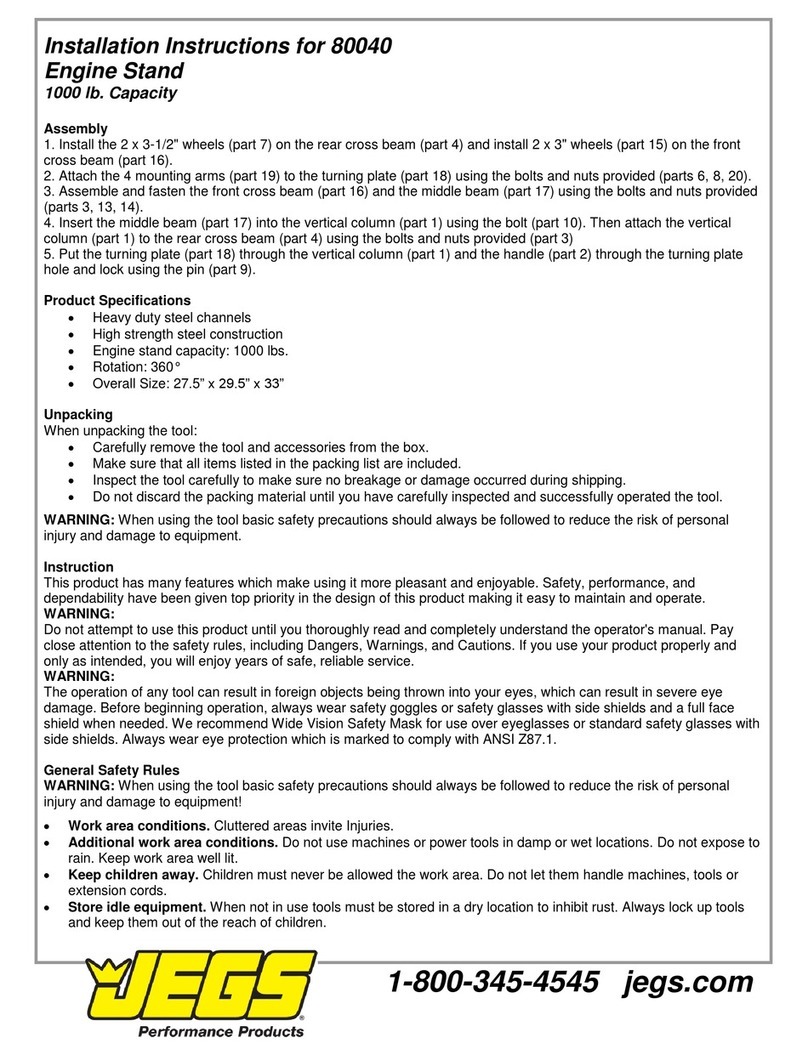

TECALEMIT TEC 4000 Manual

4000 4-Post 4-Tonne Hoist

TEC4000

TEC4011 ‘Wheels-Free’ Beams

Page

2 - 6

6 - 7

7

8 - 9

10

11 - 22

Subject

Installation Instructions

Operating Instructions

To raise hoist

To lower hoist

Wheels-free system (where fitted)

Routine Maintenance

Monthly

Yearly

Service and Repairs

Wire rope inspection

Wire rope replacement

Cylinder removal

Hydraulic pump removal

Hydraulic hose replacement

Fault Diagnosis

Illustrated Parts Lists

Contents

Safety Precautions

1. Do not operate the hoist while people are on or near it.

2. Always check the column hooks are engaged before starting work.

3. Consider the stability of the vehicle before removing parts.

4. Always keep the tracks and lifting pads clean and free from oil or grease.

5. Do not directly spray or hose the hoist with water as it will eventually cause corrosion and shorten the

life of the hoist.

6. Always return the operating switch to the horizontal “off” position when stopping the hoist after raising

or lowering. This will immediately stop and isolate the hoist if there is any malfunction in the electrics.

7. If any accident occurs during operation, check the cables are still on their pulleys and are not damaged.

TEC4000 Statutory Design Approvals

South Australia

Western Australia

New South Wales

Northern Territory

Queensland

Tasmania

Victoria

New Zealand

CLF/DH

31/49/7

75730/C

N4036

CH13166

C1090

L87/2126/00

21.903.01

29 Nov 1988

25 Nov 1987

25 Jan 1988

04 Feb 1988

19 Feb 1988

21 Apr 1988

19 Jul 1988

25 May 1989

State Approval Reference No. Date

INSTALLATION INSTRUCTIONS

By following these instructions carefully, your new hoist

can be assembled quickly to give safe, smooth and

efficient operation and an extended, trouble-free life.

1. Select an undercover position for the hoist allowing

for direct access for vehicles (or as specific

regulations may require).

Mark out the floor plan as per FIG.A

2. Inspect the quality of the floor at the proposed site.

It must be a flat concrete floor of minimum

thickness 100mm and minimum strength grade 28

Mpa. If expanding-type masonry anchors are to be

used to hold down the columns they must not be

installed within 150 mm of any edge, crack or other

fastener in the floor and must be a minimum of

16 mm diameter (thread size). (Some authorities

may not approve expanding-type masonry anchors

- if so, 16 bolts of 16 mm diameter will need to be

concreted into the floor and allowed to cure for one

month minimum. If the floor is not satisfactory it

must be relaid or, if this is impractical, 600mm

squares must be cut through the existing floor and

new concrete bases of minimum thickness 150mm

and minimum strength grade 28 Mpa laid to provide

sound foundations for the four columns. Allow to

cure for a minimum of one month before using the

hoist.

3a.Install a mains isolator switch on a wall or column

next to where the hoist power column will be

situated. The power supply must be 415V, 3-phase

plus neutral, 50Hz. The wire (conductor) size must

2

be a minimum 7-strand, 2.5 mm cross sectional

area and copper.

3b.An air supply to the hoist is required with 5.5 to 8

bar pressure (70 to 100 Psi) and connected to a

filter and lubricator installed on a wall or column

adjacent to the hoist power column.

4. Place the tracks on trestles or other suitable

supports in accordance with the floor plan. The

power track containing the hydraulic cylinder and

cables must be on the power column side of the

plan with the hydraulic hose at the power column

end. The overhanging lips of the tracks go on the

outside of the hoist.

5. Remove the four cables and the hydraulic hose

from the power track channels. Feed the two long

cables through the ends of the slave track. Feed

the 4.33 mm long black nylon tube through the

track outer U channel that the hydraulic hose

passes through.

up the bolt holes and position the crossmember

ends to where the columns will be.

Note:The two crossmembers are different - refer

Fig. B.

