Starfood BQ116Y1 User manual

1

Thank you for choosing our ice cream machines. Our ice cream machines have applied

the international advanced refrigeration industry, the famous brand compressors and good

quality refrigeration components. With good looking and reliable performance, our products

measure up the national safety standard of food processing machinery and electric appliance,

and can be used in bars, fast food shops, hotels, schools and cold drink stores. We have

achieved the certificate for ISO 9001:2000(International Standard for Quality Management

System 9001:2000). Some ice cream machines have got CB and CE approval.This model is

commercial ice cream machine, which should be operated by the qualified trained staff or

follow the instructions of trained staff. Please read the operation manual carefully and follow

the instructions strictly then install, adjust and operate the machines.

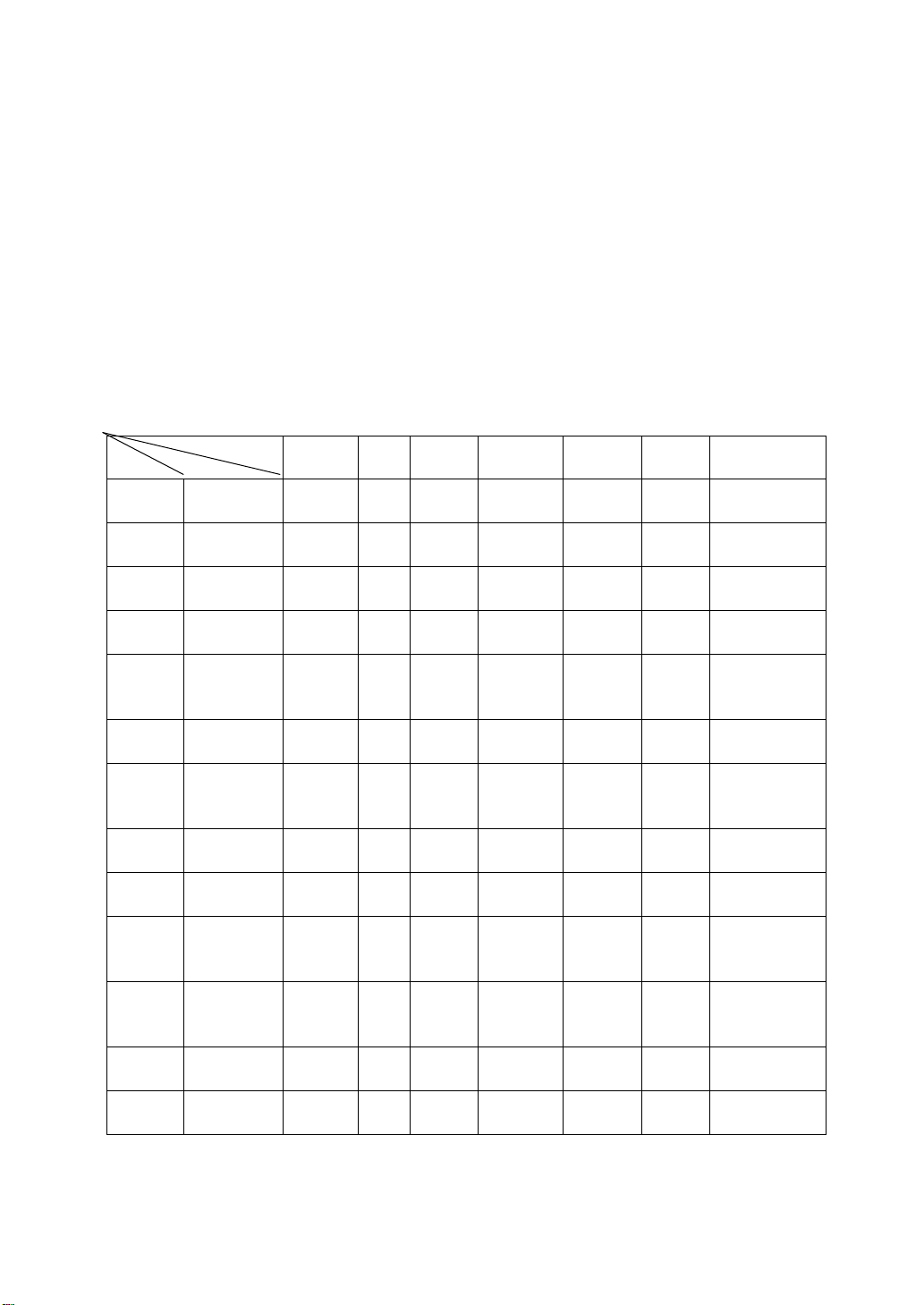

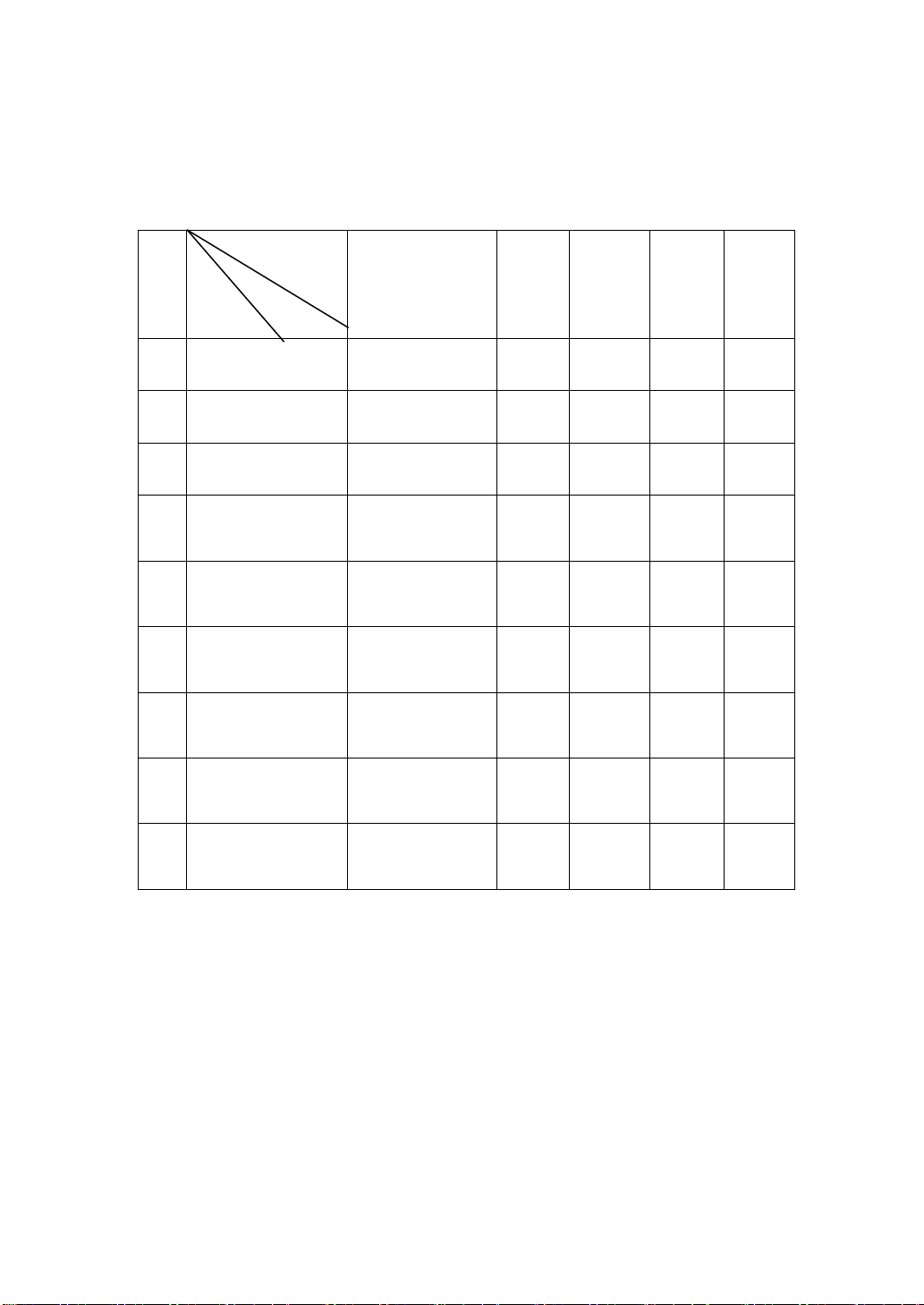

Major Technical Data

Item Figure

Model

Main

Power Rating

kW Refr Capacity

Kg/h Cups per

hour

Net

Weight

㎏

Measurement

mm

BQ116Y1 BQJ-10BY1 220V/50Hz

(60Hz) 1.7 R404a

(R22)

10-14kg

(14-20L) 160-230 105 518×745×756

BQ116PY1

BQJ-10BPY1 220V/50Hz

(60Hz) 1.7 R404a

(R22)

10-14kg

(14-20L) 160-230 110 518×745×756

BQ816Y1 BQJ-11/2AY1 220V/50Hz

(60Hz) 1.7 R22

(R404a)

12~18 kg

(17~28L)200~300 116 518×745×770

BQ620Y1 BQJ-10/2CY1 220V/50Hz

(60Hz) 1.7 R22

(R404a)

12~18 kg

