Tecfluid LU Series User manual

R-MI-LU9X2 Rev.: 0

Series LU

Ultrasonic level transmitter LU9X2

Instructions manual

The art of measuring

2

Thank you for choosing a product from Tecfluid S.A.

This instruction manual allows the installation, configuration,

programming and maintenance. It is recommended to read it before

using the equipment.

This document shall not be copied or disclosed in whole or in any

part by any means, without the written permission of Tecfluid S.A.

Tecfluid S.A. reserve the right to make changes as deemed

necessary at any time and without notice, in order to improve the

quality and safety, with no obligation to update this manual.

Make sure this manual goes to the end user.

Keep this manual in a place where you can find it when you need

it.

In case of loss, ask for a new manual or download it directly from

our website www.tecfluid.com Downloads section.

Any deviation from the procedures described in this instruction

manual, may cause user safety risks, damage of the unit or cause

errors in the equipment performance.

Do not modify the equipment without permission. Tecfluid S.A. are

not responsible for any problems caused by a change not

allowed. If you need to modify the equipment for any reason,

please contact us in advance.

PREFACE

WARNINGS

3

TABLE OF CONTENTS

SERIES LU9X2

1 INTRODUCTION ........................................................................... 6

2 WORKING PRINCIPLE ................................................................... 6

3 RECEPTION .................................................................................. 6

3.1 Unpacking .......................................................................... 6

3.2 Storage temperature............................................................. 7

4 INSTALLATION ............................................................................. 7

4.1 Measuring range ................................................................. 7

4.2 Obstacles in the vessel ....................................................... 8

4.3 Filling entries ........................................................................ 9

4.4 Foams ............................................................................... 9

4.5 Standpipe measurement ....................................................... 9

4.6 Temperature ...................................................................... 9

5 ELECTRICAL CONNECTION ........................................................... 10

5.1 Power supply and analog output wiring ................................ 10

5.2 Alarm outputs wiring ............................................................ 11

6 OPERATION ................................................................................. 12

6.1 Without display module ....................................................... 12

6.2 With display module ........................................................... 12

7 MAIN MENU .................................................................................. 13

7.1 Access codes to the menus ................................................ 14

8 INSTALLATION PARAMETERS ........................................................ 16

8.1 Tank .............................................................................. 16

8.1.1 Bottom distance ..................................................... 17

8.1.2 Top distance ......................................................... 17

8.2 Dead zone .......................................................................... 18

8.2.1 Dead zone current .................................................. 18

8.2.2 Dead zone length ................................................... 19

8.3 Diagnosis ............................................................................ 19

8.4 Operating mode .................................................................. 20

4

9 PROGRAMMING PARAMETERS ..................................................... 20