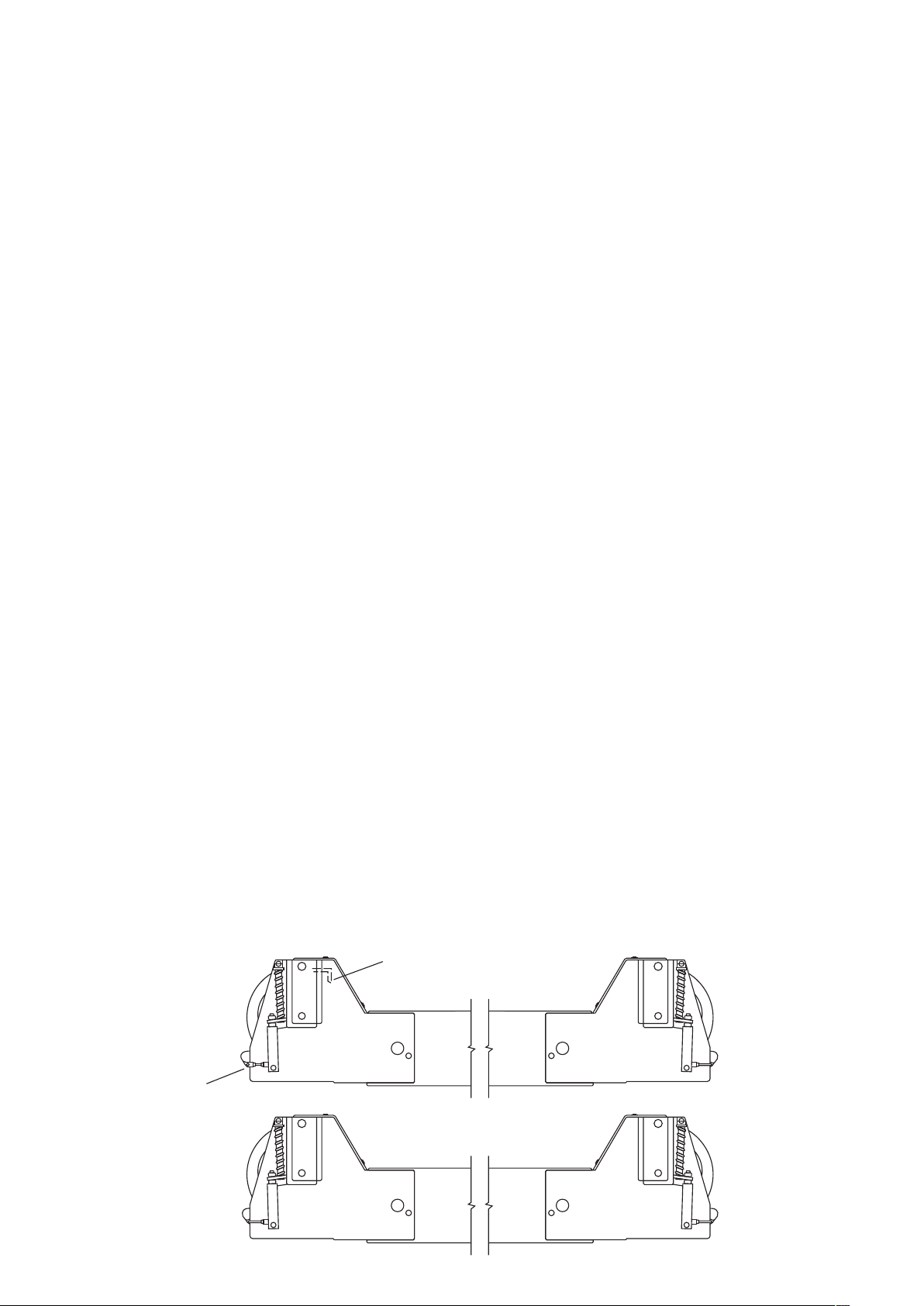

7a.On Basic Hoist

Line up the bolt holes. Fit the fixed wheel stops and

drive-on ramps to the crossmember and bolt the

tracks, etc. tightly together with M10 x 20 mm long

grade 8.8 screws. Refer Fig. C. Connect the black

nylon tube in the track to the tee connectors in the

crossmembers.

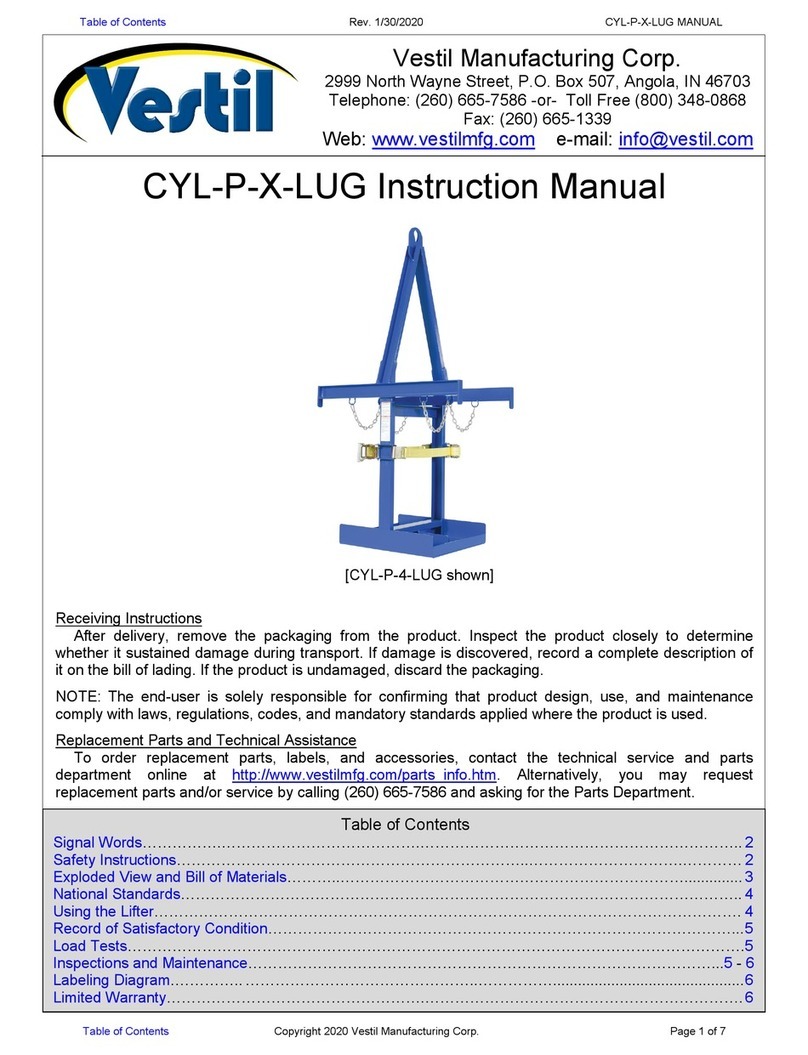

FIG. A Floor Plan

600mm

approx

4346mm

200mm

200mm

225mm

205mm

2998mm

POWER

COLUMN

POWER

CROSSMEMBER

SLAVE

CROSSMEMBER

600mm

SQ.

POWER TRACK

SLAVE TRACK

4725mm

Page 2

6. Fit the two crossmembers on to the ends of the

tracks. Move the tracks and crossmembers to line

7b.On Wheels-Free Hoist

(A) Remove the column hooks, air cylinders,

springs and swivel blocks from the outside of

both crossmembers. Remove the air lines from

inside the crossmembers.

(B) Line up the holes in the tracks and

crossmembers, fit the four extension U-brackets

using the M10 x 25 mm long grade 8.8 screws

supplied with the wheels-free beam kit. Do not

tighten yet.

(C) Place the wheels-free crossmembers into the U-

brackets over the locating pins.

Note: The crossmembers are not the same. The

operating handles must be on the power column side

of the hoist.

(D) Engage the interlock pins to lock the wheels-

free crossmembers and the hoist crossmembers

together. Adjust the U-brackets so the interlock

pins engage freely. Now fully tighten the M10

screws. Remove the wheels-free crossmembers

to tighten all the screws.

(E) Fit the wheel stops and drive-on ramps to the

outside of the U-brackets with the M10 x 20mm

long screws and nuts. Refer Fig.C. Refit the

wheels-free crossmembers.

wheels-free crossmember, down into the U-

brackets so that the crossmember is not leaning

out and does not wobble.

(G) Adjust the locating screws on the top inside

edge of the wheels-free crossmembers until the

crossmember is not leaning inward. Check the

interlock pins still engage freely.

8. Carefully remove the clutches (Fig. D) and the cable

retainers from the end of the crossmembers and

feed the cables through the ends of the

crossmembers and around the cable pulleys. Refit

the cable retainers. Place a clutch spring and guide

ferrule over the guide pin on the clutch and refit the

clutch to the crossmember.

Note: The four clutches are preset for each corner and

must not be mixed up or damaged in any way.

9. Remove the clutch rods from the columns and offer

each column up to the crossmembers so that the

notches are on the outside in line with the column

hooks on the crossmembers.

Note: The power column (which has two holes in the

back) must go on the crossmember beside the

hydraulic hose.

(A) On Wheels-Free Hoist

Fit a coiled hose, bulkhead connector and

elbow connector to the column furthest from the

power column.

(B) On All Hoists

Connect the bottom of the coiled tube inside the

column(s) to the connector(s) at the end of the

crossmember(s) inside the column. Feed the

guide tube(s) down through the top of the

column(s)and through the middle of the coiled

tube(s).

10.Remove the plastic plug from the end of the

hydraulic hose and pull hard on the cables to

extend the cylinder. Now feed the cable adjusting

screws through the top of each column and fit two

nuts to each screw. Leave the nuts loose.

11.Feed the clutch rods down through the top of the

columns. Hold the clutch square against the clutch

spring stop and lower the clutch rod through

the hole in the clutch and the guide bush just below

the clutch. Now check that the spring on the clutch

is still straight and is not buckled. Screw the clutch

rod into the base of the column while still holding

the clutch square. (If the clutch is not held square,

it will mark the clutch rod and cause the guide bush

to wear rapidly.) Tighten the nut on the top of the

rod sufficiently to tension the rod.