(17~28L)200~300 143 518×760×1420

BQ620Y BQJ-10/2CY 220V/50Hz

(60Hz) 1.8

R404a/

R134a

(R22)

12~18 kg

(17~28L)200~300 158 518×760×1420

BQ820Y1 BQJ-10/2BY1 220V/50Hz

(60Hz) 1.7 R22

(R404a)

12~18 kg

(17~28L)200~300 145 518×745×1420

BQ820Y BQJ-10/2BY 220V/50Hz

(60Hz) 1.8

R404a/

R134a

(R22)

12~18 kg

(17~28L)200~300 160 518×745×1420

BQ633Y1 BQJ-20/2BY1 220V/50Hz

(60Hz) 2.6 R22

(R404a)

20~25 kg

(28~36L)330~420 158 518×760×1420

BQ633PY1

BQJ-20/2BPY1 220V/50Hz

(60Hz) 2.6 R22

(R404a)

20~25 kg

(28~36L)330~420 168 518×760×1420

BQ633Y BQJ-20/2BY 220V/50Hz

(60Hz) 2.7

R404a/

R134a

(R22)

20~25 kg

(28~36L)330~420 173 518×760×1420

BQ633PY BQJ-20/2BPY 220V/50Hz

(60Hz) 2.7

R404a/

R134a

(R22)

20~25 kg

(28~36L)330~420 183 518×760×1420

BQ833Y1 BQJ-20/2AY1 220V/50Hz

(60Hz) 2.6 R22

(R404a)

20~25 kg

(28~36L)330~420 160 518×745×1420

BQ833PY1

BQJ-20/2APY1 220V/50Hz

(60Hz) 2.6 R22

(R404a)

20~25 kg

(28~36L)330~420 170 518×745×1420

1.

2

Note: 1) The capacity is measured when the environment temperature is 25 degrees

centigrade, and the ingredient temperature 7 degrees centigrade.

2) Cups per hour is measured at 60g to 70g per cup.

3) For P, it means the machine is equipped with air pump system.(Please refer it in

Operation Instruction for Air Pump System.)

4) For Y1, it means hopper pre-cooling and keeping temperature at night.

5) For Y, it means hopper pre-cooling, keeping temperature at night and independent

compressor to control hopper cooling.

