IMS ROBOTICS TURBO User manual

1

2

3

Machine specifications

Designation: IMS cutter TURBO

Manufacturer: IMS Robotics GmbH

Am Bauhof 6

01458 Ottendorf-Okrilla

Phone: +49 (0)35205 75550

Fax: +49 (0)35205 53749

Website : www.ims-robotics.de

User information: As of 04/05/2022

Translation of the original instruction

Article number: 011 24 000

4

Introduction

This user information is meant to facilitate safe and proper operation and

maintenance of IMS devices and should therefore be given the attention it deserves.

Note

When operating the unit, be sure to comply with accident prevention rules and

general safety regulations.

Important information, as on security engineering, is accompanied

by symbols and should be observed in order to prevent accidents

and equipment damage.

Liability, warranty

All data and information for miller operation and maintenance embodies the

manufacturer's past experience and findings to the best of his knowledge. The right

to make technical modifications resulting from the improvement of the unit described

in these instructions is reserved. During the warranty period, the system may be

repaired or modified only by the manufacturer or on his instructions, otherwise no

liability or warranty will be accepted for the unit as a whole.

5

Table of contents

Table of contents...................................................................................................... 5

1Intended Use...................................................................................................... 7

2Technical data ................................................................................................... 8

2.1 Specifications ................................................................................................ 8

2.2 Main dimensions............................................................................................ 9

3General safety rules ........................................................................................ 10

4Description, setting ......................................................................................... 11

4.1 Modules....................................................................................................... 11

4.2 General description ..................................................................................... 12

4.3 Universal cable drum................................................................................... 12

4.3.1 Manual cable drum ............................................................................... 12

4.3.2 Motorized winding (optional) ................................................................. 12

4.4 Robot........................................................................................................... 14

4.4.1 Carriage ................................................................................................ 14

4.4.1.1 Pressure rail ................................................................................... 14

4.4.1.2 Reversing safeguard ...................................................................... 15

4.4.2 Milling arm............................................................................................. 16

4.4.3 Swivel head color camera..................................................................... 17

4.4.4 Additional lighting.................................................................................. 19

4.5 Optional features ......................................................................................... 21

4.5.1 Circular profile mounts, nominal dia. 450-800....................................... 21

4.5.2 Analog data input with meter counting (optional) .................................. 21

4.5.3 Meter counting calibration (optional) ..................................................... 23

4.5.4 Swivel drive for milling motor with flushing water (optional) .................. 23

4.5.5 Water supply (optional) ......................................................................... 24

4.5.6 Vehicle installation kit (optional)............................................................ 25

4.5.6.1 Basic kit .......................................................................................... 25

4.5.6.2 Winch with movable arm and electrical winch ................................ 28

4.5.6.3 Drawer module ............................................................................... 29

4.5.6.4 Controlling desk.............................................................................. 30

4.5.7 Connection to the Quick-Lock System .................................................. 31

5Operating instructions .................................................................................... 32

5.1 Media supply ............................................................................................... 32

5.2 Startup......................................................................................................... 33

5.3 Operation..................................................................................................... 34

5.3.1 Operation cutting robot ......................................................................... 34

6

5.3.2 Operation with Quick-Lock Offset Packer ............................................. 35

5.4 Conversion to other nominal dias. ............................................................... 36

5.4.1 Format parts and assignment to nominal dias. ..................................... 37

5.4.2 Nominal width-dependent setup............................................................ 38

5.4.3 Convert pressure rail............................................................................. 39

5.4.4 Installing the mount............................................................................... 41

5.4.5 Extension for egg shaped profile ESP (optional)................................... 43

5.4.6 Nominal diameter extension DN800 (optional)...................................... 48

5.5 Cutting tools ................................................................................................ 50

5.6 Pressure control .......................................................................................... 51

5.6.1 Function check...................................................................................... 51

5.6.2 Control operation .................................................................................. 51

5.6.3 Inspection after completion of work....................................................... 52

6Repairs and maintenance ............................................................................... 53

6.1 Cleaning ...................................................................................................... 53

6.2 Transport ..................................................................................................... 53

6.3 Inspection .................................................................................................... 53

6.4 Service, care ............................................................................................... 53

6.4.1 Nitrogen charging.................................................................................. 54

6.4.2 Oiling the air motor................................................................................ 56

6.4.3 Change V-belts ..................................................................................... 59

6.4.4 Change air motor .................................................................................. 62

7Additional regulations to be observed .......................................................... 65

8Accessory overview........................................................................................ 66

9EC-Declaration of Conformity ........................................................................ 67

7

1 Intended Use

Operational safety of the equipment supplied is ensured only when used as intended.

