Teagle Telehawk User manual

Telehawk Quick Start Guide page 1

A

C

B

D

E

TELEHAWK

QUICK START GUIDE

ATTACHING POWER

CABLE AND HOSES TO

THE TELEHANDLER

Connect the curly cable multi-plug into

the boom bracket socket. Connect the

feed and return hoses on the telehandler

making sure the ow direction is correct.

When you connect the junction box plug

in, you should hear a “click” from the

machine which tells you it has power.

HOW TO GET THE BEST FROM YOUR TELEHAWK

2

FITTING THE CONTROL BOX

IN THE CAB & BLUETOOTH

The control box is supplied with a suction

cup attachment. This should be tted in the

cab in a suitable position that is convenient

to the operator on a smooth, clean dust

free surface.

The control box requires a 12v supply and

is shipped with a cigarette lighter plug as

standard. If the supply cable is connected

with the wrong polarity the control box will

not switch on.

Plug in the control box in the cab. Once the

bluetooth light has stopped ashing and is

illuminated bluetooth is paired and you are

ready to proceed.

INITIAL START

Set the oil owing with the loader at low revs

and the fan will instantly start to spin. Note: To

stop the fan motor, you will need to stop the

hydraulic oil ow. Press the“power on” button

when the bluetooth is illuminated. Check

chute rotation & deector functions work.

CROSSBEATER /

BED FORWARD

Press the working button to start

the crossbeater and bed chain. If the

bed chain is set to ‘0’ the bed should

be stationary. Pressing this button

again will stop the bed chain and

crossbeater.

Stopping the bed will not stop the

fan. To do this the hydraulic ow

must be cut o.

BED CHAIN SPEED

The bed chain speed can be varied

in the cab by twisting the dial

independently of the crossbeater

speed. If the bed is rotating when the

dial is set to “0”, then you need to re-

calibrate the bed speed (see page 20

of the manual).

CROSSBEATER

BED REVERSE

To reverse the machine at any time

press the “crossbeater & bed chain

unloading” button.

SEE THE MANUAL FOR

MORE INFORMATION

ON PAIRING THE DEVICES.

C

D

E

FITTING THE

TELEHAWK ONTO

THE LOADER

Make sure the appropriate loader

brackets are central and secure. Attach

the Telehawk to the loader headstock

engaging the locking mechanism

to prevent the machine detaching.

Carefully crowd up and check there is

clearance between the fan motor cover

and headstock.