9.1 Measuring units .................................................................. 21

9.2 Decimals ............................................................................ 21

9.3 Filter ............................................................................... 21

9.3.1 Filter time .............................................................. 22

9.3.2 Hysteresis ............................................................. 22

9.3.3 Interference time ..................................................... 22

9.4 Outputs ............................................................................... 23

9.4.1 Analog output ......................................................... 23

9.4.1.1 Programming output 4-20 mA .................. 23

9.4.1.2 Current calibration for 4 and 20 mA .......... 24

9.4.2 Alarm outputs .......................................................... 24

9.4.2.1 Level ....................................................... 24

9.4.2.2 Dead zone ................................................ 26

9.4.2.3 No echo ................................................... 26

9.4.2.4 Disabled .................................................. 26

9.5 Default screen ..................................................................... 26

10 SERIAL NUMBER .......................................................................... 27

11 FIRMWARE VERSION ..................................................................... 28

12 CONTRAST ............................................................................... 28

13 OPERATION SCREEN ................................................................... 28

13.1 Indication of echo in dead zone ........................................... 29

13.2 Indication of absence of echoes ........................................... 29

14 ASSOCIATED SOFTWARE WINSMETER LU ................................... 30

14.1 USB cable connection and software installation ................... 30

14.2 Port connection .................................................................. 31

14.3 Password ........................................................................... 32

14.4 Access to “Installation” ....................................................... 35

14.4.1 Limits .................................................................... 35

14.4.2 Mode .................................................................... 35

14.4.3 Dead zone ............................................................. 35

14.5 Acces to “Programming” ..................................................... 36

5

14.5.1 Level ..................................................................... 36

14.5.2 Filter ..................................................................... 36

14.5.3 Current loop .......................................................... 37

14.5.4 Alarm outputs ......................................................... 37

14.5.5 Current loop calibration .......................................... 37

14.6 Visualization ....................................................................... 37

14.7 Datalogger ......................................................................... 38

14.8 Firmware updates ............................................................... 39

14.9 Configuration file ................................................................ 40

15 TECHNICAL CHARACTERISTICS .................................................. 41

16 SAFETY INSTRUCTIONS ................................................................ 41

16.1 Certificate of conformity TR CU (EAC marking) ..................... 42

17 TROUBLESHOOTING .................................................................... 42

18 DIMENSIONS ............................................................................... 43

6

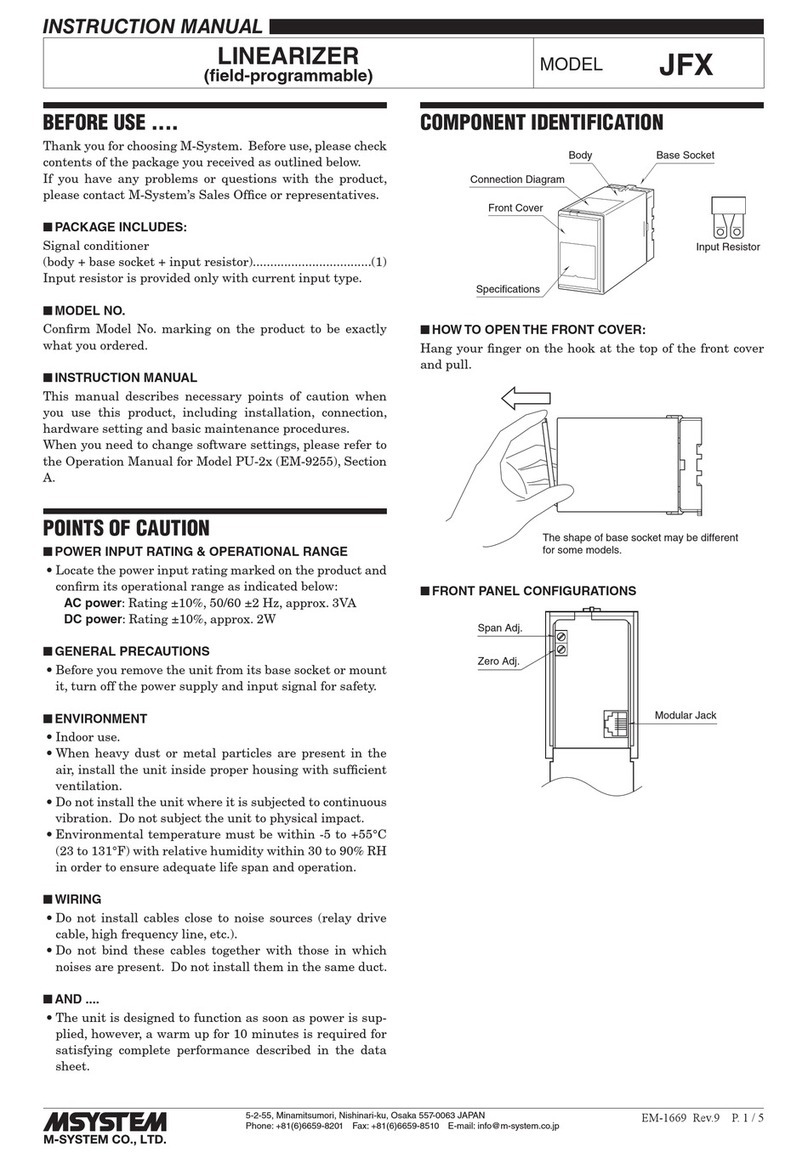

1INTRODUCTION

The series LU level transmitters are electronic equipment based on the transmission of

ultrasonic waves to measure the distance to a liquid or solid in a vessel.

