TEA TMM-100 User manual

TMM-100

Temperature Measurement Module

Operating Manual

Thermal Engineering Associates, Inc.

3287 Kifer Road

Santa Clara, CA 95051 USA

Revision 4

TEA

TMM-100_User_Manual_r4.doc Rev3 i

CONTENTS

1. Introduction

2. Operation

3. Applications

4. Installation

5. Accessory Items

6. Terminal Command Codes

7. Warranty & Repair

8. Addendum: LabView™ Drivers & VIs

TEA acknowledges the contributions to the TMM-100 design and software made by:

John Keenan, MicroReady Inc.

James Christofferson, Electro-Thermo-Optic

This manual is intended solely for TEA customers in the application of the Temperature

Measurement Module product described herein. The product is designed for the specific

tasks detailed herein and any use of this product in other application tasks is at the user's risk

and responsibility.

©2019 by Thermal Engineering Associates, Inc. (TEA), Santa Clara, CA USA. All rights re-

served. No part of this manual may be copied or otherwise reproduced without prior written

authorization from TEA.

Thermal Test Chips mentioned in this manual are offered for use in characterizing assembly

processes, packages, materials and any other applications requiring precise control of heat

flux generation and temperature measurement. Applying the data from the test die to a func-

tional system is the responsibility of the user. TEA makes no warranty, expressed or implied

including the implied warranties of merchantability and fitness for a particular purpose, that

the user's system designed using that data will perform as intended by the user.

TMM-100 INTRODUCTION

TEA

TMM-100_User_Manual_r4.doc Rev4 1-1

DESCRIPTION

The TMM-100 is designed to simplify the

gathering of temperature data from eight

Thermal Test Chip diode temperature sen-

sors. The system contains precision current

sources for supplying diode measurement

current (IM), voltmeter capability for diode

measurement (VM), and Type-T thermocouple and 10KΩ NTC thermistor measurement ca-

pability for monitoring the environment temperature. Front-panel mounted connectors pro-

vides for up to eight temperature sensing diodes, two thermocouples and two thermistors. All

temperature sensor channels can individually be enabled or disabled using simple com-

mands.

For any of the selected eight diode temperature sensing channels, the internal precision IM

current source provides 1.00mA with a voltage compliance of 2V. The internal voltage meas-

urement circuit measures to 1.999V with 1mV resolution. The temperature measurement

resolution of 0.1C for all sensors provides for accurate temperature differential measure-

ments.

The TMM is powered through its USB connection to a computer, so no external power supply

is required.

FEATURES

Self-contained for easy setup and operation

8 diode voltage measurement channel circuitry

Diode channels use 1.0mA current source.

2 Integrated Type-T thermocouple measurement circuitry

2 10KOhm NTC thermistors measurement circuitry

Thermistor channels use 100µA current source

1mV resolution on differential voltage measurements

Rear Panel connector for controlling temperature environment fan

USB connection for power, programming, and data logging.

LabVIEW Virtual Instrument Option (model TMM-100-01)

TMM-100 INTRODUCTION

TEA

TMM-100_User_Manual_r4.doc Rev4 1-2

SPECIFICATIONS

Diode Current Source

Number of Channels 8

Measurement Current 1.00mA

Accuracy 0.1%

Voltage compliance 1.999V

Polarity - or + to GND

Connection Front Panel, IDC Ribbon Cable Connector

Diode Voltage Measure

Number of Channels 8 (integrated with Current Source)

Range 1.999V

Resolution 1mV

Accuracy 0.01% of fs 1 mV

Temperature Measure (Thermocouple)

Number of Channels 2

Type T

Range 0 to +199C

Resolution 0.1C

Accuracy 0.1% of fs 1.4C

Connector Front Panel, Miniature Jack (Omega NMP-T or equivalent)

Temperature Measure (Thermistor)

Number of Channels 2

Type 10KΩ (nominal @ 25ºC)

Operating Current 100µA

Range 0 to +199C

Resolution 0.01C

Accuracy 0.1% of fs 1.4C

Connector Front Panel, (type TBD)

Power Indicator

Type LED

Color Green

Data Indicator

Type LED

Tx Color Green

Rx Color Red

Computer Connection

Type USB 2.0 or higher

Connector Rear Panel, USB Type B

Relay Connection

Configuration Type Single Pole, Double Throw (SPDT)

Connector Rear Panel

TMM-100 INTRODUCTION

TEA

TMM-100_User_Manual_r4.doc Rev4 1-3

SPECIFICATIONS (continued)

Physical

Height 51.0mm (2.00in)

Length 179.50mm (7.067in)

Width 154.00mm (6.063in)

Weight 0.42Kg (14.7oz)

GETTING STARTED

Unpack Your Module

Your box should contain the following items:

TMM-100 Temperature Measurement Module

USB 2.x Cable (Type A on one end, Type B on other end)

Combination Diode/Thermistor Sensors connection cable

Type-T #36 Gauge Thermocouples with mating connectors

USB Flash Drive containing operating software and module operating manual

TMM-100 INTRODUCTION

TEA

TMM-100_User_Manual_r4.doc Rev4 1-4

Hardware Description

Before you cable your router, take a moment to become familiar with the label and the front

and back panels. Pay particular attention to the LEDs on the front panel.

Module Front Panel

The TMM-100 front panel has:

Green Power LED

Red LED for USB Tx Data

Yellow LED for USB Rx Data

2 x 8 connector for Diode connections

2 x Thermistor connector

2 x Thermocouple sockets

The TMM-100 rear panel has:

Standard USB B-type connector

Fan Control connector

SOFTWARE INSTALLATION

See Section 4.

