Metallkraft RBM 1270-25 E User manual

State 11.2008

I

In

ns

st

tr

ru

uc

ct

ti

io

on

n

m

ma

an

nu

ua

al

l

Motorized plate bending machine

RBM E-Series

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

2

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

Index

1.

General notes............................................................................................................................................................. 3

1.1.

Introduction...................................................................................................................................................... 3

1.2.

Transport ......................................................................................................................................................... 3

1.3.

Electrical Information ....................................................................................................................................... 4

1.4.

Maintenance.................................................................................................................................................... 4

1.5.

Safety............................................................................................................................................................... 4

2.

Transport and lifting of the machine........................................................................................................................ 5

3.

Technical properties ................................................................................................................................................. 6

4.

Adjustment for parallelism ....................................................................................................................................... 7

5.

Electrical connections............................................................................................................................................... 8

6.

Start-up instructions ................................................................................................................................................. 9

6.1.

Materials and Products.................................................................................................................................... 9

6.2.

Electrical Connection....................................................................................................................................... 9

6.3.

Electric Box...................................................................................................................................................... 9

6.4.

Standard foot pedal........................................................................................................................................ 10

6.5.

Starting the machine...................................................................................................................................... 10

6.6.

Basic Operation Terms.................................................................................................................................. 10

7.

Safety directives...................................................................................................................................................... 11

8.

Bending operations................................................................................................................................................. 16

9.

Opening the top roll................................................................................................................................................. 21

10.

Maıntenance............................................................................................................................................................. 22

11.

Parts list of RBM models ........................................................................................................................................ 23

12.

Parts of the machine 1 ............................................................................................................................................ 24

13.

Parts of the machine 2 ............................................................................................................................................ 25

14.

Electric schemes..................................................................................................................................................... 26

15.

Liability claims for defects / warranty.................................................................................................................... 34

16.

EG-declaration of conformity................................................................................................................................. 35

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

3

1. General notes

1.1. Introduction

Thank you for choosing a Metallkraft Sheet / Metal Working Machine. We are proud to have you in

our long list of satisfied customers all over the world.

This User’s Manual is absolutely for your safety and is essential for the machine to have a long pro-

duction life. As long as you keep up with our Manual you will be able to run your machine smoothly

and safely. Keep in mind that the machine is designed absolutely to perform maximum safety and for

efficient working.

In this Manual you can find instructions and information about:

Correct installations of the machine

Description of the functional parts of the machine

Set-up and start-up adjustments

Correct standard and scheduled maintenance

Simple safety regulations and accident prevention.

Therefore, as far as the user’s safety is concerned, in this handbook the possible risks connected with ma-

chine operation are pointed out as follows:

Attention: Showing the risks of accident, if instructions are not followed.

Warring: Showing the probable damages to the machine or equipment, if the instructions are

not strictly followed.

Note: It gives useful information.

It is certainly necessary that the operator should read and understand all the Attention,

Warring,

Note

specified in this Manual before starting with operation of the machine and before any lubrication or

maintenance intervention

On all steps of installation, operation and maintenance safety must be your first concern for the pro-

tection of yourself, other users and the service of the machine. In case of any failure please first refer

to this Manual, and then if a solution cannot be found contact first of all the distributor where you

purchased our product. Do not forget to refer to the drawings and the numbers for any spare part

needed or to define any problem. Make sure you have the serial number and production year of the

machine.

Our technical staff will make their best to help you in the most convenient way.

1.2. Transport

As soon as you receive the machine, check for any visible transport damages. Should there be any visible

damages; report it straight away to the transporter company and of course Metallkraft or your supplier.

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

4

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

Remove any protective crates around the machine and read the instructions on related chapters of this Ma-

nual carefully to set up the machine. If the machine is damaged while transport, immediately take some

photographs for insurance claims.

Take precautions while loading / unloading or moving the machine to avoid any injuries. Refer also to re-

lated chapter of this Manual for the best way of handling the machine.

1.3. Electrical Information

All necessary connection procedure can be found on this Manual. Do not try to connect the machine before

reading these procedures and fully understanding the drawings. For any unclear matters get in touch with

Metallkraft or any of the Metallkraft distributors. Have the machine connected by a qualified electric techni-

cian. For, as we made clear in the “general conditions of guarantee”, under no circumstances installing mis-

takes, including electrical connection mistake, can not be covered by guarantee agreement. Always turn off

power before making any connections or disconnecting the machine.

1.4. Maintenance

Your machine is designed and produced to work efficiently and smoothly. To achieve this you should also

take care while operating the machine. Regard Maintenance sections to have the longest life from your ma-

chine. Try and use original spare parts where necessary and most importantly do not overload the machine

or do not make any unauthorized modifications.

1.5. Safety

Take all precautions possible to avoid any personal injury while using the machine. Keep in mind to protect

the third party people around the machine. Refer to safety directives.