The microprocessed electronic circuit offers the following features:

Emission and reception circuits for the ultrasonic signals, and microprocessor

treatment.

Alarm outputs with programmable hysteresis level.

Programmable current output proportional to the distance or level.

Quick current range programming by means of internal keys.

Keyboard and 128x64 pixel graphic display module (optional).

2WORKING PRINCIPLE

An emitting circuit sends an electrical signal to a transducer that converts it into an ultrasonic

signal that propagates through the medium until it bounces off the surface of a liquid or solid.

The echo signal travels back until it reaches the transducer again and is converted into an

electrical signal.

By multiplying the time it takes for the signal to propagate by the speed of sound in the

medium, the travelled distance is obtained.

3 RECEPTION

The LU level transmitters are supplied conveniently packaged for their protection during

transportation and storage, together with their instructions manual for installation and

operation.

All the instruments are supplied tested in our facilities.

3.1 Unpacking

Unpack the instrument carefully, removing any remains of the packing .

Distance = vsound (t1+t2) / 2

7

Screw the instrument in the socket with an appropriate key, always by the flat sides for this

purpose. The maximum torque is 25 Nm.

Never use the electronics housing for threading the device to the vessel.

Excessive tightening can damage the transducer irreparably.

4.1 Measuring range

The minimum distance that the instrument can measure is called dead zone. If the product

gets closer than that distance, the level transmitter indicates an alarm by means of the

current loop, that will be 3.6 mA or 22 mA depending on the programming (see point 8.2.1

on page 18). If the instrument has a display it will show the message “Dead zone”.

Never work within the dead zone. In certain circumstances, false level readings may occur.

3.2 Storage temperatures

Sensors of : PVDF -20ºC ...... +60ºC

PP -5ºC ...... +50ºC

4 INSTALLATION

To make the instrument work in the best conditions, it is important that the bottom face of

the sensor is installed parallel to the surface of the product to be measured. In the case of

liquids, the face of the transducer should be horizontal.

It is important to avoid installing the instrument at the center of the vessel. In some cases

unwanted echoes that affect the measurement may appear. The installation at the center is

only advantageous in vessels with tapered bottom, since distances can be measured to the

bottom.

The LU transmitters should be installed at a minimum distance of the walls of the vessel of

about 200 mm, so that they could not give unwanted reflections.

The socket where the instrument is installed should be such that the bottom of the

instrument exceeds at least 10 mm below it, as shown in the following figure.

