thefirebeam firebeam User manual

user guide

issue 0025-05

distance & positioning guidelines

these guidelines are given as a guide only and it is important

that you refer to your appropriate governing standards at all

times.

5m

standard 5-40m beam

standard beam+40-80m reflector kit

standard beam+80-100m reflector kit

40m 80m 100m

what distance?

The standard fire beam will be suitable for distances of over 5m to 40m to the

reflector.If you require 40m to 80m you will need to use the mid range reflector

extension kit. For ranges of 80m t0 100m you will require the long range reflector kit.

5-40 metres the standard firebeam The standard firebeam comes boxed with the head unit, low

level controller, one reflector, 3mm allen key, test filter and quick start installation guide

this should be used for distances over 5m and up to 40 meters

40 - 80 metres = the standard firebeam + mid range 40 to 80m kit

for distances 0f 40 metres to 80 meters you will need to use the standard firebeam and a mid range extension kit (the mid range kit comes with a back-

ing plate and 3 extra reflectors, you will need to add the reflector from the standard kit to the mid range kit with the screws provided)

40 - 80 metres

add the reflector from the standard firebeam to the

mid range kit with the screws provided

5-40 metres

2

80 - 100 metres

80 - 100 metres = the standard firebeam + long range 80 to 100m kit

for distances 0f 80 metres to 100 metres you will need to use the standard firebeam and a long range extension kit (the long range kit comes with a

backing plate and 8 extra reflectors, you will need to add the reflector from the standard kit to the long range kit with the screws provided)

add the reflector from the standard firebeam to the

long range kit with the screws provided

what position?

A roof is considered flat unless the height of the apex is greater then 0.6m. If the roof

is flat thefirebeam system can be placed anywhere under the roof between 0.3m and

0.6m below the roof,

up to a maximum height of 40m from the floor.Thefirebeam

has a

detection area of 7.5m ether side of the beam.

If the roof is considered to have an apex, place thefirebeam system 0.3m to 0.6m down from

the top of the apex, up to a maximum height of 40m from the floor. The maximum protected

area either side of the beam can be extended by 1% for every degree of roof pitch, see the

example below

Always mount thefirebeam system on a solid construction that is unlikely to flex

Mount over 2.7m from floor level to avoid to people walking through the beam, and

consideration should also be given to the possibility of obstruction by fork lift trucks

and the like.

Avoid pointing the head into direct sunlight.

40m

max

0.3m - 0,6m

flat roof

7.5m

0.3 - 0.6m

7.5m

extra coverage due to apex angle

10

o

0.3 - 0.6m

15m + (15 X10%)

=15m + 1.5m = 16.5m

16.5m detection area

15m detection area

8.25m 8.25m

min 0.5m

wall

you should always position the beam at least 0.5m

away from any protrusion

field of view should be a 50cm radius from

the centre of the beam head

plan view

3

installing and commissioning

screw in through holes

provided outside of the

rubber seal

then screw down

the head screws

with the 3mm allen

key provided

wire into system as required

See generic wiring diagram on

the following page. For other

configurations contact us or

view our website.

2 knock outs are provided

on both sides

wire to low level controller

using bottom colour coded

terminals

connect the head

to the base plate

by first plugging in

the connector

step one. mounting the head

screw the head backing plate to the wall - always try to use as

sturdy location as possible, such as brick or major structural

steels (avoid mounting to outer metal cladding etc)

step two. mounting the controller

Important mount the controller at eye level and with easy access

screw in through holes

provided outside of the

rubber seal

wire to head using colour

coded terminals

Also available adapter plate

use this accessory for easy mounting to unistrut fabrication. Holes are pre drilled to the

correct pitch of the head and conveniently positioned for use with unistrut

4

generic wiring configuration

to fire panel

to controller

switch 4 on all rest off

BROWN + supply (10.2-30 Vdc)

BLUE - supply (return)

BLACK zone +

GREY zone -

GREEN earth (screen)

Supply Voltage 12Vdc to 24 Vdc +25% -15%

Quiescent Current 3mA

Alarm Current 3mA

Aligning Current 3mA

Fault / Fire relay contact rating 2A @ 30Vdc

FIRE and EOL

components as specified by

the panel manufacturer

5

step three. commissioning

to commission the fire beam you must follow the simple procedure below

1. do NOT put up the reflector or COVER it if in place already!