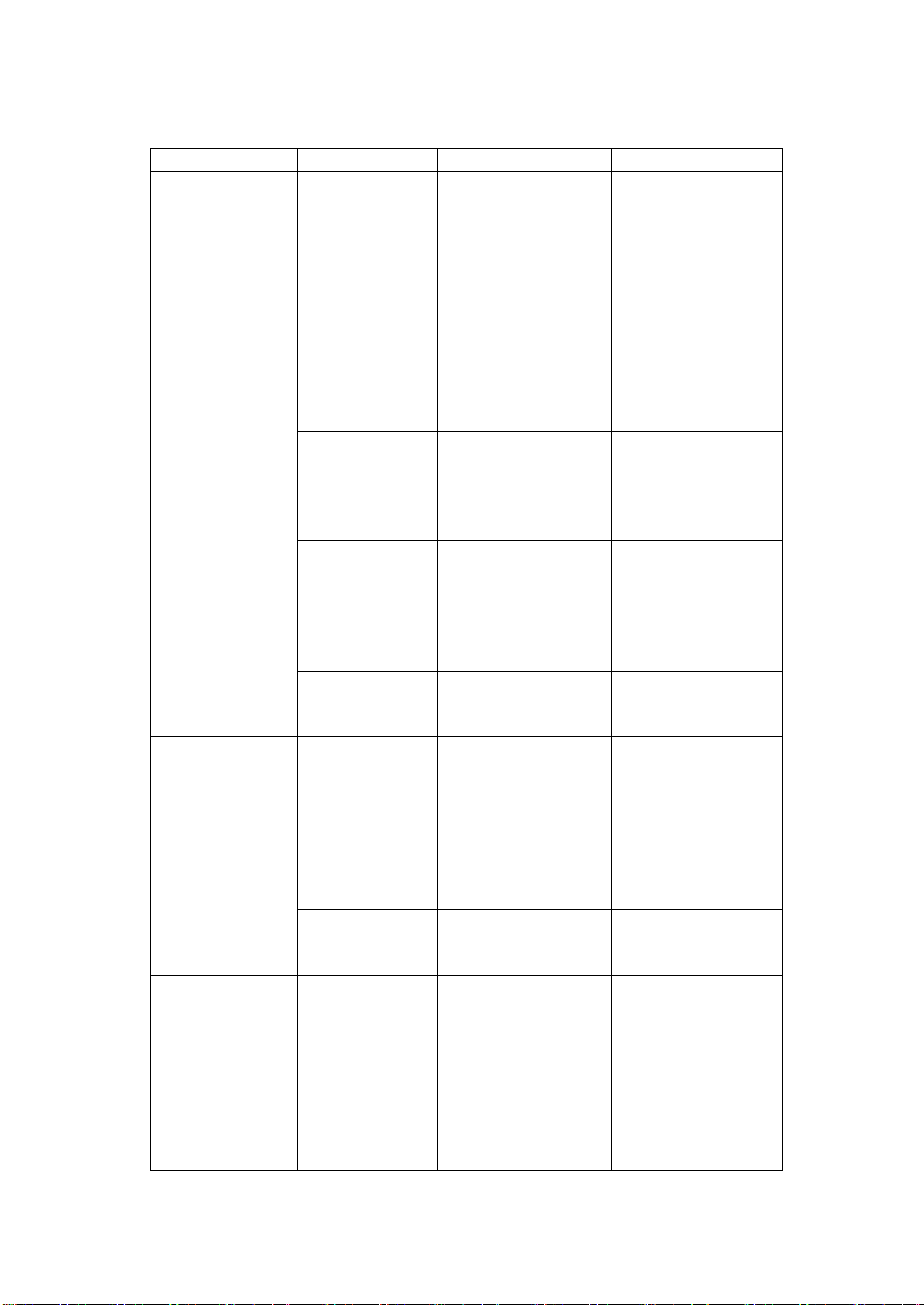

Item Figure

Model

Main

Power Rating

kW Refr Capacity

Kg/h Cups per

hour

Net

Weight

㎏

Measurement

mm

BQ833Y BQJ-20/2AY 220V/50Hz

(60Hz) 2.7

R404a/

R134a

(R22)

20~25 kg

(28~36L)330~420 175 518×745×1420

BQ833PY BQJ-20/2APY 220V/50Hz

(60Hz) 2.7

R404a/

R134a

(R22)

20~25 kg

(28~36L)330~420 185 518×745×1420

BQ747Y BQJ-45/4Y 3-380V/50Hz

(60Hz) 2x2.8 R404a

(R22)

45~50 kg

(62~70L)750~830 320 880×830×1420

BQ836Y1 BQJ-22/2AY1 220V/50Hz

(60Hz) 2x1.6 R22

(R404a)

22~28 kg

(32~40L)360~460 194 540×775×1414

BQ836Y BQJ-22/2AY 220V/50Hz

(60Hz) 3.3

R404a/

R134a

(R22)

22~28 kg

(32~40L)360~460 210 540×775×1414

BQ818PY BQJ-12/2PY 220V/50Hz

(60Hz) 1.8

R404a/

R134a

(R22)

12~18 kg

(17~28L)200~300 135 518×860×880

BQ818Y BQJ-12/2Y 220V/50Hz

(60Hz) 1.8

R404a/

R134a

(R22)

12~18 kg

(17~28L)200~300 125 518×860×880

BQ368PY BQJ-32/2PY 3-380V/50Hz

(60Hz) 3.6

R404a/

R134a

(R22)

28~35 kg

(40~55L)460~580 210 642×835×1435

BQ368Y BQJ-32/2Y 3-380V/50Hz

(60Hz) 3.6

R404a/

R134a

(R22)

28~35 kg

(40~55L)460~580 210 642×835×1435

BQ112Y1 BQJ-8Y1 220V/50Hz

1.0 R404a 7-10kg

(10-14L) 110~160 83 420×720×815

BQ112PY1

BQJ-8PY1 220V/50Hz

1.0 R404a 7-10kg

(10-14L) 110~160 88 420×720×815

BQ816Y1 BQJ-11/2AY1 220V/50Hz

(60Hz) 1.7 R404a

(R22)

12~18 kg

(17~28L)200~300 116 518×745×770

BQ8530Y1

BQJ-20/3Y1 220V/50Hz

2.6 R404a

(R22)

20~25 kg

(28~36L)330~420 175 676×740×1414

BQ8533Y BQJ-20/3AY 3-380V/50Hz

(60Hz) 2.6 R404a

(R22)

22~28 kg

(32~40L)380~460 185 676×740×1414

3

2.