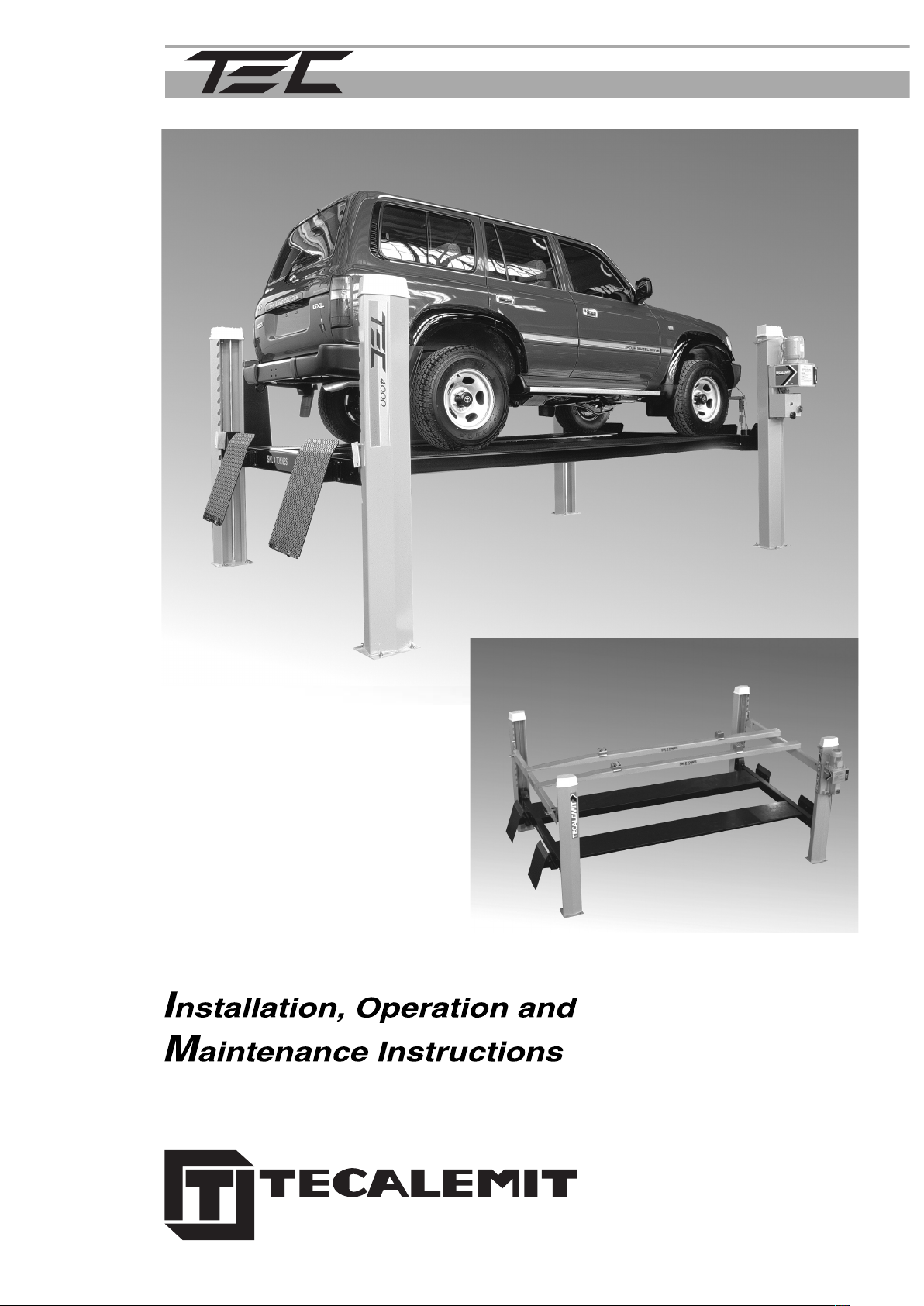

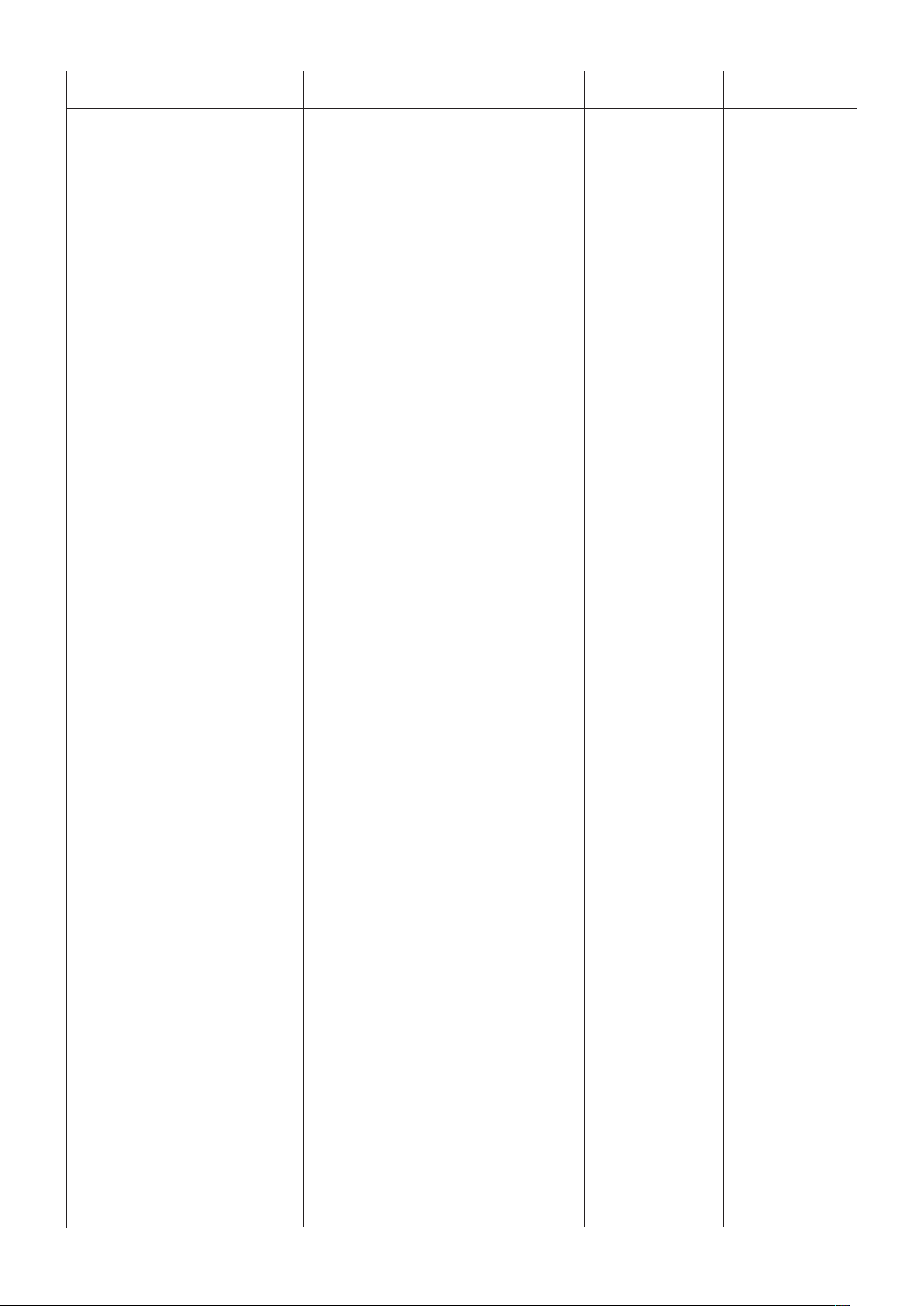

FIG. B Power Crossmember

LIMIT SWITCH TRIGGER

TEE

CONNECTOR

Slave Crossmember

(F) Adjust the screws in the bottom outer edge of the

12.Use a spirit level to establish the slope of the floor

and which column is at the highest point. The other

three columns must be packed up to exactly the

same height.

THIS REQUIREMENT IS CRITICAL FOR ACCURATE

WHEEL ALIGNMENT

Now adjust the power column by packing until it is

vertical when checked using a spirit level on the

clutch rod. Fit one hold-down bolt to the front of the

base plate on the power column only. Do up snug

tight only.

Note: The hold-down bolts must be a minimum of 16

mm diameter (thread size). If expanding-type masonry

anchors are used, they must not be installed within 150

mm of any edge or crack or other fastener and must be

a minimum of 16 mm (thread size), e.g. Ramset Trubolt

T16100 or Hilti stud anchor HSAM 16x110.