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

5

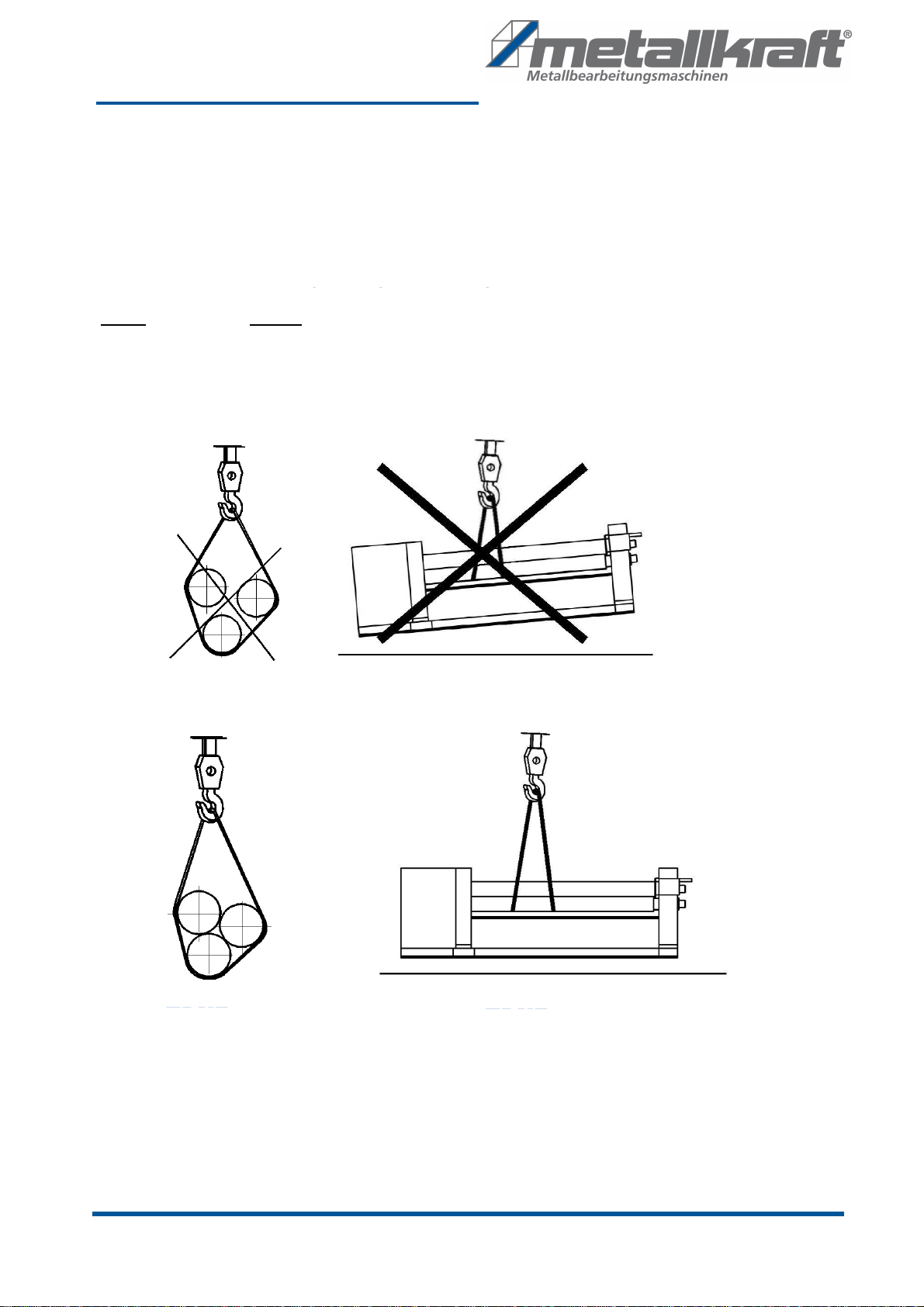

2. Transport and lifting of the machine

The machine weight is approximately. Use necessary cranes and lift as shown. Please take extra care dur-

ing lifting and moving. If necessary consult with specialized companies for lifting.

Model Weight

RBM 1050-30 E 450Kg

RBM 1270-25 E 490Kg

RBM 1550-20 E 600Kg

RBM 2050-15 E 800Kg

Opening the package

If any visible damage exist on the machine when you receive the machine immediately informs the dealer or

manufacturer. Also never forget to state the visible damage on transport documents.

The packing material is completely safe and do not consist any environmentally dangerous articles. However

they must be kept out reach of children as some nylon products in packing may cause suffocation if used as

a toy etc.

APPROX MACHINE WEIGHT

TRUE

TRUE

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

6

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

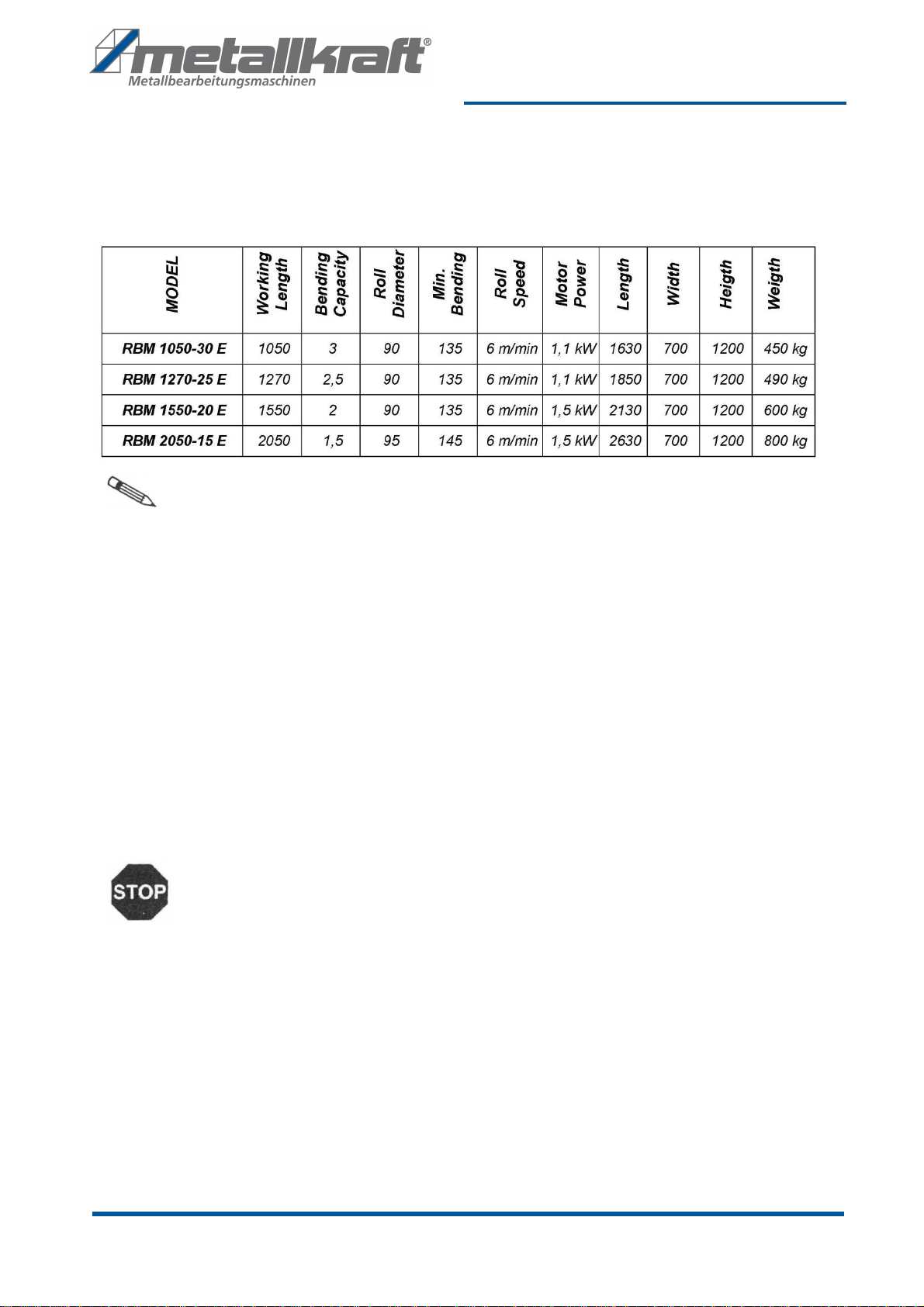

3. Technical properties

The RBM Model Motorized three roll benders have these specifications:

Technical specifications and standard equipments

Two rolls powered by a single gearbox and gear system

SAE 1050 Quality certificated steel rolls with high tensile strength

Cast iron main frame

Mobile control panel one RM models

Conical bending device

Precicion bending with brake motor on RM models

Worldwide available components used in production ( Telemecanique, Siemens for electric )

User manual book

Built according to EC safety directives

( CE – Mark )

Optional accessories

Induction hardened rolls

Motorised back roll adjustment

Warning: Do not feed profiles having a higher thickness than specified for the c

a-

pacity of the machine. Do not feed more than one piece at a time. Do not use the

machine for any other job the one for which it has been designed.