TMM-100 OPERATION

TEA

2-1

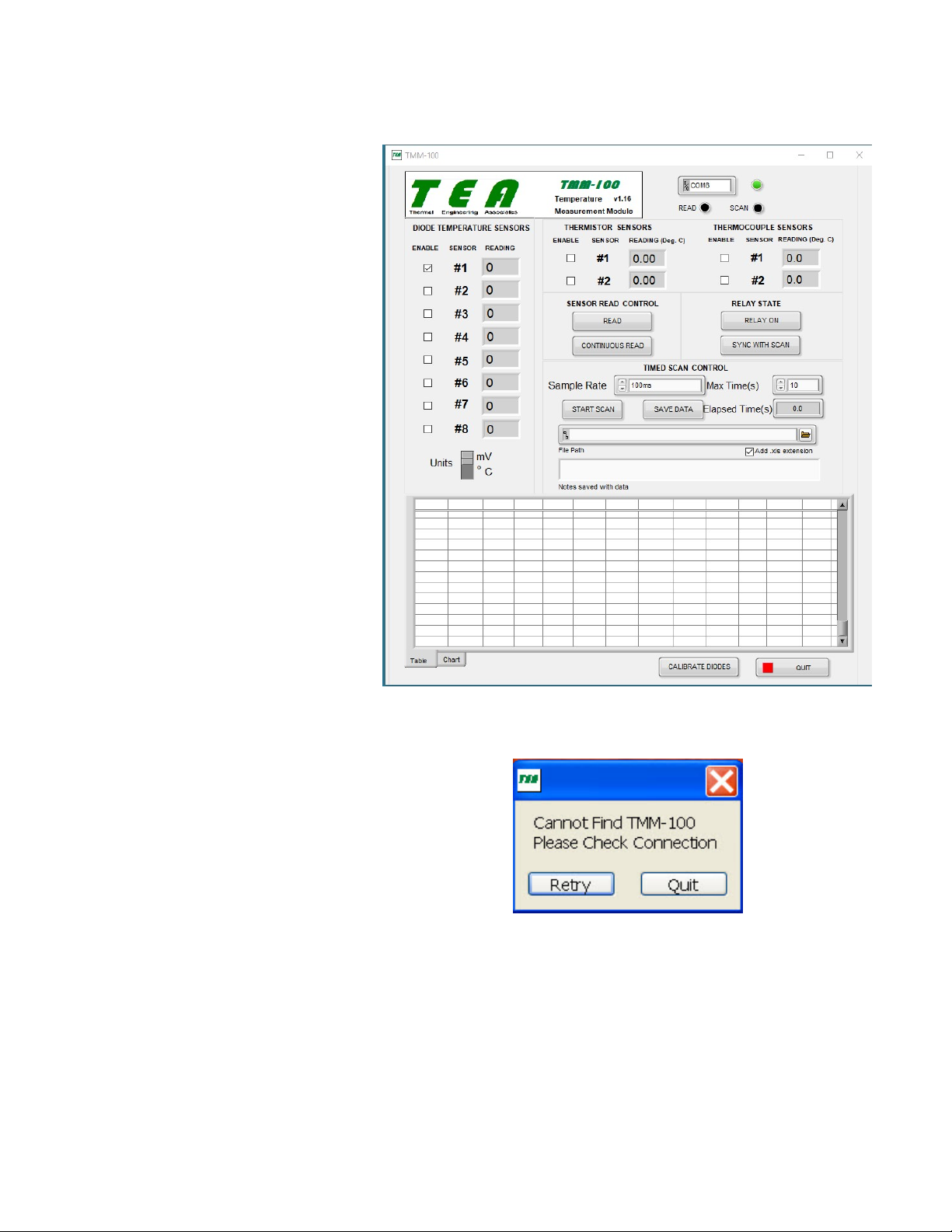

Once the TMM-100.exe file

has been started, the Opening

Screen shown in Figure 1 will

appear.

TMM-100_User_Manual_r4.doc Rev4

If the TMM-100 unit is already

connected to the computer,

the green indicator to the right

of the COM port box (near top

right of the screen) will turn

green and the connected COM

port number will appear in the

port box.

If the TMM-100 unit is not

plugged into the computer, the

indicator next to the COM port

box will be red and a message

box (see Figure 2-2) will ap-

pear. Plug the unit’s USB into

the correct computer port, wait

about 10 seconds, and then

click on the Retry button. After

a few more seconds, the con-

nection indicator will turn

green and the COM port ac-

tually used will appear in the

COM port box.

Figure 2-1 Opening Screen

Figure 2-2 Missing Module Message

The TMM-100 is now ready for use.

TMM-100 OPERATION

TEA

2-2

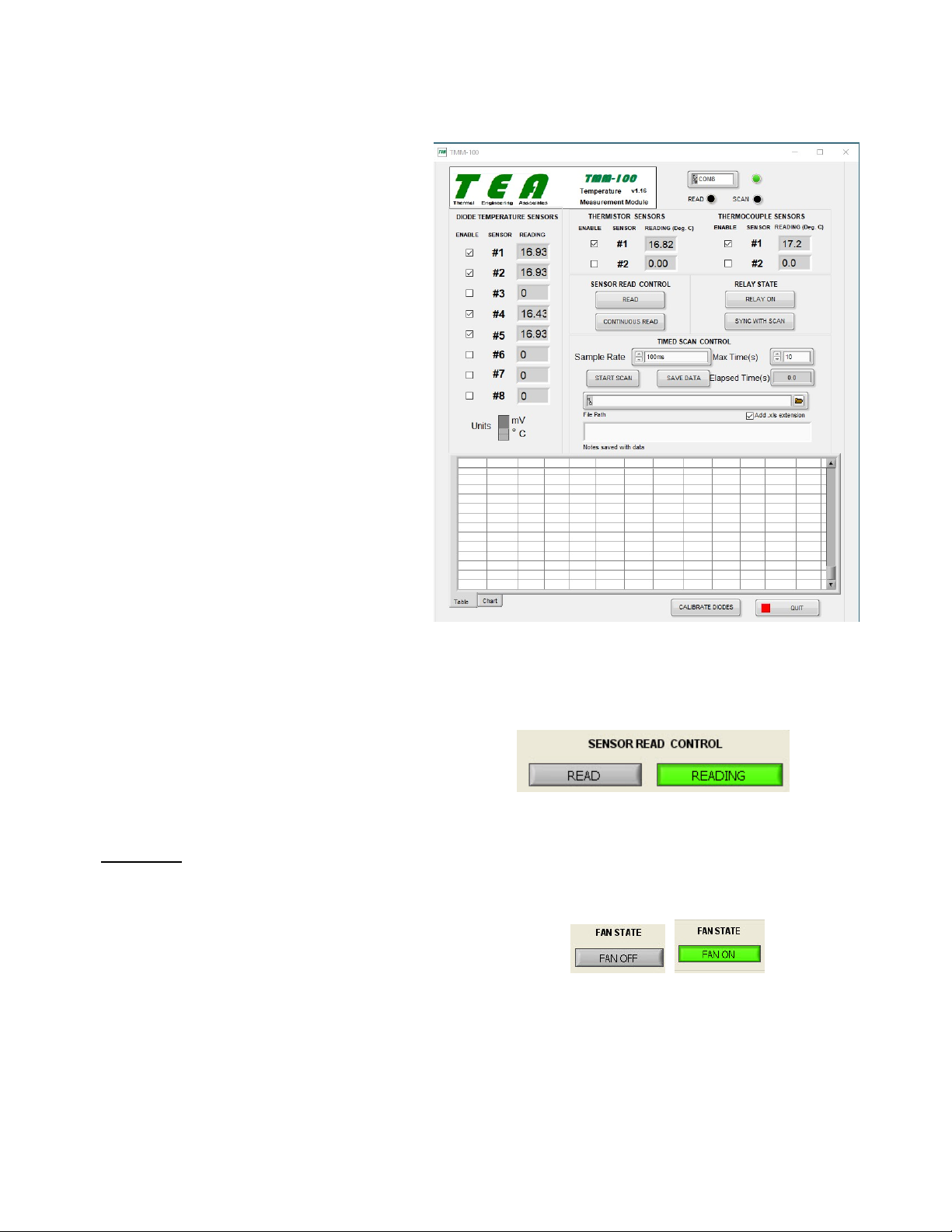

The TMM-100 Operating

Screen is divided into several

sections:

TMM-100_User_Manual_r4.doc Rev4

Communications Status

Located in the top right (see

Figure 2-1). This section con-

tains the COM port box and

COM port status indicator.

Immediately below are the

status indicators for data

READ and SCAN.

Sensor Selection

Down the left center are the

selection check boxes for Di-

ode Temperature Sensors

numbered 1 through 8. At the

bottom of the diode selection

is a slide to select between di-

ode readings in millivolts and

degrees centigrade.

Immediately below the unit

model number and name are

the Thermistor Sensor selec-

tion check boxes.

Figure 2-3 Sensor Selection

Under the Communications Status section is the Thermocouple Sensor selection check

boxes.