2. power up the unit - you will see

then the screen will default to

3. access the menu system by pressing enter

4. scroll through the menus until you get to commissioning

5. enter commissioning and enter pre-alignment

(pre alignment is probably the most important part of commissioning)

6. you will see this screen

received signal

P=pre-alignment

signal power receiver sensitivity

X (horizontal)

motor position

Y(vertical)

motor position

6

7. signal power starts at 10% and the receiver sensitivity starts at

5% and automatically increases until a received signal from the

blank wall without the reflector of between 5 and 7% is

achieved, it will then stop

if you are covering a distance of over 50 meters you should be

achieving signal power of over 60%, if you are receiving less it’s

possible that you are picking up a reflection from something

other than the target blank wall. By moving the beam

(looking at the wall) left (x-) right (x+) up (y+) and down

(y-) you can move the beam away any obstacles to

achieve higher signal power

8. Once you are happy with the power readings press enter

and confirm by pressing the right key. The manual alignment

menu will appear press enter to enter.

you will now seen this screen

Y +

X+

X -

Y -

obstacle roof line

target wall

received signal

press enter in

pre-alignment and then

confirm by pressing the

right key

press enter to

enter manual

mode

7

9. NOW place or uncover the reflector on the blank

wall directly opposite the beam head with a clear path though

obstructions such as girders etc.

It is important that there is a clear line of vision between the reflector and any

obstruction -the beam head must see at least 200mm of clear wall around the reflec-

tor to enable successful auto alignment.

Once the reflector is in place the AQ value should jump up

meaning that the head is now seeing the

reflector.

If you have received a AQ reading of over 40% go to Auto

Alignment point 10.

you need a reading of at least 40% to proceed to Auto align-

ment. If you do not receive an AQ signal of 40% it means the

beam head is not seeing the reflector. You will need to move

the beam head until you receive an AQ reading of above 40%

ideally over 100%

If you are presented with the screen below (AQ-air quality could be any number up to 40%)

Now look at the position of the reflector in relation to the beam head. You will need to

angle the beam toward the reflector by moving the head about its X or Y axis

using the internal motors

In the example on the next page you will notice that the reflector is below the line of

fire of the beam. So in this case you would need to lower the angle of the beam (-Y)

until you receive a AQ (Air Quality) reading above 40% sensitivity. (40 steps of the motor =

1degree of movement)

The minimum response you need to see is 40%

(below this figure the beam will not self align in the

next procedure) the higher the number the better - this

can be over 100%

clear vision around

the reflector

8

Y +

X+

X -

Y -

Y -

40 steps = 1 degree of movement

Adjustments can now be made to the Xand Yaxis by using the

left(x-), right(x+), up(y+), down(y-) keys. Looking at the reflector

this will move the beam across the reflector like so

(40 steps = 1degree) (you can hold the key down for faster increments)

in the example above moving the yaxis down(y-) results in a greater

% air quality

Wait for x / y values to finish moving to asses your AQ result

beam head reflector

Press enter to exit manual mode and enter Auto Alignment

Try and achieve as good a result as possible - it must be over

40% or auto align will abort. (the better the result the shorter the

auto align time will be - a result over 100 is good!)

10. Having received a AQ reading of over 40% in manual mode

press enter to exit manual and enter again to enter

auto alignment

press enter and the beam head will automatically align on the reflector

9

Note: if you break the beam whilst it’s auto aligning it

will automatically abort, reset by pressing the left back

button and pressing enter to re-start auto alignment

the alignment could take up to 30 minutes or more

depending on how much aligning is required. Once com-

plete you will see a Align Complete notification, simply

press the left back button to exit and your firebeam is now

ready and commissioned

you will now see this screen. Air Quality may fluctuate

slightly around a couple of %.above and below 100

first you will see the signal power readings and receiver

sensitivity drop if the received signal reading is over 100%.

once at 100% or if the reading is under 100% thefirebeam

will automatically move its X and Y axis until it is positioned

on the reflector. (This operation could take 30 minutes or

more)

step four. testing

to test that the firebeam is aligned correctly you will need to carry out two tests.

Your firebeam has now been commissioned and tested.

