TABLE OF CONTENTS

1. UNPACKING ...........................................................................................1- 1

1.1 Procedures ......................................................................................1- 1

1.2 Checks.............................................................................................1- 1

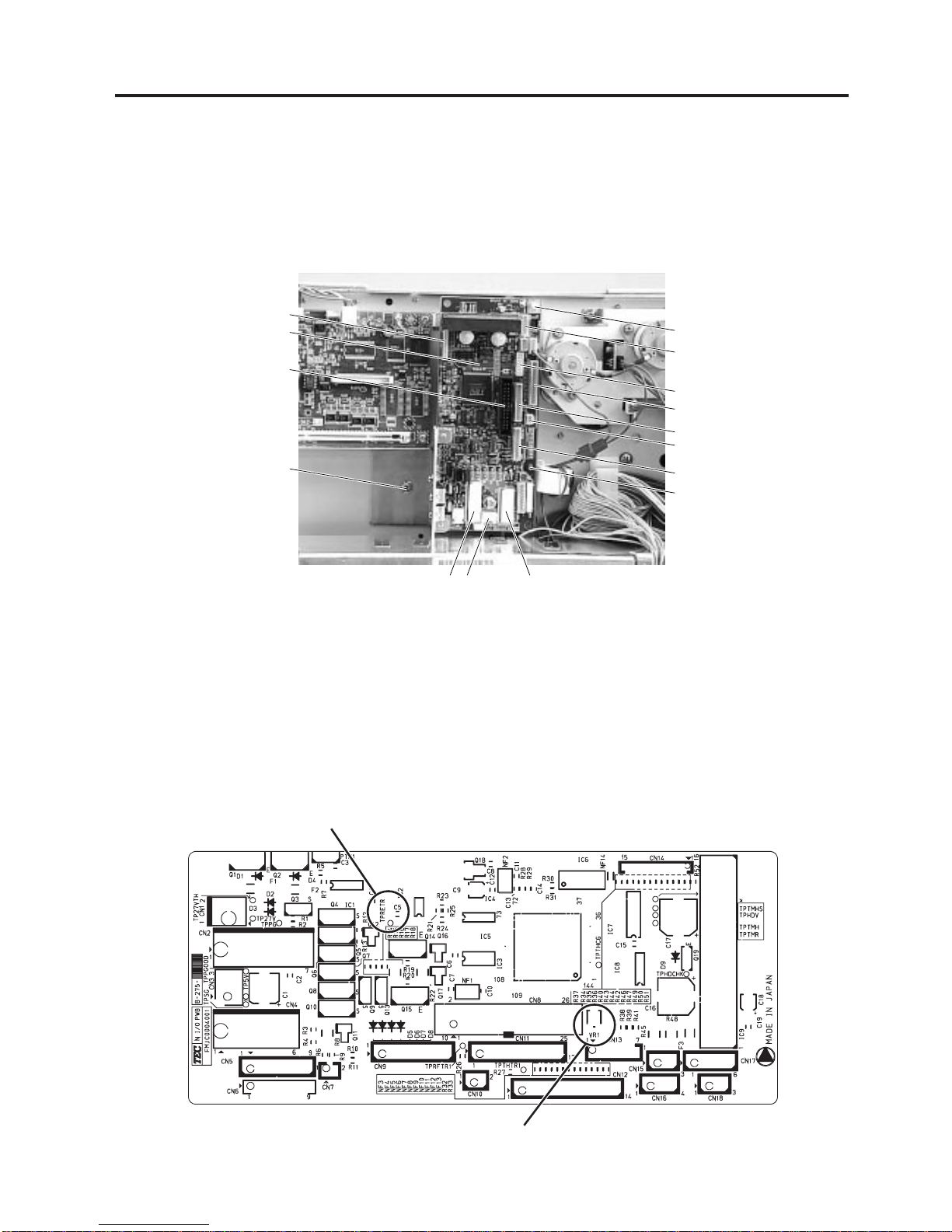

2. MAJOR UNIT REPLACEMENT ..............................................................2- 1

2.1 Replacing the PS Unit .....................................................................2- 2

2.2 Replacing the CPU PC Board .........................................................2- 3

2.3 Replacing the Centronics I/F PC Board...........................................2- 4

2.4 Replacing the I/O PC Board ............................................................2- 5

2.5 Replacing the Stepping Motor .........................................................2- 6

2.6 Replacing the Ribbon Motors ..........................................................2- 7

2.7 Replacing the Solenoid (QP Model only).........................................2- 8

2.8 Replacing the Print Head................................................................2- 10

2.9 Replacing the Platen and Feed Roller............................................2- 11

2.10 Replacing the Paper Sensor...........................................................2- 13

2.11 Replacing the Ribbon Back Tension Block.....................................2- 14

2.12 Replacing the Pinch Roller Shaft Ass'y ..........................................2- 15

2.13 Correcting Skew Printing ................................................................2- 17

3. INSTALLATION PROCEDURE FOR THE OPTIONAL EQUIPMENT ....3- 1

3.1 PCMCIA PC Board (B-8700-PC-QM)..............................................3- 1

3.2 EXP I/O PC Board (B-8700-IO-QM) ................................................3- 4

3.3 Cutter Module (B-4205-QM) ............................................................3- 6

3.4 Ribbon Saving Module (B-4905-R-QM)...........................................3- 8

3.5 Strip Module (B-4905-H-QM)..........................................................3- 10

3.6 Fanfold Paper Guide Module (B-4905-FF-QM) ..............................3- 13

3.7 Cutter Module (B-8204-QM) ...........................................................3- 14

4. TROUBLESHOOTING.............................................................................4- 1

5. DIAG. TEST OPERATION.......................................................................5- 1

5.1 Outline of the Diag. Test Operation .................................................5- 1

5.2 Self Test Mode ................................................................................5- 3

5.3 Parameter Setting Mode.................................................................5- 14

5.4 Test Print Mode ..............................................................................5- 53

5.5 Sensor Setting Mode ......................................................................5- 60

5.6 RAM Clear Mode ............................................................................5- 65

5.7 IP Address Setting Mode................................................................5- 70

5.8 BASIC Setting Mode.......................................................................5- 72

EO18-33004

(Revision Date: Dec. 14, 2001)

Page