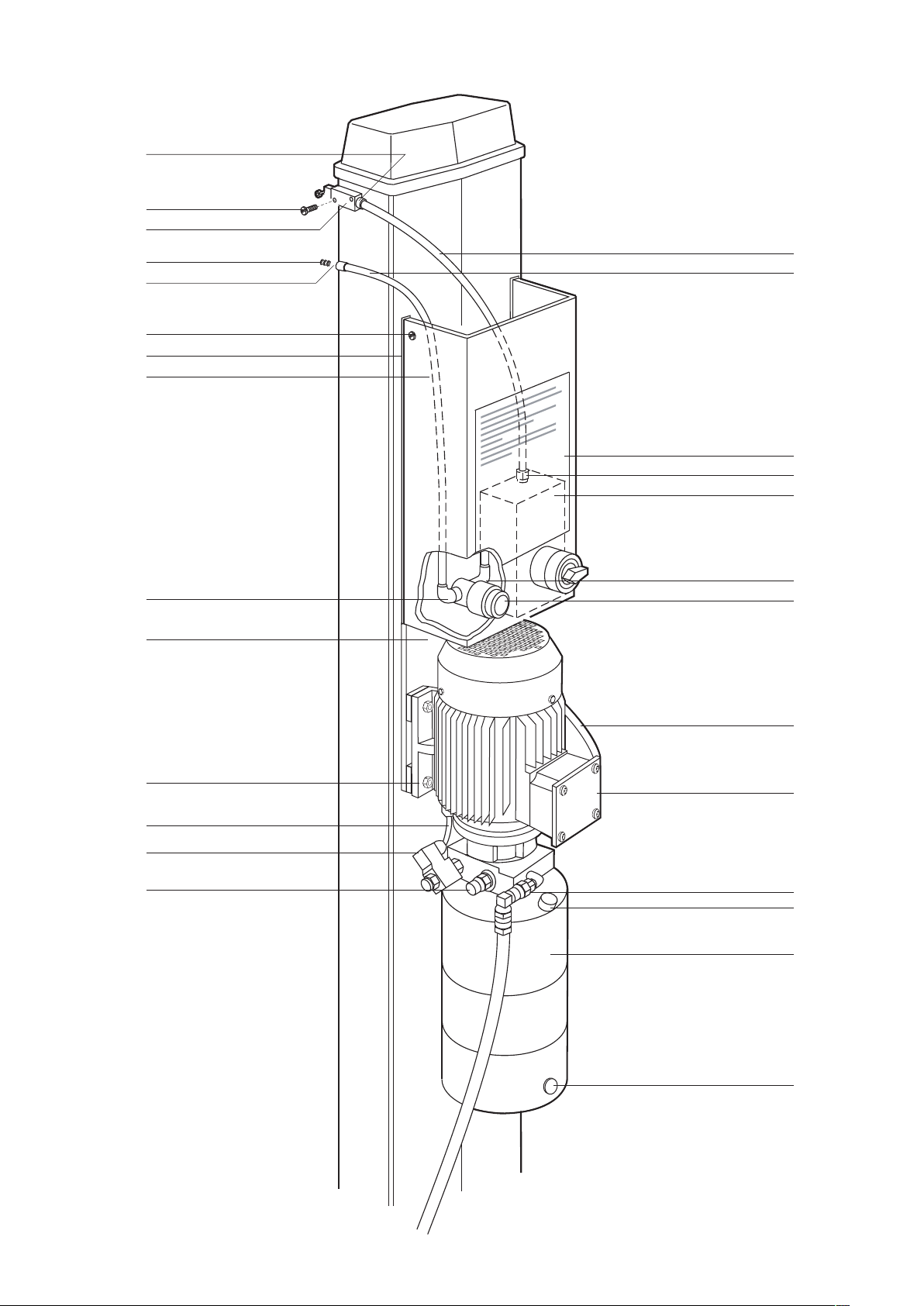

13.Fit the two rubber strips to the edges of the power

pack and mount it on the column with two M6 nuts

and spring washers. Mount the top limit switch to

the column. Check the limit switch roller lever is

sloping down at 30° and does not rub on the

column. Connect up the hydraulic hose to the

power pack. Make sure the hose hangs straight

down beside the column and across to the track

and does not rub on the side of the column. If the

hose will not hang correctly, rotate the hose fitting at

the hydraulic cylinder to remove any twist in the

hose. Pour 8 litres (two containers) of hydraulic oil

into the reservoir. Do not fill completely

.

(A) On Basic Hoist

Connect the right hand black nylon tube from

the power pack to the elbow connector on the

back of the column.

(B) On Wheels-Free Hoist

Fit a tee connector and 40 mm long tube to the

right hand black tube from the power pack. Fit

the 40 mm tube to the elbow connector on the

power column. From the other branch of the

tee run a length of tube up and across the roof to

the diagonally opposite column and fit to the elbow

at the back of the column.

(C) On Both Hoists

Connect an air line from the filter lubricator to

the left hand black nylon tube on the power

pack. Press the column hook button on the

power pack and check all four column hooks

operate. Listen for any air leaks.

14.Connect the power supply from the mains isolator

switch, adjacent to the hoist, to the terminal strip in

the control box using 7-strand copper wire of

2

2.5 mm cross sectional area. Turn the main switch

to up momentarily and check the motor direction - it

must be anti-clockwise rotation when viewed from

above. If the direction is wrong, switch off the

mains isolator and reverse two of the wires to the

control box. Switch on the isolator and recheck the

motor direction.

