technoswitch DP-PSUEN Series User manual

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx

DP-PSUEN

EN54-4 Fire Alarm Power Supply Series

Rev 11.1

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 2 -

CONTENTS

1GENERAL ____________________________________________________________________________ 3

1.1 Product Range ___________________________________________________________________ 3

1.2 Features_________________________________________________________________________ 3

2ELECTRICAL AND OPERATIONAL SPECIFICATIONS ________________________________________ 3

3COMPLIANCE _________________________________________________________________________ 4

4POWER SUPPLY PHYSICAL DIMENSIONS AND FEATURES __________________________________ 5

4.1 Large Box _______________________________________________________________________ 5

4.2 Medium Box _____________________________________________________________________ 6

4.3 Printed Circuit Board ______________________________________________________________ 7

5INSTALLATION AND OPERATION ________________________________________________________ 7

5.1 Mounting ________________________________________________________________________ 7

5.2 AC Power Connection and Wiring ___________________________________________________ 8

5.3 Jumper Links ____________________________________________________________________ 8

5.4 LED Display______________________________________________________________________ 9

5.5 OP1 and OP2_____________________________________________________________________ 9

5.6 SWI and SW2 Inputs_______________________________________________________________ 9

5.7 DATA and LED Interfaces __________________________________________________________ 9

5.8 Fault Detection and Outputs ________________________________________________________ 9

5.9 Batteries _______________________________________________________________________ 10

5.9.1 Battery Temperature Remote Sensor Fitting____________________________________________ 11

5.9.2 Battery Protection ________________________________________________________________ 11

5.9.3 General Maintenance _____________________________________________________________ 11

6DECLARED PERFORMANCE ___________________________________________________________ 12

7ORDERING INFORMATION _____________________________________________________________ 12

8WARRANTY __________________________________________________________________________ 13

9DISCLAIMER _________________________________________________________________________ 13

10 REVISION INFORMATION ______________________________________________________________ 13

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 3 -

1GENERAL

1.1 PRODUCT RANGE

The DP-PSUEN series of product consists of the following products:

▪DP-PSUEN1.5 EN54 24(27.6)VDC 1.5 Amp PSU, Space for 2x 7Ah batteries

▪DP-PSUEN3-L EN54 24(27.6)VDC 3.0 Amp PSU, Space for 2x 17Ah batteries

▪DP-PSUEN3-S EN54 24(27.6)VDC 3.0 Amp PSU, Space for 2x 7Ah batteries

▪DP-PSUEN5 EN54 24(27.6)VDC 5.0 Amp PSU, Space for 2x 17Ah batteries

The power supplies can be supplied in either a medium or large box which can house 7Ah or 17AH batteries

respectively.

1.2 FEATURES

The DP-PSUEN series of power supplies are designed to be used for fire alarm control and indicating equipment

complying with EN54-2 and EN54-4.

The power supply range consist of a 5 amp, 3 amp and 1.5 amp devices, providing a nominal 27V with two 12V

lead acid batteries for standby operation without AC power. The power supplies share the following features:

▪Microprocessor controlled operation and protection

▪On-demand battery charging and load output current sharing

▪Automatic output reconnection after short circuit fault

▪No user serviceable fuses, outputs protected by electronic E-fuses

▪Two independent switched outputs with programmable (jumper selectable) control inputs

▪On board or remote temperature sensing (jumper selectable) with optional remote sensor

▪Separate AC healthy, battery fault and power supply fault outputs

▪Three fault outputs, AC Power Fail, Battery Fault, PSU Fault

▪Form A, normally closed floating relay fault outputs

▪Four LED status display

▪Over-voltage output protection

▪Battery-free option selected by a jumper

The on-demand load sharing capability gives the power supply range exceptional flexibility. This allows rapid large

capacity battery charging with either extended standby hold-up duration at light loads, or short high current peak

loads where spare output capacity is diverted to battery charging.

2ELECTRICAL AND OPERATIONAL SPECIFICATIONS

SPECIFICATIONS

AC Input Voltage

230VAC ±10%, 50Hz.

Maximum Input Continuous

Current

DP-PSUEN5, 1.5A

DP-PSUEN3, 0.9A

DP-PSUEN1.5, 0.45A

Peak inrush current limit

20A maximum.

Recommended Switched Spur

Input Fuses

DP-PSUEN5, 250V T3.15A

DP-PSUEN3, 250V T3.15A

DP-PSUEN1.5, 250V T1A

Voltage Output AC Present

Minimum 25.0Vdc, Maximum 28.5Vdc.