The intended use includes following the regulations contained in these operating

instructions as well as compliance with all maintenance and service tasks.

The IMS cutter TURBO must only be used for cutting work for the restoration of

pressureless pipes or lines. The device can be used to open inliners after restoration

and remove obstacles (roots, protruding seals, minor offsets, or the like). The

machine may not be used for unintended purposes.

Unauthorised structural changes to the equipment may cause damage to the

machine thus representing a hazard to persons. IMS is not liable for resulting

damages. In the event of damage the operating company remains responsible and

responsibility cannot be transferred to IMS.

8

2 Technical data

2.1 Specifications

System components: Universal carriage

TURBO cutting arm

Camera

Add-on mount

Universal control unit

Universal cable drum

Milling performance: Milling cutter max. dia. 120 mm for concrete

Travel speed: max. 10 m/min. with wheel, dia. 140 mm

Format: Pipes, nominal dia. 200 mm (without sleeve offset) with

add-on mount/parts for nominal pipe dias. up to 800 mm

Change of nominal dias.:between approx. 10 and 20 min. depending on nominal

pipe dia.

Power: 230 V +/-1% /50 Hz / 6A and 110 V / 60 Hz

Weight: TURBO : ca. 70 kg

Universal cable drum: ca. 115 kg

Universal control unit: ca. 10 kg

Compressed air: Consumption: ca. 3 m3/ min

Supply pressure: 10 bar

Quality: filtered, dry,

max. temperature 40C

Caution! contaminated/moist air will damage the air motor

and seals on the robot!

Workplace: operating console

Temperature range: + 5 ... + 40C

(Caution: do not operate control system in widely varying

temperatures (condensate) or in the open when it rains!)

Supply line: 100 m on cable drum

Camera signal: PAL

9

2.2 Main dimensions

Universal carriage with milling arm:

Device mounted for pipes 300 mm

approx. 400 mm approx. 650 mm

approx. 1050 mm

10

3 General safety rules

Caution!

System may only be operated by persons who have been

instructed in its use. A lack of information may cause damage to

the unit or create hazards for the operator.

Caution!

Pull out mains plug before opening a unit.

Caution!

When lowering individual components or the robot as a whole

make sure no-one is standing in the shaft or under the load.

Observe accident prevention rules for work in pipelines and for earthmoving

machinery, winches, hoists and drawgear, and safety regulations for pipeline building

work.

11

4 Description, setting

4.1 Modules

Overall view

1

Universal cable reel, motorized

(optional)

9

Electric swivel drive (optional)

2

Universal control unit

10

Water nozzle (optional)