FIG. C Drive on Ramps and Wheel Stops

WHEEL STOP

CROSSMEMBER

RAMP ANGLE

CROSSMEMBER

NOTE: THIS BRACKET GOES

NEAREST THE COLUMNS

RAMP ASSEMBLY

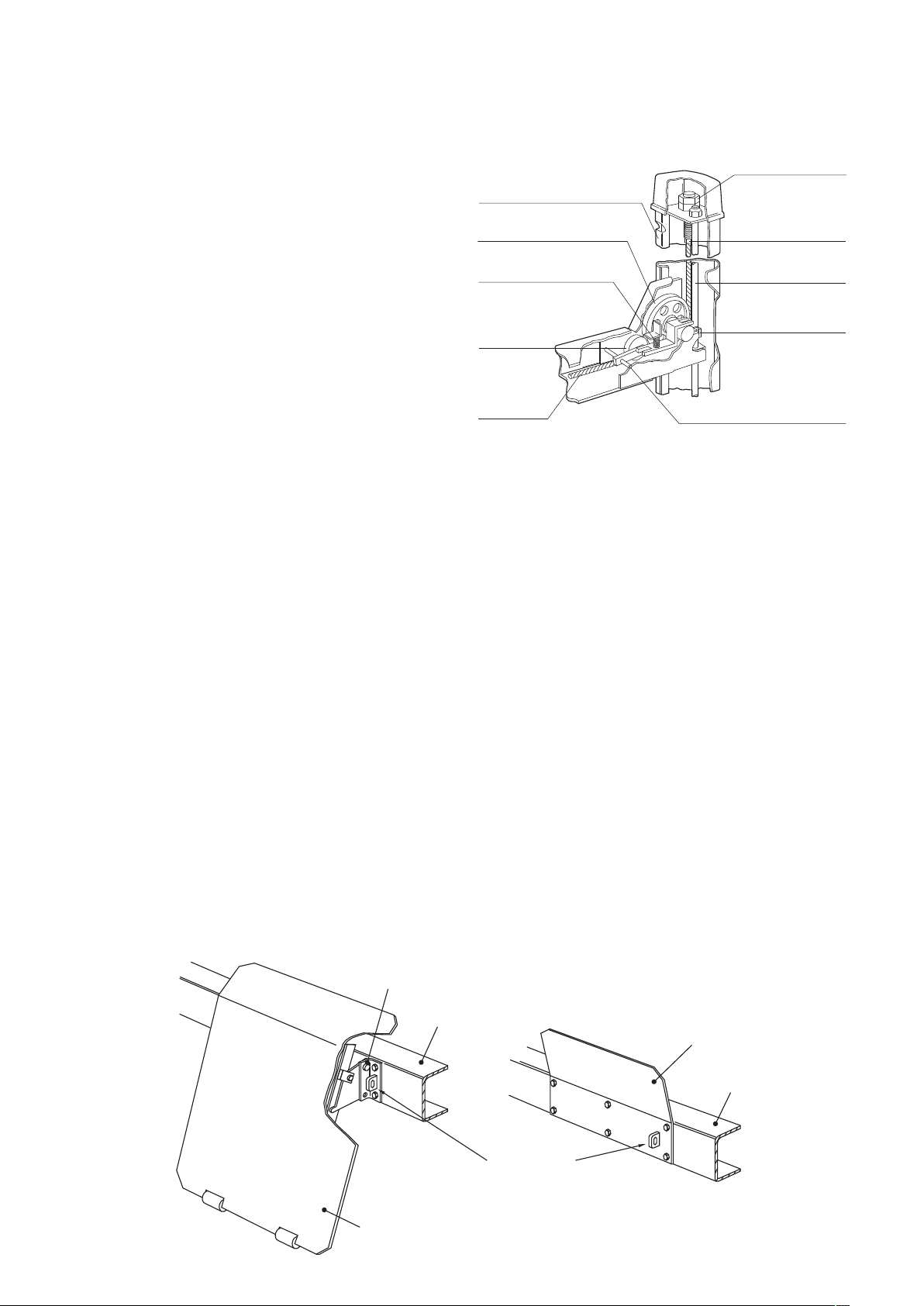

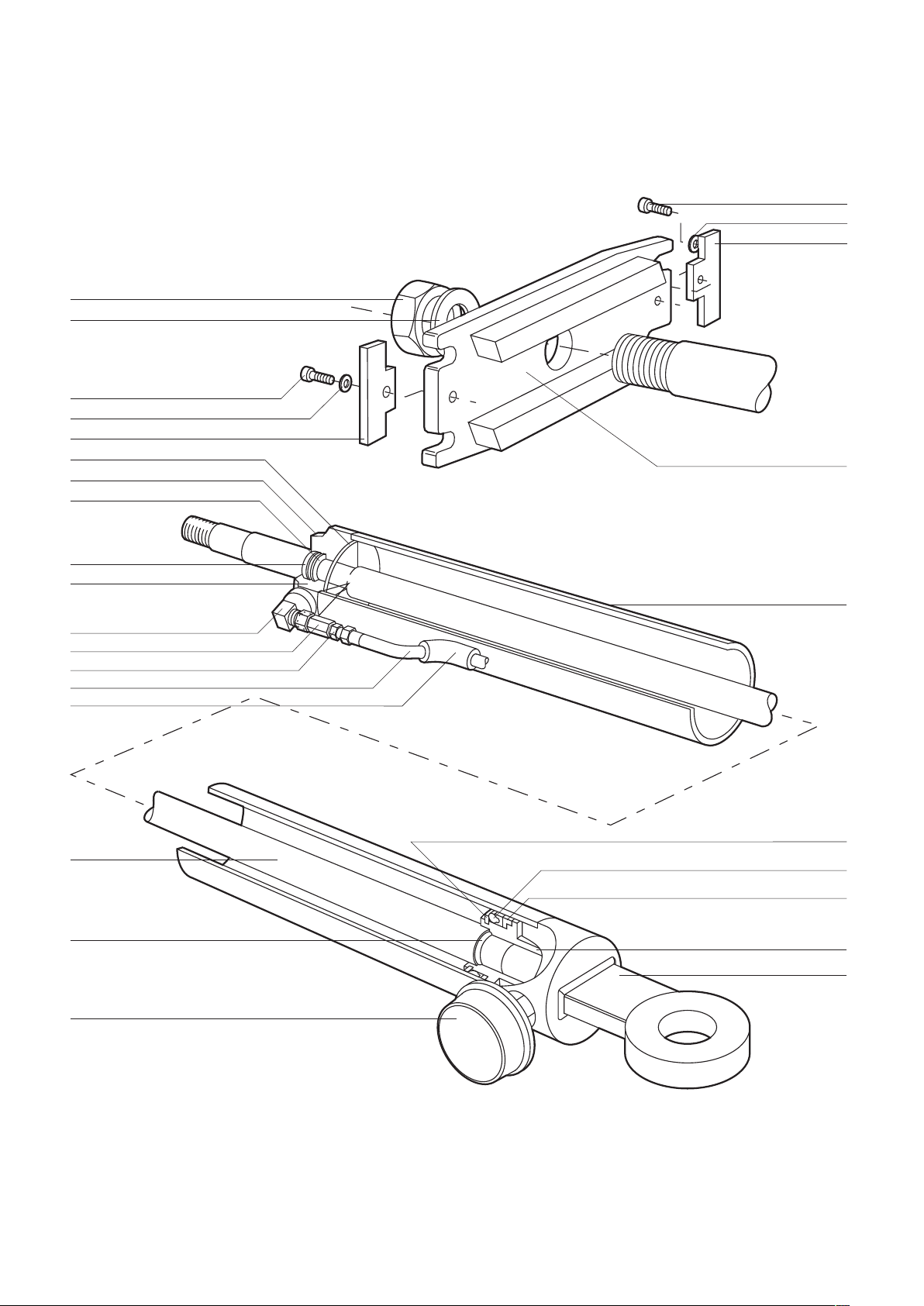

Clutch

Actuator

Pulley

Cable Pulley

Column

Cable

Cable

Adjusting Nut

Spanner Flats

Clutch Rod

Clutch

Clutch

Actuator Pivot

FIG. D Column Safety Devices

Clutch Spring

Page 4

15.Operate the up switch and raise the hoist sufficiently

to remove the supports under the tracks (it may

take up to 20 seconds for the cylinder to fill before

the hoist will rise. Visually check the clutch actuator

pulleys are on the cables and the four clutches are

being held square to the clutch rods. Tighten the

cables if necessary.

16.Push the push button to disengage the column

hooks and turn the switch to down and allow hoist

to slowly settle to the floor. As the hoist is lowered,

the slave columns should be moved slightly as

necessary to come into alignment. If any of the

clutches engage, raise the hoist to release the

clutch and tension the cable.

17.Adjust the three slave columns by packing until they

are vertical when checked using a spirit level on

their clutch rods. Square up the four columns by

sighting across the front face of each column to the

column at the other end of the hoist. Before

installing all remaining hold-down bolts and

tightening, ensure all columns are packed to the

same height. Fit the remaining hold-down bolts and

tighten. Recheck that all columns are vertical and

square. (It is very important that the four columns

are accurately adjusted to ensure smooth, trouble-

free operation of the hoist.)

18.With the down switch held on, adjust all four cables

until the ends of the crossmembers just start to lift

off the column base plate. Lock the cable adjusting

nuts together. On wheels-free hoists, adjust the two

adjusting screws on the outside ends of the wheels-

free crossmembers so they just clear the outside

of the columns by 2-3 mm.

19.Raise the hoist about 1 metre off the floor. Check

the clutch rods are not being bowed due to

misalignment of the columns (recheck column lean

and repack if necessary). On wheels-free hoists,

check the adjusting screws on the wheels-free

crossmembers are not rubbing on the column or

have no more than 4 mm gap.

20.Drive the hoist up until the column hooks engage

in the next notch in the columns. Check that all

hooks engage in the notches at the same time

(adjust the cables if necessary). Check the hooks

all engage fully under spring pressure and

disengage freely under air pressure. With the

hooks engaged, lower hoist until the hooks are

supporting the tracks and check the tracks are level

using a spirit level (if not, repack the columns as

per step 18).

22.Lower and raise the hoist several times to expel any

23.Apply a liberal coating of SAE 140 oil to the clutch

rods and to the cables over their entire lengths

(raise and lower the hoist to get full coverage).

Apply some oil to the clutch actuator pulley axle and

pivot, the ramp rollers and pivots, the column hook

pivots and the wheels-free interlock pins.

2

24.Bolt the four Inner Toeguards (20 mm tubes) under

the tracks with the M6 x 35 mm long screws and the

thick flat washers. Also attach the hydraulic hose to

the outer screw, using the bracket on the hose.

25.Position the two outer toeguards at each end of the

hoist. Fit four bushes to the toeguards. Fit M6 x 20

mm long screws to the slotted brackets on the

wheel stops, with a thick flat washer on each side.

Screw the bush onto the screw. Leave loose.

Repeat at the other end.

26.Lower the hoist to the floor. Fit the covers to the

crossmembers and columns. Adjust the outer

toeguard pivots until they are flat on the floor, then

tighten them. On wheels-free hoists, bend the ends

of the outer toeguards towards the column base

plates until there is 80 mm gap, (this is to prevent

eye damage when the hoist is raised). Place the

wheels-free support beams together on the hoist

between the tracks.

27.Drive the heaviest available vehicle (4 tonne

maximum) on to the hoist. Raise the hoist to full

height.

28.Engage the interlock pins on wheels-free hoists.

Check all column hooks are fully engaged at the

same height. If the heights vary greatly, adjust the

cables to correct. Lower the hoist so all the weight

is on the hooks. Check hooks for proper

engagement. On wheels-free hoists check for any

tilting of the wheels-free crossmembers under load.

If tilting occurs, raise the hoist to unload the hooks

then adjust the locating screws on the top inner

edge of the wheels-free crossmember to take up

excess clearance. Retest for tilting.

29.On wheels-free hoists:

Locate the support beams under suitable pickup

points approved by the vehicle manufacturer.

Position the adaptor pads and extensions as

required.

Raise the hoist slightly to unload the interlock pins,

and disengage the pins.

21.Raise the hoist higher. If the hoist slows down and

gets noisy, add 1 litre of oil, then continue raising.

Add more oil as required until the hoist reaches

full height. Check that the top limit switch is

operated by the crossmember trip arm. On a

wheels-free hoist, check the adjusting bolts on the

outside ends of the wheels-free crossmembers

are not rubbing on the column or have no more

than 4 mm gap.

air trapped in the hydraulic system. Fully lower the

hoist, check oil level and top up if necessary.

Lower the hoist platform until the vehicle is fully

supported by the wheels-free beams. Check safety

at all pickup points and column hooks.

30.Raise the hoist to unload the column hooks.

Remove the adaptor pads, etc. Check the floor

area beneath hoist is clear of people and

obstructions. Disengage the hooks and lower the

hoist to the floor. Remove the vehicle.

The hoist is now ready for operation

OPERATING INSTRUCTIONS

To raise hoist

1. Park the vehicle centrally on the hoist. Stop the

engine and apply the parking brake.

2. Place chocks in front of and behind the wheels.

Manual chocks should be used on at least one

wheel.

3. Check the hoist area is clear of people and

obstructions, then raise hoist to desired height for

working on the vehicle.

4. On the wheels-free hoists, engage the

crossmember interlock pins.

5. Lower the hoist on to the column hooks and check

engagement of hooks visually. Turn the main switch

to the horizontal “Off” position before commencing

work.

To lower hoist

1. Check the floor area beneath the hoist is clear of

people and obstructions.

2. Raise the hoist until the column hooks are free.

3. Disengage the column hooks and lower hoist to the

floor.

4. Remove the wheel chocks, check the driveway is

clear, then drive the vehicle off the hoist.

Page 6

Wheels-free system (where fitted)

1. Park the vehicle centrally on the hoist. Stop the

engine and apply the parking brake.

2. Check the hoist area is clear of people and

obstructions, then raise hoist to desired height.

Turn the main switch to the horizontal “Off” position.

3. Position the longitudinal support beams under the

pickup points approved by the vehicle

manufacturer.

4. Position the adaptor pads under the pickup points

(adjust the beams if necessary). Use extension

pads if required.

5. Disengage the interlock pins on both ends of hoist.

Check disengagement visually.

6. Slowly lower the hoist and verify by checking

visually that all four column hooks are engaged fully

in the column notches.

Caution: It is vital that full engagement of each hook is

checked.

7. Continue lowering the hoist until the vehicle is being

supported by the adaptor pads. Check the position

and security of the adaptor pads.

Caution: It is vital that the pads are correctly

positioned. Check visually and adjust if required.

8. Lower the hoist tracks to give access to the vehicle.

For safety, keep the tracks as close as practical to

the vehicle.

9. Turn the main switch to the horizontal “Off” position

before starting work.

To remove vehicle

1. Check the hoist area is clear of people and

obstructions then raise hoist tracks until the vehicle

is being supported by the tracks and the column

hooks are free.

2. Remove the adaptor pads and extension pads from

the support beams and move the beams to the

centre of the tracks, clear of the vehicle.

3. Engage the interlock pins at both ends of the hoist.

4. Check the floor area beneath the hoist is clear of

people and obstructions. Disengage the column

hooks and lower the hoist to the floor.