Voltage Output Standby

Minimum 20Vdc, 24 V Nominal

Total Continuous Output Current

(Imax.b)

DP-PSUEN5, 5A

DP-PSUEN3, 3A

DP-PSUEN1.5, 1.5A

Current output with battery

charging (Imax.a)

DP-PSUEN5, 4.3A

DP-PSUEN3, 2.3A

DP-PSUEN1.5, 1.2A

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 4 -

SPECIFICATIONS

Battery Charging Current

On demand. Maximum.

DP-PSUEN5, 5A,

DP-PSUEN3, 3A,

DP-PSUEN1.5, 1.5A

Low Voltage detection thresholds

<22V ±2%, low voltage restore, >23V ±2%.

Battery Circuit Impedance

Threshold (Ri max)

>0.18 Ohm ±5%, at a nominal test current of 5A.

Deep Discharge Disconnection

Threshold

<21V ±2%.

Overvoltage Detection Shutdown

Threshold

>30V ±2%.

Output Monitoring Threshold

Battery charging voltage <2V ±2%.

On-Board AC Power Input Fuses

DP-PSUEN5, T3.15A

DP-PSUEN3, T3.15A

DP-PSUEN1.5; T1A timed

All non-replaceable.

Battery Fuse

PTC, self-resetting, non-replaceable.

Fault Relays

Normally closed, 100mA at 60V. On-Resistance 16 ohms

maximum, 1500VRMS Isolation voltage

PSU Standby Current

32mA.

Maximum Ripple Voltage

0.7V peak to peak.

Battery Type

Sealed Lead Acid Gel, YUASA NP7-12F/RETARD, YUASA

NP17-12F/RETARD, YUASA NP7-12, YUASA NP17-12I

Operating Temperature and

Humidity Range

-10oC to +40oC, 95% maximum humidity, non-condensing

Minimum Output Current

(I min)

200mA for all DP-PSUEN series

Battery current drawn by power

supply without AC supply

Maximum 55mA (Depending on fault output status)

3COMPLIANCE

The power supplies comply with the following European Directives:

Low Voltage: 2006/95/EC

EMC: 2004/108/EC

WEEE: 2012/19/EU

RoHs: 2011/65/EU

IEC61140: Protection against electric shock –Common aspects for installation and equipment:Class 1

EN54-4: 1997 + A1 + A2 Part 4:Power Supply Equipment

0359

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 5 -

4POWER SUPPLY PHYSICAL DIMENSIONS AND FEATURES

4.1 LARGE BOX

Dycon Ltd

D2435 PSU

INPUT

230V ; 1.5A

50Hz

OUTPUT

24V 5A

12.00

50.00

50.00 50.00

390.00

184.00

60.00

128.00

195.00

97.50

Ø20.00

Knockout

Knockout

Knockout

Knockout Knockout

Knockout

Knockout

Knockout

Knockout

Knockout

Overall dimensions including lid are 394.5mm x 379mm x 90mm

Side knockout centres are 46.5mm above mounting surface, top and bottom

knockouts are 50mm above mounting surface.

375.00

Knockout

51.00

36.00

36.00

36.00 36.00

Knockout

290.00

274.00

First fix keyhole

mounting slot

Mounting

Hole

Mounting

Hole

PCB mounting

pillars x 4

LED light pipe

mounting

bracket

Case earth

stud

110.00

145.00

Rating

Label

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 6 -

4.2 MEDIUM BOX

Overall dimensions including lid are 329.5mm x 294mm x 85mm

Side knockout centres are 44mm above mounting surface, top and bottom

knockouts are 45mm above mounting surface.

