TABLE OF CONTENTS

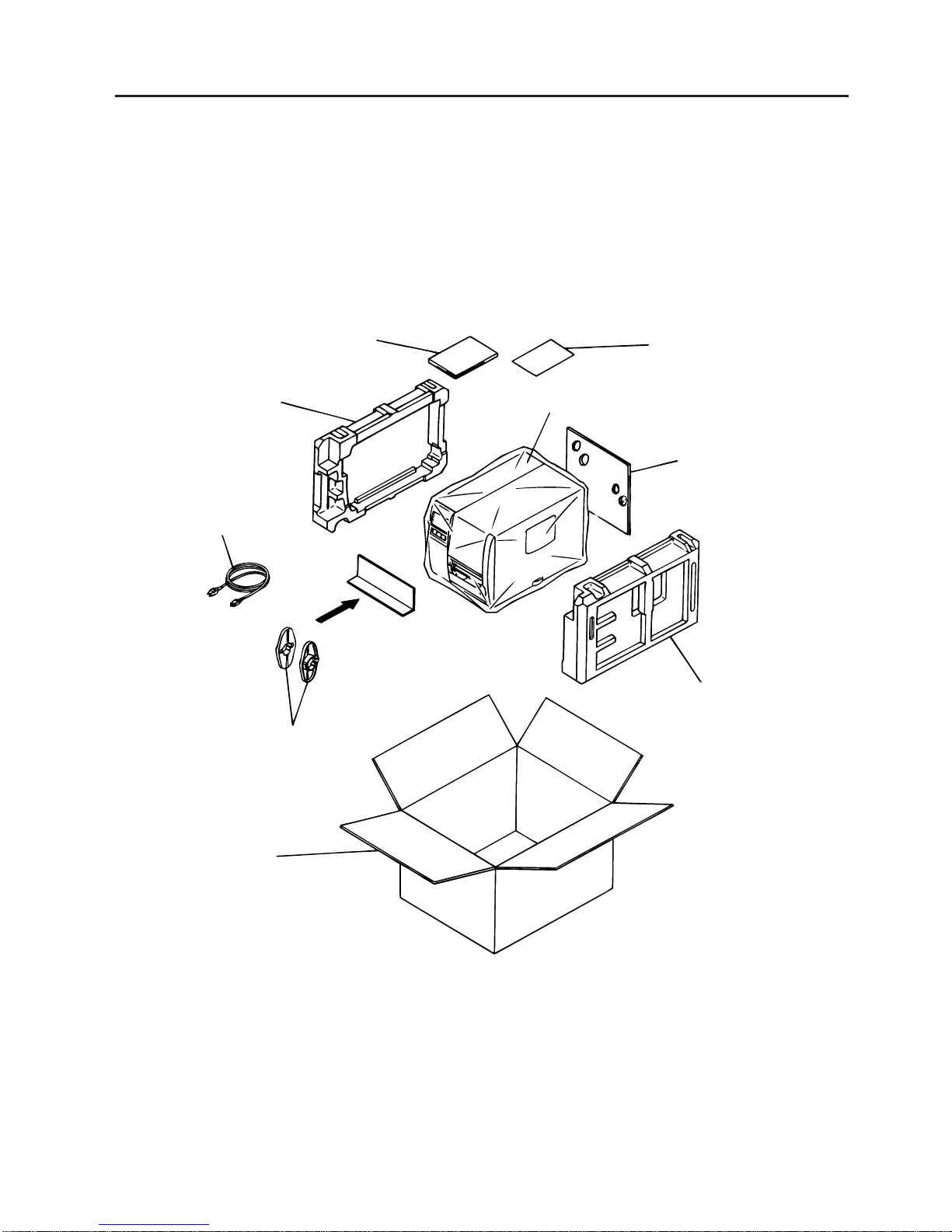

1. UNPACKING ...........................................................................................1- 1

1.1 Procedures ......................................................................................1- 1

1.2 Checks.............................................................................................1- 1

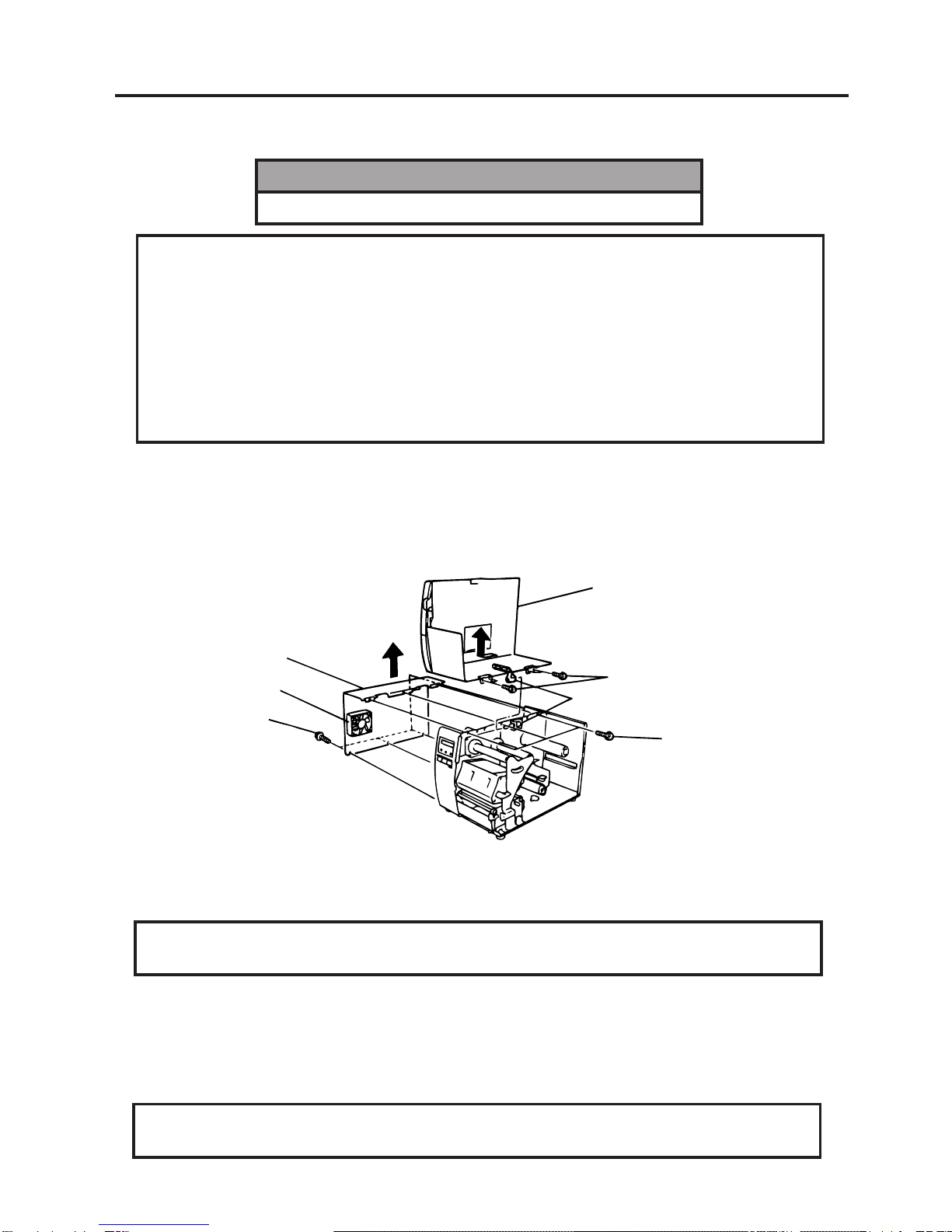

2. MAJOR UNIT REPLACEMENT ..............................................................2- 1

2.1 Replacing the PS Unit, I/F PC Board and CPU PC Board ..............2- 2

2.2 Replaceing the Stepping Motor .......................................................2- 4

2.3 Replacing the Ribbon Motors ..........................................................2- 5

2.4 Replacing the Take-up Motor ..........................................................2- 5

2.5 Replacing the Solenoid....................................................................2- 7

2.6 Replacing the Print Head.................................................................2- 8

2.7 Replacing the Platen and Feed Roller............................................2- 11