The data will only be read for those sensors that have check marks in their boxes, as shown

in Figure 2-3.

Sensor Read Control

Located in the center right portion of the screen, this second deals with the actual collection

sensor reading collection.

Clicking on the READ button, will cause a single data reading for each selected sensor. The

collected readings will appear in the data box to the right of the individual sensors.

If a sensor is not selected, its data box will contain a “0”, as shown in Figure 2-4.

TMM-100 OPERATION

TEA

TMM-100_User_Manual_r4.doc Rev4 2-3

The Diode Temperature Sensor data

is in terms of millivolts (mV) or de-

grees centigrade (ºC), as determined

by the slide control below the diode

selection column. In order for the di-

ode results to be in centigrade, the

diode voltage must be correlated to

temperature by clicking on the

CALIBRATE DIODES button near

the QUIT button at the bottom right

of the screen. The calibration proce-

dure is described below.

The data for both the Thermistor and

the Thermocouple Sensor is in terms

of ºC.

The CONTINOUS READ button is a

toggle type which is either OFF, as

shown in Figure 2-4 as a grey but-

ton, or ON, as shown in Figure 2-5

as a green button. Clicking on the

button will change the operational

state.

Figure 2-4 Sensor Read

Clicking on the CONTINOUS READ

button will cause the data for all the

selected sensors to be updated

every 100ms.

Figure 2-5 CONTINUOUS READ button

Fan State

Immediately to the right of the SENSOR READ CONTROL section is the FAN STATE sec-

tion. As shown in Figure 2-6, the but-

ton in this section toggles between

FAN OFF and FAN ON states. A relay

connection on the module’s rear panel

allows either for direct control of a

power supply for powering (≤50V, ≤0.75A) a measurement system fan or for providing a digi-

tal signal for fan control circuitry or other measurement environmental system.

Figure 2-6 FAN STATE button

TMM-100 OPERATION

TEA

TMM-100_User_Manual_r4.doc Rev4 2-4

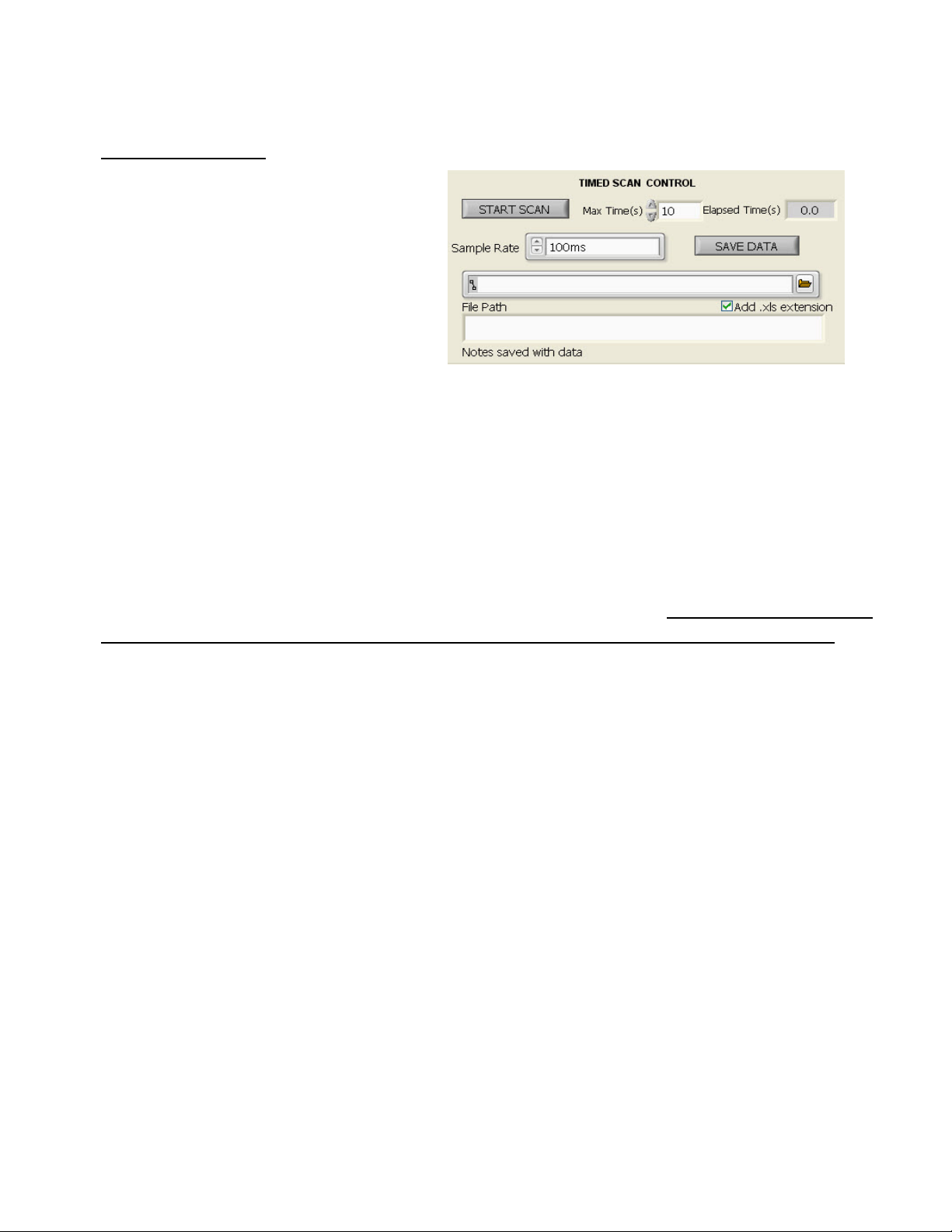

Timed Scan Control

This section is dedicated to the

controls required for collecting data

at a fixed sample rate over some

period of time. Clicking on the

START SCAN button begins the

collection of data from all the se-

lected sensors. When clicked, the

grey START SCAN turns into the

yellow ABORT SCAN button caus-

ing the scan operation to cease.

Figure 2-7 Time Scan Controls

In the top middle of the section is the control for setting the maximum time period from 1 sec-

ond to 10,000 seconds in steps of 1 second. The Max Time in seconds can be set by either

using the up/down arrows on the left of the time set box or by actually entering the max time

in the box. To the right of the setting box is an Elapsed Time indicator box to show where

within the max time the current data scan is.

The Sample Rate selection control has three fixed rates – 10ms, 100ms, and 1s – that can be

selected by clicking the up/down arrow on the left of the data box. The 10ms selection only

works when a single sensor (i.e.,either Diode, Thermistor, or Thermocouple) is selected. The

100ms and 1s selections will work for any combination of selected sensors.

Immediately below the Sample Rate control is the entry box for the datafile path and file-

name.

If the TMM-100 is running on a Windows XP Pro computer, then the full path and filename

must be entered here in order to save the data file.

If the TMM-100 is running on a Windows 7.X, 8.1 or 10 computer, then clicking on the

folder button to the right of the filename area brings up the Windows Save As dialog box

that allows for setting the path but the filename still have to be entered.

If the box is checked for Add .xls extension, then the datafile will be saved with the .xls

suffix. Otherwise, the filename is saved as a text file.

The Notes area is designed to accept up to 4 lines of entered alphanumeric information that

can be use to describe the measurement run operating conditions, information about meas-

urement samples, or other information.