50.00

50.00 50.00

330.00

60.00

126.50

Ø20.00

Knockout

Knockout

Knockout

Knockout

Knockout

Knockout

290.00

Knockout

180.00

56.00

Knockout 135.00

165.00

230.00

184.00

First fix keyhole

mounting slot

Mounting

Hole

Mounting

Hole

LED light pipe

mounting

bracket

PCB mounting

pillars x 4

Case earth

stud

Dycon Ltd

D2433 PSU

INPUT

230V ; 900mA

50Hz

OUTPUT

24V 3A

106.75

65.00

Rating

Label

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 7 -

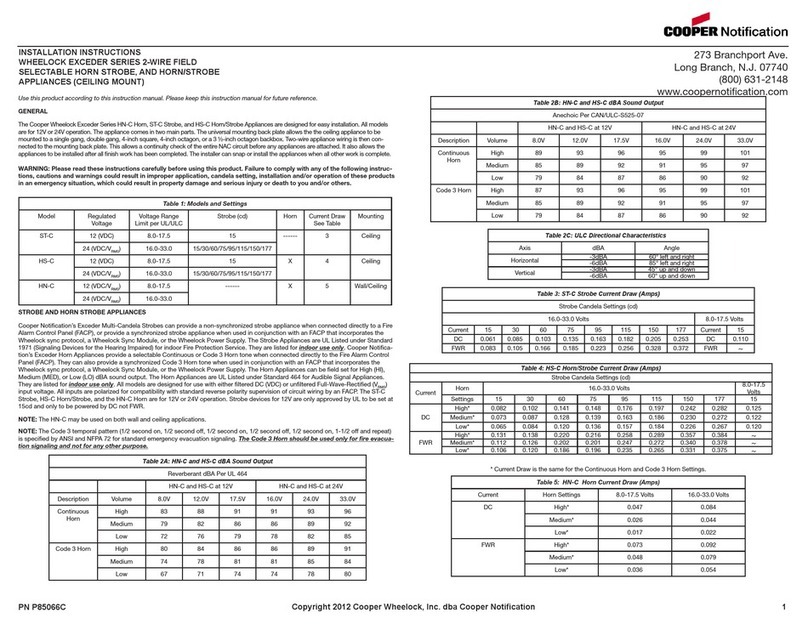

4.3 PRINTED CIRCUIT BOARD

All three power supplies have a very similar form, fit and function, the dimensions are identical. The DP-PSUEN5 is

shown as an example below. NOTE: Plastic cage is not fitted on the DP-PSUEN5 power supply:

168.00

141.00

145.00 6.00

10.007.00

129.50

6.00 5.50

Power DCstatus LED, yellow: Indicates

that DC power is available

ACOKled, green: Indicates

availability of external AC power

Battery Fault, yellow: Indicates

if any battery faults are present

PSU Fault, yellow: Indicates

any power supply system faults

are present

Battery

Connectors

Nominal 24V

output 2 to load

Nominal 24V

output 1 to load

3.2mm Mounting Holes x 5

Live AC power connection

Caseand earth connection tab

Protective earth connection

Neutral AC power connection

SW1 and SW2 control inputs

inversion jumper

Battery-free operation jumper

Optional external temperature

sensor connector

On-board temperature sensor

disable jumper

24V output switching control

inputs with 0V return

External Power Supply (ACpower)

faultnormally closed relay output

Serial data interface

External LEDinterface

Auxiliary Power Supply (battery)

faultnormally closed relay output

Power Supplyfault normally

closed relay output

Plastic safety cage

5INSTALLATION AND OPERATION

NB: WARNING: Isolate the AC power supply before working on the power supply. Only suitably qualified

personnel should install these power supplies and wiring should comply with the latest edition of IEE

Wiring Regulations (BS 7671) or local national electrical standards.

5.1 MOUNTING

The power supplies are designed for indoor use, within the specified operational temperature and humidity limits.

The metal enclosures should be mounted on a solid, flat and dry surface using the three mounting points provided.

The screws should have a minimum shank diameter of 5mm (No 11 gauge) and use suitable wall plugs where

needed.

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 8 -

When a final sighting for the power supply has been decided it is highly recommended that the 20mm knockouts

that are going to be used are removed before fitting the box by a sharp tap with a hammer and flat bladed

screwdriver at the edge of the knockout. Separate knockout holes should be used for AC power entry and low

voltage wiring and the wiring kept apart. The knockout holes are designed to accept cable glands.

The power supplies should not be mounted near sources of heat or moisture and should be accessible for ease of

fitting heavy batteries.

The printed circuit assembly will have to be removed from the medium sized enclosure before mounting. This is

done by pushing the four light pipes towards the lid until they unclip, removing the earth lead by pulling the earth

connector off the tab and unscrewing the four board securing screws. The printed circuit assembly can then be

removed before mounting.

The keyhole slot at the top of the enclosure may be used as a first fix to hang the unit where the bottom two holes

can be marked off when level and then removed for drilling. Using the enclosure directly as a drilling template

should not be done as it risks dust damage.

Care should be taken when refitting the board using the shake proof washers and ensuring they are tight to make

good electrical contact with the printed circuit board and the metal base. The light pipes can then be clipped back

into place and that they are positioned over the LEDs. The earth cable can then be pushed back on to the

connector tab.