5. Check the driveway is clear, then drive the vehicle

off the hoist.

ROUTINE MAINTENANCE

Monthly

1.

2. Wipe the cables clean with a solvent-soaked cloth

and check for any frayed ends or other damage.

Lubricate with cable grease or SAE 140 oil. Adjust

the cables if necessary. (The cables should be tight

enough to prevent the clutches from operating

when the hoist is fully lowered, but not so tight as to

prevent the crossmembers resting on the column

base plates.)

3. Check the safety clutches in the crossmembers are

not damaged and are operating correctly. Check

the column hooks are operating properly. Adjust if

necessary.

4. On wheels-free system, clean out the U-brackets

that support the crossmembers. Check the column

hooks and crossmember interlock pins are

operating properly. Adjust if necessary

.

5. Lubricate the clutch rods, clutch actuator pulley axle

and pivot, the ramp rollers and pivots, the column

hook pivots and the wheels-free interlock pins with

SAE 140 oil.

6. Check the airline lubricator is filled with oil and the

filter bowl is empty.

Yearly

1. Thoroughly inspect the cables over their full length

as per wire rope inspection.

2. Check that all cable pulleys are running true and are

not excessively worn.

3. If the hydraulic oil appears discoloured, drain the oil

reservoir and refill with hydraulic oil (mineral oil

based) of ISO viscosity Grade 32.

4. Check all nuts and bolts are tight.

Fully lower the hoist. Check the oil level is up to

the dip stick. If low, top up with hydraulic oil of

ISO viscosity Grade 32.

SERVICE AND REPAIRS

Wire rope inspection

The design of this hoist allows a complete inspection of

the full length of each wire rope without removal from

the hoist. Conditions to look for include crushing,

deforming or kinking, corrosion, excess wear, or if

more than 15 broken wires can be seen in any 90 mm

(3.5 in.) length of cable.

1. With the hoist fully lowered, wipe the cables in the

columns clean with a solvent-soaked cloth and

inspect. Mark with chalk.

2. Raise the hoist 1 metre (1.15 m to top of track).

Clean and check the cables in the crossmember

between the tracks and under the power track.

Mark with chalk.

3. Raise the hoist to full height. Clean and check the

wire ropes in the crossmembers between the tracks

and under the power track - this will cover the

remaining sections.

Should any single wire rope need replacing, the

complete set should be replaced. Wire rope

specification: 6 x 25 (12/6 +6F/1) independent wire

rope core, right hand ordinary lay, grade 2070 Mpa,

galvanised, 11 mm diameter.

Wire rope replacement

1. Remove covers from crossmembers and columns.

2. Raise hoist approximately 1.5 m. Engage column

hooks (and interlock pins) then lower hoist until

supported by hooks. Check engagement.

3. Switch off and lock the isolator switch.

4. Remove the cable retainer nuts from below the

cable pulleys in the ends of the crossmembers.

5. Remove the cable adjusting nuts from the top of

each column.

6. Remove the axles at both ends of the power track.

Remove the pulleys at both ends, noting the

position of thrust washers and spacers. Take care

to support the cylinder when the pulleys are

removed.

7. Remove the cable retaining plates from the cable

anchor plate on the end of the cylinder. Remove

the cables from their slots one at a time, noting their

positions.

8. Pull the cables out of the top of each column.

9. Feed the new cable through the top of each

column, around the crossmember pulley and into

the power track.

10.Refit the cables to the cable anchor plate and fit

the retaining plates.

11.Refit the track pulleys, spacers, thrust washers and

cylinder, nesting the cables in their respective pulley

grooves. Refit the axles and retain with plates and

screws (refer Fig. 2).

12.Fit cable adjusting nuts to each cable on top of

each column.

13.Check that the cables are not twisted or crossed

over and are running in the grooves of all pulleys.

14.Switch on isolator and raise hoist to unload the

column hooks. Check that the clutches are not

engaged. Tighten cables if necessary.

15.Refit the cable retainer nuts, button head cap

screws and shake proof washers to the ends of the

crossmembers.

16.Lower the hoist to the floor, checking that the

clutches do not engage.

17.With the down switch held on, adjust the four cables

until the crossmembers just start to lift off the

column base plate. Lock the adjusting nuts

together.

18.Place the heaviest available vehicle (4 tonne

maximum) on the hoist and raise and lower the

hoist several times. Check the hoist is level and that

none of the clutches engage. Tension cables if

necessary.

19.Lubricate the cables, clutch rods and clutch

actuator pulleys. Refit crossmember and column

covers.

Cylinder removal

If oil is leaking from the cylinder breather or from

around the piston rod, the seals must be replaced.

1. Raise the hoist to a comfortable working height.

Engage the column hooks (and interlock pins) then

lower hoist until supported by the hooks. Check

engagement of the hooks.

2. Switch off and lock the isolator switch.

3. Disconnect the hydraulic hose from the cylinder.

Catch oil in a clean container under the cylinder.

Remove the four cable ties on the cylinder.

4. Extend the cylinder to drain the oil. Slide the cable

anchor plate along the cylinder rod to expose the

spanner flats and remove the Nyloc nut and cable

anchor plate.

Page 8

5. Remove the axle holding the cylinder and cable

pulleys in the track. Carefully support the cylinder.

Place cylinder on a clean bench.

6. Wrap the cylinder rod thread with masking tape.

Undo the cylinder gland and slide it off the rod,

taking great care not to let the rod drop down.

Extract rod from the cylinder. Be very careful, as the

piston passes over the thread inside the cylinder.

7. Examine and renew defective seals. Check piston

rod and cylinder walls for signs of scoring or flaking.

Renew if necessary. Thoroughly clean all parts.

8. Reassembly is a reversal of removal procedure, but

ensure all cylinder parts are clinically clean before

assembly. Lightly oil seals before fitting.

9. Tighten Nyloc nut to 105 Nm (75-80 ft lbs) torque.

Check cables are not twisted.

10.Switch on isolator, raise and lower hoist several

times to expel air from the cylinder. Top up the

reservoir.

Check the cylinder is free from leaks.

Hydraulic pump removal

To repair the hydraulic pump, the reservoir must be

removed. The pressure relief, check, and solenoid

valve are accessible without removing the reservoir.

1. Lower the hoist fully. Switch off and lock the isolator

switch.

2. Undo the four screws holding the top of the

reservoir to the main body and remove the reservoir.

3. The pump is now accessible for cleaning or repair

as necessary.

4. Installation is a reversal of the removal procedure.

Take care to ensure all parts are clinically clean.

5. Switch on isolator. Raise and lower hoist several

times to expel any air and ensure proper operation.

Check oil level.

Hydraulic hose replacement

If the hydraulic hose should burst, the flow control

valve at the cylinder will prevent the hoist from falling.

The hoist will lower at the normal speed

1. Option (a) if it is necessary to remove a vehicle

from the hoist urgently, disengage the column

hooks and lower the hoist to the floor (If possible).

Try to catch as much oil as possible.

After the hoist is lowered, remove the vehicle. Now

jack the hoist up to gain access to the hose under

the power track. Place supports under the track.

Clean up the spilt oil.

Option (b) If the hoist does not need to be lowered,

then engage the column hooks (and interlock pins),

and let the hoist lower until it is supported by the

hooks. Check engagement of the hooks visually.

Clean up the spilt oil.

2. With the hoist securely supported, switch off and

lock the isolator switch.

Disconnect the hose at both ends by undoing the

swivel nuts. Cut the four cable ties and remove the

clamp bracket, remove the hose and the plastic

sleeve from the hoist.

3. Remove the reducing bush, (and flow control valve)

and the sleeve and bracket from the burst hose.

Fit the parts to the new hose. Apply thread sealant

to the 1/4” BSP male end of the hose then fit and

tighten the reducing bush.

4. Feed the hose back into the track.

Connect the column end of the hose and tighten.

This will orientate the hose. Now connect the hose

at the cylinder end, making sure the hose is not

twisted when tightening the swivel nut.

Check the hose hangs straight down beside the

column and is not rubbing on it.

5. Position the plastic sleeve to protect the hose from

the edges of the hole in the track. Refit the four

cable ties and the clamp bracket.

6. Switch on the isolator then raise the hoist off its

supports. Raise and lower the hoist several times to

expel any air, and top up the reservoir

.

1. Motor will not run.

2. Motor runs but hoist will not lift.

3. Hoist squeaks when operating.

4. Hoist creeps down under load.

5. Safety clutches operate when

hoist is fully lowered to floor.

6. Hoist motor will not stop at full

height.

7. Hoist will not lower.

8. Column hook will not engage

freely.