The data, with Notes can be saved after collection by clicking the SAVE DATA button.

TMM-100 OPERATION

TEA

TMM-100_User_Manual_r4.doc Rev4 2-5

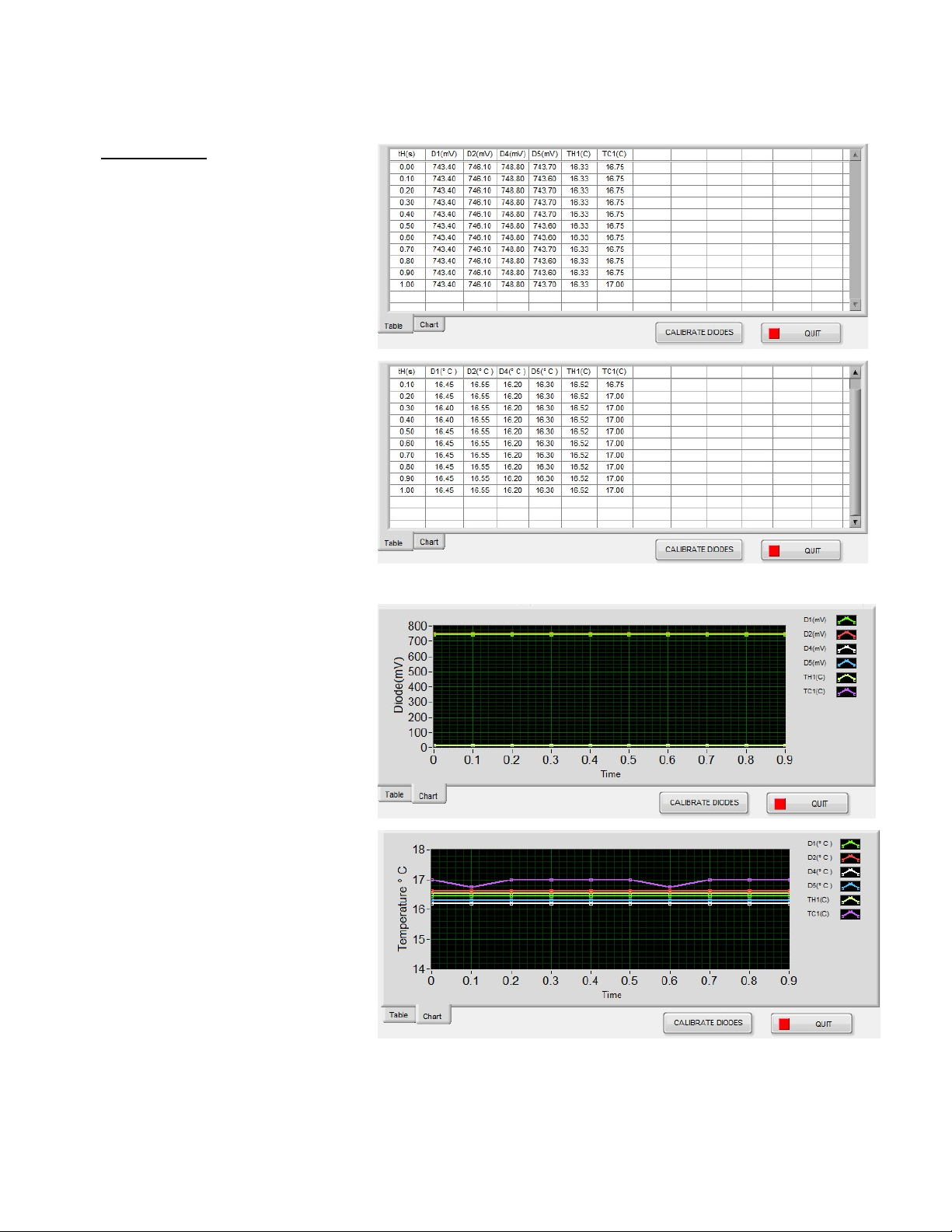

Data Display

In the TIMED SCAN mode,

the collected data is shown

near the bottom of the screen

in either tabular form, as

shown in Figure 2-8, or in

chart form, as shown in

Figure 2-9. The tabs at the

lower left of the data area are

for selection of either Table or

Chart mode.

Figure 2-8 Table Data Display

In the Table mode, the

heating time shown is in the

left-most column (tH(s)), with a

column header name for each

temperature sensor selected.

A few seconds after starting

the scan, data will appear in

the table on a row-by-row

basis. The last data collected

is shown on the last line. The

top table in Figure 2-8 shows

mV for each diode and ºC for

the thermistor and thermo-

couple sensors. Bottom table

shows ºC for all sensors if the

Units slide is in the ºC setting.

Figure 2-9 Chart Data Display

In the Chart mode, the

heating time remains in

seconds but the diode sensor

data is in mV or ºC depending

on the Units slide position.

The vertical scale minimum

and maximum values can be

changed by using the

computer cursor to highlight

the existing number(s) and

then typing in the desired number. The chart will automatically adjust to the new min/max

values.

TMM-100 OPERATION

TEA

TMM-100_User_Manual_r4.doc Rev4 2-6

Diode Calibration

In order for the diode temperature sensors to produce readings in units of ºC, the diode volt-

age must be correlated to temperature. The DIODE SENSOR CALIBRATION routine per-

forms this function. The steps to using this routine are as fol-

lows:

1) Determine which of the other sensors (either Thermistor or

Thermocouple) best represents diode junction temperature

when the diode and other sensor are in the same tempera-

ture ambient. For example, consider the case of a Thermal

Test Chip (TTC) diode sensor and a thermistor that is inte-

grated into heat sink mounted on top of the chip.

2) To insure that both the diode sensor(s) and reference sen-

sor (Thermistor or Thermocouple) are at the same tem-

perature, allow all sensor readings to stabilize (i.e., not

change) over some significant period of time period of time

(for example, 5 to 10 minutes). This can be done by select-

ing the appropriate sensors and then clicking on the CON-

TINOUS READ button described above.

3) Click on the CALIBRATE DIODES button below the data

area bottom right. This will bring up one of the calibration

screens shown in Figure 2-10, the top screen for a single

diode sensor and the bottom screen for multiple diode sen-

sors.

4) If a single diode sensor is being used, enter in the K Factor

(K) value for the diode in units of ºC/mV. (See Diode Temperature Sensing section in

Chapter 3.) For multiple diode sensors, individual K values can be entered or sensor #1

value can be used for all the sensors by checking the box in the lower left of the screen.

Figure 2-10 Diode Calibration

5) The reference temperature sensor used in step 1) above can be selected in the Ref 1

scrolling list. Typically, it is best use a thermistor as a reference because of greater accu-

racy compared to a thermocouple. The same reference sensor can be used for all the se-

lected diode sensors by checking the box in the lower left of the screen.

6) Once all the values have been entered and the appropriate boxes checked, clicking the

SAVE CAL DATA will write the information to a file that will be used whenever the TMM-

100 program is run.

TMM-100 OPERATION

TEA

TMM-100_User_Manual_r4.doc Rev4 2-7

To cease operation of the TMM-100 software, click on the QUIT button at the lower right of

the screen. The unit can be left connected (the front panel green indicator will remain on) to

the computer but will be inactive until the TMM-100 program is again loaded and run.