2.8 Replacing the Paper Sensor...........................................................2- 13

2.9 Replacing the Ribbon Back Tension Block.....................................2- 13

2.10 Replacing the Pinch Roller Shaft Ass'y ..........................................2- 14

2.11 Correcting Skew Priting ..................................................................2- 16

3. INSTALLATION PROCEDURE FOR

THE OPTIONAL EQUIPMENTS ..........................................3- 1

3.1 High Speed PC Interface Board (B-4800-PC-QM) ..........................3- 1

3.2 Cutter Module (B-4205-QM) ............................................................3- 3

3.3 Memory Module...............................................................................3- 5

3.4 Ribbon Saving Module (B-4905-R-QM)...........................................3- 6

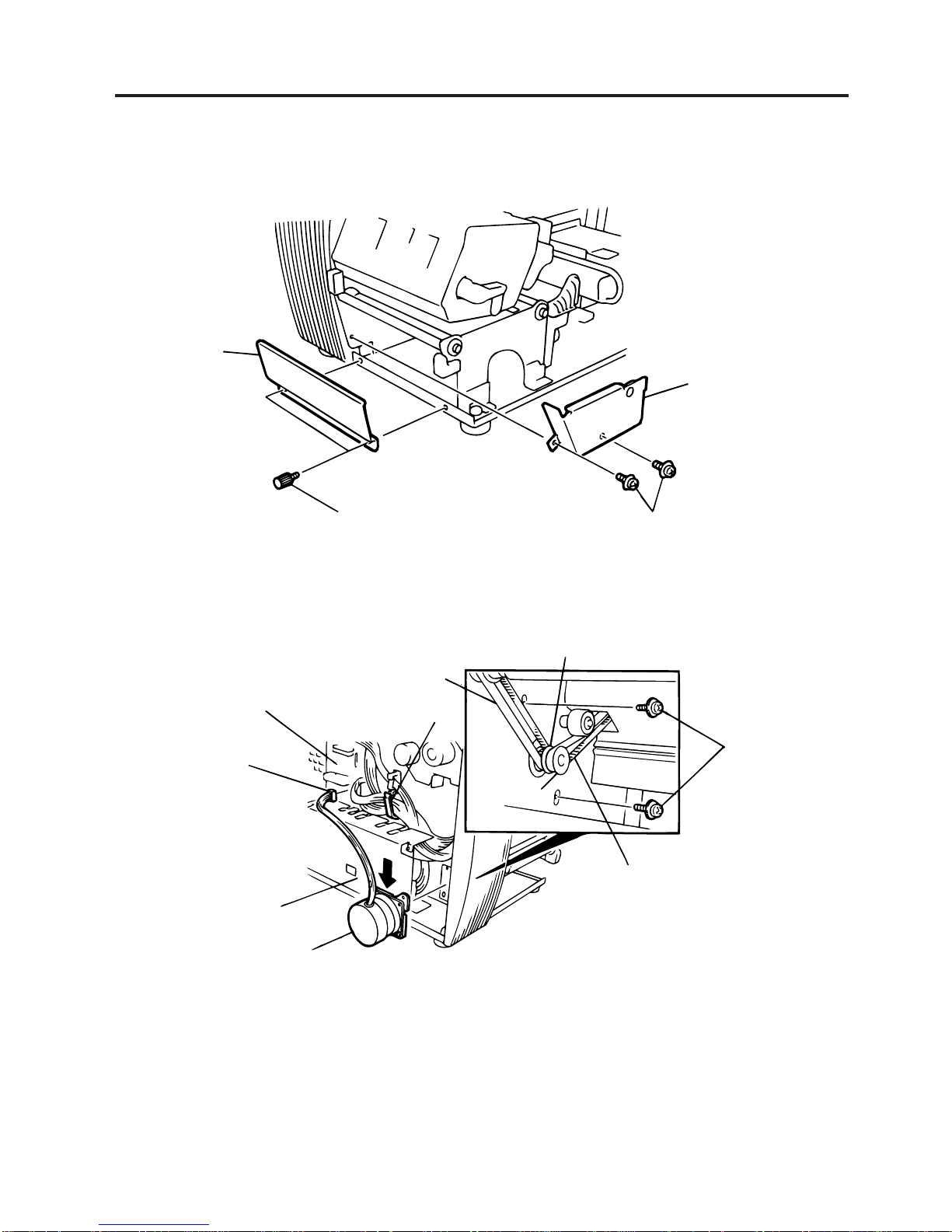

3.5 Strip Module (B-4905-H-QM)...........................................................3- 8

3.6 I/F PC Board (B-4700-IO-QM)........................................................3- 11

3.7 Fanfold Paper Guide Module (B-4905-FF-QM) ..............................3- 12

4. MECHANISM DESCRIPTIONS ...............................................................4- 1

4.1 Cutter Drive (Cut mode) ..................................................................4- 1

4.2 Harness Wiring ................................................................................4- 2

5. TROUBLESHOOTING.............................................................................5- 1

6. DIAG. TEST OPERATION.......................................................................6- 1

7. PROGRAM DOWN LOAD.......................................................................7- 1

7.1 DOS VERSION................................................................................7- 1

7.2 WINDOWS VERSION .....................................................................7- 4

EM18-33011

(Revision Date: Feb. 10, 2000)

CAUTION:

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorized Service representative with regard to any queries you may

have in this manual.

Page

Copyright © 2000

by TOSHIBA TEC CORPORATION

All Rights Reserved

570 Ohito, Ohito-cho, Tagata-gun, Shizuoka-ken, JAPAN