1

A

B

Telehawk Quick Start Guide page 2

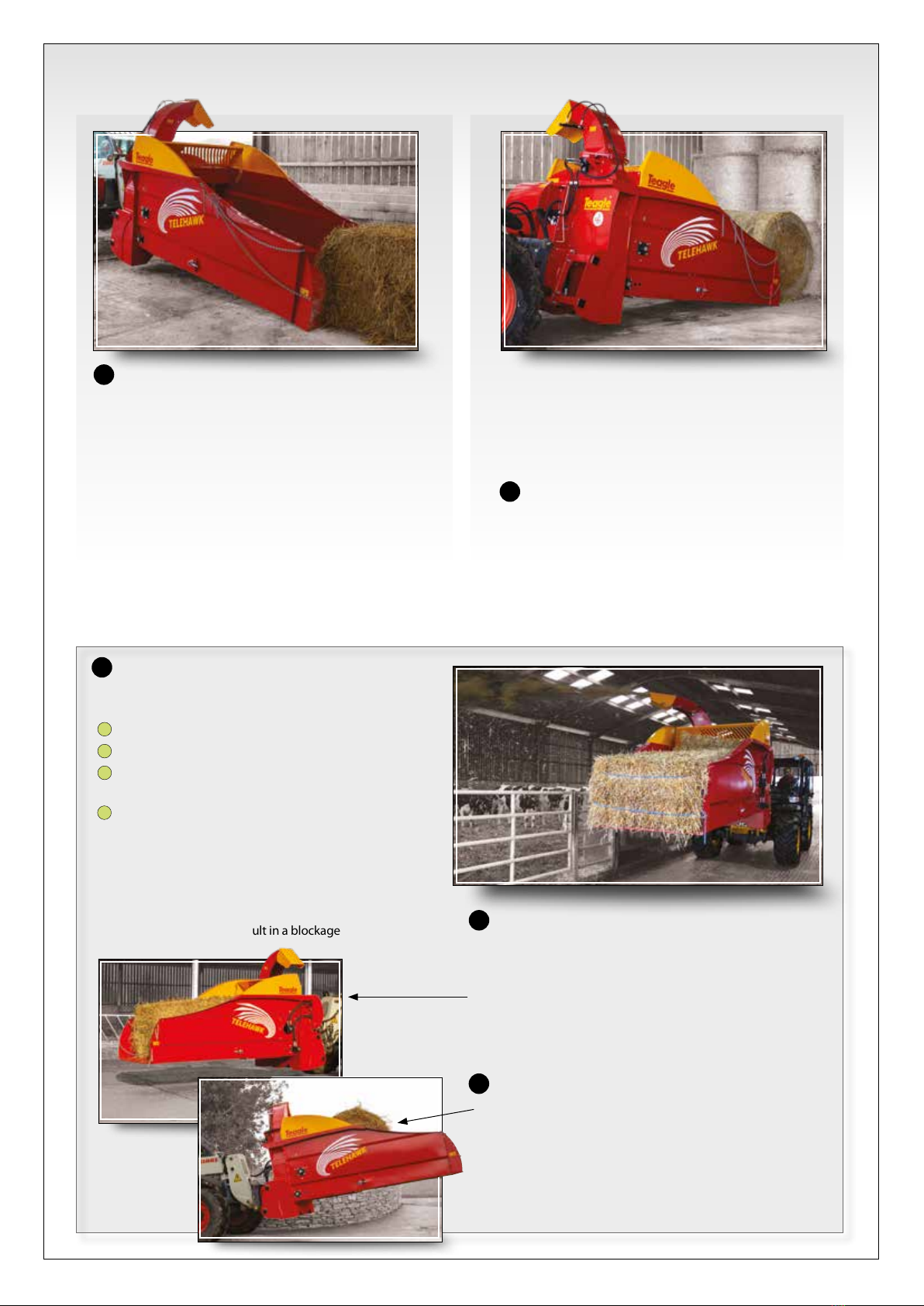

The strings or net should be removed from the bale

before spreading, if they are not removed they will wrap

around the crossbeater. Putting twine or netwrap through

the machine is not recommended as it will eventually be

spread on the land, polluting future crops.

Loading rectangular bales: If you are using a loader with the

driver positioned to the left hand side of the loading boom

and loading direct from a stack of bales. We recommend

starting from the right hand side of the stack and working

to the left. This enables the driver to see the gap between

two bales. Once the end of the bale is inside the Telehawk,

slightly lift the bale and continue driving until the bale is

3

ROUND BALES

With a round bale in the chamber make sure that the bed

chain is inclined at 5°. To maximise performance for round

bales, keep the machine slightly angled upwards and keep

the bed speed on a setting of approx. 5. This will keep the

round bale tumbling. Stripping a thin layer of straw from the

bale with each rotation is the most ecient way.

7

in the machine. Do not force the bale into the crossbeater.

This will cause the machine to go into unblocking mode

once the crossbeater is engaged. Place the chains around

the rear of the bale. Cut and remove the strings.

For easy removal of the strings place the bale on its side so

that the strings are not in contact with the oor.

Loading round bales:

To load round bales drive the

machine forwards forcing the front lip under the bale. Place

the chains around the rear of the bale. Cut the strings /

netwrap on the bale as low as possible on the crossbeater side

of the bale. Crowd the machine rolling the bale into the bale

chamber before removing the strings / netwrap completely.

SQUARE BALES

To maximise performance for square bales, keep the

machine horizontal. This allows the rst section of bale to

rotate freely within the bale chamber. The speed of the bed

chain will require adjustment according to the quality of the

bale. For brittle wheat bales a higher speed of 6 to 8 can be

achieved. For longer damp material a slower speed of 3 to 5

is recommended.

6

With both parts of the electronics connected via

bluetooth, switch the control box ON (making sure the

bed chain dial is set to ’0’). Start the following sequence:

Engage the spool valve on the loader.

Wait for the discharge rotor to rotate at working speed.

Rotate the chute and adjust the deector to give the

desired spread direction and distance.

Start the bed chain and cross beater by pressing the bed

chain working button. Spreading will now start. Once the

straw has cleared, increase the bed speed to the desired

feed rate.

It is important to ensure that the fan motor is turning

at full working speed before engaging the bed chain.

Failure to do so is likely to result in a blockage.

4

5

LOADING THE MACHINE

SPREADING MATERIAL/PERFORMANCE

1

2

3

4

Telehawk Quick Start Guide page 3

SPREADING

MATERIALPERFORMANCE

Once you have spread the rst part of the bale. We

recommend stopping the crossbeater before crowding

up the Telehawk to allow the next part of the bale to fall

onto the bed chain. Once the straw has fallen onto the bed

chain. The machine can be levelled out and the crossbeater

and bed chain re-started.