Exit Program

To cease operation of the TMM-100 software, click on the QUIT button at the lower right of

the screen. The unit can be left connected (the front panel green indicator will remain on) to

the computer but will be inactive until the TMM-100 program is again loaded and run.

TMM-100 APPLICATIONS

TEA

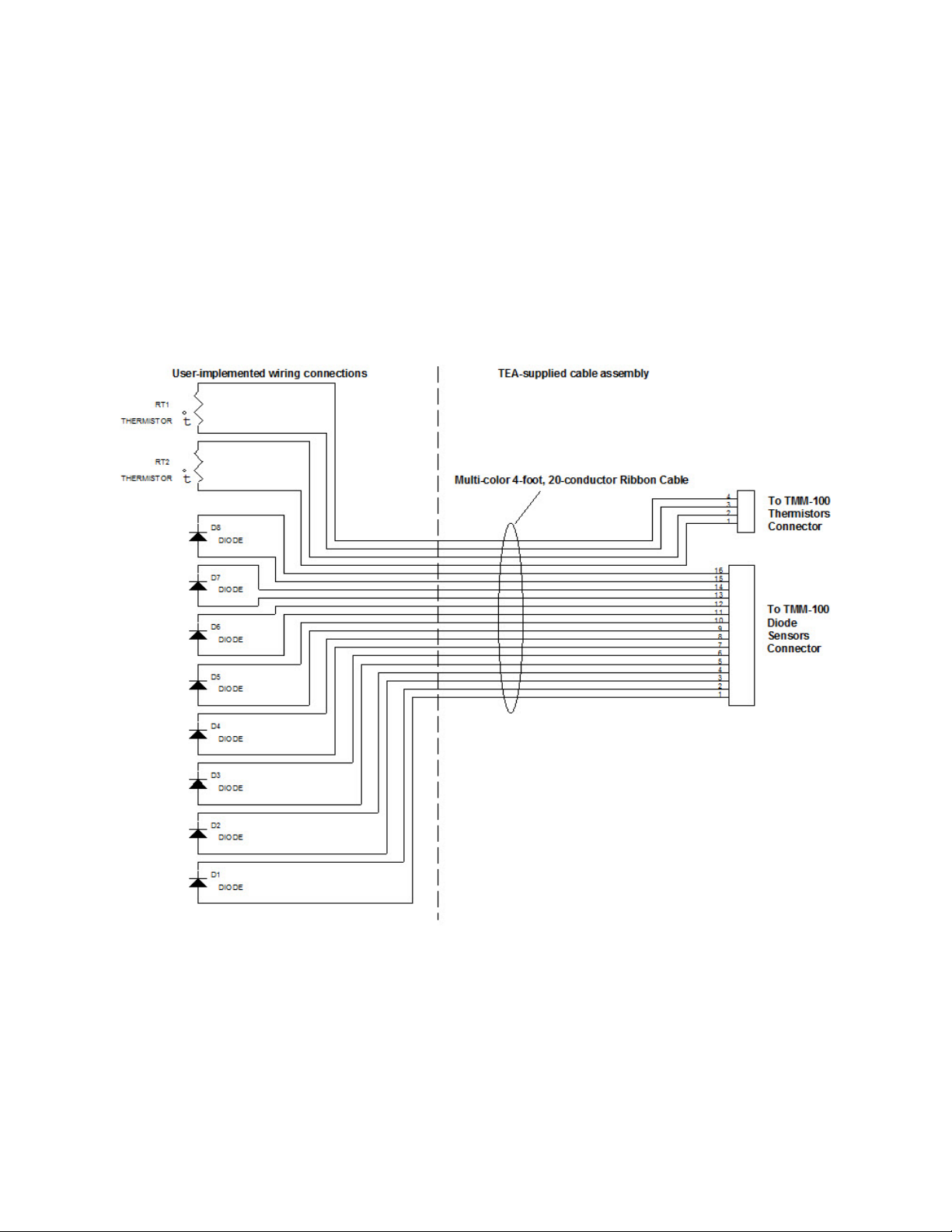

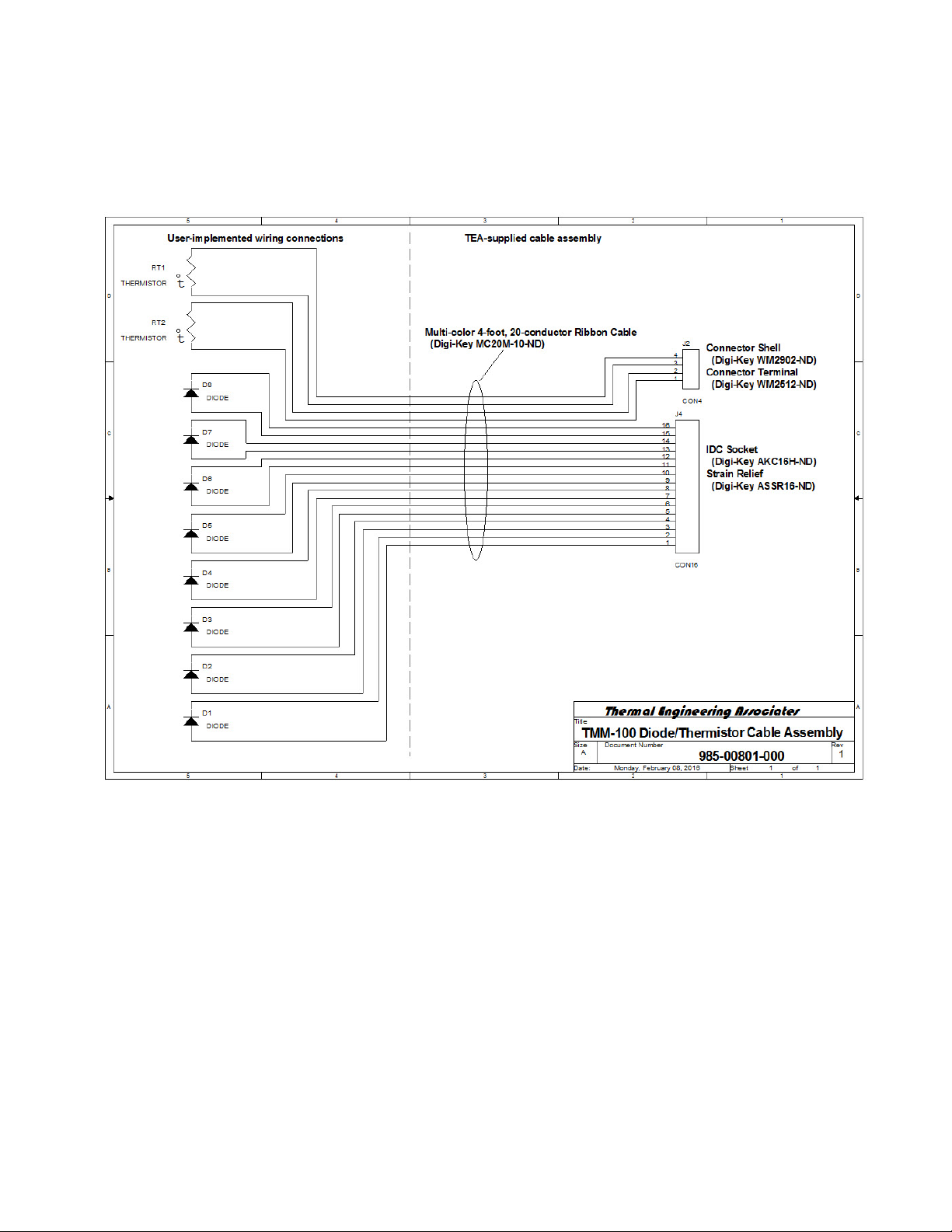

Electrical Connections

The TMM-100 unit is supplied with cables and thermocouples to facilitate user connection to

the various temperature sensors measured by the unit. The user is responsible for making

the electrical connection between the unit and sensors according to the schematic shown in

Figure 3-1.