Note : Machine dimensions are approximate

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

7

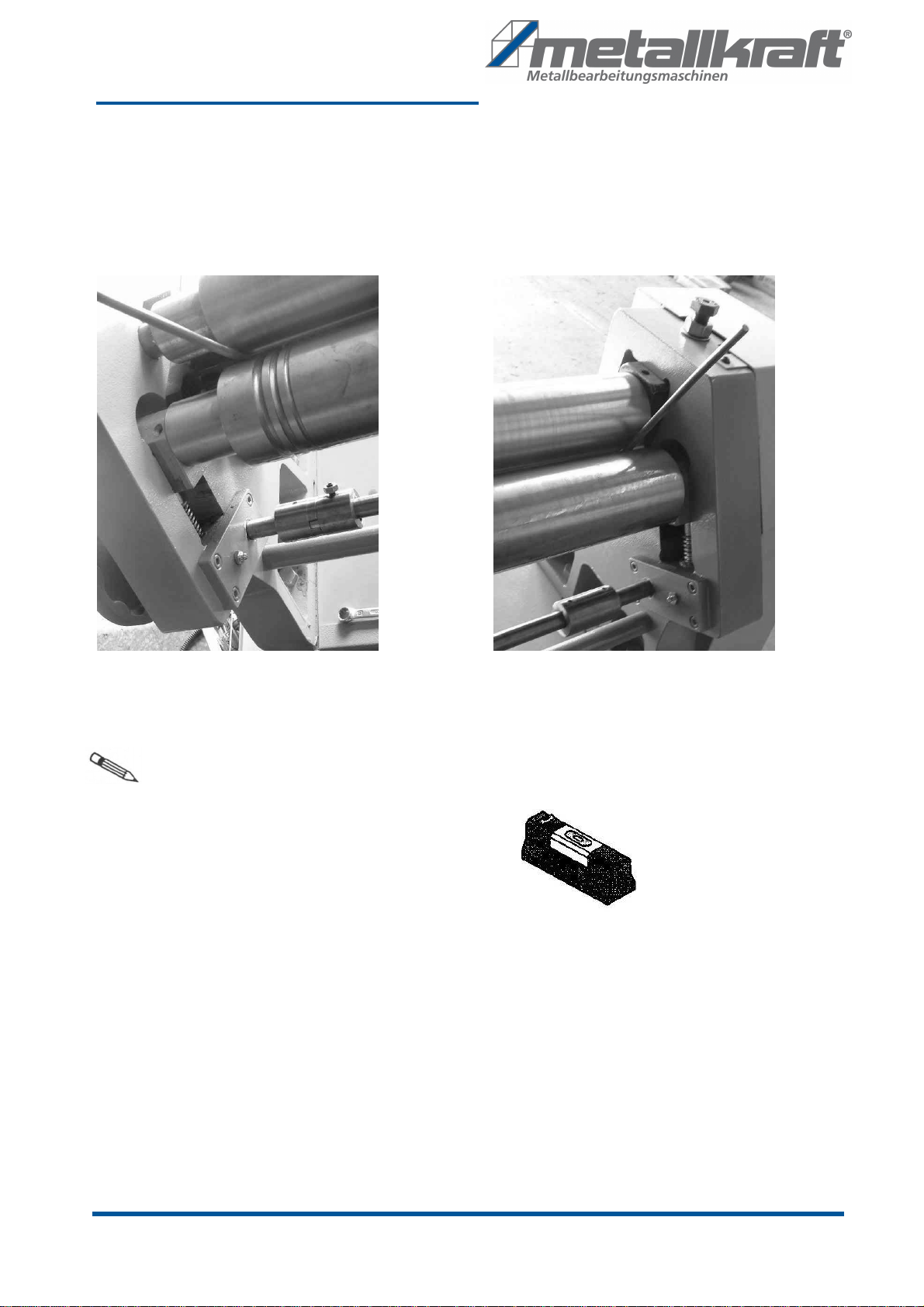

4. Adjustment for parallelism

Check parallelism of the rolls before bending with a round bar.

Note: After placing the machine make sure all areas of the machine is flat and check parallelism of

the machine periodically by a water gauge.

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

8

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

5. Electrical connections

Warning :

All electrical connections must be performed and completed by a qualified electric technician in order to mi-

nimize chance of personal injury or damage caused by wrong connection.

The cable must be directly connected to the machine. No intermediates should be used. The User’s manual

contain the necessary diagram of electrical connections.

Double-check the grounding for a safe operation. ( look at electricity plan )

Rotation of motor

After all the electrics have been completed, start the machine as below and check the rotationary axis of the

motor.

Main Switch to Pos 1

Push start button

Press the foot pedal

Check the rotation direction of the rolls.

If necessary reverse connect the electrics by qualified electric technician to achieve right rotation direction.

Installation figure

Connection of operation plug to machine;

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

9

6. Start-up instructions

6.1. Materials and Products

The machine is mainly steel and it is not designed for handling inflammable or detrimental products. It is duty

of the customer to check if the processed materials respond to these requirements. Also, it is duty of the cus-

tomer to check if the processed materials can be dangerous for the operator working nearby.

When selecting the most appropriate operation material you should keep in mind those instructions:

Material must be clean out of oil and dry (without oil).

Material diameter must be regular with advised instructions.

Hardness value must always be same thorough the material. So, we recommend you to buy certificated

steel.

Parts to be bended should have smooth surface to fulfill the procession correctly and easily.

Note: The thorough cleaning of the rolls is absolutely necessary in order to avoid possible slid-

ing of the profile due to grease residues on the rolls.

6.2. Electrical Connection

Have a qualified electrician connect the machine to the electric supply. In some cases inverse electrical con-

nection causes the motor burn out. To avoid such an undesirable event, after having connect the machine

see that the motor turns to the direction shown by arrow when activated. Or you can check to see if the rolls

are rotating to the same direction of the pedals. That is, if the right pedal is pushed, the rolls should rotate

right and if the left pedal is pushed, the rolls should rotate left. If the machine does not comply then inverse

the electric cables.