8

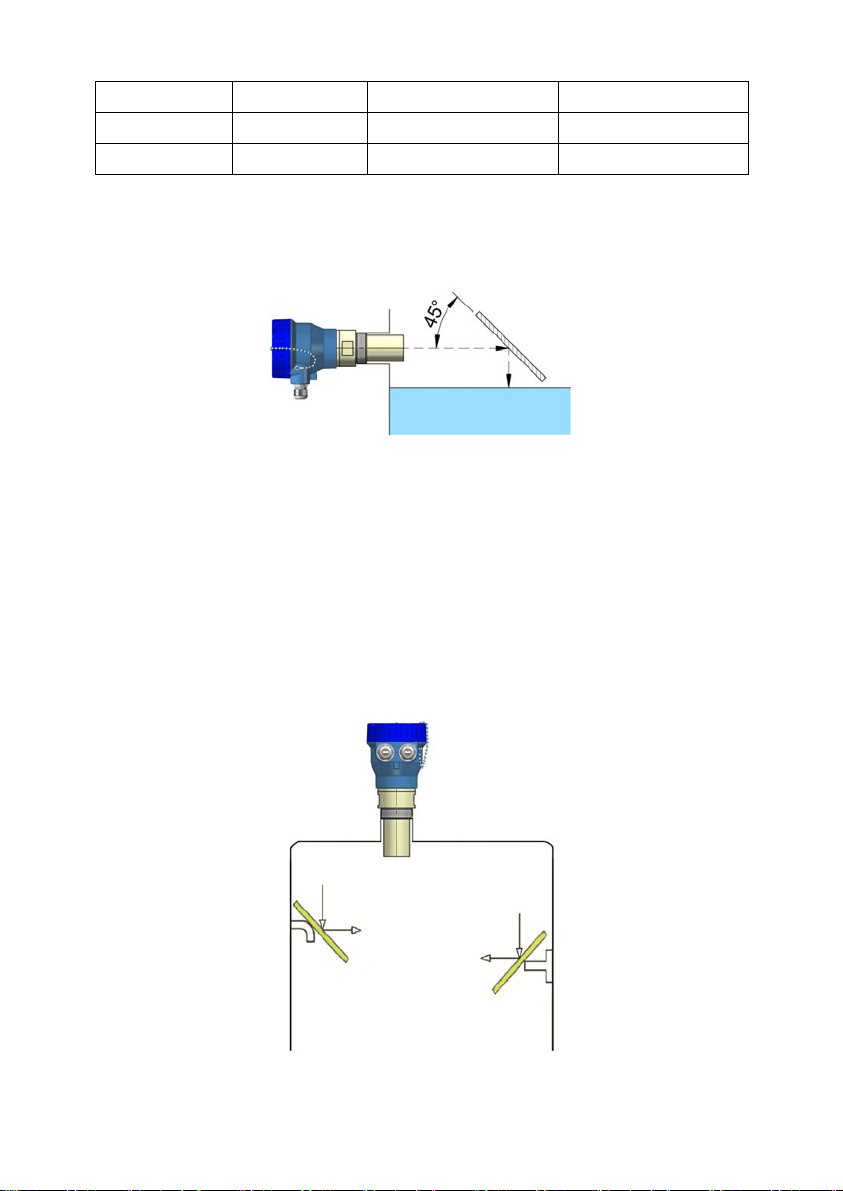

Model Dead zone Max. distance (liquids) Max. distance (solids)

LU912 0.3 m 5 m 2.5 m

LU932 0.45 m 10 m 5 m

In cases where it is necessary to measure distances shorter than the dead zone, a reflector

can be installed as shown in the figure.

The measured distance will be the addition of the real distance plus the distance between

the transducer and the reflector.

It should be avoided that the product reaches the instrument, since accumulations might

form on the transducer, and that would affect the measurement.

4.2 Obstacles in the vessel

The transmitter must be installed so that the ultrasonic beam cannot find anything on its

path, as this could lead to unwanted echoes and incorrect measures.

In some cases, inclined reflectors can be placed in front of an obstacle, so that the beam in

this region is diverted and the reflected signal does not return to the instrument.

9

4.3 Filling entries

It is not recommended to install the level transmitter in the upper zone of a filling entry,

because the instrument could detect the level of the jet filling instead of the level of the

stored product.

4.4 Foams

Some liquids generate foams when in movement. In vessels with agitators, or in the filling

processes, important layers can be generated that weaken the reflected signal which is

essential for measuring the level.

In a lot of cases the problem of the foam and wave turbulences can be solved by putting a

standpipe.

4.5 Standpipe measurement

It can be appropriated in cases of waves or foam. It is based on placing a tube in the tank so

that the instrument measures the level inside the tube.

The length of the tube depends on the distance that you want to measure, or the minimum

level desired.

The diameter of the tube should be bigger than the threaded connection size of the

instrument (> 2 inches or 50 mm for the LU912 and > 2 1/2" or 65 mm for the LU932).

The standpipe should incorporate a drill top vent grilled hole with a diameter between 5 and

10 mm.

If the standpipe is composed of several sections, it is necessary that the inner wall is free

from defects (welding, edges, etc.) that could be interpreted as a false measurement. In the

same way, if the product is susceptible to leaving adherences or inlaid inside the tube, these

can lead to false readings.

4.6 Temperature

In outdoor installations, the measurement margins can be reduced due to environmental

conditions such as rain or wind, since the ultrasonic signal that travels through the air can be

affected.

It is also recommended to install a protection to avoid direct sunlight on the level transmitter.

The maximum working temperatures are indicated on page 41.