Note: The supplied temperature sensor cable is rated for use in a

temperature environment below 105ºC.

The ribbon cable conductor color coding follows the standard numerical coding used for re-

sistors –

Figure 3-1

TMM-100_User_Manual_r4.doc Rev3 3-1

TMM-100 APPLICATIONS

TEA

TMM-100_User_Manual_r4.doc Rev3 3-2

Brown 1 Red 2

Orange 3 Yellow 4

Green 5 Blue 6

Violet 7 Grey 8

White 9 Black 0

For example –

For diode D1, anode connects to the first Brown conductor and cathode connects to first

Red conductor.

For diode D5, anode connects to the first White conductor and cathode connects to first

Black conductor.

For diode D6, anode connects to the second Brown conductor and cathode connects to

second Red conductor.

The TMM-100 is designed to used 10KΩ NTC (Negative Temperature Coefficient) thermis-

tors. A surface mount device, such as Murata NCP18XV103J03RB [Digi-Key part # 490-

6944-1-ND] or equivalent, is a small chip that can be mounted to a printed circuit board near

a heat source without impacting air flow.

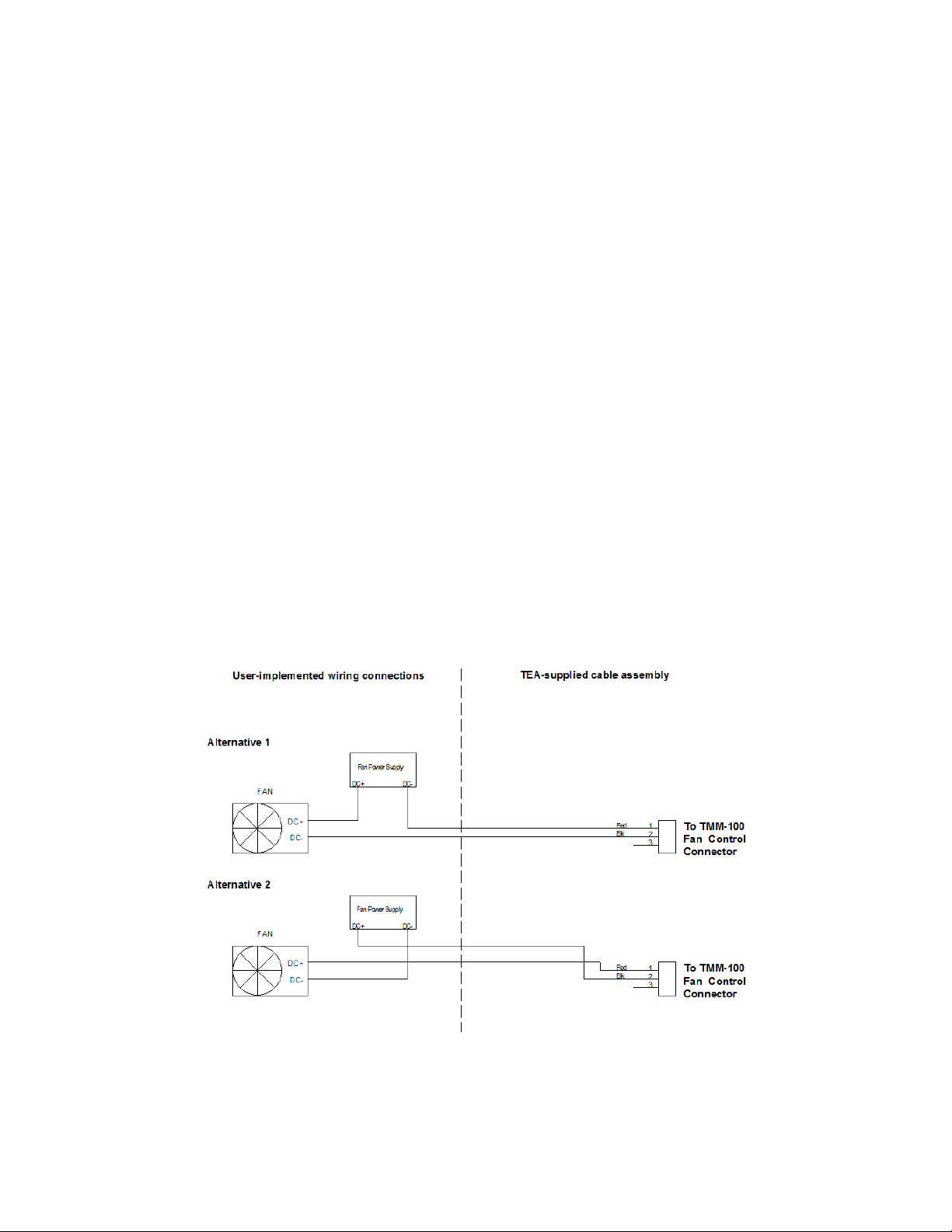

A Fan Control cable is also supplied with the TMM-100. Two alternative wiring configurations

are shown in Figure 3-2. The relay load capability should be limited to <50V and <0.5A.

Figure 3-2

TMM-100 APPLICATIONS

TEA

TMM-100_User_Manual_r4.doc Rev3 3-3

Diode Temperature Sensing

Temperature sensing can be done in either of two ways –

Absolute measurement which requires calibration of a specific diode voltage at a specific

measurement current against a known temperature, or a

Differential measurement which requires the difference between two diode voltage meas-

urements at a specific measurement current multiplied by the K Factor (see Tech Brief TB-

02) to calculate a temperature differential.

Because thermal measurements are typically based on temperature differentials, the latter

approach is typically used. K Factor values at a measurement current of 1mA for TEA’s

Thermal Test Chips are:

TTC-1001 0.5598ºC/mV

TTC-1002 0.5046ºC/mV

The TMM-100 supplies 1mA to each of the diodes connected and measures the voltage for

each of the diodes selected (see Figure 2-8). The diode voltage will decrease as the sensor

heats up. The diode voltage value at equilibrium before heating occurs minus the diode volt-

age at a specified time during the heating produces a voltage difference that is multiplied by

the K Factor to produce a temperature difference. For example using the TTC-1002 –