3

Universal carriage

11

Additional lighting

4

Oil sight glass

12

Air connection

5

Milling arm

13

Electrical connection

6

Camera with nitrogen valve

14

reverse drive sensor

7

Carriage nitrogen valve

15

Water connection

8

Swivel arm nitrogen valve

8 6 9

3 4 7 5 10

11 12 13 14 15

2 1

12

4.2 General description

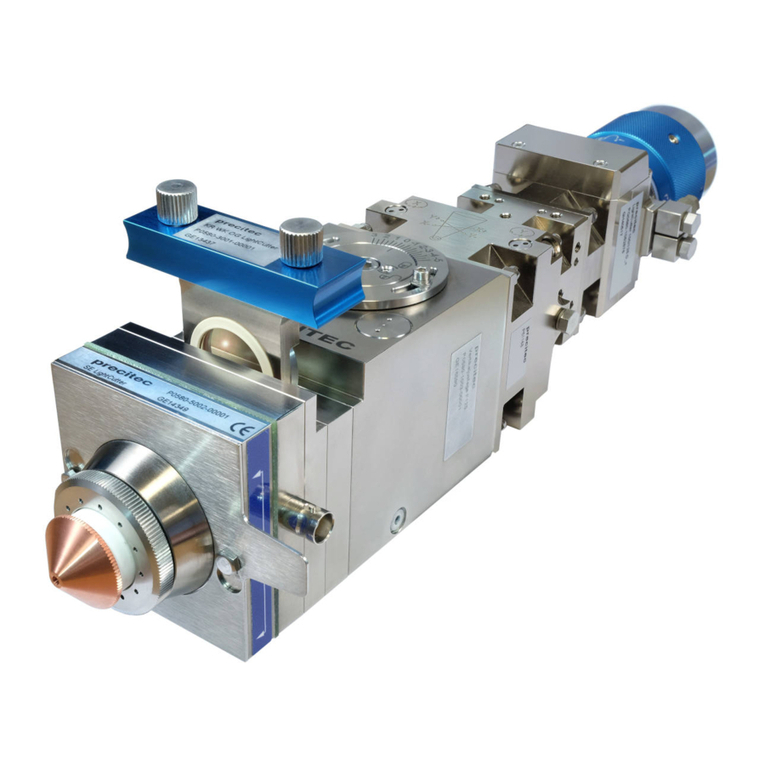

The IMS universal carriage with milling arm TURBO III in conjunction with the multi-

purpose control system and universal cable drum with 100 m media cable is

designed for milling work in the repair of sewers. The use of format parts makes it

possible to convert the basic version from nominal dia. of 200 mm (inside) to a max.

of 800 mm (depending on scope of supplies). For use in shafts the overall length of

the unit may be reduced by connecting media only inside the shaft or swinging the

milling arm out of the way and straightening it on insertion.

Units should generally be stored in a frost-free environment.

4.3 Universal cable drum

4.3.1 Manual cable drum

This accommodates 100 m of lines for electricity, pneumatic and water supplies. The

air duct in the hub of the drum is maintenance-free. The control lines are connected

via slip ring contacts. If the flushing water connection is not used, it should be

covered with a dummy cap.

4.3.2 Motorized winding (optional)

This supports the winding up/paying out of hose from the package. The air motor in

the cable drum should be oiled after each using and afterwards should be moved by

hands. This can be done through the air inlet hose.

13

Caution!

Do not reach into the drum or its drive when in Operation. Prior to

working on the drum remove the air supply.

The media hose must not be overstretched, due to high tensile

forces, (> 1000 N/ ca. 100 kg) because of the hose and the

internal lines can be damaged or can rip.

The crack resistance of the media hose and the tensile forces of

the motor cable winding enable a rescue in emergency case, if the

robot in the pipe is not jammed. In no case additional forces must

be used. (vehicle, winches, etc.)

Be sure to use the deflection sheave supplied for winding up/paying out supply line in

the manhole.

14

4.4 Robot

This has electric drives for travel and turning/swivel of the head.

Caution!

All electrical driven axes of the robot (driving movement, turning,

swivelling, 4. axis), as well as the rotation movement of the

camera must not be moved by hand.

The couplings of the power feed line are watertight when plugged together (IP 65).

The milling cutter is driven by an air motor.

4.4.1 Carriage

4.4.1.1 Pressure rail

To prevent wheel slip during forward travel, the pressure rail may be pressed against

the crown of the pipe when moving to the place of work. Please note that the milling

motor is active. If the valve on the universal cable drum is only partly open it can be

used to control the pressing force of the pressure rail.

Caution!

During robot travel with pressure rail in the duct the milling motor

has full capacity at full air pressure.

During milling, the pressure rail is pressed against the crown and thus gives the robot

extra stability during operation. Using a switch, the pressure rail can be switched on

and off. When it is off, work with caution as there is a greater risk of the robot

overturning.

15

Caution!

Under normal conditions, the milling robot may operate without a

pressure rail. The latter is an auxiliary and makes it possible for

the operator to deal with extreme situations such as working at

greater depths or on smooth pipe walls.