Schematic Diagram For the Basic Structure: (Fig.1)

1) Main Body 2) Feed Hopper Lid 3) Top Cover

4) Bulk Inner Tube 5) Bulk Outer Tube 6) Automatic Controlling Assembly

7) Plug of the Throat Block 8) Handle 9) O-ring Gasket of the Plug

10) Bridge Gasket 11) Horizontal Bar 12) Bolt of the Throat Block

13) Socket Wrench

*

14) Discharge Throat Block 15) Star Screw of the O-ring Gasket

16) Gasket 17) Star Shape Screw 18) Star Screw Wrench

*

19) Square Gasket 20) Ingredient Leakage Holder 21) Stirrer Shaft

22) Ground Terminal

Note:‘*’is the spare parts, it would be different from each models.

Fig.1

4

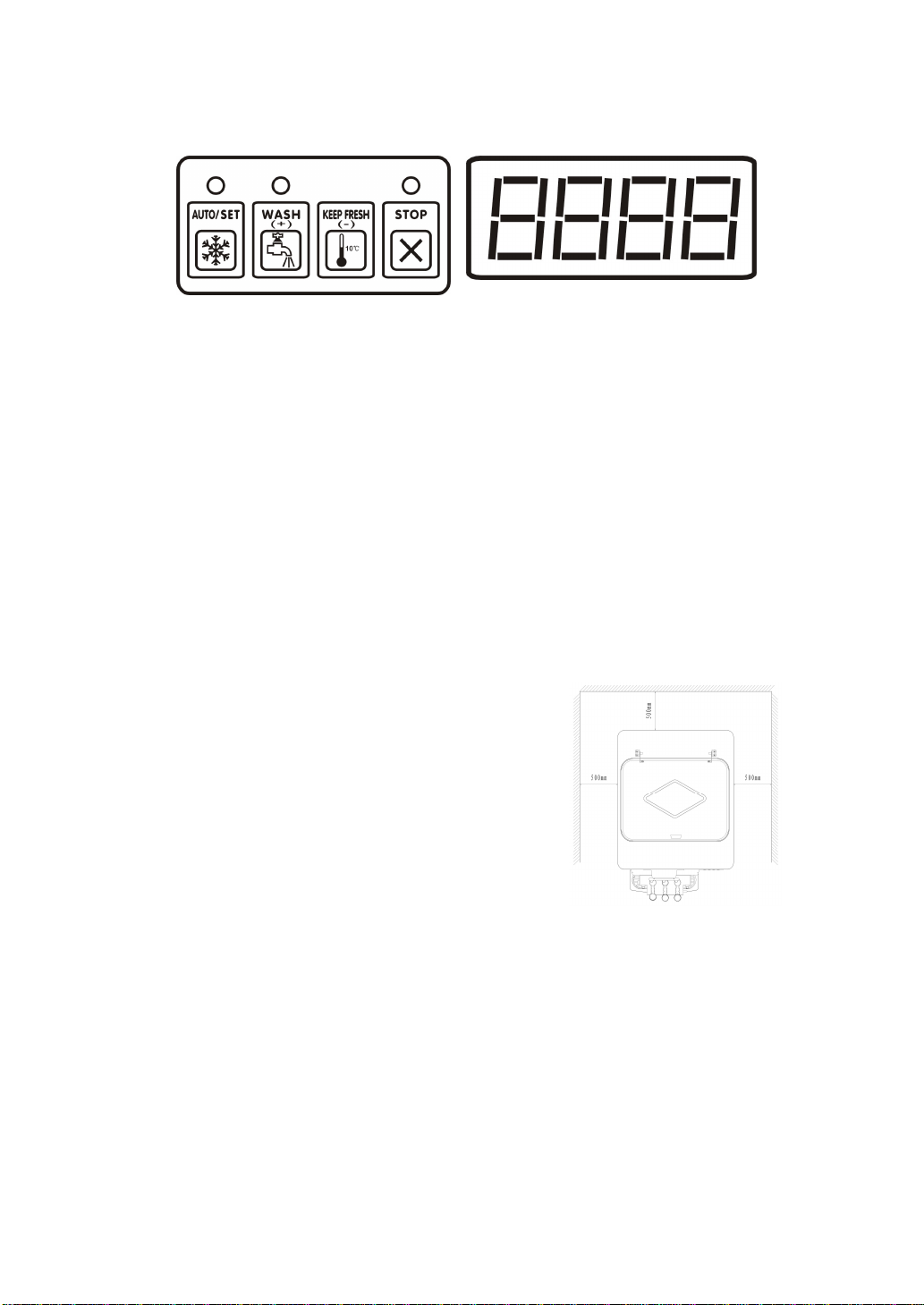

3. Control Panel(Fig.2)

Control Panel Indicator

Fig.2

4. Notice

Using Environment

●

Environmental Temperature:10℃~38℃。

● Relative Humidity:55%~85%。

Power

●Please do install the ground wire according to the national electric safety standard. The

section area of the ground wire can not be smaller than 1mm².

● Use the connection of power supply which is measured up the safety standard, including the

acceptable wire connection and electric equipment.

● Make sure the power supply of the machine has the short-circuit and electricity

leakage-protector.

●Single phaze electricity is 220V/50HZ. Voltage range is 198V-242V.

●Three phase electricity is 380V/50HZ.

●Three phase four wires electricity is 380V/50Hz and

one wire is neutral wire.

●The section area of the power cable should not be

less than1.5mm2.

● For 380V machines: Observe the turning direction of

the stirrer shaft. The shaft should run in clockwise direction.

If the shaft runs in wrong direction, just alternate any two of

the power phases.