10

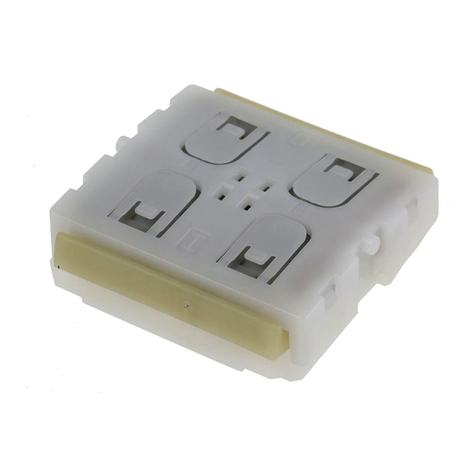

5 ELECTRICAL CONNECTION

For the electrical connection, the LU level transmitter is provided of terminal strips. To help in

the wiring of the equipment, the description of the terminals is marked next to each terminal

strip.

For the electrical installation it is recommended to use multiple conductor cables with

individual cable sections in the order of 0.25 to 0.5 mm2in order to make it easier to

connect.

Before starting the installation, check that the cable glands are the right size for the cables to

be used, this will guarantee the instrument will stay watertight. The M16 x 1.5 cable glands

used are for cables with outer diameters between 5 mm and 12 mm.

To connect the cables, peel the outer insulation to free the inner cables. Then pass the

cables through the cable glands and screw down in the corresponding positions of the

terminal strip as indicated in the following point.

Grip carefully the cables with the cable glands to maintain the ingress protection.

Incorrect installation of the cable gland or inadequate cable placement can cause

unrepairable damage to the converter.

5.1 Power supply and analog output wiring

Before starting the installation of the equipment, check that the supply voltage available is

the same as marked on the label of the level transmitter.

Models LU912 and LU932 are two-wire instruments, that is, the equipment is powered

through the current loop.

The positive terminal of the power supply is connected to the position + and the positive

terminal of the load to the position -. The negative terminals of the power supply and the

load are connected together.

Since it is a 2-wire instrument, the supply and signal line is the same. It is recommended to

use a twisted pair wiring or shielded cable to avoid interferences in the current loop.

It is recommended to use a load with a resistance lower than 700 Ω to guarantee a good

performance.

11

Terminal

S1 Source output 1

D1 Drain output 1

S2 Source output 2

D2 Drain output 2

The alarm outputs are connected in the positions D and S of the terminal block.

Outputs are N-channel MOSFET transistor isolated from the rest of the circuit and potential

free.

Example of the connection of the alarm output to a PLC

NOTE: The analog output has protection against reversed polarity. Due to another

protection against overvoltages, if a loop supply voltage with inverted polarity and higher

than 32 V is connected, the equipment may be damaged.

5.2 Alarm outputs wiring

12

6 OPERATION

6.1 Without display module

The instrument allows programming the current loop limits by means of the 4 mA and 20 mA

keys. To do this, the top cover must be remove, previously releasing the DIN913 M3 x 8

safety screw.

The procedure is the following:

Point the equipment to a flat surface and place it at the distance corresponding to 4 mA.

Press the 4 mA button until the led blinks (about 4 seconds).

Then place the equipment at the distance corresponding to 20 mA. Press the 20 mA button

until the LED blinks (about 4 seconds).

From this moment, the level transmitter will transmit the current proportional to the distance

between the two programmed values.

6.2 With display module

The instrument is delivered generally calibrated and programmed to indicate a distance. To

change any configuration parameter, the keyboard can be accessed by removing the top

cover.

LU level transmitters have a graphic display and 4 keys.

13

In the following figure the operation of each key is described.

(Down / Left) To change between

operating screens.

To decrease a digit or to move to the

left digit.

Inside the menus, to shift into the below

element.

(Up) To change between display

screens.

To increase a digit.

Inside the menus, to shift into the

upwards element.

(Enter) To validate a data.

To enter the different menus of the

device.

To exit an informational text.

(Escape) To go back to the previous

menu. To exit a screen without

validating a data.

NOTE: The function of the key (Down / Left) that changes to the left digit is done by

pressing the key for more than one second.

7 MAIN MENU

To access the main menu of the converter, press the key (Enter). The following screen

appears:

The "Installation" option allows to configure the instrument, in order to obtain a correct

indication. It is explained in Chapter 8 of this manual.

The "Programming" option allows to program all parameters of the converter, as explained in

Chapter 9 of this manual.

The “Language” option selects the language in which all the menus will be displayed.