If spreading wet or poor quality bales it may be an

advantage to stop both the crossbeater and bed chain

before inclining the machine.

Do not force bales against the crossbeater by inclining the

body steeply while spreading. This may cause a blockage

and could also damage the machine.

If you are moving from one shed to another. We suggest

stopping the bed chain by turning the speed to zero and

then stopping the crossbeater. Before starting again, make

sure the fan is running at normal speed then re-engage the

crossbeater. The bed chain speed can then be increased.

The length of material will vary with the condition of

the bale. Fresh clean straw will tend to result in a longer

material whereas old, slightly damp, weathered or matted

bales will tend to have a shorter length. The power

consumption will also vary with the material being spread.

In general damp or matted straw will require a relatively

high power input.

8

REVERSE TIME

Generally, the taller the bale in the chamber, the longer the

reverse time of the bed chain is required. The reverse time

can be increased by pressing the increasing reverse time

button and decreased using the decreasing button.

Guidance table: (LED lights on control box)

Round bales ........................................................ 2 lights

Rectangular (quadrants) bales....... 2 or 3 lights

Rectangular (hesston) bales ............ 3 at rst, 4 lights

.............................................................. 2nd half of bale

PRESSURE SWITCH

The machine is tted with a pressure sensing system

to prevent the fan being overloaded. This works

automatically by briey reversing the crossbeater and

bed chain, this is called the reversing time. The reversing

time can be altered on the control box in the cab. The

pressure sensor setting can be altered on the side of the

machine. The factory setting is 100 bar (1450psi).

The pressure at which the bed chain reverse movement

is triggered can be varied by rotating the knob on the

outside of the rotor housing. We recommend a starting

setting of 100bar. The higher oil ow rate the higher

the pressure setting. With a higher oil ow loader the

fan is rotating at a higher speed, hence the fan can

spread more straw. With a lower oil ow loader the fan

is rotating slower, hence can be more easily blocked. To

avoid this the pressure switch needs to be set lower.

If the pressure switch is set too high you can easily block

the fan. If the pressure switch is too low the machine

will keep going into automatic reverse and take a long

time to spread the bale (bleed the pressure switch if the

machine goes into reverse at random times).

