have any difficulties in understanding any

parts of this manual, please contact your KUHN dealer.

Safety shutdown procedure

Before leaving the tractor or before adjusting,

maintaining or repairing the machine, depressurize

hydraulics, turn off the engine, remove ignition key,

apply parking brake and wait until all moving parts have

come to a complete stop.

Introduction

The machine must only be operated, maintained and repaired by qualified persons who are familiar with the

machines' operation and understand safety regulations and procedures for preventing accidents.

The operator must follow the safety instructions in this manual and in the warnings posted on the machine. The

operator is also obliged to respect current legislation concerning accident prevention, work safety and public

traffic circulation.

The intended use of the machine includes following all operation, maintenance and repair recommendations

given by the manufacturer, and using only genuine spare parts, equipment and accessories, as recommended

by the manufacturer.

The manufacturer is not held liable for any damage resulting from machine applications other than those

specified by the manufacturer. Any use other than the designated operation is at the risk and responsibility of

the operator.

The manufacturer is not held liable for any damage or accident resulting from machine modifications carried out

by the operator himself or by a third party without previous written agreement from the manufacturer.