At equilibrium, VFlo = 0.724V

At some time after heat is applied, VFhi = 0.678V

Voltage difference = 46mV

Temperature change = 46mV x 0.5046ºC/mV = 23.21ºC

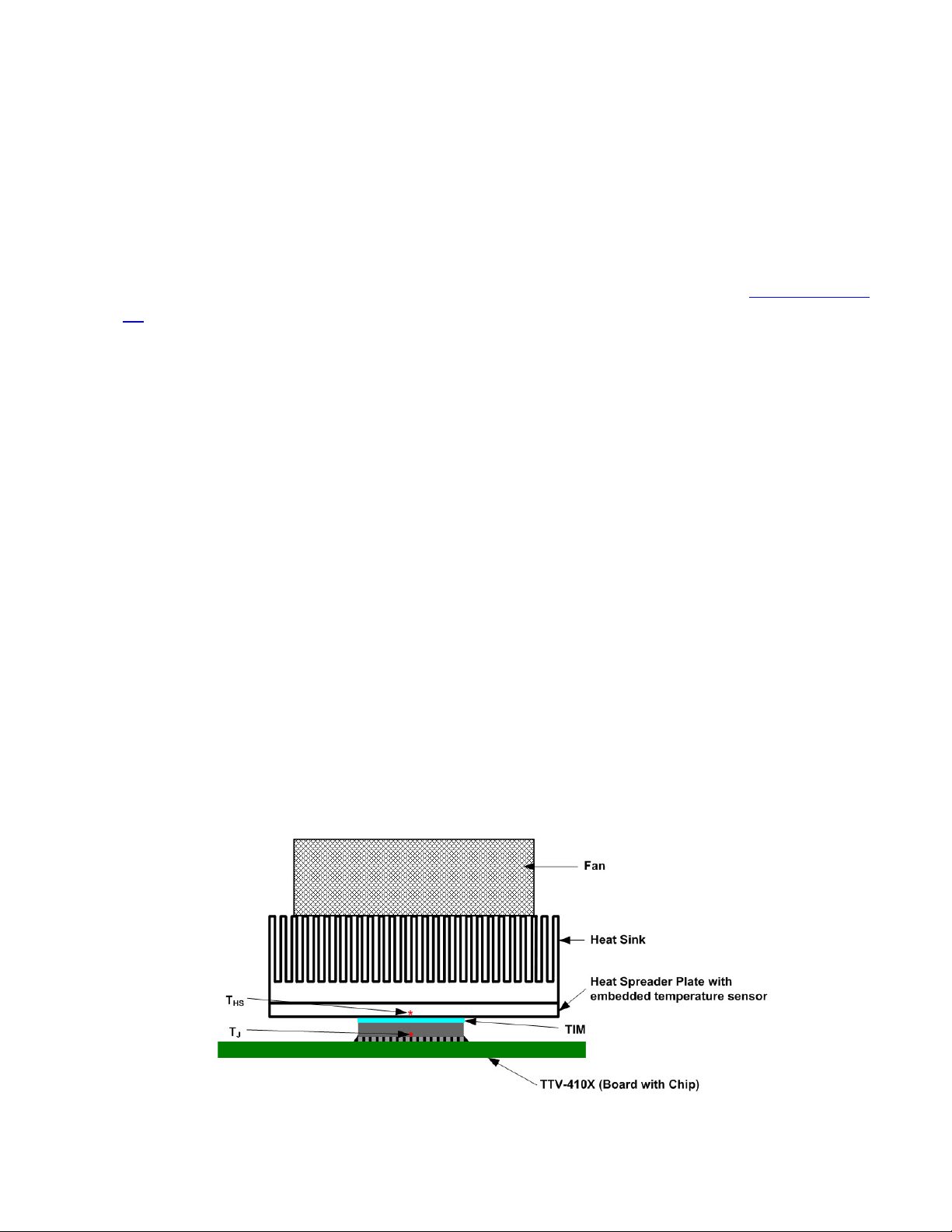

Example Measurement Procedure (TIM Application-Oriented Thermal Resistance)

1) Mount the heat sink solution, including the TIM, on the TTV-410X unit, as shown in Figure

3-3.

Figure 3-3

TMM-100 APPLICATIONS

TEA

TMM-100_User_Manual_r4.doc Rev3 3-4

2) Connect up the power supply and measurement equipment shown in the Apparatus

Setup.

3) Apply the 1.0mA Measurement Current to the diodes used for temperature measurement.

4) Wait for thermal equilibrium to occur - i.e., when the diode voltages stop changing - to re-

cord the diode voltage. Also record the Heat Sink temperature and the ambient tempera-

ture.

5) Apply power to the TTV Heating Resistors by setting the power supply to reach the de-

sired power level.

6) Monitor the diode voltage with the 1.0mA current applied until a steady-state condition has

occurred - i.e., when the diode voltages stop changing - to record the diode voltage and

the Heat Sink temperature.

7) Monitor the heat sink temperature until a steady-state condition has occurred - i.e., when

the diode voltages stopped changing - to record the heat sink temperature

8) Remove the power to the TTV Heating Resistors.

9) Calculate the Thermal resistance from Junction to Heat Sink as follows:

P

TTKVV HSiHSfDfDi )()(

ΘHSJ

ºC/W

where:

VDi and THSi are from step 4

VDf and THSf are from steps 6 and 7

P is from step 5 recorded just before step 6 readings

K is the K Factor value - either the nominal value shown in the TTC Application Manual

(http://www.thermengr.net/TTC/TTC_Manual_R7.pdf) or calibrated as described in the man-

ual (see Chapter 3).