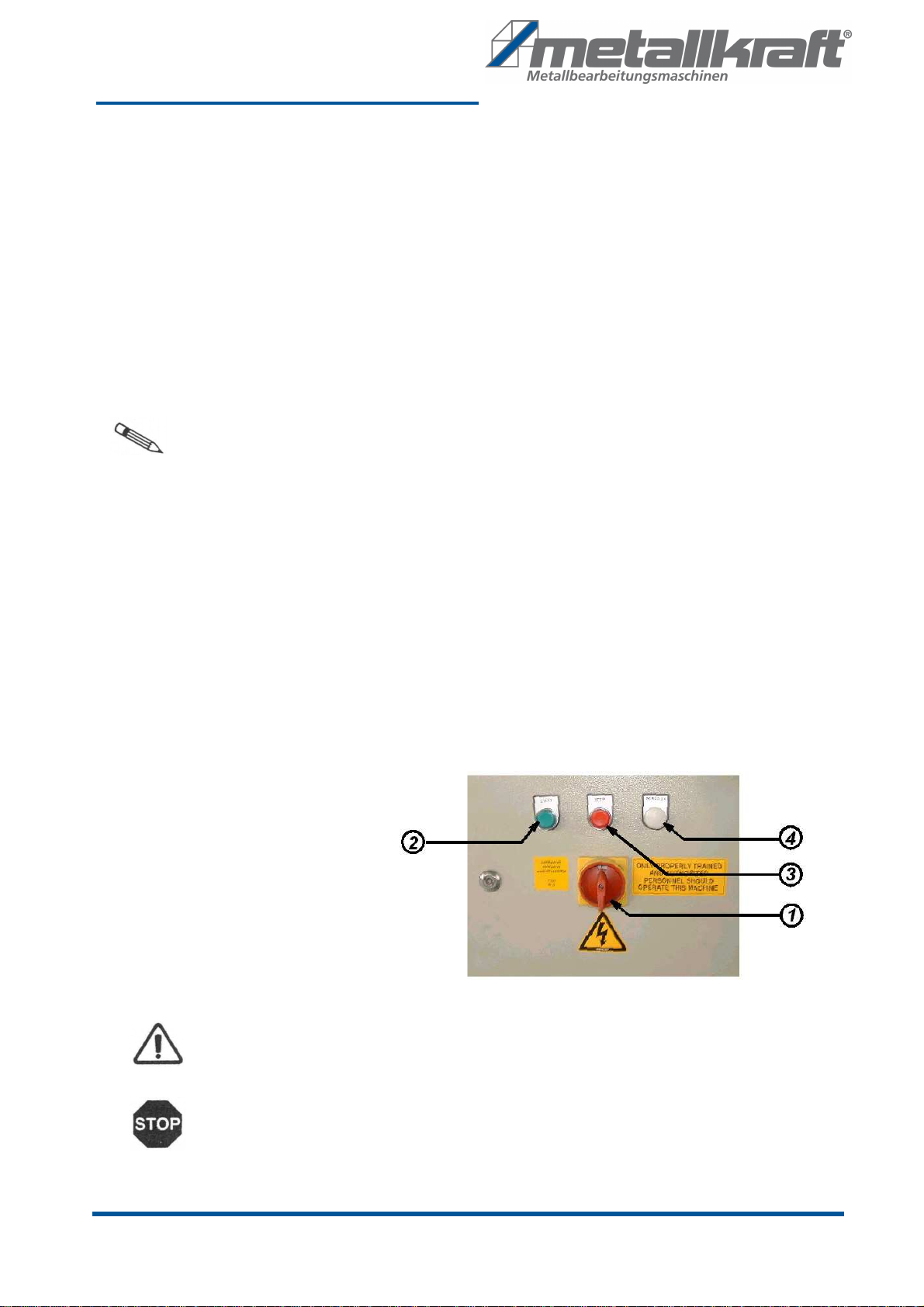

6.3. Electric Box

The RBM model’s electric box includes very important controls of the machine and is also connected to the

below shown foot pedals. The keys on the electric box are shown and explained here:

1. Main switch

2. Start indicator

3. Stop indicator

4. Electric on

Attention: Do not open electric Box except for maintenance or adjustment

Warning: It is suggested to protect the main electric line from possible overloads

by means of safety switches.

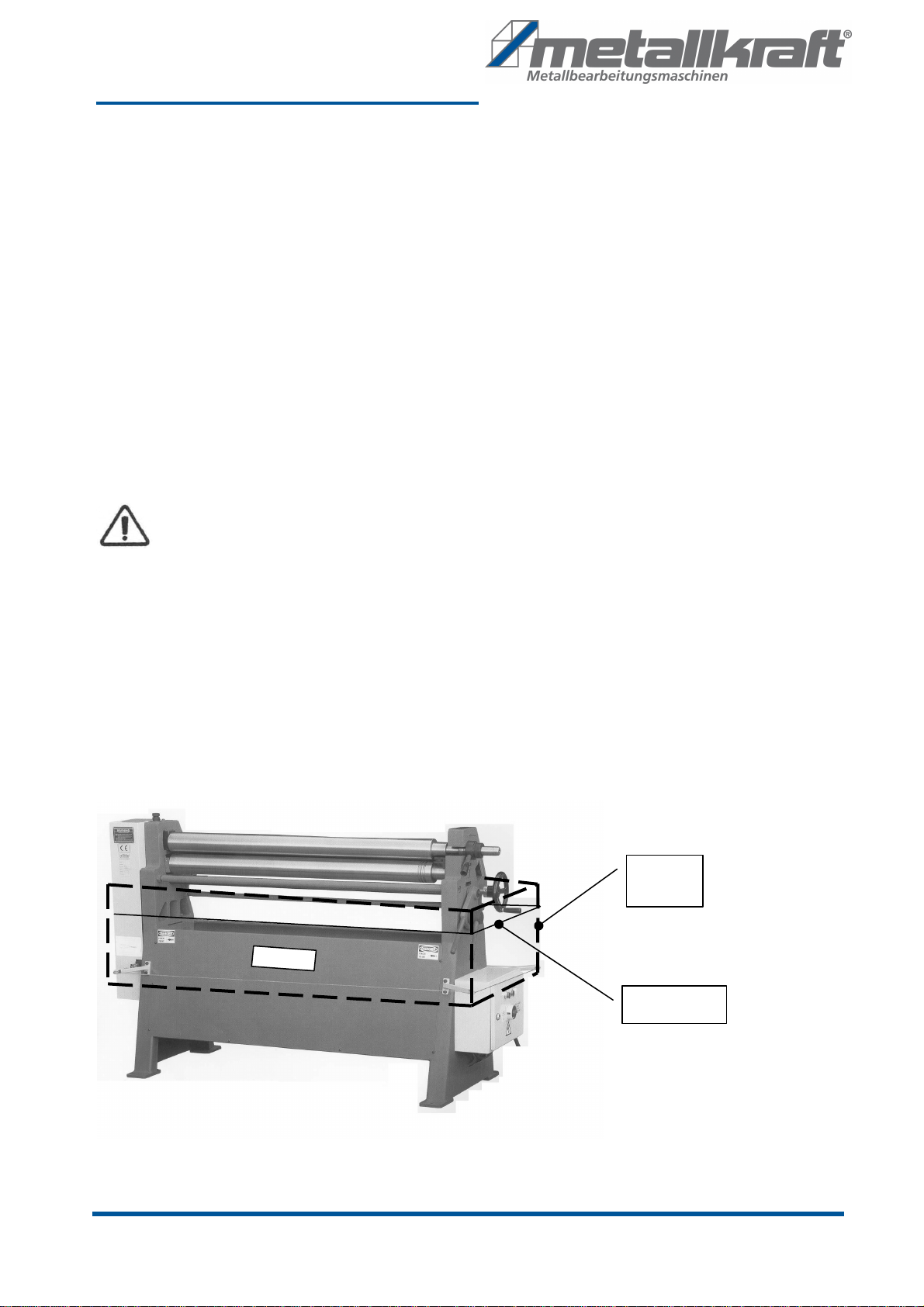

Figure 1

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

10

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

6.4. Standard foot pedal

The standard foot pedal is equipped with an “emergency button” which instantly stops all the machine activity

by disabling the electric supply until released.

6.5. Starting the machine

Following steps will help you start the machine and get ready for the bending operation. See the sections

identifying the necessary switches and buttons.

Make sure the electrical connection is correct

Turn on the “main switch”

You will see electric on “indicator”

Push “start button”

Use the “foot pedals” to rotate the rolls

Make bending

Use the “emergency button” on “foot pedal” to stop the machine

Turn off the “main switch”