1. a filter test for ‘Fire’

place the filter provided over the eyes of the firebeam.

having done this (after 10 seconds) the red fire LED will flash on

both the head and on the controller and the word FIRE will

replace NORMAL on the low level

controller display

2. a reflector test, to check that the beam is reflected

back from the reflector

cover the reflector completely within one second. If the beam is

correctly targeted on the reflector a fault condition will occur (after

10 seconds). A amber LED will flash on both the head and on the

controller, the word FAULT will appear

in the display

10

screen and menu system

issue 0026-02

NORMAL FIRE FAULT ERROR ALIGN

default 35% adjustable between 25% and 50%

to enter sub menus

to exit sub menus

default autoreset

press enter / menu to enter

menu system

shows (

*

) when updating

If alarm is set to latching and you need to reset

from fire press ‘enter’ to see this screen and

‘enter’ again to reset and return to the normal

screen, if in fire you will need to press ‘back’to

go back to the main menu. If set to auto reset it

will reset to normal automatically

no

comms

beam head is

performing

a self

re-alignment

procedure

to increaseto decrease

use left and right buttons to change

shows (

*

) when updating

use left and right buttons to change

shows (

*

) when updating

default 10s

default 10s

default off

use left and right buttons to change

shows (

*

) when updating

use left and right buttons to change

11

view amount of internal gain made to

compensate for dirt build up on beam lenses

-128% to +128%

to test beam press enter - the power will

slowly drop as can be seen in the

dropping air quality.

When the air quality drops past the pre set

threshold the beam will fall into fire

remember that there is a delay time

set for time to fire

to enter sub menus

counts events since alignment or reset 0-255

back to exit

sub menus

12

pre- alignment is the first stage of

alignment - this should only be used

without the reflector

to enter sub menus

make adjustments by using the

left, right, up and down keys

(this moves the beam in these

directions across the face of

the reflector- with your back to

the beam)

make adjustments by using the

left, right, up and down keys

(this moves the beam in these

directions across the face of

the reflector- with your back to

the beam)

this symbol will

appear next to

the number when

you move the

beam

this symbol will

apear next to the

number when

you move the

beam

to exit sub menus

13

if the beam is obstructed during auto alignment

the alignment will be aborted press back to

return to auto alignment and enter to resume

auto-alignment once alignment is complete you will

see the screen below

press back to return to the main

screen

14

to enter sub menus

shows output power strength

compensation amplifier

shows sensitivity of receiver

to exit sub menus

shows temperature at beam head

screen used by The Fire Beam

help desk

screen used by The Fire Beam

help desk

software versions for the head

and controller

shows (

*

) when updating

to increaseto decrease

shows (

*

) when updating

to increaseto decrease

shows (

*

) when updating

to increaseto decrease

15

Electrical Specifications:

Supply Voltage. 10.2 to 40 VDC

Supply Current. 3mA (constant current)

in all operational states

Environmental Specifications:

Temperature. -10°C to +55°C

Humidity. 10 to 95% RH Non-condensing

Protection Index. IP65 when suitably

mounted and terminated

Mechanical Specifications:

Beam Head.

180mmH x 155mmW x137mmD

Weight 1.1Kg

Controller.

185mmH x 120mmW x 62mmD

Weight 0.55Kg

40KIT80 Mid-Range Reflector.

293mmH x293mmW x 5mmD

Weight 0.8Kg

80KIT100 Long Range Reflector.

394mmH x 394mmW x 5mmD

Weight 1.8Kg

ADAPTER.

270mmH x 250mmW x 5mmD

Weight 0.6Kg

(mounts the Beam Head onto unistrut)

Optical Specifications:

Optical Wavelength. 870nm

Maximum Angular Alignment. ±15°

Maximum Angular Misalignment.

(static not auto-aligning)

Beam Head ±0.75° Reflector ±2°

Operational Specifications:

Protection Range:

FIREBEAM.

Standard Product 5 to 40 metres

40KIT80.

Mid-Range Reflector Kit 40 to 80 metres

80KIT100.

Long Range Reflector Kit 80 to 100 metres

Alarm Sensitivity Levels:

25%(1.25dB) to 50%(3dB) in 1%(0.05dB)

increments (default 35% (1.87dB))

Alarm Condition:

Obscuration drops to below pre-defined

sensitivity level.