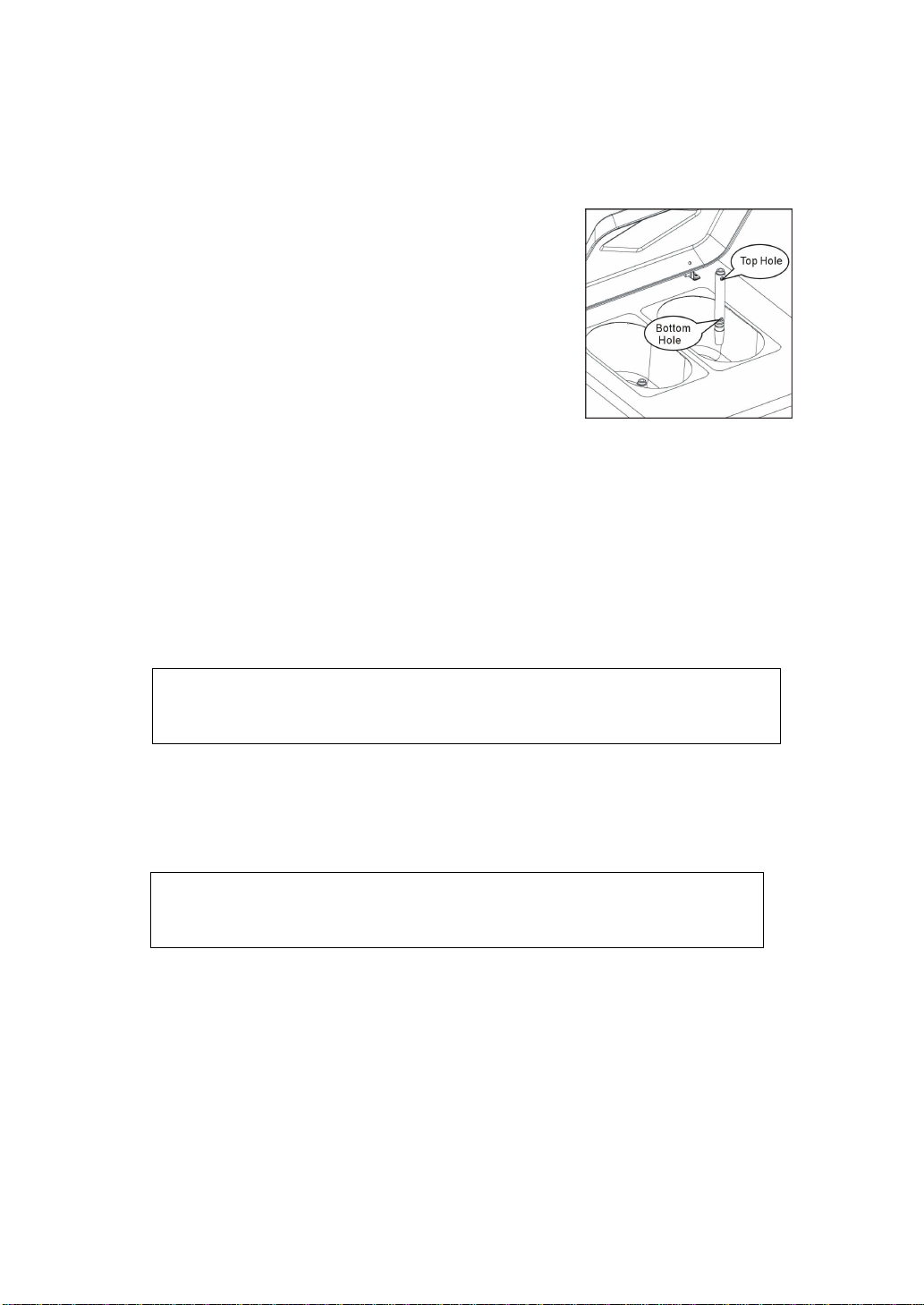

Installation

●

The machine should be used indoors. It should be placed on a flat dry solid ground.

500mm around the machine there should not be heat source over 70℃.

●

Distance between machine and wall or the one between machine and other objects are

shown in Fig.3. The air inlet and outlet of condenser should be kept smooth. There should

not be any inhaled thing around the machine.

●For machine with truckle brake, to avoid shift during operation, please stamp the

5

truckle brake after placing the machine at using place. (For some models only)

Operation

●

To ensure safety, machine must be operated or supervised by qualified staffs, who

possess enough safety common sense on electric appliance and mechanism as well as

know special requirements of the machine fully.

●

The product from the machine is direct food. The operator should know food hygiene

fully and have emdical certificate which is approved by sanitary administration of local

government and accordance of law.

●

The operation procedure should meet sanitary requirement. Sanitized aiding tools,

containers and sanitation material (headgear, respirator, glove, etc.) should be used

and used in a correct way.

Machine testing

After installing all the accessories, to make sure all functions in a good state, before

production a necessary operation test for functions of machine should be taken.

●

Switch the WASH BUTTON, the stirrer motor works, and the driving device will bring

along the stirrer shaft, thus the stirrer shaft works. Switch STOP BUTTON, the stirrer

motor stops.

● Switch the AUTO BUTTON, the machine will enter refrigeration mode. The stirrer

motor works first, after 30 seconds the compressor and condenser fan work. There is

hot air from the condenser outlet, the temperature in the stirrer drum decreases

quickly, there will be frost in it after 1 minute. Switch the STOP BUTTON, the

machine will stop working.

Safety

Note

●

It is unavoidable that the machines will get vibrated during transportation. Please leave

the machine unused for above 24 hours before operation.

● Keep the machine from sunshine and high temperature radiant source.

Warning

● To ensure safety, machine must be operated by trained staffs, who know special

operation requirement of the machine fully.

● If the machine malfunctions or the cable is damaged, it must be serviced or replaced

by the manufacturer or its service agent or a similarly qualified person in order to

avoid a hazard.

Caution:

Caution:Caution:

Caution:

Please take out the stirring shaft when the machine is tested without

Please take out the stirring shaft when the machine is tested without Please take out the stirring shaft when the machine is tested without

Please take out the stirring shaft when the machine is tested without

material.And testing time should not be longer than 3 minutes. Long time

material.And testing time should not be longer than 3 minutes. Long time material.And testing time should not be longer than 3 minutes. Long time

material.And testing time should not be longer than 3 minutes. Long time

testing without material will make ice in the refrigeration tank and damage

testing without material will make ice in the refrigeration tank and damage testing without material will make ice in the refrigeration tank and damage

testing without material will make ice in the refrigeration tank and damage

the machine greatly.

the machine greatly.the machine greatly.

the machine greatly.

6

● If the machine is not used for a long time, please cut off the electric supply and let

out the water in water inlet soft tube.

● Keep the machine clean at any time. Clean the alterative waste ingredients to avoid

accessory rust.

● Pay attention when you open and close the top cover to avoid hands hurt.