14

The options "Serial Number" and "Firmware Version" are informative and are discussed in

Chapters 10 and 11 of this manual.

Finally, the option "Contrast" allows to adjust the contrast of the information on the screen,

to adapt it to the ambient light of each installation.

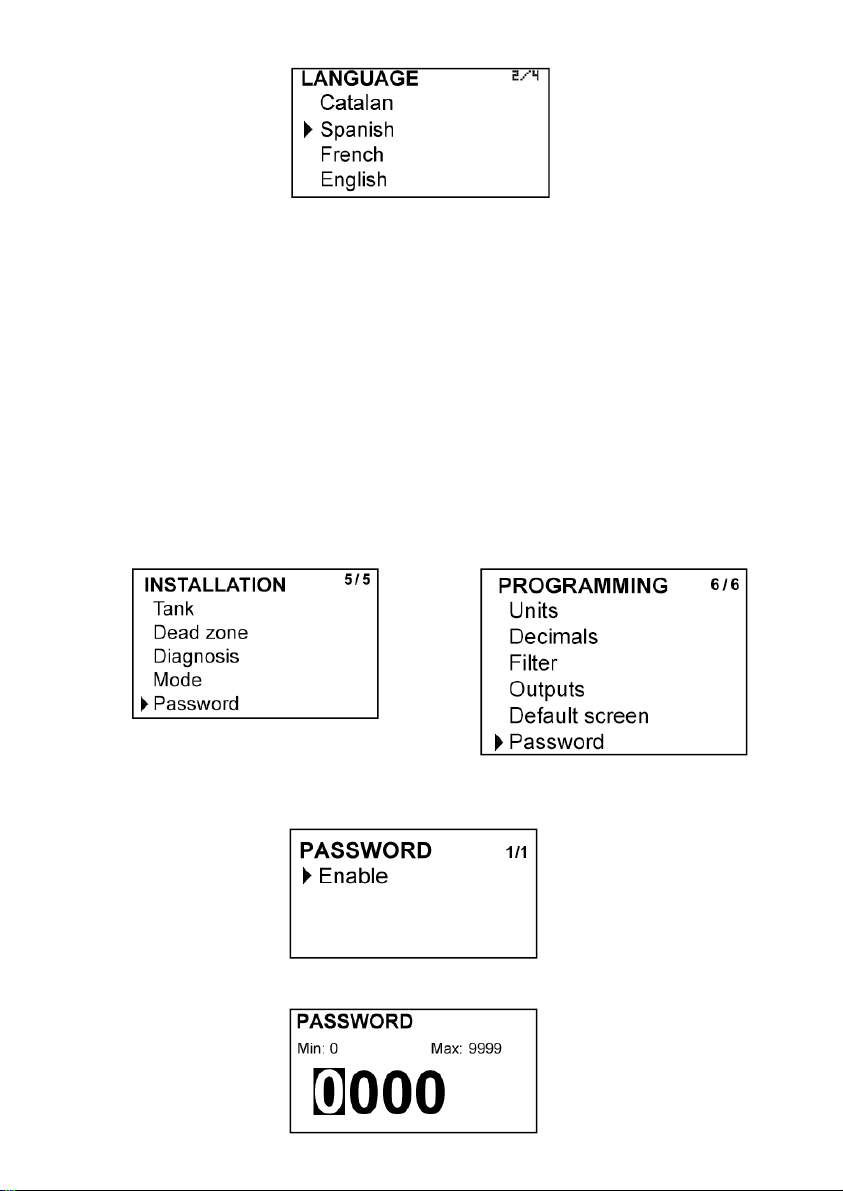

7.1 Access codes to the menus

It is possible to program a different password for the “Installation” menu and for the

“Programming” menu.

By default, the equipment is factory configured with the passwords disabled.

To change any of these passwords, it is necessary to enter the corresponding menu and

once inside, access the submenu "Password".

To change the access password of

the installation menu, select

"Installation" on the main menu and

then "Password".

To change the access password of

the programming menu, select

"Programming" in the main menu and

then "Password".

When the "Password" option is selected, a screen that indicates the password status for this

menu appears.

Selecting “enable”, the screen to enter the new password appears.

