Techsys SWORDFISH+ User manual

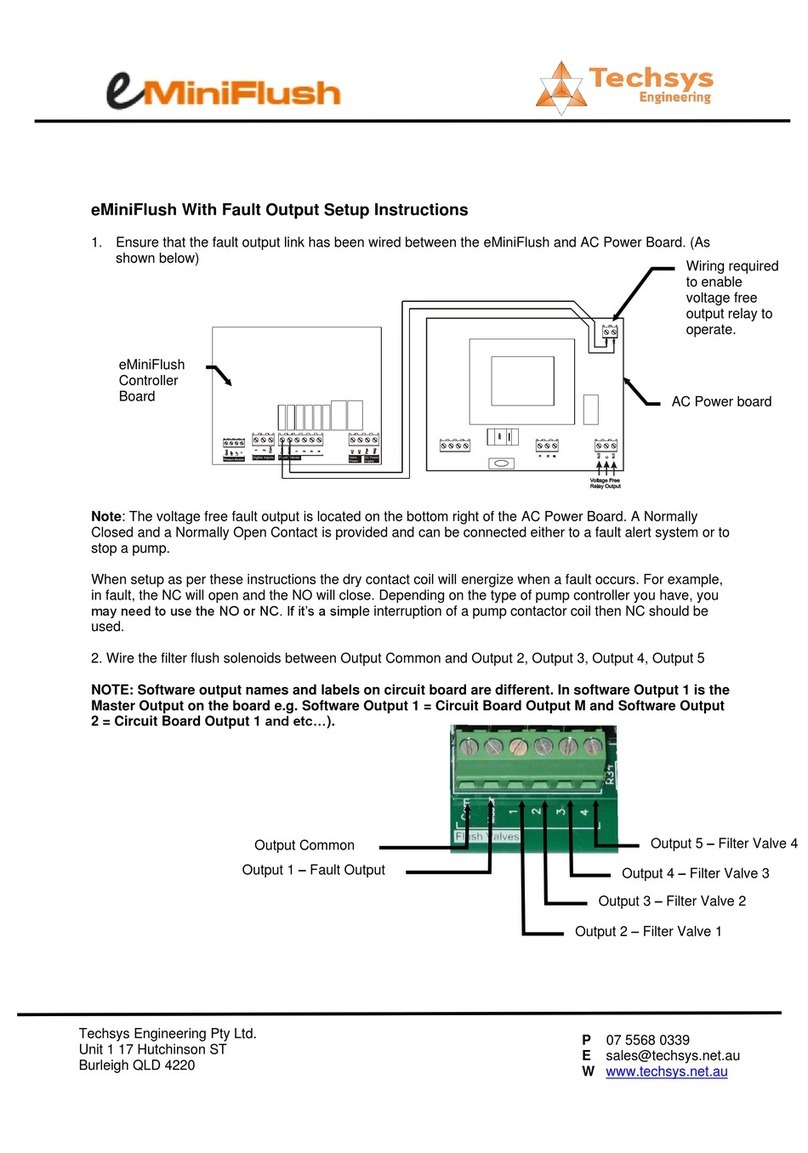

Corpor at ion

MULTIPLE PUMP

FIXED SPEED PUMP

LEVEL CONTROL SYSTEM

Version 1.3

L

LE

EV

VE

EL

L

O

OP

PE

ER

RA

AT

TI

IO

ON

N

M

MA

AN

NU

UA

AL

L

www.techsys.com.au Version 1.3 11/12/11

2

Corpor at i on

INTRODUCTION

SWORDFISH + Pump Controller

The SWORDFISH + pump control system is a fully integrated pump controller for single

or multiple pumps required to operate via either single, multi level control or switched

inputs.

SWORDFISH + is suitable for up to 6 pumps of any type plus a jockey pump. The unique

electronic - hydraulic control allows each pump to operate at the maximum performance

level.

Easy access menu items and in-built pump and system protection allows simple

adjustment for any pump application.

SWORDFISH + also offers a full complement of telemetry outputs for simple integration

into central control applications.

Swordfish+ Level control is suitable for both Tank Fill & Tank Empty applications

therefore some logic will reverse in this manual pending upon the intended use.

The SWORDFISH + Pump Control system is part of the Techsys Pump Control range.

Pump Controllers are available in a range of options to suit particular applications and

user requirements.