9

10

Telehawk Quick Start Guide page 4

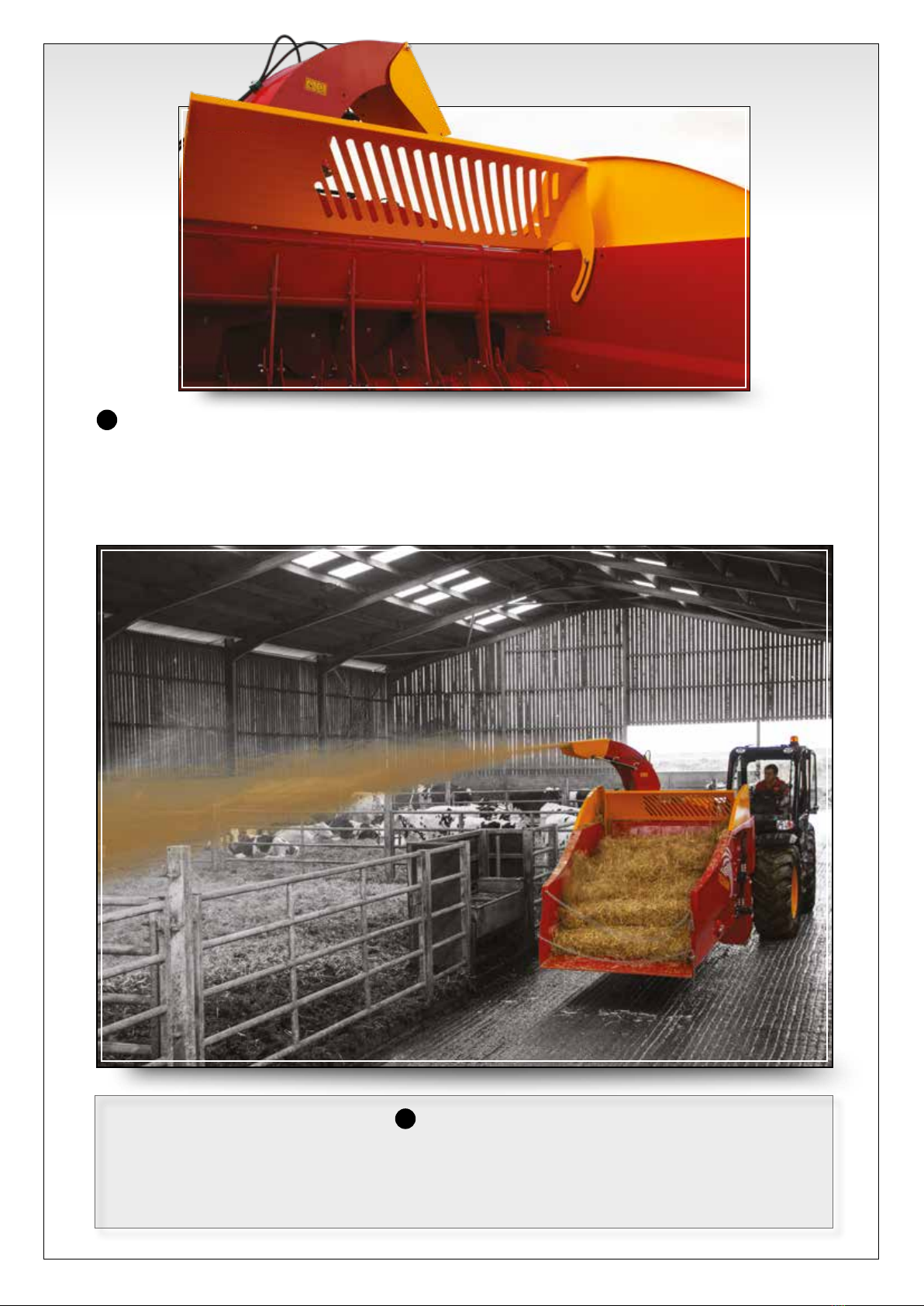

BALE RESTRAINT

The position of the bale restraint has an important role on

how much of the bale is exposed to the crossbeater. The closer

the bale restraint is to the fan motor the more straw will ow

through the machine. If you have damp, matted bales we

suggest moving the bale restraint away from the fan of the

11

machine and slowing the bed speed down.

To adjust the bale restraint beam remove the three M12 bolts

located in the holes on both sides of the restraint beam, and

loosen the fourth bolt in the slot. Reposition the bale restraint

beam by aligning the necessary holes, replace and tighten bolts.

PERFORMANCE

The blow distance is dependant upon a number of factors. The main factor is the ow of oil to the fan motor. The higher the oil

ow the greater the blow distance. Keeping the fan motor spinning at high speed is important. Other factors include bed chain

speed, bale restraint position, bale condition and material type.

Higher output is achieved by a rapid tumbling action of the straw on the bed chain.