15

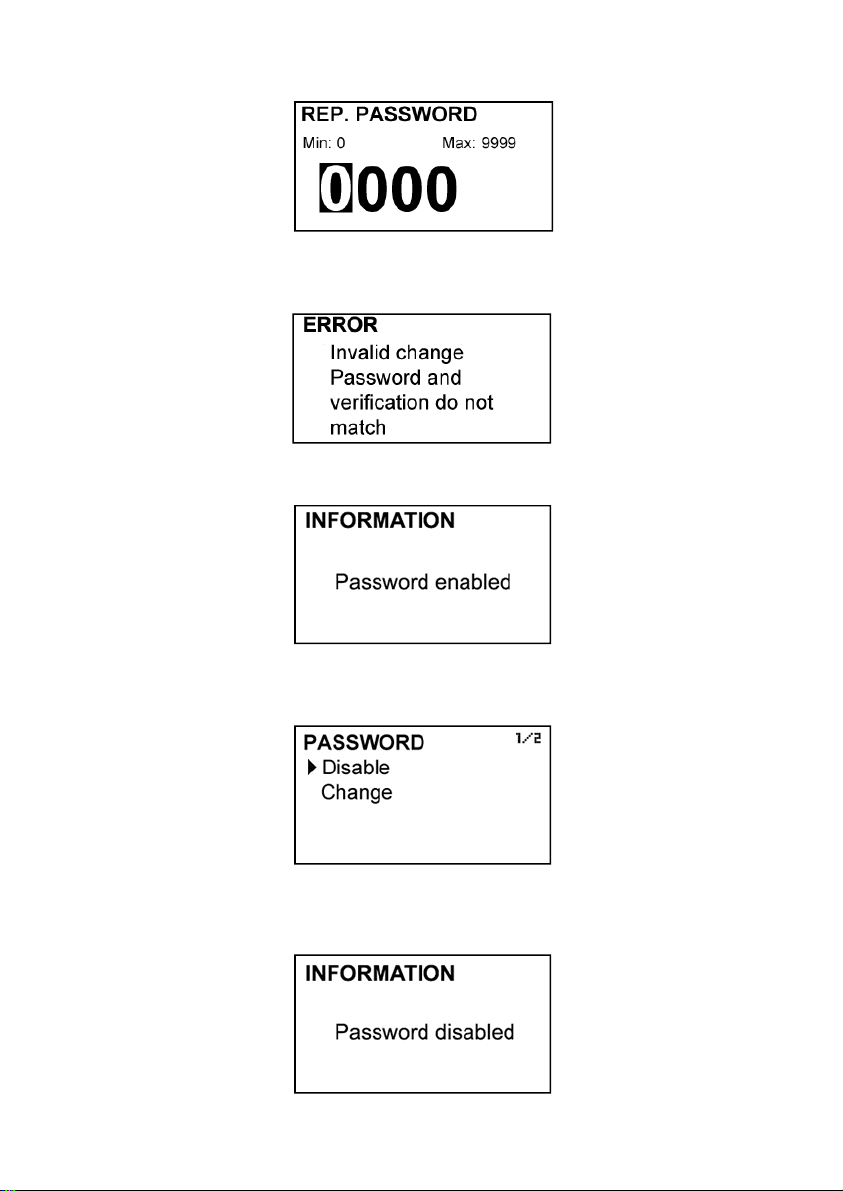

Once entered, the new password is asked again to avoid possible inadvertent error.

If the re-entered password does not match the first one, the following error message

appears and the process should be carried out again.

If both passwords match, the following information message is displayed.

If the password needs to be changed or disabled, the procedure is the same. Once entered

the "Password" menu, the following screen appears:

If “Change” is selected, the equipment will ask for a password again. If “Disable” is selected,

the following message will appear:

16

8 INSTALLATION PARAMETERS

Power on the electronic converter with the voltage indicated on the label.

Press the (Enter) key in order to enter the main menu.

With the keys (Down / Left) and (Up), select “Installation”, and then validate with the key

(Enter).

If the instrument has a password enabled, it must be entered to access the menu. For more

details about the password, see point 7.1 on page 14.

Once in the “Installation” menu, the first screen allows to choose between the different

options.