● Don’t clean any part inside the machine by water faucet.

● For ice cream machines with three flavours, do not make only one refrigeration tank

work or add ice cream material to one hopper and other material to the other

hopper. (except BQ836*)

Danger

● Don’t touch electriferous plug or switch when your skin is exposed or wet, or you are

wearing wet glove or wet clothes.

● Don’t operate the machine which is not connected to the ground in a correct way.

● Don’t do any maintenance to the machine before cutting off electric

supply.

Transportation and Storage

●

During transportation, collision, over 45 degrees inclination and strong vibration is not

allowed.

● The machine should be stored at a place where the environmental temperature is

around -15℃~55℃and relative humidity is not more than 85%. Also it should be

kept from sunshine and rain.

Maintenance area

● Maintenance area can be entered after side boards (or other boards) are opened.

● Maintenance area should be operated by qualified trained staff.

. Ice Cream Material

Buy packaged ice cream powder directly and prepare it with water according to the manual.

Note:1. When making the ice cream slurry, do stir it well. Do not leave any deposit.

Otherwise the hole at the bulk tube may be blocked, causing the material to fail

in going down quickly, making the refrigeration tank frosted and damaging the

stirrer shaft.

2. If the ice cream slurry can not go down smoothly, please remove the bulk tube

for a while to make sure the slurry can go down smoothly.

3.Temperature of ice cream material should be between 5℃and 40℃otherwise

the machine will be damaged.

7

Special Advice:

It would be better if our ice cream powder is used. (There are tens of flavor to meet your

choice, such as milk, chocolate, vanilla, mango, etc.)

6. Cleaning

1) Cleaning before Production

a. By hand in counterclockwise direction unscrew throat screws(or by spanner unscrew four

throat bolts.)

b. Clean the feed hopper, refrigeration tank, stirring shaft, bulk tube and hopper lid with

cleanser essence water of sanitary standards, brushes or dishcloth.

c. Put the throat block in cleanser essence water of Point b, push and pull each handle 2 to 3

times. Remove the horizontal bar at the handles, pull out every plug of the throat block,

and then clean the throat block and plugs. After cleaning put them into the disinfector for

3-5 minutes and clean them with clean water. Lubricate the circle around the plug gasket

with edible oil. Install the throat block and plugs as before.(See Fig 4、5)

Fig 4

Fig 5

2) Cleaning after Production

a. Fill the feed hopper with clean water. Push the CLEANING button, then the

CLEANING LIGHT is on; make the stirrer shaft run for about 3 minutes. When the

rest of ice cream in the refrigeration tank has melted, pull the handle at the throat

block and drain the water. Then repeat the above several times. When the cleaning

is finished, push STOP BUTTON, then the machine stops production.

b. Clean the discharge throat block.

Repeat Point a and c in Cleaning before Production.

7. Machine Operation

1) Production

a. Connect the electric power, then the indicator shows the temperature of the hoppers

and the refrigeration tanks(The first two numbers on the left side are for hoppers while

the two on the right side are for the refrigeration tanks). For example, if the indicator

shows12-2, it means the hopper temperature is 12℃while the refrigeration tank

temperature is -2℃(only for the machine with Y and Y1 function).

b. Insert two bulk tubes into the discharge hole of the hoppers respectively.

Note: Do not clean the machine with hot water which is above 40 degrees

centigrade. Otherwise the sealing accessories inside the machine will be

damaged.

8

c. Pour the prepared ice cream slurry into two hoppers. The liquid surface should not be

higher than the top hole of the outer tube. Screw the outer tube making the top holes

for the inner tube and outer tube coaxial. Then the bottom holes are completely open.

The ice cream slurry can go to the refrigeration tank through the bottom holes. (Fig. 6)

d. When the ice cream slurry flows into the tank, after

about 3 minutes, push the AUTO button and start the

stirrer motor. After about 30 seconds, the compressor

starts and the machine gets in RUN mode. At this time,

the indicator shows the rate of progress of ice cream by

percentage. When the indicator shows FlnE(FINE),

then the ice cream is ready. Pull the handle then

appetizing ice cream can be discharged.

e. Push the STOP button when production needs to be

stopped. And then the indicating lights are off. Then

the machine will stop production.

f.

According to the speed of ice cream

discharging, adjust the outer tube of the bulk tube, control the open state

of the bottom holes. Then the air and ice cream slurry go into refrigeration

tank together.

And an excellent bulky and soft effect can be achieved.

2) Discharge, Automatic Reset & Continuous Running

a. When the machine shows“F1nE”, pulling any one of the handles of the throat block,

the stirrer motor can be started, and then the ice cream in the refrigeration tank will be

discharged. The ice cream discharged from left and right of the throat block is in

single color and is made from the material in left and right refrigeration tank

respectively. The ice cream discharged in the middle is in double colors and is made

from the mixed material in both tanks.

Note: When part of ice cream is discharged, the material in the refrigeration tank will

decrease. If the amount of material is too little, there will be abnormal noise in the

refrigeration tank. What’s worse, the stirrer shaft will be damaged. In this case, check whether

the bottom holes of the bulk tube are blocked or not open adequately.

b. When the ice cream reaches the preset hardness, the indicator will show FlnE and the

machine will stop automatically. In about 5 minutes the machine will restart

automatically. During this period, if production needs to be continued, push the

RESET button (or pull the throat block handle), the machine will start production at

once.

2) The Hardness Setting of Ice Cream

The principle of hardness adjustment is as follows. First, increase the load of stirrer motor.

Second, the current is increased and the circuit is controlled. Then the machine stops working.

Before delivery, the ice cream hardness has been set according to our recipe. If different recipe

is used, reset the hardness again.

a. The hardness setting is divided into 20 points, from point 01 to point 20. The bigger

the number is, the harder the ice cream is.

b. Pressing AUTO BUTTON for 10 seconds, the indicator shows the points at work and

flashes, such as 1-01.One point will be increased if BUTTON + is pressed. One point will be

decreased if BUTTON – is pressed. When the setting is finished, after 10 seconds the indicator

shows SAVE and exits.

