Tecfluid CP420R User manual

Programmable

flow rate transmitter

CP420R & CH420R

Instructions Manual

R-MI-CH420R Rev.: 0 English version

1. INTRODUCTION

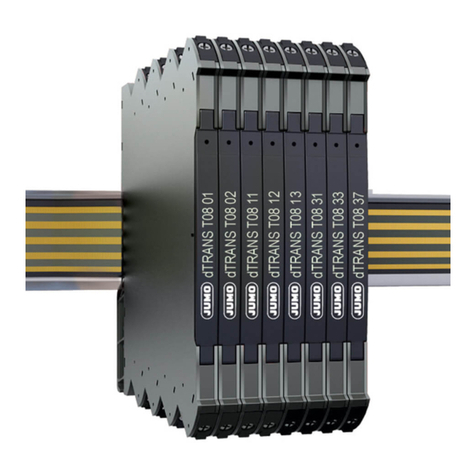

The electronic transmitters CP420R and CH420R are DIN rail modules designed to work with

Tecfluid’s volumetric counters (COVOL) and turbines. The instruments are supplied already

configured for the type of input.

The circuit is based on a microprocessor that, in function of the pulses per litre programmed,

calculates the flow rate and totalizes the volume that flows through the meter and shows

these values on a local indicator.

The CH420R differs from CP420R in that it is also HART protocol compatible.

2. OPERATION

To adapt the transmitter to the meter, the pulses per litre factor specified on the meter must

be programmed.

If the instrument has not been previously programmed or, due to an alteration in the data

memory the instrument recovers the default factory values, then the display will show

“PRESET”. This indication will disappear when the programming sequence has been

completed.

There are three push buttons with the following functions:

2.1.Programming

In all the programming screens, the “RESET” push button exits the screen without saving

the data in the memory, even if changes in the digits have been made or not .

By pushing the two push buttons PROG at the same time, the display will change to the

programming mode. In this mode there are 7 digits (four whole numbers and three

decimals). The value that must be introduced is the pulses per litre factor given on the

label of the COVOL or Turbine.

To do this, pushing the push button marked with the arrow pointing upwards, the blinking

digit will increase. Once the desired value of the digit is achieved, by pressing the push

button marked with the arrow pointing left, the cursor will pass to the next digit to be

modified. On the seventh digit, by pressing this push-button the cursor will pass to the first

digit on the display.

When the value of the pulses per litre is correct, by pushing the two push buttons PROG

at the same time, this value will be automatically saved in the memory and it will appear the

units selection screen.

2

3

To change the flow rate units, the push button marked with the arrow pointing upwards,

must be pushed. To change the totalized volume units, the push button marked with the

arrow pointing left pointing upwards, must be pushed.

The possible flow rate and totalized volume units are the following:

Flow rate:

There are 9 combinations made from 3 volume units and 3 time units.

Volume / time

l (litres) / s (second)

m3 (cubic meters) / m (minute)

ga (gallons) / h (hour)

Totalized volume:

There are 3 possible volume units, l (litres), m3 (cubic meters), ga (gallons)

Note: 1ga = 3.785 litres.

With the working units chosen, by pressing the two push buttons PROG, we go to the loop

current programming.

In the first screen we program the flow rate equivalent to 4 mA (lower range). The

measuring units will be the ones chosen in the previous screen. The push buttons have

the same function as the pulses per litre programming.

After that, we program the flow rate equivalent to 20 mA (upper range).

In a CH420R, if during the programming sequence we receive a HART command that

must be attended, the local programming will not be valid and all the data previously

programmed will be lost. The screen will return to the normal working model and the word

PROG will light on the screen, indicating this event. To remove the word PROG from the

display, press any of the two PROG push buttons.

2.2.Serial number indication

By pressing the three push buttons, the display will show the serial number. To return to

the usual screen, press any of the push buttons.

2.3.Reset

By pushing the RESET push button, the counter will be set to zero and it will continue to

count.

3. MAINTENANCE

It doesn’t require any special maintenance.

4. MEASUREMENT ERROR CORRECTIONS

The calibration of the mechanical flow meters is made with water at 20 oC to obtain a

calibration for a liquid of density 1 kg/l and viscosity of 1 mPa·s. If the flow meter is used with

a liquid of other characteristics from the above specified or for reasons of turbulences in the

flow, measurement errors can be induced.

To correct these types of errors we can modify the pulses per litre factor programmed in the

instrument.