8.1 Tank

First, a screen appears where the bottom and top distances can be selected. These

distances allow the instrument to indicate measurements in level mode or percentage mode

(see point 9.5 on page 26).

17

8.1.1 Bottom distance

The bottom distance is the distance between the transducer face and the bottom of the

vessel. It allows to calculate el level with respect to that point. This parameter is necessary to

visualize data in level mode or percentage mode, because the instrument takes this distance

as a reference (see point 9.5 on page 26).

The following figure shows the bottom distance. In case of non flat bottom vessels, the

bottom distance should be taken between the end of the instrument, and the desired point

of zero level.

8.1.2 Top distance

This distance is necessary to visualize data in percentage mode (see point 9.5 on page 26).

Bottom

Distance

18

The percentage of filling is calculated given the bottom distance and the top distance (see

points 8.1.1 and 8.1.2 on page 17) , according to the following equation:

When the distance between the product and the sensor is “di”, the visualized percentage is

0%.

When the distance between the product and the sensor is “ds”, the visualized percentage is

100%.

8.2 Dead zone

In this screen the dead zone current and the dead zone length can be chosen.

8.2.1 Dead zone current

When the distance between the instrument and the product surface is shorter than the

minimum measuring distance, that is, when the product is in the dead zone (see section 4.1

on page 7), the instrument can transmit an alarm by means of a value of current out of

range. This value can be either 3.6 mA or 22 mA.

Top

Distance

%

Bottom

Distance

di: bottom distance

ds: top distance

19

When programming this value, the no echo alarm is automatically programmed with the

opposite value.

8.2.2 Dead zone length

In some installations it may be convenient to increase the dead zone value. For example, in

cases of vertical tube measurement.

In this screen the dead zone distance in m can be programmed.

8.3 Diagnosis

It allows to check some parameters of the instrument quickly.

Pressing the key (Enter) when Alarm 1 or Alarm 2 are selected, this output will be activated or

deactivated. When the output is activated, the text is shown as inverse.

Pressing the key (Enter) over 4 mA, the analog output alternates between 4, 8, 12, 16 and

20 mA, which allows to check the analog output adjustment.

20

In all cases the echo intensity is displayed by means of a value between 0 and 100. This

intensity depends on the distance to the target, the type of product where the wave is

reflected and the conditions of installation.

If the distance of the product at the time of verification is longer than half the maximum

measuring distance, it is normal that the intensity has a low value.

In the event that the distance is shorter, if the value of the intensity is low, it may be due to

two reasons:

a) That the product has a high absorption coefficient. This means that an important part of

the wave is absorbed by the product and is not reflected to the instrument. In this case, the

maximum measuring distance will be shorter than specified in the characteristics of the

instrument.

b) That the instrument has not been installed correctly. As the face of the transducer is no

longer parallel to the surface of the product, part of the reflected signal does not return to the

instrument, thus decreasing the intensity of the echo.

8.4 Operating mode

Distance or level can be selected. The reference point to calculate the level is the one

programmed as bottom distance (see point 8.1.1 on page 17).

The instrument will always be working in this mode even if there is a power fail.

Parameters related to the analog output and alarm outputs will be programmed in the

chosen mode.

9 PROGRAMMING PARAMETERS

By the programming parameters the visualization and the outputs of the instrument can be

configured.

Turn on the converter and press (Enter) to enter the main menu. The following screen

appears:

With the keys (Down / Left) and (Up), select “Programming”, and then validate with the key

(Enter).

If the instrument has an enabled password, it must be entered to access the menu. For more

details about the password, see point 7.1 on page 14.

Once in the “Programming” menu, the first screen allows to choose between the different

options.

This manual suits for next models

3

Table of contents

Other Tecfluid Transmitter manuals

Popular Transmitter manuals by other brands

Extech Instruments

Extech Instruments HDV-WTX Informational sheet

WAREMA

WAREMA WMS Wall-mounted transmitter plus Operating and installation instructions

Ritron

Ritron RQT-150 PB user guide

Kvaser

Kvaser Air Bridge Light HS user guide

Simu

Simu LiveIn2 instructions

Sony

Sony Walkman WLA-NWB1K operating instructions