Note: BQJ Model is designed for intermittent production. i.e. After a certain amount of ice

cream is discharged from the refrigeration tank, it will take several minutes for

refrigeration before the machine is ready to discharge the next batch.(The time is

depended on the amount of refrigerant in each model.)

Fig 6

9

c. If you want to change the point, please change it after the machine runs for one minute.

Otherwise the effect of hardness adjustment is affected.

4) Keeping fresh function of ice cream machine

a. When the machine is in the state of AUTO, the machine precools the material in the

hoppers automatically, making the material at a certain low temperature and fresh.

b. When the machine is not in production mode for a short time and there is still some ice

cream material not used, press KEEP FRESH BUTTON, then the machine can automatically

keep the material in the hoppers and refrigeration tanks fresh.

5) Function of Low Mix Indicator (Only for some special models at customers’request)

a. Single Low Mix Indicator

When the material in the hoppers is not enough, the indicator shows -CL-. Meanwhile the

buzzer will sound every 20 seconds to remind the user to add the material in time. And the

production state of the machine is not affected.

b.

Double Low Mix Indicator

When level of ice cream material in hopper reduces by one half, the indicator shows -CL-.

Meanwhile the buzzer will sound every 20 seconds to remind the user to add the material in

time. At that time the production of the machine is not affected. But when level of ice cream

material reaches the bottom of the hopper, the machine will stop working at once and will

be in locked state.AUTO light is on and the indicator shows -CL-.Meanwhile the buzzer

will sound every 20 seconds. At that time, please press STOP button, add ice cream material

in the hoppers and press AUTO again. Then locked state will be off.

6) Ice Cream Calculator&Indicator

a. When the machine is in the state of AUTO, pull the handle, and then it takes count of one

time. (The figure ranges from 000 to 999.)

b. Keep on pressing AUTO for 10 seconds, then the indicator shows 1-XX and flashes. Again

press AUTO for three times, then the indicator shows 4-XXX. XXX shows the quantity of ice

cream discharged. (When the indicator reaches 999, the calculator comes to zero. In other

words, the calculator starts again.)

c. If no action takes on the keys for 10 seconds, the indicator shows SAVE and exit. Then the

previous state is kept.

8. Maintenance

1) Clean the dust of the condenser every half year. Otherwise the refrigeration effect will be

affected.

2) Cleaning Procedure

①Cut off electric supply of the machine.

②By screwdriver remove locking screw at the side board of air outlet of

condensor. Then remove the side board.

③By brush remove the dust and fuzz accumulated on the condensor.

Note: Hopper precooling is not in effect(except the machine with Y function) when the

machine is making ice cream. The temperature range of precooling is 0-10 ℃.

Note: ①Don’t clean the section between the wings by prick or other metal objects.

②If the dust is hard to clean, please ask help from professional refrigeration

maintenance.

10

9. Electrical Drawing

Please refer to the electrical drawing which is stick to the cover of the electrical case

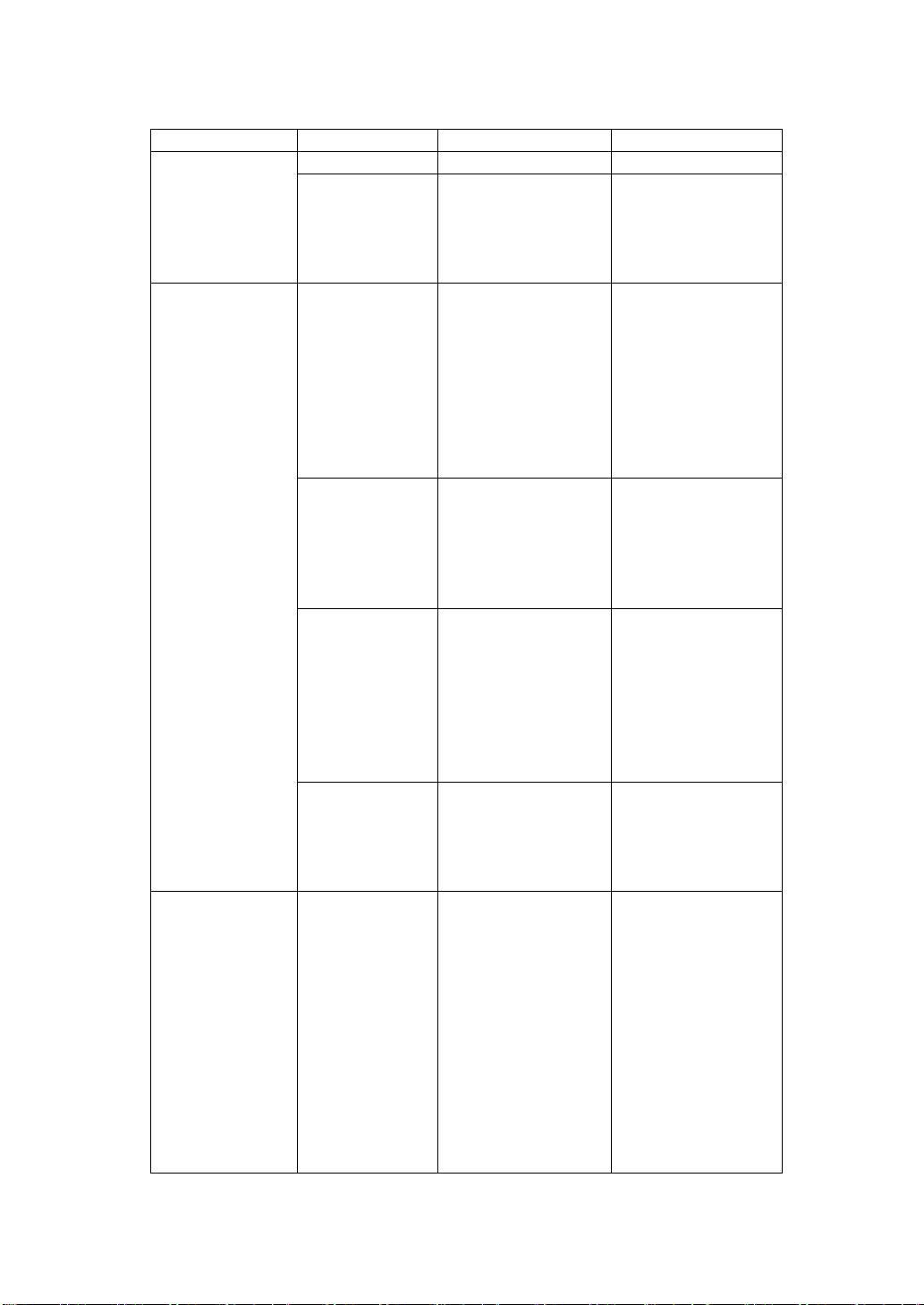

10. Easily Worn-out Parts List

No.