9. Column hooks will not

disengage.

a) No power to hoist.

b) Thermal overload has tripped.

c) Top limit switch is damaged.

d) Wiring has loose connections.

e) Contactor faulty.

f) Raise switch faulty.

g) Motor faulty.

a) Lack of oil.

b) Hoist is overloaded.

c) Motor direction is wrong.

d) Solenoid valve stuck open.

e) Relief valve stuck open.

f) Burst hose.

g) Failure of motor - pump

coupling.

a) Dry clutch rods or clutch

pulleys.

b) Failed cable pulley bearing.

a) Dirt under solenoid valve seat.

b) Dirt under check valve seat.

c) Dirt under relief valve seat.

d) Leaking seal in cylinder.

e) Leak in pipework.

a) Hoist is on an obstruction.

b) Cables have stretched.

a) Cables have stretched.

b) Lack of oil

c) Limit switch arm is loose.

d) Limit switch is faulty.

a) Burst hose.

b) Clutches engaged.

c) Failed cable.

d) Solenoid valve not opening.

e) No power to hoist.

f) Solenoid faulty.

g) Lower switch faulty.

h) Wiring is loose.

a) Pivot is dry or corroded.

b) Spring is broken.

c) Air cylinder seized.

a) No air pressure.

b) Air line has leak.

c) Air line is kinked.

d) Air cylinder seal is leaking.

e) Air cylinder head seized.

Check the mains isolator is on and

fuses are OK.

Reset thermal overload.

Replace limit switch.

Tighten all connections.

Replace contactor.

Replace switch.

Replace motor.

Top-up reservoir.

Check load (4t maximum).

Reverse direction.

Clean valve assembly.

Clean valve.

Replace hose.

Replace coupling.

Lubricate with SAE 140 oil.

Replace pulley bearing.

Clean valve assembly.

Clean valve.

Clean valve.

Replace seal.

Raise hoist, remove obstruction.

Adjust cables.

Adjust cables.

Top-up reservoir.

Tighten arm.

Replace switch.

Replace hose.

Raise hoist to release clutches, adjust

cables.

Replace cables.

Clean and check operation of valve.

Check the main isolator is on and

fuses are ok.

Fit new solenoid.

Replace switch.

Tighten all connections.

Clean & lubricate pivot.

Replace spring.

Repair cylinder.

Check for air at filter/lubricator.

Find and fix leak.

Find and replace kinked tube.

Dismantle & repair cylinder.

Lubricate cylinder.

FAULT POSSIBLE CAUSE REMEDY

FAULT DIAGNOSIS

Page 10

Tighten fittings.

V16883

V16884

V16909

V15711

V16863

V16854

NMB1124.1

NMA1136.4

V16924

V17901P

V17901S

V17902P

V16850

V16844

PAP5030P10

V16868

V16864

V16867

V16866

V16865

1500.343E

SME1712.30

V16876

V16888

SME1706.12

V16886

V16842

V16846

SME906.12

AM1800.200

AM1400.125

V16859

WMA1006

WWA1007

V17907

V17906

V17908

V17909

AM1800.25

V17910

V17928

BME1106.35

NMA1106.1

163905.59

V16950

V17904L

V17904R

V17931

V17932

V17930

V17918

V17917

V17717

V16925

V16877L&R

SME1110.20

NMA1110.1

V18535

SME1506.16

DIN1500.7

COLUMNS

Columns, Right Hand

Columns, Left Hand

Columns, Power

Ferrule

Clutch Spring

Clutch Rod

M24 Hex. Nut, Plated

M36 Lock Nut, Plated

Column Cover, Finial

CROSS MEMBER ASSEMBLIES

Cross Member Assembly Power

Cross Member Assembly Slave

Cross Member Assembly, Welding

Axle Cross Member

Cable Pulley

Dia. 50 x 30 Plain Bearing

Clutch Assembly

Clutch Pulley

Clutch Axle

Clutch Pulley Tube

Clutch Pivot

E Circlip 438” Shaft

Cap Screw

Hook Bush

Cross Member Cover

M6 x Socket Head Cap Screw

Retaining Washer

Thrust Washer

Locking Plate

M6 x Socket Head Cap Screw

Cresent Clip 2” Shaft

Circlip 1 1/4” Shaft

Guide Bush

Washer 6 mm Flat

Washer

Hook Spring

Spring Guide

Swivel Block

Rod Pivot Bush

C. Circlip .250”

Air Cylinder Assembly

ø6 Tube 40 mm Long

Bolt M6 x 35L Hex. HD

Hex Nut M6

Shakeproof Washer

Cable Tie 190 mm

Hook Assembly Left

Hook Assembly Right

ø6 Tube 745 Long (Power)

ø6 Tube 785 Long (Slave)

ø6 Tube 2465 Long

Equal Tee Connector ø6 mm

Straight Adaptor ø6 mm Tube

Recess Cover

Ramp Assembly

Wheel Stop Left and Right

M10 x 20 Hex. Screw G8.8

Nut M10 x 1.5

Cable Retainer Nut

M6 x 16 Button Head Cap Screw

E-Circlip ø7 Shaft

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

4

4

4

4

8

4

1

1

1

2

2

2

2

2

2

2

2

10

2

2

2

4

2

4

2

2

2

2

2

4

2

2

2

2

4

4

2

1

16

6

6

2

1

1

1

1

1

2

2

2

2

1

24

4

2

2

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

48

49

50

51

52

53

54L&R

55

56

56A

56B

56C

Fig. No. Part No. Description Quantity Item no.

42

53

40

41

51

38

48

46

35

21

36

23

44

1

52

54R

57

10

55

56

63

3

2

9

64

11

58

54L

60

62

61

60

59

65

47

35

39

39

40

34

37

25

33

4

5

7

8

6

16

30

26

27

14

13

44

32

28

31

43

45

29

42

37

27

51

20

49

39

42

22

50

17

12

18

19

24

21

FIG. 1

Page 12

38

38

15

43

V16848

V17702

V18902

V18900

V18578

V16736

SME1106.20

V18577

V18916

V16889

V18914

WMA1006

NMA1106.1

V16946

V16934

V16935

V16936

V16937

V16844

PAP5030P10

V16842

V17716

V16845

V16846

SME906.12

BMA1106.50

28463M6

V17715

V16949

V17925

V17924

V17926

V17919

TRACK ASSEMBLIES

Track Assembly

Slave Track (recessed)

Track Power

Track Power (recessed)

Inner Toe Guard

Retaining Washer

Screw M6 x 20L

Toe Guard Bush

Outer Toe Guard

Ramp Angle

Ramp Angle-Outer

Washer 6mm Zn Plate Bright Steel

Nut Hex M6

Strap

Cable Assembly (B)

Cable Assembly (C)

Cable Assembly (A)

Cable Assembly (D)

Cable Pulley

Dia 50 x 30 Plain Bearing

Thrust Washer

Spacer

Axle Track

Locking Plate

M6 x 12 Countersunk Cap Screw

Screw M6 x 50 Len

Spring Washer M6

Spacer

Cable Tie 300M TY-RAP T

Male Elbow ø6 Tube

Bulkhead Adaptor

Coiled Tube

Guide Tube

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

1

1

1

1

4

16

4

4

2

2

2

2

2

1

1

1

1

1

6

6

7

2

2

2

2

2

2

2

4

1

1

1

1

57

57

58

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84A

84B

84C

84D

Fig. No. Part No. Description Quantity Item no.

84B

84A

75

73

74

75

73

74

75

73

74

79

77

78

83

75

73

74

67

82

66

81

80

68

77

74

73

75

76

76

75

74

73

75

78

79

84D

84C

Ropes Detail

B (69)

D (72)

C (70)

A (71)

FIG. 2

Page 14

V20594

V16942

V20600

NSA1116.6

WWA1016

V17714

SME1710.25

28463.10M

V16928

V16928.1

V16928.2

V16928.3

V16928.13

V16928.14

V16928.4

V16928.5

V16928.6

V16928.7

V16928.8

V16928.9

V16928.11

V16928.12

V18556

V17711

V16908

V18907

V16901

Reducing Bush 1/2 - 1/4” BSP

Elbow 3/4” UNF x 3/8” BSP

Flow Control Valve

1” UNF Nyloc Nut, Plated

Washer 1” x 14G Bright Steel

Cable Retainer Plate

M10 x 25 Cap Screw

Spring Washer

Hydraulic Cylinder Assembly

Barrel and End Cap Assembly

Air Breather, Ryco No. 67

Seal Piston, Hallite Hallprene R10984S

Circlip DIN1400.0570

Wear Ring 040118

Piston

“O” Ring BS - 117

Piston Rod

“O” Ring Gland BS - 232

Gland

Seal Gland Ludowici H Seal `1250 1250.250

Wiper Rod

Insert, Nylon

Hydraulic Hose

Cable Anchor Plate, Assembly

4 Litre Container, Hydraulic Oil

Operation Manual

Warranty Card

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

-

-

-

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

85

86

87

88

89

90

91

92

93

94

95

96A

96

97

98

99

100

101

102

103

104

105

106

107

-

-

-

Fig. No. Part No. Description Quantity Item no.