Time to Alarm Condition adjustable

2 to 30 seconds in 1 second increments

(default 10 seconds)

Alarm Indication:

Controller Status – FIRE

Controller Red Flashing LED 0.5 Second

Head Red Flashing LED 1 Second

Alarm Relay Change Over (CO) Contact

Rating 2A @ 30 VDC

Test/Reset Features:

Beam test function by controller

Alarm latching/auto-reset selectable

(default auto-reset)

Alarm reset in latching mode by controller reset

function, removing power for >5 seconds,

apply 12 to 24 VDC to reset connections in

Beam Head.

Fault Sensitivity Level:

90%

Fault Condition:

Obscuration drops to below the fault

sensitivity level within 1 second

Power Down or Supply Voltage < 9 VDC

Commissioning modes, Pre-Alignment

and Auto Alignment

Beam turned off during Beam Maintenance

(auto resets in 8 hours to normal)

Time to Fault Condition adjustable,

2 to 60 seconds in 1 second increments

(default 10 seconds)

Fault Indication:

Controller Status – FAULT

Controller Yellow Flashing LED 1 Second

Head Yellow Flashing LED 1 Second

Fault Relay Change Over (CO) Contact

Rating 2A @ 30 VDC

Normal Condition:

Obscuration level is above the

Alarm sensitivity level

Controller Status – NORMAL

Controller Green Flashing LED 1 Second

Programmable on/off

Head Green Flashing LED 1 Second

Programmable on/off

Auto-align/Beam Contamination

Compensation:

Auto-align during normal operation if

obscuration drops below 90%

(doesn’t effect normal operating mode)

Beam Contamination Compensation 4 hour

monitoring. Compensation data available at

the controller

technical specifications

Table of contents

Popular Fire Alarm manuals by other brands

Fire-Lite Alarms

Fire-Lite Alarms LCD-40 Series manual

Ziton

Ziton ZP2-LB Installation sheet

Adicos

Adicos M-BUSMASTER XF operating manual

Maxfire

Maxfire CROSSFIRE LCD manual

Teletek electronics

Teletek electronics SensoIRIS BSOU installation instructions

Fire-Lite

Fire-Lite SENSISCAN 2000 Nstallation, operation and programming manual

Firesense

Firesense DA Series Operation, installation & programming manual

DM TECH

DM TECH FP9000L-4 Installation, setup and operation

Secutron

Secutron MRM-800MP Series installation instructions

Siemens

Siemens Cerberus CS1140 Commissioning Extinguishing

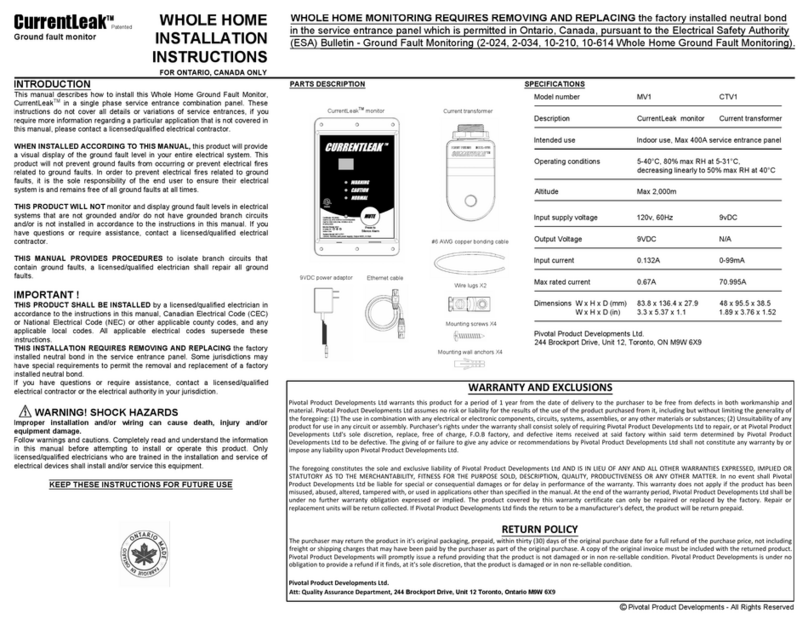

pivotal

pivotal CurrentLeak Whole Home installation instructions

Aritech

Aritech FP2000 reference guide