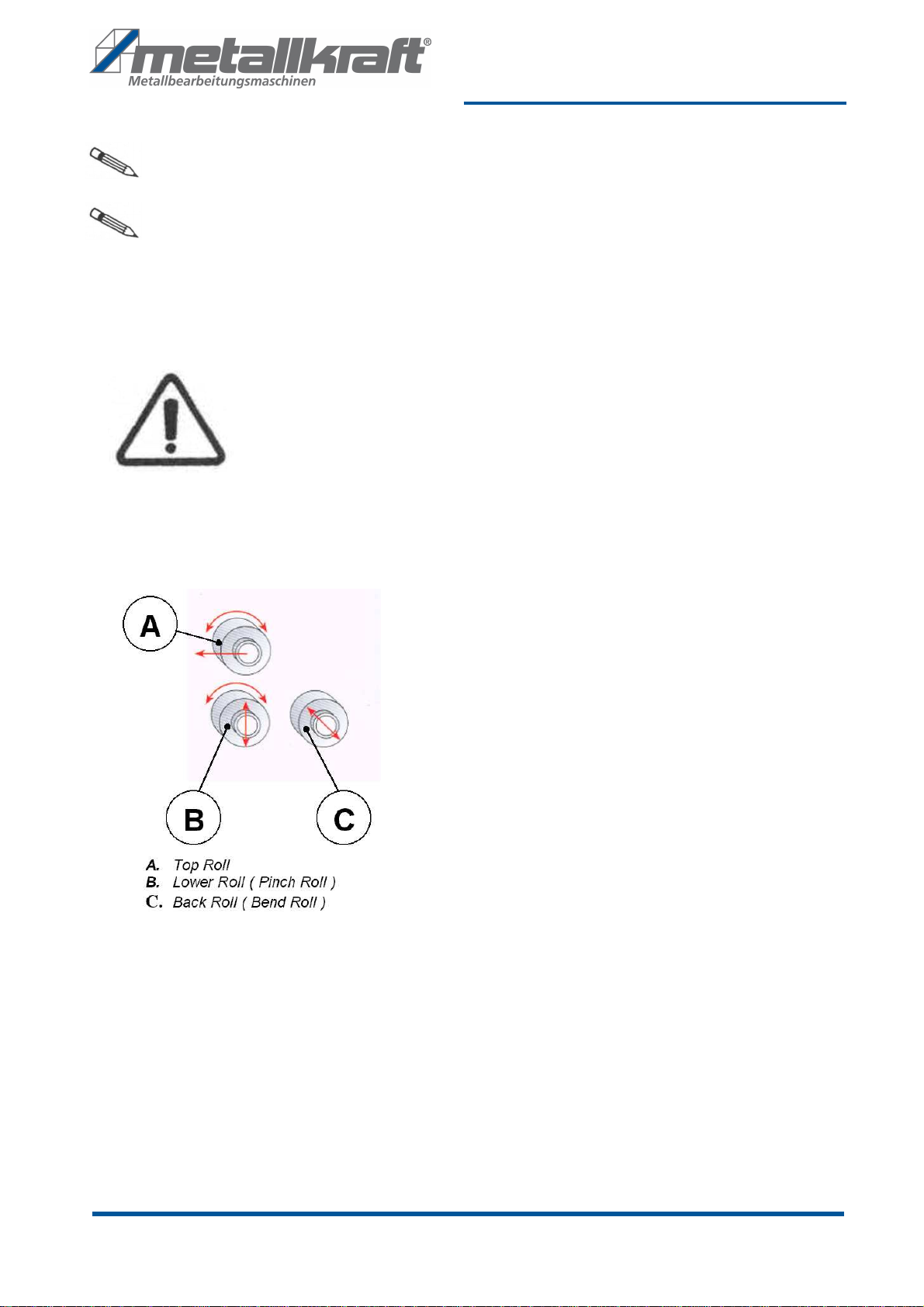

6.6. Basic Operation Terms

The RM model has two rolls powered. The rolls are driven by a motor and a chain gear system. Top roll is

fixed. Therefore, bending operation is simple and smooth however requires experience for efficient working.

Following recommendations will be helpful during operation:

It is recommended that the user have basic bending information with this kind of machines.

Making a tight bend in one pass is not possible. So you need several passes before you can achieve a

certain radius. Tighter curves and full radius always need more passes.

During operation never wear garments with loose parts, which may be dragged by the machine parts,

long loose hair, necklaces, rings etc.

Use emergency button in case of any emergency.

Optional foot pedal (for back roll motorized)

Emergency stop

Foot pedals

Back roll upper

part

Back roll lower

part

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

11

7. Safety directives

The Metallkraft three-roll plate bending machine is supplied with necessary guards to protect from injuries by

worm-type gearbox and other gears. The only other area which needs to carefully monitored during use is

the rotational area of the rolls.

Also abuses and misuses risk the following:

Serious injury of the user

Serious damage to the machine

All persons who are involved in using of the machine should carefully read and fully understand this manual

for the of benefit themselves.

This is for your safety!

Attention:

Never try to bend very hard or fragile material on the machine (e.g. hard steel, glass)

Any modification on the machine without written confirmation from the manufacturer is strictly

forbidden as such changes in the machine can cause unintended damages and injuries.

All orders and advises in this machine should be strictly obeyed for a safe working environ-

ment.

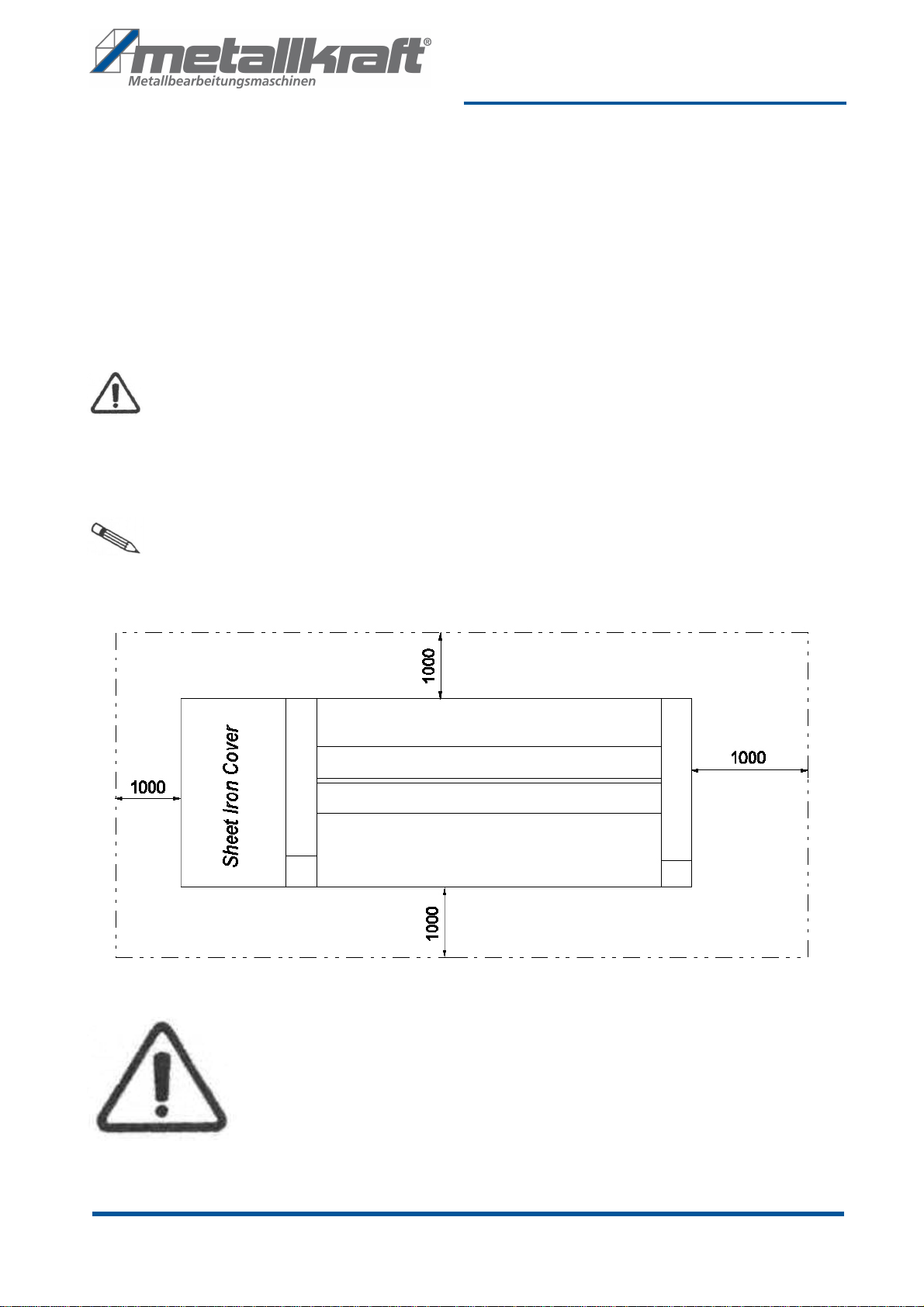

Danger zones

The below shown danger zones must be kept clear during operation

NOISE: The noise of the machine is about <70 dB.