12

Other manuals for Telehawk

2

Other Teagle Spreader manuals

Popular Spreader manuals by other brands

Blizzard

Blizzard ICE CHASER 78903 installation instructions

Douglas Dynamics

Douglas Dynamics SnowEx HELIXX 1.5 yd3 installation instructions

Neilsen

Neilsen CT2206 Instruction & assembly manual

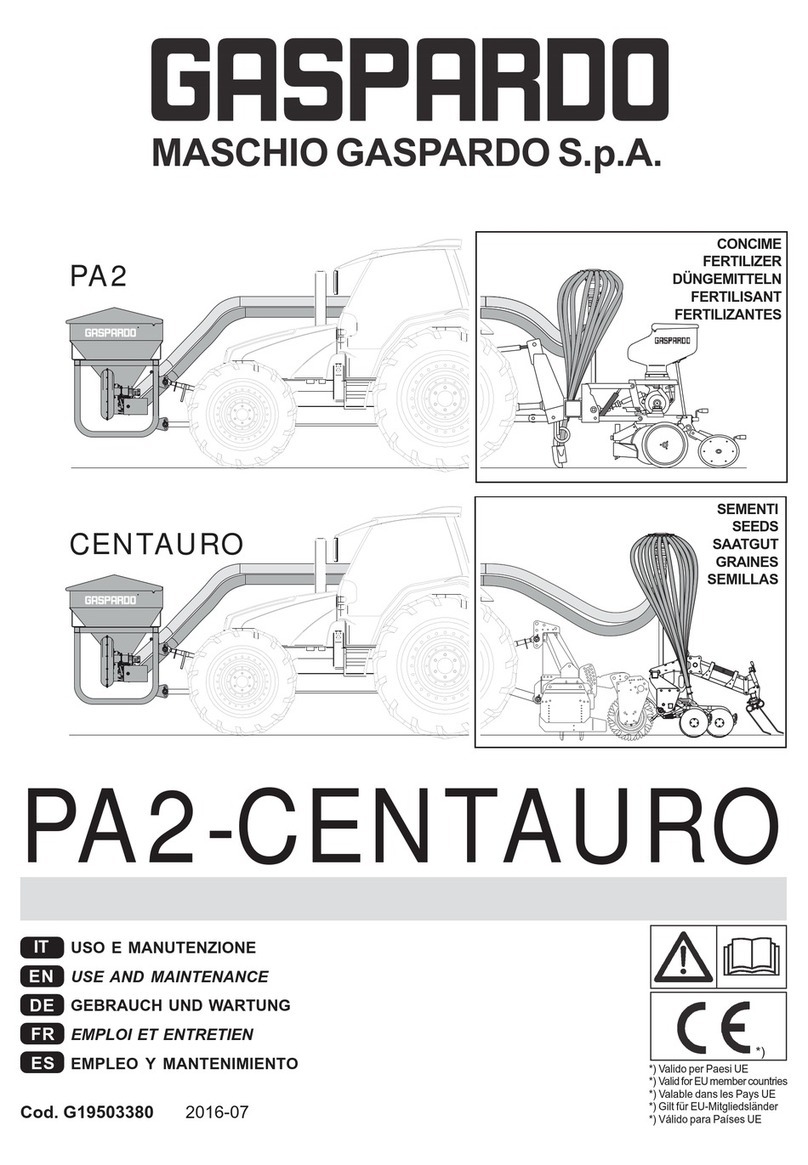

Gaspardo

Gaspardo PA2 Use and maintenance

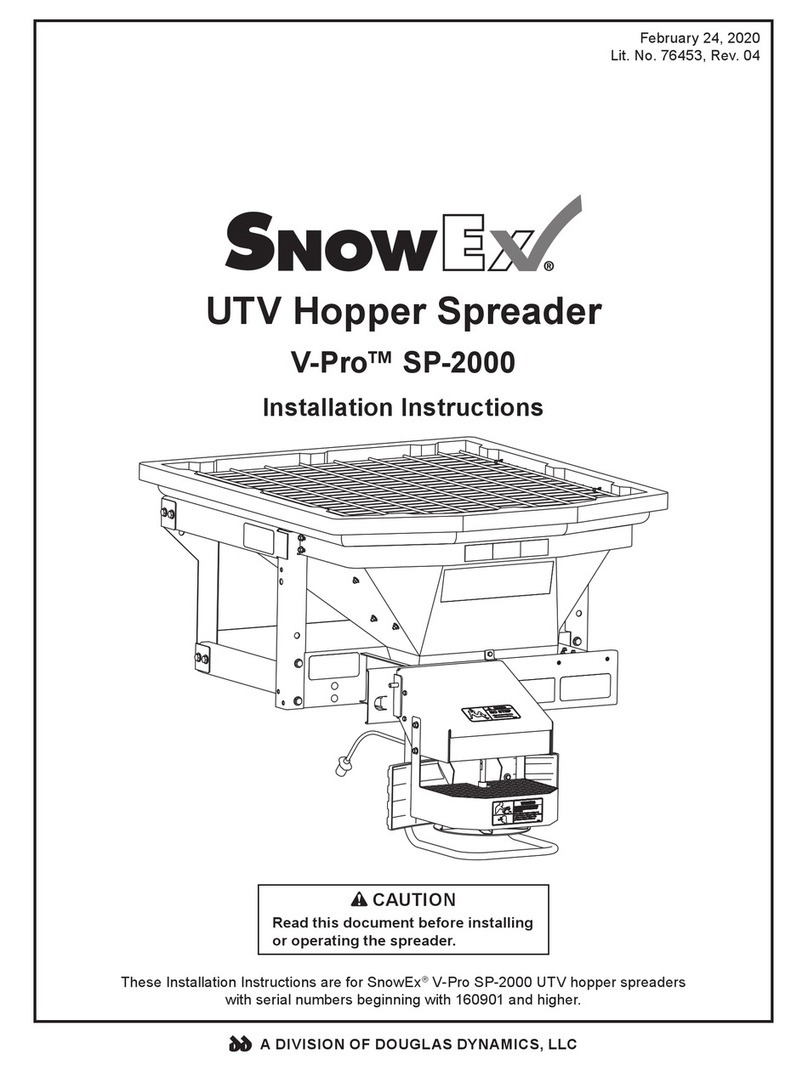

Douglas Dynamics

Douglas Dynamics SnowEx V-Pro SP-2000 installation instructions

LEHNER

LEHNER SuperVario operating manual