5.2 AC POWER CONNECTION AND WIRING

AC power with a protective earth for Class 1 equipment is to be used with an isolating switched spur using the

recommended fuse ratings or a fuse rating of not greater than 5A. The fused switched spur should be fitted as

close to the power supply as practicable to allow isolation when the unit is serviced. AC power cable with

conductors of a cross sectional area greater than 0.75mm should be used.

The AC power cables shall be segregated from the low voltage control wiring and outputs to load. 20mm diameter

knockouts on the four sides of the box are provided for cable glands including mineral insulated copper-clad cable.

Where batteries are fitted, the knockouts at the bottom of the box will not be available.

To comply with EN54 requirements both AC power and low voltage wiring must use cable glands to meet IP30

enclosure protection standards.

5.3 JUMPER LINKS

NB: WARNING: The AC power supply and the batteries must be disconnected before the jumper

positions can be changed. Failure to do so can cause damage to the PSU, batteries and connected

equipment.

The power supply must not be used with the INT jumper in the off position without a DP-PSUEN

external temperature sensor fitted, as this could result in a battery fire or explosion risk.

The NO BAT link must be in the off position to comply with EN54-4 requirements.

Three jumper links are provided for configuring the PSU, the “off” position is when the jumper is “parked” on a

single pin and the “on” position is when the jumper is placed across two pins:

JUMPER

DEFAULT

OPERATION

INV

(Invert inputs)

Off

(Not inverted)

When left in the off position the outputs associated with the SW1 and

SW2 inputs will be switched on when they are at a logic high. When in the

on position the outputs associated with the SW1 and SW inputs will be

switched off when they are at a logic high.

NO BAT1

(Battery free

operation)

Off

(Battery

monitoring

enabled)

With the jumper left in the off position, the PSU will operate as normal with

battery standby when AC power is not available. If operation without a

battery being fitted is required, then the jumper should be in the on

position.

INT2

(Internal/external

temperature

sensing)

ON

(Internal

temperature

sensing)

When the jumper is fitted the PSU will use the internal on-board

temperature sensor, the link must be put into the off position to use an

external temperature sensor.

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 9 -

NOTES

1. This jumper can also be used to supress a battery fault condition until a new battery can be fitted. The jumper

disables the battery monitoring only and allows the battery to be charged and provide standby power as normal.

NOTE: Disabling the battery monitoring with a battery fitted will cause an EN54-4 non-compliance.

2. The power supply must not be used with the jumper in the off position without a DP-PSUEN external temperature

sensor fitted, as this could result in a battery fire or explosion risk.

5.4 LED DISPLAY

Four board-mounted LEDs are used to provide a status and fault display. These

LEDs are brought out to the lid via light pipes and identified with the label as shown.

24 VDC OUTPUT ON: The yellow LED indicates that DC power is available.

AC INPUT ON: The green LED is lit when AC power is available.

BATTERY FAULT: The yellow LED is lit when any battery related faults are

detected.

PSU FAULT: The yellow LED is lit when any power supply related faults

are detected.

5.5 OP1 AND OP2

Due to high instantaneous current that can flow under fault conditions, the DC output wire is recommended to be

1mm cross sectional area or greater for all DP-PSUEN series power supplies.

The outputs are individually protected against short circuits. The outputs can be switched using the SW1 and SW2

output control inputs. The outputs are fully protected against switching transients and are suitable for switching

highly inductive loads such as door strikes and magnets.

The combined output current of the two outputs must not exceed the power supply ratings.

5.6 SWI AND SW2 INPUTS

These inputs can be used to switch on and off their associated outputs. The polarity of these inputs are selected by

the INV jumper, with the jumper in the off position the outputs can be switched off when the input is low and when

in the on position (inverted) the output can be switched off with a positive input.

The wiring to these inputs shall not be more than 3 meters in length.

The inputs have a 100K pull-up resistor and are 30V tolerant. They are designed to be easily driven by a 5V logic

output, relay contacts or open collector transistors, see drive examples below:

100K

5V

INV in off position, output

switched off when

transistor conducts

100K

5V

INV in on position, output

switched on when

contacts close

100K

5V

INV in off position, output

switched on when

contacts open

SW1SW2

Internalpull-up

SW1

Internalpull-up Internalpull-up

5.7 DATA AND LED INTERFACES

These interfaces are used for factory testing and are reserved.