88

106

85

87

86

103

104

105

102

101

90

92

91

100

99

95

88

89

91

92

90

96

96a

97

98

94

93

FIG. 3

Page 16

107

V17951P

V17951S

V17954R

V17952

V17124

V17159

V17954L

V17141

DIN1400.0160

V17125

V17939

GPS08.12

V17121

V17117

NMA112.4

V17941

V16939

SMA1106.12

NMA1106

SME1506.10

V17122

V17910

V17942

V17917

V17958

BME1106.35

163905.59

V17960

V17962

V17918

V17934

V17908

V17963

V17928

V17933

V15057

V17909

AM1800.25

1500.343E

WWA1007

V17956

V17957

V17110

V17158

V17130

V17128

V17133

V17134

V17120

SME1110.25

NMA1110.1

V17202

V17188

V17194

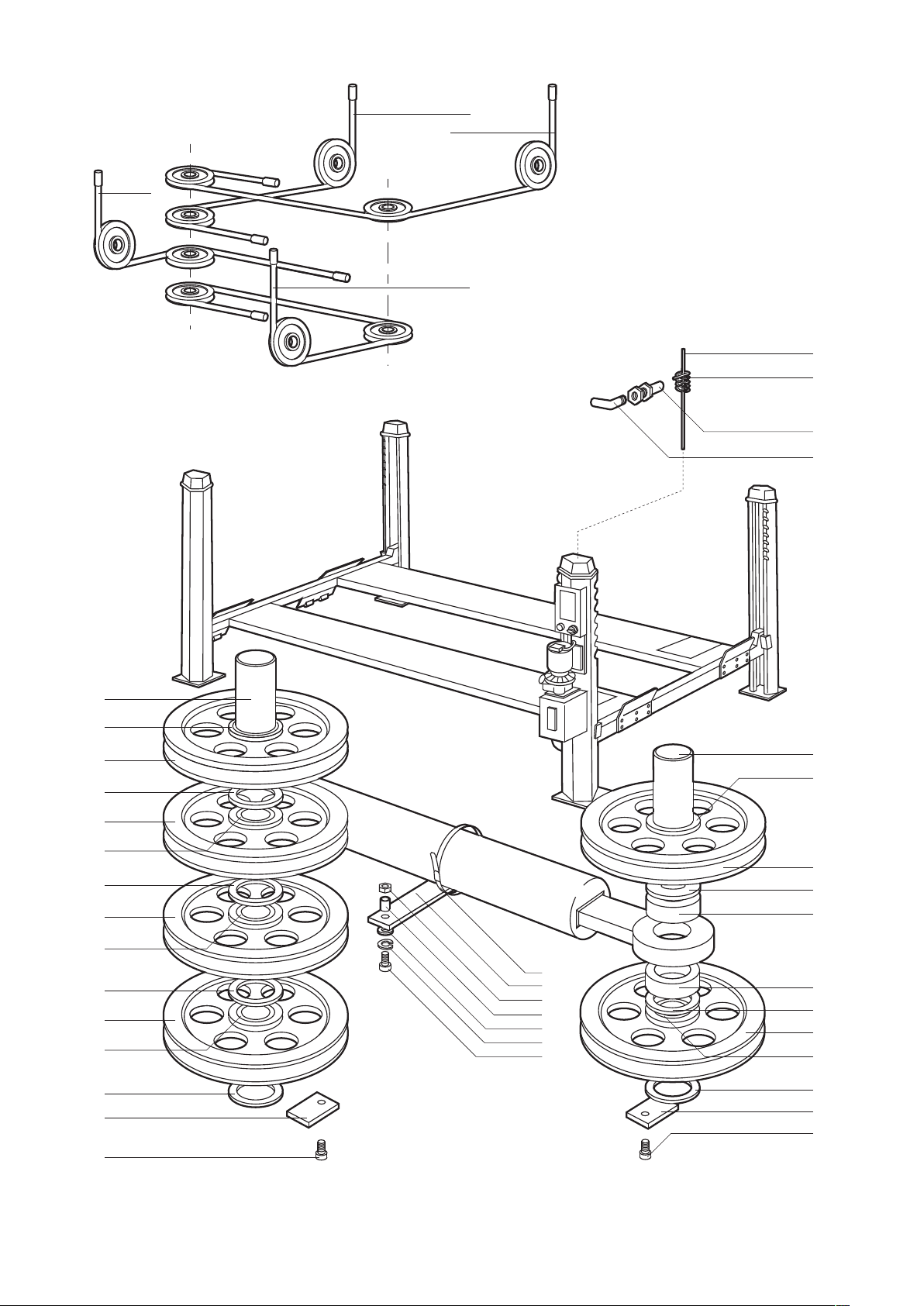

TEC4011 WHEELS FREE BEAM KIT

CROSS MEMBER ASSEMBLIES

Cross Member Assembly, Power

Cross Member Assembly, Slave

Hook Assembly, Right

Cross Member Welding Assembly

Interlock Link Tube

Label SWL 4 Tonnes at 800mm

Hook Assembly, Left

Hook Pivot

Circlip, Dia. 16mm Shaft

Interlock Plain Arm

Interlock Link Lever

Spring Pin, 1/8” x 3/4”

Interlock Handle Arm

Adjusting Screw

Lock Nut (Thin), M12

Interlock Pin

Handle

Hex Head Plated Screw M6 x 12

Hex Nut M6

Screw M6 x 10L Button Head

Link Bush

Air Cylinder

Elbow 1/8 BSP M + F

Straight Adaptor ø6 Tube

Spring Stop

M6 x 35 Hex Hd. Bolt

Shakeproof Washer

Air Pipe Assy.

Elbow Connector ø6 Tube

Equal Tee Connector ø6 Tube

ø6 Tube

Swivel Block

Straight Connector ø6 Tube

ø6 Tube

ø6 Tube

Label - Serial No.

Rod Pivot Bush

Crescent Clip ø1/4” Shaft

E Circlip ø0.438” Shaft

Washer 7/16” Flat

Spring

Spring Guide

WHEEL FREE BEAM ASSEMBLY

Wheels Free Beam

Label SWL, 2 Tonnes

Location Pad

Vee Pad

Extension Pad, 100mm

Extension Pad, 50mm

Support Bracket

M10 x 25 Hex. Screw G8.8

M10 Nut

Plastic Cap

Extension Pad 28mm

Rubber Pad

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

6

1

1

1

1

1

1

1

2

4

1

2

2

1

6

8

2

1

4

6

2

2

2

2

2

2

4

8

1

1

1

1

2

1

1

1

1

4

4

2

2

2

2

2

4

4

2

2

4

4

24

24

4

4

4

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

Fig. No. Part No. Description Quantity Item no.

This manual suits for next models

1

Table of contents

Other TECALEMIT Lifting System manuals

Popular Lifting System manuals by other brands

stellar labs

stellar labs SHUTTLE 84-12-13 G Assembly and installation manual

Terex

Terex Genie QS-12R Operator's manual

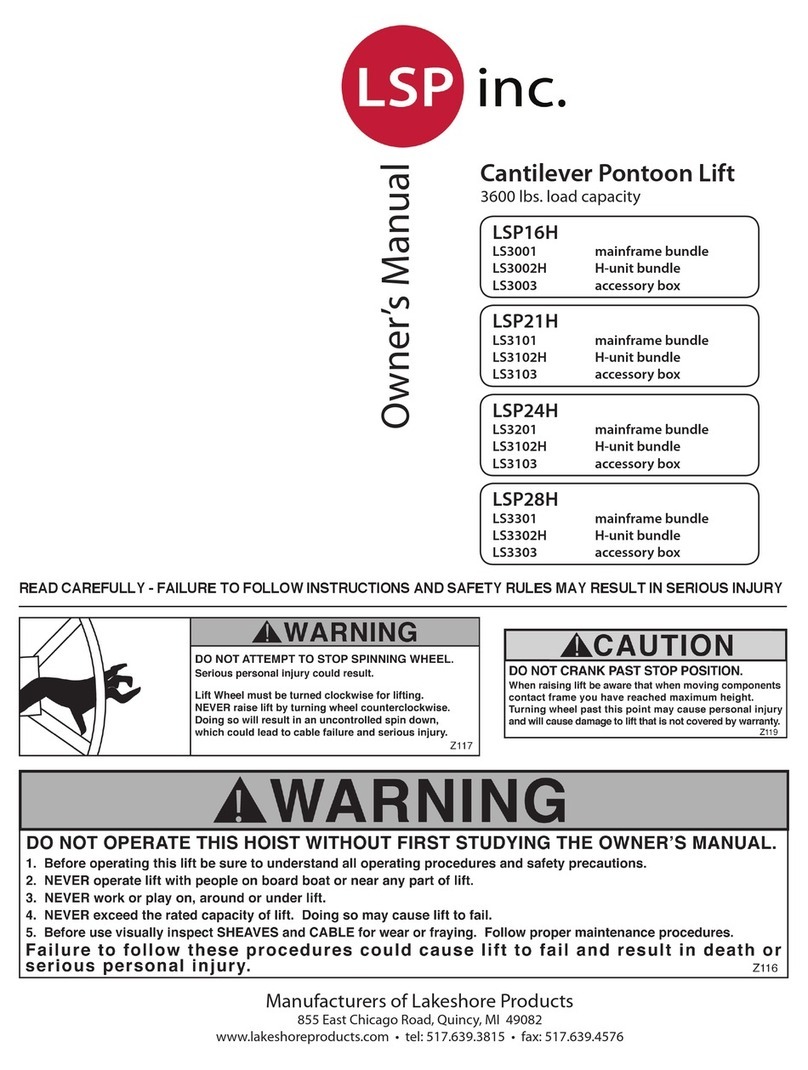

LSP inc.

LSP inc. LSP16H owner's manual

Harmar Mobility

Harmar Mobility HIGHLANDER II Installation & service manual

Terex

Terex Genie Z-45 XC Service and repair manual

Nussbaum

Nussbaum POWER LIFT HF 7000 Operating Manual and Inspection Book