Safety wire

Danger

zones

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

12

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

Explanation for operator

Operator under age of 16 years to operate the machine is strictly forbidden (EC-Directive). The operator of

the machine should carefully read this manual and understand the danger he might be in if he misuses or

abuses the machine. If any part of this manual is unreadable or illegible please contact to the dealer and

manufacturer.

The owner of the machine should be responsible for operating the machine with qualified personnel.

Personal protection

Gloves and safety glasses and safety cap are recommended during operator.

During bending work, the wearing of gloves is forbidden.

Attention:

No material should be fed if the machine is running.

All emergency stop must be easily accessible.

The user must be careful for third persons entering the operation area of the machine.

Note: If any labels are lost or unreadable contact the manufacturer for new supplies.

Working area of the machine

Attention: Before the first use of the machine always check this list carefully for a

safe start.

1.

Check the emergency stop button on the command panel

2.

Make sure that the security wire around the machine is free

3.

Check for visible oil leak

4.

Control of the buttons on the command panel

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

13

Safety and accident prevention instructions

General Safety Instructions

Following instructions are meant for the operator of the machine and it is the End-User’s responsibility to

make sure the operator reads and understands the following and the User’s Manual for safe operation.

Read the User’s manual before operating the machine.

Never touch rotating or moving parts.

Always inform electric faults to electric technicians.

Keep your working dress or long hair or necklace etc away from rotating parts.

Make sure you know the position of Emergency Stop Buttons on the machine.

Switch off the machine when NOT working.

Work with necessary safety clothes if necessary (safety shoes, glasses, earplugs etc).

Control the Safety features before working and ensure they are working properly.

See and understand Safety Labels on the machine.

Perform periodic maintenance.

DO NOT overload the machine.

If you see abnormal behavior of the machine, stop the machine and inform your supervisor imme-

diately.

Be careful of other people around the machine during operation.

Never modify electric unit.

Never remove any mechanic or electronic safety features from the machine.

Be extremely careful during transport or re-placement of the machine and follow transport instructions

in the manual to safety handle the machine.