TMM-100 INSTALLATION

TEA

TMM-100_User_Manual_r4.doc Rev3 4-1

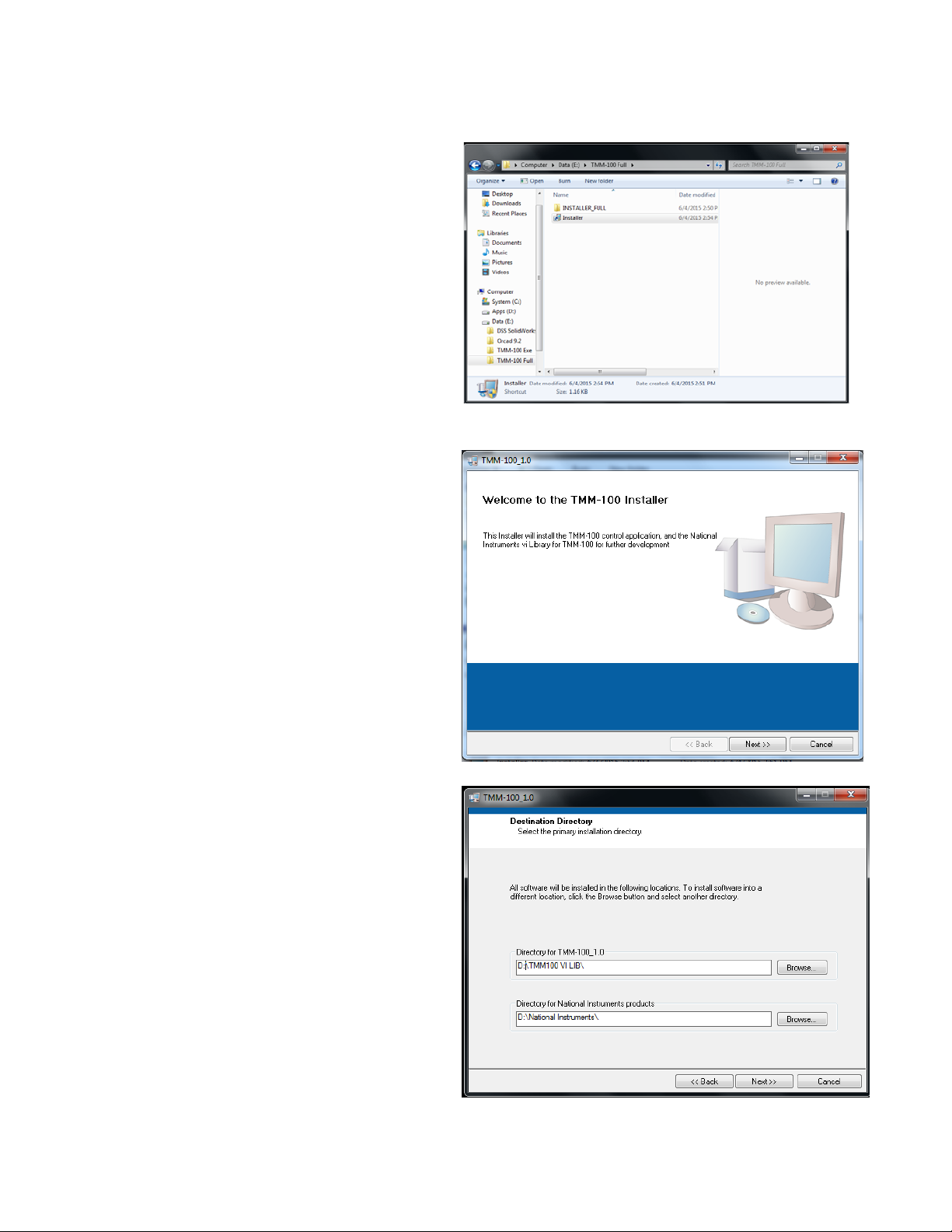

The software for installing and running

the TMM-100 is supplied on a USB

Flash Drive. The steps for installing the

software on Windows 7.x or Windows

8.x operating system computer is de-

scribed below.

Step 1. Connect the supplied USB Ca-

ble into the TMM-100 rear panel; DO

NOT plug the other cable end into the

computer’s USB port.

Step 2. After starting the computer, in-

sert the USB Flash Drive into the sys-

tem.

Step 3. Use Windows Explorer to open

the flash drive directory, as shown in

Figure 4-1.

Step 4. Select “Installer” and double-

click to run the program. The window

shown in Figure 4-2 will appear. Click

Next button to proceed.

Step 5. The next window, shown in Fig-

ure 4-3, shows the destination directo-

ries for both the TMM-100 software and

the National Instruments support files.

The operating system will automatically

determine the location and name of

these directories. The user can either

accept the directories presented or

change them to suit specific require-

ments. Click Next button to proceed.

Fig

ure 4.1

Figure 4-2

Figure 4-3

TMM-100 INSTALLATION

TEA

TMM-100_User_Manual_r4.doc Rev3 4-2

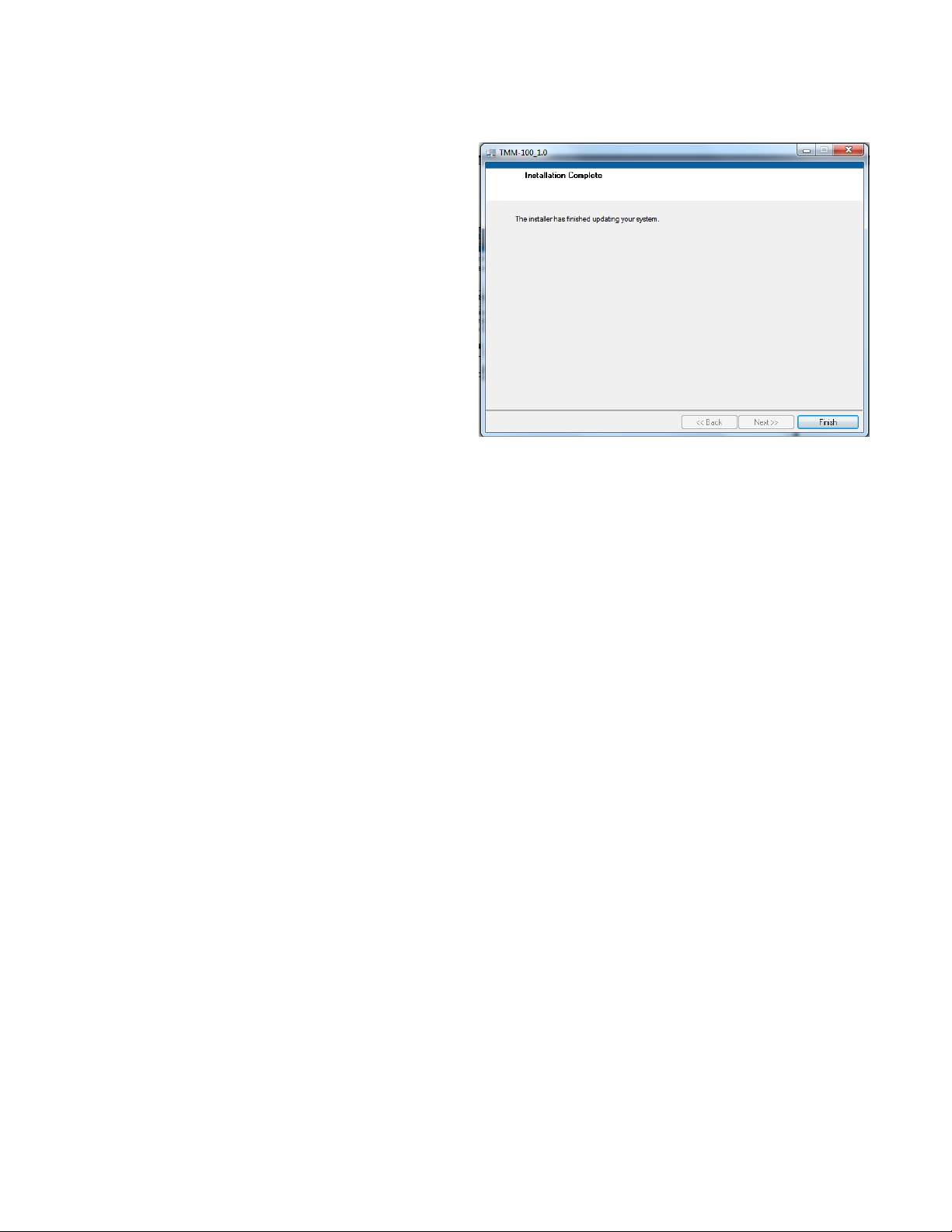

Step 6. The next window that appears,

see Figure 4-4, provides a list of files to

be loaded and/or changed. Unless

changes are required, click Next button to

proceed.

The software will then be installed. One or

more information boxes may appear

showing installation progress.

Step 7. When the software installation is

complete, the final window, see Figure 4-

5, will appear. Click Next button to pro-

ceed. Figure 4-4

Step 8. With the installation complete, the last step is to create a desktop icon for easy ac-

cess to the TMM-100 software. Follow the procedure normally used to create a desktop icon.

The TMM-100 can now be connected to the computer. Plug the cable into a computer USB

port and open the TMM-100 software.

TMM-100 Accessories

TEA

Diode/Thermistor Cable Assembly (TEA PN: 985-00801-000)

Thermocouples (TEA PN: 680-00002-001)

Type-T #36 gauge 3-feet long (Omega Engineering (SC-TT-T-36-36)

TMM-100_User_Manual_r4.doc Rev3 5-1

Table of contents

Other TEA Measuring Instrument manuals