2. Safety

MiRHook 200 Operating guide (en) 2019/08 - v.2.0 ©Copyright: Mobile Industrial 10

WARNING

Lithium battery packs may get hot, explode or ignite and cause serious injury if

they are abused electrically or mechanically.

Observe the following precautions when handling and using lithium batteries:

•Do not short-circuit, recharge or connect with false polarity.

•Do not expose to temperature beyond the specified temperature range or

incinerate the battery.

•Do not crush, puncture or disassemble the battery. The battery contains

safety and protection devices, which, if damaged, may cause the battery to

generate heat, explode or ignite.

•Do not allow the battery to get wet.

•In the event the battery leaks and the fluid gets into one’s eye, do not rub

the eye. Rinse well with water and immediately seek medical care. If left

untreated, the battery fluid could cause damage to the eye.

•Use only the original charger (cable charger or charging station) and

always follow the instructions from the battery manufacturer.

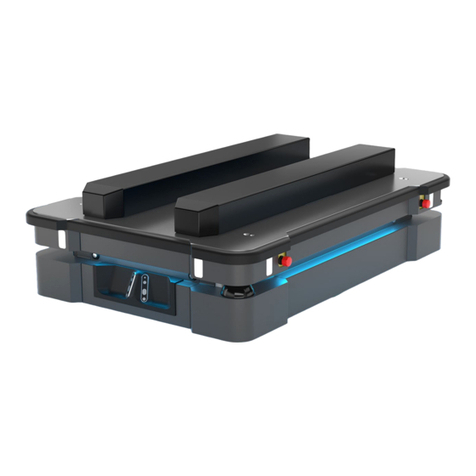

2.3. Intended use

MiRHook 200 is a partly completed machine as defined in the EU machinery directive and

does not have a CE mark. A correctly installed MiRHook 200 is covered by the CE mark of

MiR200. However, a CE marked product does not guarantee a CE marked setup. It is the

responsibility of the integrator to safely commission MiRHook 200.

MiRHook 200 is designed for MiR200. MiRHook 200 is only intended to tow carts fulfilling

the technical requirements found in Cart specifications on page21 and is commissioned

according to the guidelines found in Commissioning on page21

NOTICE

A safe machine does not guarantee a safe system. Follow the Commissioning

guide to ensure safe commissioning.

MiRHook 200 is intended to be commissioned indoor in a light industrial environment where

public access is restricted. For detailed description of the environment in which the robot

should operate, see Technical specifications on our website.