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

14

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

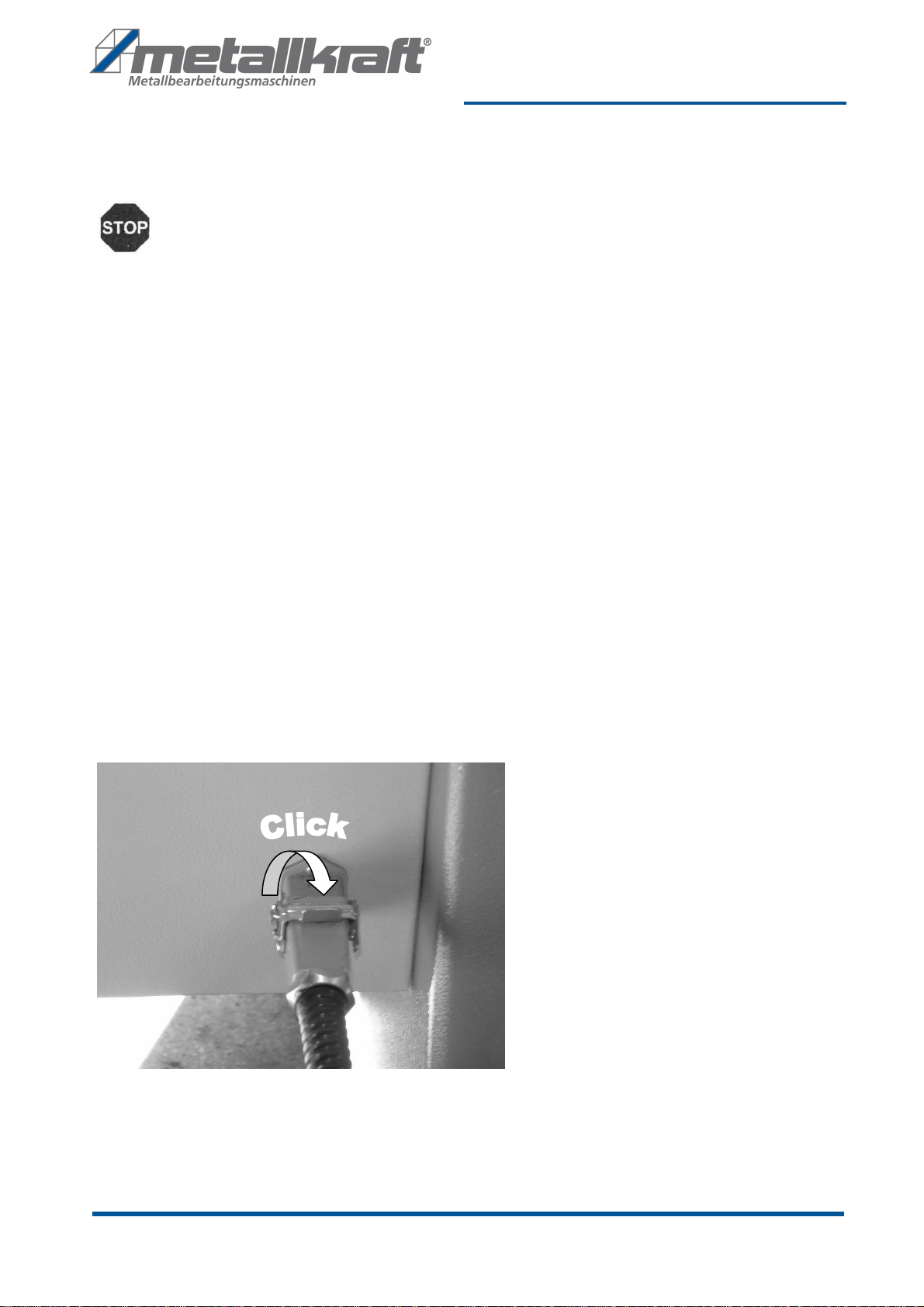

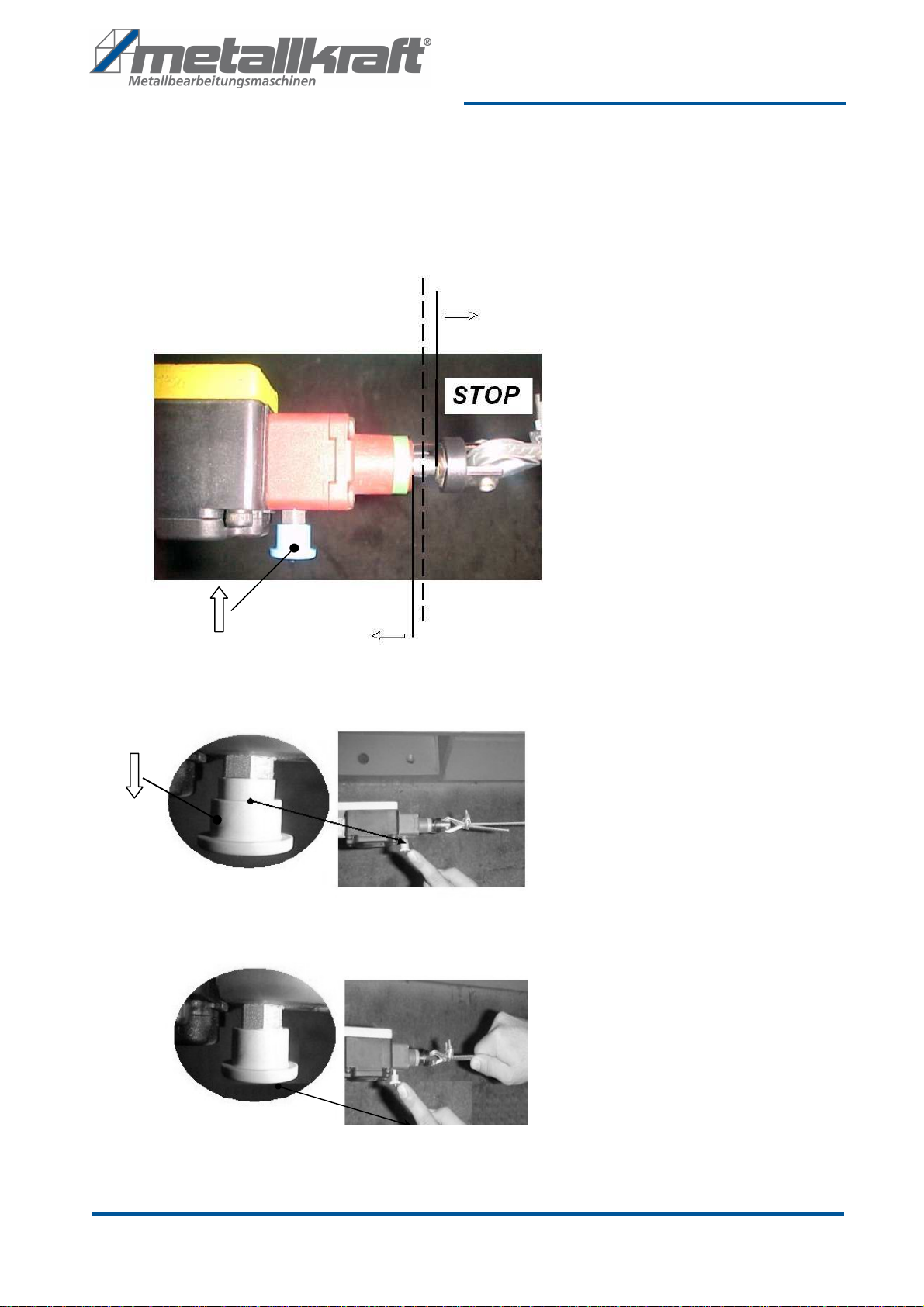

Explanation for safety switch

The machine has been equipped with a security switch and wire for the operators safety When the safety

wire is pushed it pulls the below shown ring this act as emergency stop and stops all machine activity.

To restart pull the blue knob (shown by in fig.1) while pulling the safety wire when engaged you should

see green (shown by in fig.2) line under the blue knob. Now you can restart the machine from control

panel.

Safety switch’s on and off positions as given below.

Switch on

position

Switch off

position

Figure 1

②

②②

②

Figure 2

Figure 3

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

15

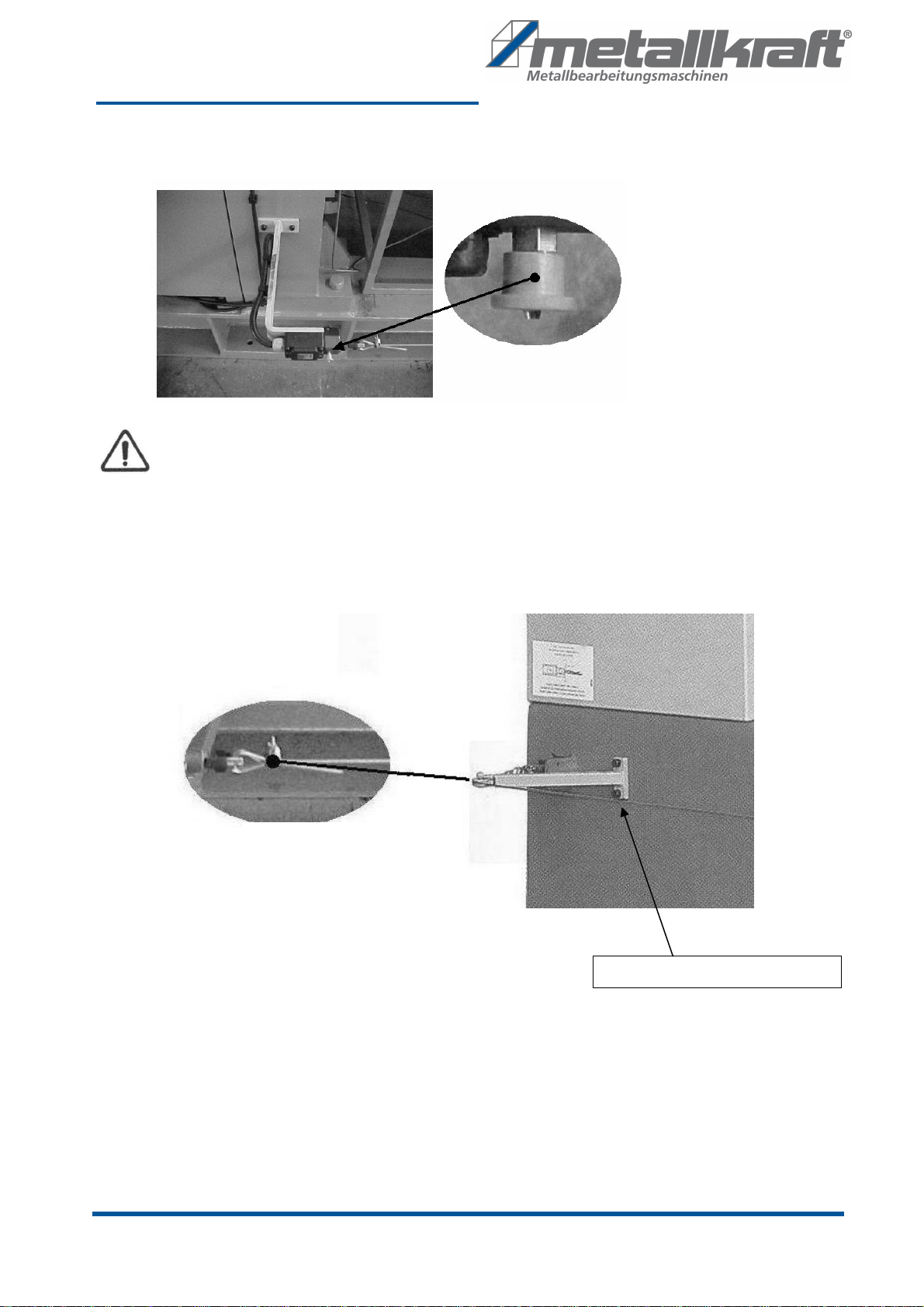

The safety wire comes unassembled for packing reasons and must be assembled by the customer as shown

above to completely surround the machine.

