5. Donotlet thewiring comeintocontact withheat-emitting

devices (fuse resistor, radiator plate, etc.).

6. Whenreplacing thewiring, make surethat itisnotincontact with

theunfinishedor rough edgeofapart.

7. Whenreplacing thepowercord (exceptfor theplug-intype), tug it

from variousdirectionstoconfirm that itdoes notslipoutof

place.

8. Spacing

Ifsoldering was doneon theACprimarycircuit, confirm that the

interval betweenthesolderedterminalsor betweentheterminal

and surrounding metallicparts isat least theminimum required

(betweentheprimarycircuitand thechassis:atleast 6.5mm;

betweenprimarycircuitterminals:at least 4.0mm;between

primarycircuitterminalsand secondarycircuitterminals:at least

6.5mm.).

2. SAFETY PRECAUTION

2.1. Safetyprecaution

1. Beforeservicing, unplug thepowercord topreventanelectric

shock.

2. Whenreplacing parts, use onlythemanufacturer’srecommended

components for safety.

3. Check thecondition ofthepowercord. Replace ifwearor

damageisevident.

4. Afterservicing, besuretorestoretheleaddress, insulation

barriers, insulation papers, shields, etc.

5. Beforereturning theservicedequipmenttothecustomer, besure

tomake thefollowing insulation resistance test topreventthe

customerfrom being exposedtoashock hazard.

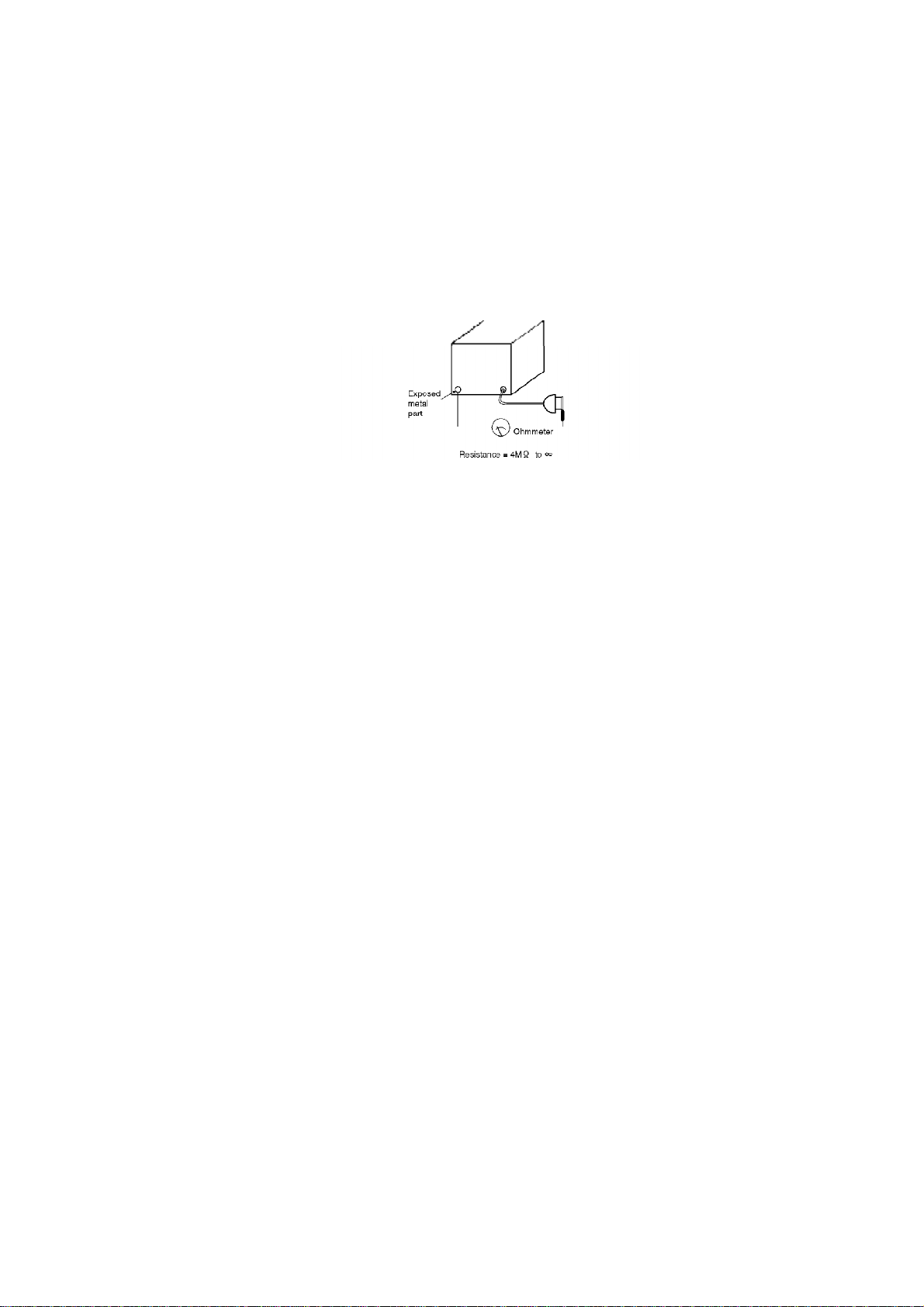

2.2. Insulation resistance test

1. Unplug thepowercord and shorttheprongsoftheplug witha

jumperwire.

2. Turn on thepowerswitch.