Example 1 - Shortage of volume

If we have a flow meter body which specifies i/l = 1.985, and when we check the volume of a

batch, we find that instead of having 100 litres as programmed, we only have 95 litres (5%

less) and we must apply the following correction:

i/l = Original Pulses per litre Factor = 1.985

V = Expected Volume = 100

Vr = Real Volume = 95

i/l n = i/l V

Vr

i/l n = New Pulses per litre Factor = ? (2.089)

Example 2 - Excess of volume

If we have a flow meter body which specifies i/l = 1.985, and when we check the volume of a

batch, we find that instead of having 100 litres as programmed, we only have 105 litres (5%

more) and we must apply the following correction:

i/l = Original Pulses per litre Factor = 1.985

V = Expected Volume = 100

Vr = Real Volume = 105

i/l n = i/l V

Vr

i/l n = New Pulses per litre Factor = ? (1.887)

4

5. HART COMMUNICATION

The CH420R transmitters have a HART communication MODEM

The details of the characteristics with respect to the HART communication are available in the

appropriate Field Device Specification

Resume of the principal communications characteristics:

Manufacturer, Model and Revision Tecfluid S.A., CH420R, Rev. 0

Device type Transmitter

Hart Revision 6.0

Device Description available No

Number and type of sensors 1, external

Number and type of actuators 0

Number and type of host side signals 1, 4 – 20 mA analog

Number of Device Variables 2

Number of Dynamic Variables 1

Mappable Dynamic Variables No

Number of Common Practice Commands 13

Number of Device Specific Commands 2

Bits of Additional Device Status 12

Alternative operating modes? No

Burst mode? No

Write Protection? Yes

Analog loop electrical characteristics for communications :

Reception Impedance :

Rx > 8,5 M

Cx < 200 pF

4. PUSH BUTTON INHIBIT AND “WRITE PROTECT”.

The transmitter has a jumper situated behind the PCB at the top left corner, which can be used to

avoid changes in the configuration. When the jumper is removed, the push buttons are disabled

and the HART write protect is activated, thus inhibiting any changes in the configuration.

To gain access, remove the left hand side cover.

5

7. MODELS

C __ 420 __ __

C COVOL input

T Turbine input

L Local mounting on the flow meter

R DIN rail mounting inside a switchboard

P Transmitter with analog output

H Transmitter with analog output and HART communication

8. TECHNICAL CHARACTERISTICS

8.1.Power supply

2 wires, by means of the loop current.

The instrument has a protection diode to avoid damage if the power supply is connected

with inverted polarity .

Nominal voltage: 7.5 ... 36 Vdc

Power consumption: 20 mA

8.2.Totalizer

N. of digits: 7

Size of the digit: 8 mm

Reset: By means of push button

8.3. Flow rate Indication

N. of digits: 5

Size of the digit: 5 mm

8.4. General characteristics

Ingress protection: IP40

Ambient temperature range: 0 … +60 ºC

8.5. Input terminals

The pulse input is connected to a screw terminal block marked as Pulse.

Terminal n. COVOL Turbine

1 Common Live

2 Live Live

8.6. Inputs characteristics

NOTE: The input terminals are not isolated from the 4-20 mA loop. Under no

circumstances can an electrical connection be made between the 4-20 mA loop and

the inputs. In the event of supplying various transmitters with the same power

supply one must make sure that the inputs isolated between each other.

6

8.6.1.COVOL

If the Pulse input is configured for Covol (jumpers in position 2-3), a potential free

contact can be connected between terminals 1 & 2. Terminal 1 is connected to the

common of the instrument. This input has a 1 Mpull-up resistor connected to

terminal 2 and to the 3,3 V power supply. The input has a hysteresis with the

switching points situated at about 1 V & 2,1 V. If an open collector transistor is to

be used as the switching element instead of a COVOL, then the aforementioned

parameters must be taken into account.

Due to the presence of a filter to avoid the effects of contact bounce, the maximum

pulse frequency for the COVOL input is 300 Hz.

The minimum input frequency is 0.06 Hz

8.6.2.Turbine

If the Pulse input is configured for Turbine (jumpers in position 1-2), a coil of a

magnetic pick-up can be connected between terminals 1 & 2.

The input impedance is 1,2 K. This input is protected to limit the maximun applied

voltage to the circuit. This protection consists of two diodes in parallel and two 100

Ohm resistors.

The maximum voltage that can be applied to the input is 10 Vpp. Voltages higher

that this can cause damage to the equipment.

The maximum input frequency is 5000 Hz

The minimum input voltage is 7 mVpp

8.7. Loop connection

The 4-20 mA loop is connected to a screw terminal block marked as mA. The right hand

side terminal is the positive (+) and the left hand side terminal is the negative (-).

Host or

Power Supply CH420

+

+

--

Complies with the Directive EMC 89/336/EEC

7

1 M

22

11

+3.3V

100

1K

100

2

2

1

3

Pick-up

9. Dimensions

TECFLUID, S.A.