Additional manuals available for:-

•Temperature control

•Pressure control

•Flow control

•Vacuum

Version History

This manual covers the software applications for Version No. 12.07v01 or later.

Please contact Techsys Corporation to obtain any verification of the currency of this

manual for your applciation.

Contact details for Support:

Techsys Engineering

Ph: 07 55341879

Email: sales@techsys.net.au

Website support: www.techsys.net.au

www.techsys.com.au Version 1.3 11/12/11

3

Corpor at i on

CONTENTS

INTRODUCTION 2

QUICKSTART 4

ROTATION 6

SYSTEM OPERATION 7

MOVING AROUND & EDITING MENU ITEMS 9

MENUS 10

SYSTEM STATUS 17

FAULT HISTORY 17

PUMP DATA LOG 19

ACCESS CODE 21

SETTINGS 21

TIMING 26

CONFIGURE 29

JOCKEY PUMP 34

OUTPUTS 35

INPUTS 39

PUMP PROTECTION 45

CALIBRATION OF ANALOGUE SENSORS 46

SPECIFICATIONS 48

PCB HARDWARE & SPECIFICATIONS 49

SPARE PARTS 51

TROUBLESHOOTING 53

INSTALLATION NOTES 54

SITE RECORD 55

INDEX

www.techsys.com.au Version 1.3 11/12/11

4

Corpor at i on

QUICKSTART

The following procedures are the minimum

required to start and operate the

SWORDFISH +. If you are concerned

regarding the Commissioning of the unit

please read the complete manual or call

your closest Techsys Corporation

representative.

The following test confirms the operational

directions of all pumps in both Manual and

Automatic Modes

ROTATION CHECK

This is a most important procedure and should be completed prior to any other

commissioning procedure.

Only Qualified Personnel should be allowed to complete this procedure as there is

High Voltage wiring within the switchboard.

1. Switch OFF all motor circuit breakers in the cabinet.

2. Turn ON power to Sowrdfish controller.

3. Make sure all Pump Mode indicators are OFF. If not press the “P” key to turn

pump off (All pumps should be off)

4. Adjust Overloads to to suit motor ratings. Switch ON all circuit breakers in the

cabinet.

5. Press “P1” to turn on Pump 1. The Running indicator will light up.

(If the message “ Key Pad Locked” appears, scroll up to the Access Code using the up key

and input the number 21)

Check Rotation against the pump manufacturer’s direction arrow. After

checking turn Pump1 to OFF by pressing “P1” again.

6. Check the balance of the pumps for direction as descibed above.

If any of the other pumps have the wrong direction of rotation change two of

the wires on the wiring connected to the motor in question.

•Re-check direction

7. Rotation check complete.

12

11

9

8

7

6

5

4

3

Swordfish+

MultiPump

Fixed Speed

Control Syst em

2

1

InputIndicators

Techsys

Corporat ion

Access to Qualified Personnel Only

www.techsys.com.au Version 1.3 11/12/11

5

Corpor at i on

KEY SETTINGS.

This sets the Operating Level of the System.

1. Press the Up Key until the Message Access Code is displayed.

2. Press the “Enter Key” once, the display should start to flash, now press the “UP Key”

until the number 21 appears in the lower part of the screen, now press the “Enter Key”

again, the display should stop flashing. The correct Access code is now set.

3. Then press the “DOWN Key” once more. The Main Menu Marked SETTINGS will appear.

4. Press the “Enter Key” to access the SETTINGS Sub Menu.

5. Press the “DOWN Key” Until the Cut In Level screen is reached.

6. Adjust the Cut In Level by pressing the “Enter Key” once, the display should then start to

flash, now press the “UP or DOWN Key” to alter the Cut In Level If when increasing any

setting you are prevented from further adjustment you may also need to adjust the

parameter above or below the current setting being adjusted. Eg. Increasing the Cut In

Level and trying to make it greater / Smaller than the Cut Out Level (pending logic

function - Note Cut In Level 1 /2 etc will appear in Multi Level mode)

7. Press the “DOWN Key” Until the Cut Out Level screen is reached.

8. Adjust the Cut Out Level by pressing the “Enter Key” once, the display should then start

to flash, now press the “UP or DOWN Key” to alter the Cut Out Level (The same

sequence of key presses is used to adjust all settings on the SWORDFISH +)

9. After the adjustments have been made, press the “DOWN Key” until the sub menu is

exited and the “SETTINGS” main screen appears.