Attention:

The safety wire is an important safety measure and must never be removed while the machine is setup. It

should be only removed for transport purposes.

While assembling it is important to fit the wire to the safety switch lock securely as shown below.

Figure 4

Correct

Figure 5

Safety wire around the machine

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

16

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

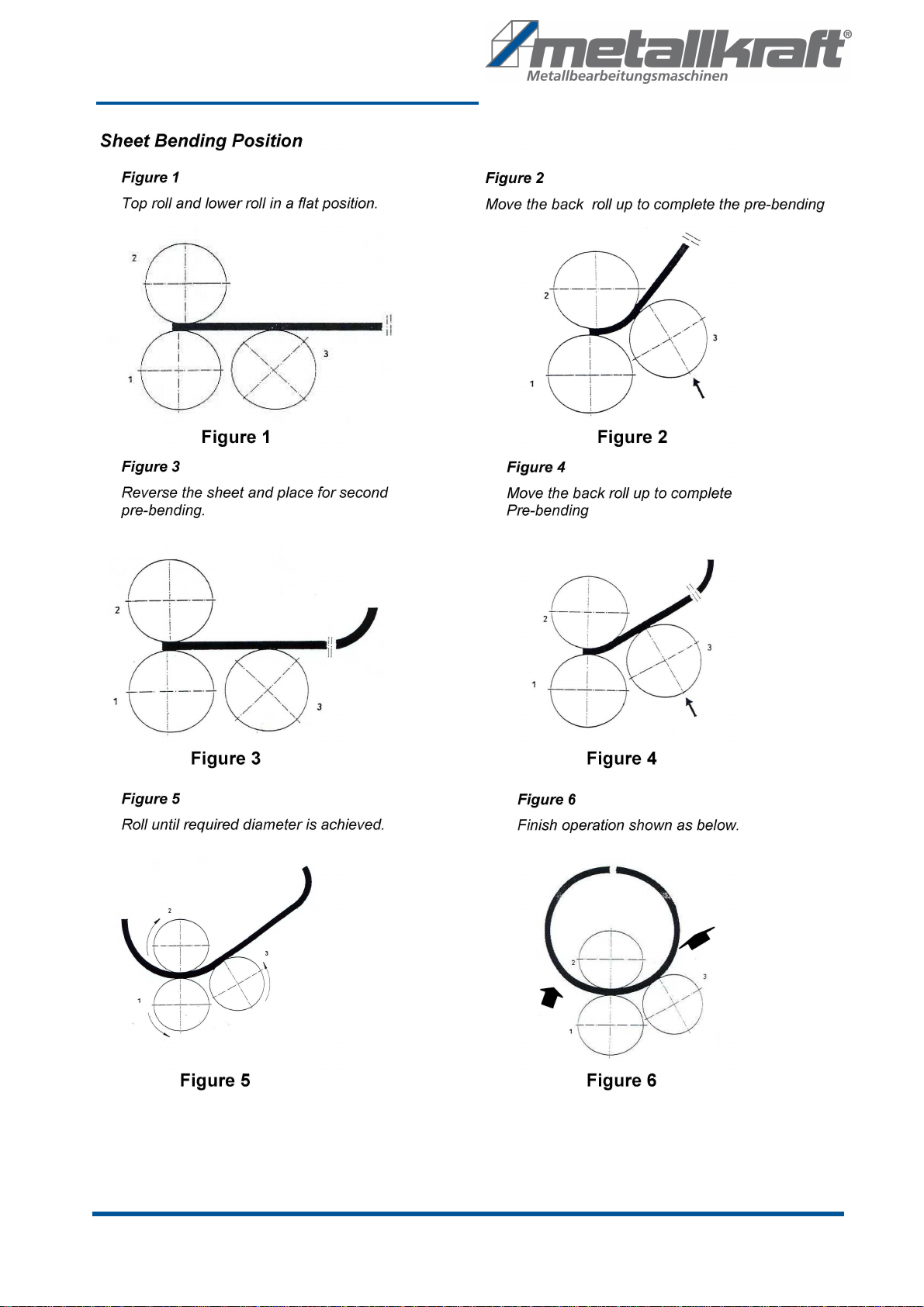

8. Bending operations

3 roll bending principles

Bending must be done by qualified personnel who have experience on such machines. Each step of the bending and

pre-bending or conical bending must be done very carefully. Remember that you can always make the radius tighter by

bending a little more but once you bend it too much there is no way of turning back.

Note: Before operating the machine, be sure that this manual is thoroughly read and understood by

the personnel who will directly operate the machine and others concerned with it.

Pre-Bending Operation

Pre-bending is the operation where the edges of the material is bent to the same radius of the end radius.

This is used to get best results in full circle bending (i.e. pipe making) or in operations where there must not

be any flat edges.

Before operation:

1. Clean the material and the rolls from dust, or grease

2. Make sure there are no chips or flame cutting left-over on the edges of the material

3. Keep in mind that if the material is cut by flame that side will be harder than the other side

4. Check the surface of the material carefully make sure its flat

5. It’s a good idea to have template of the required radius when making a bend. To make a template

cut a hard cardboard or cartoon piece with the necessary radius

6. Always work in the center of the rolls as shown below.

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

17

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

18

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

Note: That the material will progressively harden with each pass.

Note: If you are working with stainless steel it is important to finish the job in a few passes.

Because stainless steel is a work hardening material.

Attention : Be sure to clean any oil or grease on the rolls before

operation.

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

19

Conical bending

Conical bending is more difficult than normal bending. So machine capacity must be reduced to %30 - %50

to determine conical bending capacity of the machine. Also machine must be prepared for conical bending

operation as shown.

Note: When bending conical the overall max. thickness capacity decreases by 30 - 50 %.

Figure -1

Move both lower roll and back roll to the lowest position as shown above.

Figure-2

Remove couplings by a hand tool on the drop end side so that only that side of the rolls will move when you

use the handwheels. When you move the handwheels the rolls will move only in one side so that you can

make conical bending. You can now put the material by the conical bending device and start bending.

Figure-1

Figure-2

Motorized plate bending machine RBM E-Series

Instruction manual state 11.2008

20

©Metallkraft Metallbearbeitungsmaschinen. Errors excepted; all rights reserved.

Conical bending device

Conical Bending Device as shown above has been designed and hardened for supporting the part of the

plate held against it during the conical bending operation.

Normal Bending after Conical Bending

You must adjust the rolls back to parallel position after working conical. To do this simply :

Move the drop end side rolls to the lowest position by the handwheels.

Connect the couplings on Figue-2 above

The machine should be parallel to work normal bending

Counter Balance System ;

There is a counter balance bolt located on top of the top roll bushing. This is to prevent the top roll from in-

clining down too much, when opened.

Conical Bending Device

Balance bolt

Tighten CW to counter more.

Loosen CCW to decrease counter force.

CCW

CW

This manual suits for next models

4

Table of contents

Other Metallkraft Cutter manuals

Popular Cutter manuals by other brands

Wacker Neuson

Wacker Neuson RCP 20 Operator's manual

Hercules

Hercules HFS3500-Pro Translation of original instruction manual

Makita

Makita 4105KB instruction manual

Hypertherm

Hypertherm HyPerformance HPR400XD manual

eXact

eXact PipeCut 170 operating instructions

Hercules

Hercules STR 921 L Original operating instructions