Narcís Monturiol, 33

E-08960 Sant Just Desvern

Tel. + 34 933 724 511 - Fax + 34 934 734 449

E-mail: [email protected]

Internet: www.tecfluid.com

The technical data in this pamphlet is subject to modification without notification, if the technical innovations in the product or

manufacturing processes so require.

WARRANTY

Tecfluid S.A. GUARANTEES ALL ITS PRODUCTS FOR A PERIOD OF 24 MONTHS, after

consignment, against all defects in materials and workmanship.

This warranty does not cover failures which can be imputed to misuse, use in an application different

to that specified in the order, the result of service or modification by un-authorized persons, bad

handling or accident.

This warranty is limited to cover the repair or replacement defective parts which have not been

damaged by misuse.

This warranty is limited to the repair of the equipment and all further and eventually following

damages are not covered by this warranty.

Any consignment of equipment to our factory or distributor must be previously authorised. The

consignment should be done with the equipment well packed, clean of any liquids, grease or

hazardous materials. Tecfluid S.A. will not accept any responsibility for damage done during

transport.

Together with the equipment, a note should be enclosed indicating the failure observed, the name,

address and telephone number of the sender.

This manual suits for next models

1

Table of contents

Other Tecfluid Transmitter manuals

Popular Transmitter manuals by other brands

Belkin

Belkin TuneFM for iPod user manual

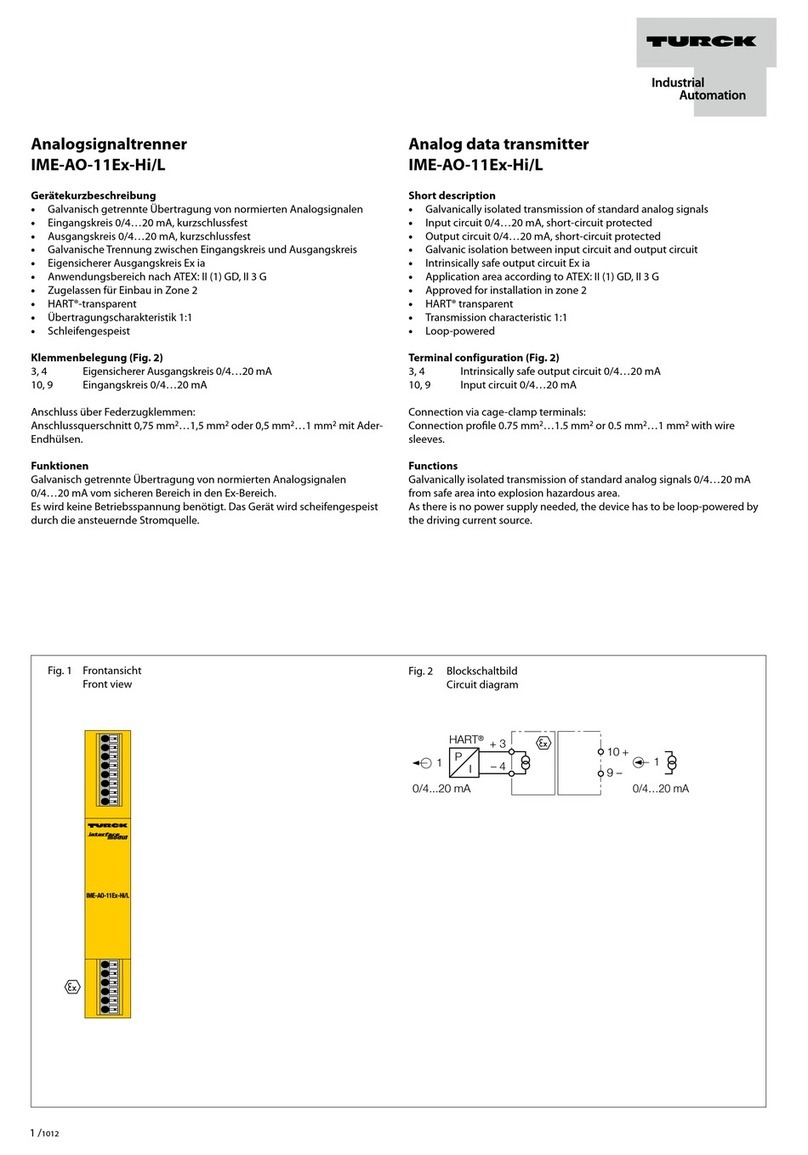

turck

turck IME-AO-11Ex-Hi/L quick guide

Sentera Controls

Sentera Controls RSMF-2R Series Mounting and operating instructions

Fukuda Denshi

Fukuda Denshi LX-7120 Operation manual

Nivus

Nivus NivuFlow 750 instruction manual

Sentera

Sentera RSCOX-R Mounting and operating instructions