CALIBRATING PRESSURE TRANSDUCER

For a full explanation go to the section marked - CALIBRATION OF ANALOGUE

SENSORS.

1. Press the “DOWN Key” until you reach the Main Menu Marked “CONFIGURE”

2. Enter the submenu by pressing the “Enter Key”

3. Press the “DOWN Key” until the “Transducer Zero” screen is displayed. (At this point

there should be NO level in the system)

4. Adjust the value in the bottom screen until the reading is “0” – Use the same key

sequence to adjust zero. (If “Value too Low” appears, increase the Zero offset value

slowly until a zero value is obtained by pressing the key).

5. Press the “DOWN key” until you reach “ADJUST LEVEL”. (At this point a constant level

needs to be introduced into the system).

6. Adjust the value in the “Adjust Level” screen until the system height level (scaled as

required i.e. 100 = 100cm or 10cm ) reads the same as the screen level.

7. The System is now Calibrated. Press the DOWN key until the main system level screen

(Status Screen) returns.

www.techsys.com.au Version 1.3 11/12/11

6

Corpor at i on

Rotation

*****IMPORTANT*****

Failure to follow this procedure will void

Warranty and cause failure of the pump

station

The rotation of each pump is checked prior to shipment on packaged units, however it is

essential to check the rotation of each pump. To do this select MANUAL for each pump

individually and check the rotation. If the rotation is not correct swap two of the phases

coming into the main isolation switch to reverse the rotation.

Note:- any wiring changes done within the switchboard should be done with the approval

of the service agent and by qualified personnel only.

In models with phase failure relays the mains phase orientation must be set to the correct

orientation. If only one light (either green or red) is showing then swap any two wires on

the main isolation switch. This orientates the main's power to the correct rotation.

www.techsys.com.au Version 1.3 11/12/11

7

Corpor at i on

System Operation

The operating constraints for the system are detailed below.

Single Level Mode

When the system level rises above the System Cut In Level the controller will start the

first pump. If one pump cannot satisfy the level requirement another pump will start after

the IN delay timer has timed out (Single Level Mode) and the system level remains above

the Cut Out level. More pumps will be started until there are no further pumps available or

the system level drops below the Cut Out Level. If at any time the level drops below the

Cut Out Level then the OUT delay timer (Single Level Mode) is started and when it times

out a pump will be turned off (Providing the minimum run time for that pump has also

timed out). Multilevel Mode utilises individual cut in / out level for each pump.

Multilevel Mode

Out Delay

In Delay

Pump 1

off

Pump 2

off

Pump 2

on

Pump 1

on

Pump 1

on

Low

Level

Shutdow

n

High

Level

Shutdow

n

L

E

V

E

L

Pump 3

on

Pump 3

off

PUMP CUT

OUT

PUMP CUT

IN

TIME

LEVEL

Cut In Level 1

Cut In Level 2

Cut In Level 3

Cut Out Level 3

Cut Out Level 2

Cut Out Level 1

Low Level Alarm or Shut Down

High Level Alarm or Shut

own

In Delay

Out Delay

www.techsys.com.au Version 1.3 11/12/11

8

Corpor at i on

Pump Control Panel

The interface for SWORDFISH + Control Panel allows access for the operator to edit

values throughout the

menus.

Each pump is controlled by an individual Auto / Off / Manual Switch.

To enable a pump for operation

Press the ON/OFF/Manual Mode switch and the associated mode indicator will light up.

The selected pump is now available for operation in Automatic mode.

To disable a pump in Automatic Mode

Press the Mode switch until the Mode indicator light turns off.

To operate a pump on Manual

In order to operate a pump in manual mode, press and hold the mode select switch for

the relevant pump, after 3 seconds the system will start this pump in manual mode. The

mode indicator led will now start flashing at 2 times per second and the RUN indicator will

be on. To turn a manual pump off, press and release the switch when the RUN led turns

off. The pump is now disabled and to return it to Automatic press the Mode switch again

and the Mode indicator should turn on.

In order for this mode to be selected the Access Code must be entered.

MANUAL MODE PROTECTION

Pump protection settings apply to all pumps including those in manual mode.

NB: By default all pumps will be off when system is powered.

To edit menu data

Press the ENTER key to edit data in the required menu, the top line will flash if the

current menu is an editable screen. Use the UP and DOWN buttons to change the

selection, then press ENTER again to confirm the change.