Model

Size Quan

633*\620*\833*\

820*\836*\818*

\816*

368*

116*

112* 8530* 747*

1

O Shape Gasket

φ19×3.9

3 3

1 5 7

2

O Shape Gasket

φ26×5.2

3 3

1 5 7

3

Bridge Gasket

1 1

2 3

4

Quadrate Gasket

φ91×φ80×4.5

2

1 3 4

5

Quadrate Gasket

φ100×φ92×4

2

6 Bulk Tube

2 2

1 3 4

7 Star Shape Screw

(Different from

Models) 2 2

1 3 5

8 Socket Wrench

(Different from

Models) 1 1

9 Star Screw

Wrench (Different

from Models) 1 1

1 1 1

Our company maintains the right to improve all the machines. We are subject to modification

without prior notification.

11

11. Trouble Shooting

Trouble Reasons Analysis Disposal

A. The

compressor

does not run.

A. The starter or

capacitor

malfunctions.

B. The compressor

or controlling board

is damaged.

C. Power voltage is

too low or the

section area of the

power cable is too

small, making the

voltage drop.

*A.B. Change the

defective parts.

*C. Increase the

size of cross section

area of the cable

and increase the

capacity of power

source.

B. The cooling

system is

blocked by ice

or foreign

material.

Moisture or foreign

material enters the

system.

*Remove moisture

and foreign

material from the

refrigeration

system.

C. Refrigerant

Leaking. The refrigeration

system is not

properly sealed.

*After checking the

leaking place do the

reparation,

vacuumize the

system and fill the

refrigerant again.

Refrigeration

Failure

D. Throttle is

not adjusted

well.

Throttle is not

adjusted well or

damaged.

*Again adjust the

throttle or replace

it.

A. The current

of the motor is

larger than the

preset.

A.Outer diameter of

stirring shaft is

expanded.

B.Voltage is too

high.

C.Capacitor of

stirring motor is

damageed.

*A. Make outer

diameter of stirring

shaft smaller.

B. Make ice cream

harder by hardness

adjustor.

C.Change stirring

motor or capacitor.

The indicator

shows FlnE, but

ice cream is not

hard enough.

B. Improper

adjustment of

the hardness.

The hardness is set

too low. Adjust the hardness

adjustor to a harder

graduation.

Material or

Water leakage. A. Throat block

leakage.

A. The plug gasket

or the rubber gasket

between the stirring

drum and throat

block is damaged.

B. The fixing bolts

for discharge throat

block are not tight

or not properly

A. Change rubber

gaskets.

B. Install the throat

block in proper

position and tighten

the bolts.

12

Trouble Reasons Analysis Disposal

installed.

B. Oil leakage

in the bearing

pedestal or

material

leakage.

The Y-gasket or

O-ring for the

bearing pedestal is

defective.

Change the

defective gaskets.

A. Not enough

slurry in the

refrigeration

tank.

A. The bottom hole

of the bulk tube is

blocked by the ice

cream ingredients.

B. The amount of

ice cream

ingredients is too

small in the feed

hopper.

A. Remove the bulk

tube for a while.

B. Refill the ice

cream ingredients.

B. Ice-cream is

too hard. A. Too little sugar

in the recipe.

B. The hardness is

not properly

adjusted.

A. Increase the

proportion of white

sugar in the recipe.

B. Turn the pointer

of hardness adjustor

to SOFT position.

C. The stirrer

shaft does not

run.

A. The motor or

control circuit is

damaged.

B. The transmission

belts are too loose.

C. The gear box is

defective.

*A. Change the

damaged

components.

B. Adjust the

position of the

motor.

*C. Repair the gear

box.

No ice-cream

discharge.

D. Discharge

throat block is

blocked by ice.

The water left by

throat block

cleaning ices over

and blocks the

throat block.

Drain the water in

the throat block or

discharge some

ingredients to

remove the water.

The machine

does not run but

whistle.

Machine is at

the protection

state.

A. Indicator shows

EO and limit switch

can not go back

over one minute

after it is pressed.

B. Indicator

displays ‘E2--’,

protection of high

voltage.

C. Indicator

displays ‘E3—‘,

protection of power

supply.

First disconnect the

power, deal with

the troubles

according to the

indicator, and then

connect the power

again.

A. Top pole is stuck

or it has not been

pushed back.

B. The condenser is

blocked or the fan

13

Trouble Reasons Analysis Disposal

D. Indicator

displays ‘E4--’,

hopper temperature

sensor

malfunctions.

E. Indicator

displays ‘E5--’,

refrigeration tank

temperature sensor

malfunctions.

F. Indicator displays

‘CU—‘, the electric

phase is lacked.

G. Indicator

displays ‘CE—‘, the

order of electric

phase is wrong.

malfuctions.

C. The voltage of

the power supply is

too low or too high.

D. E. The

temperature sensor

is short circuit or

open.

F.G. Check three

phases electric

power supply.

* means the problem should be serviced by the manufacturer or its service agent

or a similarly qualified person.

This manual suits for next models

51

Table of contents

Popular Ice Cream Maker manuals by other brands

Aroma

Aroma AIC-305EM Instruction manual & recipe guide

Steba

Steba IC20 Instructions for use

Cuisinart

Cuisinart ICE-35 user manual

HELEBES

HELEBES BL1530D instruction manual

Nostalgia Electrics

Nostalgia Electrics FDM100 Instructions and recipes

Kambrook

Kambrook Little Chefs Soft Scoops KLCIA4 Instruction booklet