5.8 FAULT DETECTION AND OUTPUTS

Three normally closed relay outputs in no-fault conditions are provided for fault signalling and will open when a fault

is detected. The PSU is factory fitted with two wire links as shown below. To comply with EN54 requirements the

three separate normally closed fault outputs should be connected in series, so should any one of the fault relays

opens in a fault condition, a generic fault condition is signalled.

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 10 -

AC

FLT BAT

FLT PSU

FLT

Wire Links

Normally Closed

Generic Fault

Output

The table below shows the relation between fault and outputs.

FAULT

OUTPUT

DISPLAY

DESCRIPTION

AC power

missing

AC

Fault

DC Power

AC Power

The front panel DC power LED will be on to indicate that DC is

available, with or without AC power, The internal AC power LED

will be off.

OP1 or OP2

shorted

PSU

Fault

PSU

The outputs will automatically retry to restore power every 5

seconds until the short is removed.

Over-

voltage1

PSU

Fault

PSU

If the power supply voltage exceeds 30 volts, both outputs will be

switched off and a latched fault generated2.

Battery

connection

fault

BAT

Fault

Battery

If any of the battery connectors are disconnected a battery fault

will be generated.

Battery high2

resistance

fault

BAT

Fault

Battery

The battery or battery connections are tested every hour and if the

resistance is over 0.18ohms, a fault is generated4.

PSU low

voltage

PSU

Fault

PSU

If the internal PSU power rail voltage is too low to charge the

battery, a fault will be generated5.

PSU

Failure

PSU

Fault

PSU

Should the switching power supply fail due to overloading, over-

temperature or a component failure, a fault will be generated.

Charging3

Failure

PSU

Fault

PSU

Should the charging circuit fail, then a fault will be generated.

Battery Low

Fault

APS3

Fault

Battery

If any individual battery is left to discharge below 11.5V when the

PSU is in standby mode, a fault will be generated.

NOTES

1. Over voltage protection is done at two levels, the first being where the internal power low voltage rail (nominal

24V) is monitored and the second is where the off-line, high voltage side of the switched mode power supply is

monitored. Should an off-line fault be found then the high voltage switching circuit will be disabled. In both

conditions the power supply should be switched off and the batteries removed for 15 minutes to reset the fault.

2. The battery and connection resistance is tested every hour, except when first powered up. On power-up the

battery is tested after 5 minutes to alert the installer to any potential battery condition fault. The fault threshold is

approximately 0.18 Ohm.

3. This fault condition is detected by comparing the internal rail voltage to the calculated temperature compensation

voltage. If more than 1 volt lower, then a fault will be generated.

5.9 BATTERIES

NB: WARNING: There is a risk of fire and explosion if the wrong batteries or battery connection cables

are fitted. Care should be taken with polarity when connecting the batteries. Used batteries should be

disposed of in accordance to the WEEE directive.

Two identical batteries of the specified type shall be used, preferably from the same batch and date of

manufacture. This is important to maintain a balance of charge between the two batteries. Two cable harnesses

are provided for individual connection to the board, where they are connected in series. The remote temperature

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 11 -

sensor as supplied is to be fitted between the batteries. The size of the batteries is dependent on the size of the

box, the load current and the amount of standby time required. The medium box will house two 7Ah batteries and

the large box two 17Ah batteries. The battery cables are to be segregated from the incoming AC power supply

wiring.

5.9.1 Battery Temperature Remote Sensor Fitting

A remote battery sensor is supplied for accurate temperature compensation to comply with EN54-4 requirements.

The sensor is plugged into the TEMP 3-way socket and the EXT jumper must be removed to enable the sensor.

The sensor is supplied with a 200mm lead so the sensor head can be fixed between the batteries with a self-

adhesive fixing plate and ty-wrap as provided. The power supply is not to be used with the EXT Jumper link

removed without a remote temperature sensor fitted.

5.9.2 Battery Protection

The batteries are reverse connection protected and the battery charging output is protected from short circuits.

The battery output is overload protected by a resettable fuse, in addition to the electronic output fuses. If this fuse is

tripped then the batteries should be disconnected for 5 minutes to allow the fuse to reset.

When in standby mode the battery is switched off when the battery terminal voltage reaches 20V to prevent battery

deep discharge damage. This fault is normally reset by restoring the AC power supply.

5.9.3 General Maintenance

NB: WARNING: Isolate the AC power supply before removing the power supply lid. Do not touch

components or heat sinks as there is risk of electric shock or burn hazard.