4.4.1.2 Reversing safeguard

This is to prevent the robot from running over media supply lines during reversing.

The strain relief device of the supply line is hung up here.

Caution!

While the robot is reversing, make sure the electrical/pneumatic

supply line is pulled back by the operating personnel at the same

time. Do not pull the robot out by motorized winding!

The robot may cover short distances even if the reversing sensor is not active.

Caution: Even though there is a risk of running over the hose, this condition may be

used to recover the robot from the duct if the reversing sensor is defective.

16

4.4.2 Milling arm

Mount this on the carriage with two screws, while at the same time making the

electrical connection with plug contacts and providing an air supply by hose. In

addition, connect the flushing water hose to the optional electric swivel drive on the

milling motor. In the absence of an electric swivel drive, five different fixing holes are

provided for the milling motor. An air hose is mounted on the milling arm side and

should be positioned as shown.

A stop on the carriage swiveling axle makes rotation of the milling head through

approx. 400° possible. A level on the air motor indicates the position of the swivel

arm in the pipe. The milling arm has additional lighting for better visibility inside pipes.

During the penetration in the pipe the cutting arm should be hold in a position, that no

dirt can penetrate in the air holes of the cutting motor.

Air hose

17

4.4.3 Swivel head color camera

This enables the operator to watch the milling operation in the entry direction. Use of

a camera limits the angle of view in the pipe, i.e. parts of the pipe are concealed by

the motor/milling cutter on entry.

From a pipe diameter of DN 250/10”, the camera can be mounted so that the angle of

view into the pipe is increasing.

The camera is equipped with a swivel motor and two halogen lamps which are

controlled by the universal control unit. For cleaning the screen of the camera and the

lamps swivel the camera head back over the wipers until the stop and return.

Caution!

It is desperate to swivel the camera until the stop, otherwise the

wipers could be damaged!

DN

200

DN 250

from DN 300

18

Additionally, a water nozzle from the water equipment (optional) can be used for

cleaning the screens.

Clean the camera periodically, to avoid strong deposits and thereby caused damages

of the wipers. To protect the electronic components, the camera is filled with nitrogen,

which should be checked daily before and after work (see 6.4.1 Nitrogen charging).

Caution!

The quality of the video image depends largely on the uniform

illumination of the area being observed. Excessive brightness will

cause dissolution of the video image and overheating, which

shortens the service life of lamps. Full lighting over several hours

may reduce the quality of video images.

Nitrogen valve Wiper blades

Halogen lamps

19

4.4.4 Additional lighting

The additional lighting can be used in pipes with an inner diameter from 225 mm/9“.

Remove a headless screw on top of the cutter arm, the cover on top of the cutter arm

and the cover of the cutter motor bearing to assemble the additional lighting.

Disassemble the swivel color camera too (see 4.4.3 Swivel head color camera).

Mount the additional lighting on the cutter arm. Ensure correct seating of the seal

ring. Align the camera with the guide pin and fasten the camera with the 2 Allen

screws.

Additional lighting

Headless screw Cutting arm cover

Cover of cutter motor bearing

Guide pin Seal ring

20

To mount the front lighting, ensure the correct seating of the seal ring (on the front

lighting) and fasten the lighting with 4 countersunk screws (M3x8).

To establish the electrical connection, screw together the plugs of both additional

lightings. Afterwards, place the cable in the cutter arm so that the swivel color camera

can be assembled.

Assemble the swivel color camera and charge nitrogen (6.4.1 Nitrogen charging).

Operation of the lighting is described in the operating manual of the universal control

unit.

Countersunk screws M3x8

Cable of front lighting Plug of front and rear lighting

Table of contents

Popular Cutter manuals by other brands

Caslon

Caslon Zip21A Operation and maintenance manual

Thermal Dynamics

Thermal Dynamics A120 operating manual

Formax

Formax FD 574 installation guide

ESAB

ESAB ARCAIR SLICE Series Safety and operating instructions

Pittsburgh

Pittsburgh 41146 Adjustment instructions

Mafell

Mafell ZAF 200 Operating instructions and spare parts list