The power supply should be regularly inspected by qualified personnel and the following checked:

1. No faults are displayed.

2. Battery terminals checked for corrosion and the terminals are securely tightened.

3. All the connections into the power supply terminal blocks are secure.

4. The battery voltages are checked and the voltages are balanced within a volt to each other. The battery

manufacturer’s specifications should be consulted when making battery voltage measurements.

5. Battery replacement is recommended after a 5-year service life.

6. Check there are no signs of water or moisture ingress and there is no mechanical damage to the enclosure.

7. Check for signs of overheating on the power supply board and battery cases.

8. Check the voltage outputs, they should be nominally between 26.5V and 28.5V depending on temperature.

9. There are no replaceable input, battery or output fuses. In the event of a fault the power supply board will have

to be replaced.

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 12 -

6DECLARED PERFORMANCE

0389

Dycon Power Solutions Ltd, Unit A, Cwm Cynon Business Park, Mountain Ash, CF45 4ER, UK

14

D2431, D2433, D2435/2014/09/19

Harmonised Technical Specification

EN54-4:1997 + A1:2002

+ A2:2006

Essential Characteristics

Performance

Clause

Performance of power supply

- - General requirements

- - Functions

- - Materials, design and manufacture

Pass

Pass

Pass

4

5

6

Operational reliability

- - General requirements

- - Functions

- - Materials, design and manufacture

- - Documentation

- - Marking

Pass

Pass

Pass

Pass

Pass

4

5

6

7

8

Durability of operational reliability

(temperature resistance)

- - Cold (operational)

Pass

9.5

Durability of operational reliability

(vibration resistance)

- Impact (operational)

- - Vibration, sinusoidal (operational)

- - Vibration, sinusoidal (endurance)

Pass

Pass

Pass

9.7

9.8

9.15

Durability of operational reliability

(electrical stability)

- - Electrical Compatibility (EMC), - Immunity tests (operational)

Pass

9.9

Durability of operational reliability

(humidity resistance)

- - Damp heat, steady state (operational)

- - Damp heat, steady state (endurance)

Pass

Pass

9.6

9.14

Products covered by this standard are assumed to function during the alarm condition, in an event of fire, before the

fire becomes so large as to affect their functioning. There is therefore no requirement to function when exposed to

direct attack from fire.

7ORDERING INFORMATION

Product Code Product Description

DP-PSUEN1.5 EN54 24(27.6)VDC 1.5 Amp PSU, Space for 2x 7Ah batteries

DP-PSUEN3-L EN54 24(27.6)VDC 3.0 Amp PSU, Space for 2x 17Ah batteries

DP-PSUEN3-S EN54 24(27.6)VDC 3.0 Amp PSU, Space for 2x 7Ah batteries

DP-PSUEN5 EN54 24(27.6)VDC 5.0 Amp PSU, Space for 2x 17Ah batteries

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx E&OE

- 13 -

8WARRANTY

General Terms and Conditions are available from the Technoswitch website (www.technoswitch.co.za). Alternatively,

please contact your local Sales Office for further information.

9DISCLAIMER

Although the contents of our product literature have been prepared with the greatest care, Technoswitch can accept no

liability whatsoever for any direct or indirect damages of any kind that may arise due to either errors or omissions in them

or amendments to products or other specifications following publication.

10 REVISION INFORMATION

Revision

Date Issued

Reason for Change

Reference

Rev 11.1

20220322

New Manual

Version 11.1: 20151207

DP-PSUEN EN54-4 Fire Alarm Power Supply Series –INSTALLATION & OPERATION MANUAL

DP-PSUEN Series Installation & Operation Manual Rev 11.1 220323.docx

E&OE

HEAD OFFICE —JOHANNESBURG

T+27 (0)11 794 9144

Einfo@technoswitch.co.za

Cussonia Park, 3 Ridge Road, Laser Park, Johannesburg

PO Box 1752, Randpark Ridge, South Africa, 2156

CAPE TOWN

T+27 (0)21 948 4575

Tyger Terraces II, Block 2B, DJ Wood Street, Bellville Business Park

Cnr Mike Pienaar Blvd & Voortrekker Road, Bellville, 7530

DURBAN

T+27 (0)31 266 8843

Colchester Building, Essex

Gardens

1 Nelson Road, Westville

3629

www.technoswitch.co.za

This manual suits for next models

4

Table of contents

Other technoswitch Fire Alarm manuals