12

11

9

8

7

6

5

4

3

Swordfish+

MultiPump

FixedSpeed

ControlSystem

2

1

InputIndicators

Techsys

Corporation

Access to Qualified Personnel Only

Pump ON/OFF/Manual

Switch (Mode)

(One for each pump)

Pump RUN Indicator

(One for each pump)

Input Activation

Indicators

Two line LCD

Display

ON/OFF Indicator

(One for each pump)

www.techsys.com.au Version 1.3 11/12/11

9

Corpor at i on

LoLevlShutDown

150

SETTING

LoLevlShutDown

150

LoLevlShutDown

200

LoLevlShutDown

150

LoLevlShutDown

150

LoLevlShutDown

200

Moving Around & Editing Menu Items

To move between the Main Menu screens press the UP or DOWN key.

To Enter an adjustable sub menu press the ENTER key. Access to these menus is controlled

by an Access Code, which needs to be entered prior to accessing the editable section of the

menus. If the Access Code is not inserted correctly the system will disable entry into the

Submenus and the use of any pump select or enable keys.

To scroll through the menus select the UP or

DOWN keys

Once the required Menus is selected press

the ENTER Key to enter the specific menu

To edit a value press the ENTER key once,

the display should now flash, now press the

UP or DOWN key until the desired value is

displayed.

Press the ENTER Key again to save the

value selected.

To move out of a submenu press the up or down key to scroll to the top or bottom of the

submenu and the display will return to the main menu area.

www.techsys.com.au Version 1.3 11/12/11

10

Corpor at i on

Main Menu Sub Menus

System Level Multi Level Mode

Shaded areas will cahnge

or disapear pending the selected option

Flow Rate/ min

Faults Fault 1

Pump Data Log Average Flow Rate Fault 2

Access Code Hours Run 1 Fault 3

Settings LoLevel Shutdown Hours Run 2 Fault 4

Timing LoLevel Delay Cut Out Level 1 (ump) Hours Run 3 Fault 5

Configure Operating Mode HiLevel Delay Cut Out Level 2 Hours Run 4

Jockey Pump JP Cut In Level Control Mode IN Delay Timer Cut Out Level 3 Hours Run 5 Faults

Outputs Digital Output 1 JP Cut Out Level Number Of Pumps OUT Delay Timer Cut Out Level 4 Hours Run 6

Inputs Program Input 1 Digital Output 2 JP Run On Time Transducer Value Restart Delay Timer Cut Out Level 5 Pump Starts 1

Program Input 2 Digital Output 3 JP In Delay Time Adjust Level No Flow Timer Cut Out Level 6 Pump Starts 2

Program Input 3 Digital Output 4 Averaging Input Delay Timer Cut In Level 1 (Pump) Pump Starts 3

Program Input 4 Analogue Output 1 Jockey Pump Scale an Output Min Pump Run Time Cut In Level 2 Pump Starts 4

Program Input 5 Pump Flow Rate Cut In Level 3 Pump Starts 5

Program Input 6 Outputs Auto Rotation Cut In Level 4 Pump Starts 6

Program Input 7 Lo Level Restarts Cut In Level 5 Starts Last Hour

Program Input 8 Sensining Input Cut In Level 6 Analogue Input 1

Program Input 9 Cycle Protection HiLevel Alarm Analogue Output 1

Program Input 10 Low Limit Action Digital Input State

Program Input 11 High Limit Action Digital Output State

Program Input 12 User Acess Code Timing Settings Pump Data Log

Inputs Configure

www.techsys.com.au Version 1.3 11/12/11

11

Corpor at i on

System Level Single Level Mode

Shaded areas will cahnge

or disapear pending the selected option

Flow Rate/ min

Faults Fault 1

Pump Data Log Average Flow Rate Fault 2

Access Code Hours Run 1 Fault 3

Settings LoLevel Shutdown Hours Run 2 Fault 4

Timing LoLevel Delay Cut Out Level Hours Run 3 Fault 5

Configure Operating Mode HiLevel Delay Cut In Level Hours Run 4

Jockey Pump JP Cut In Level Control Mode IN Delay Timer Hi Level Limit Hours Run 5 Faults

Outputs Digital Output 1 JP Cut Out Level Number of Pumps OUT Delay Timer Alt Cut Out 2 Hours Run 6

Inputs Program Input 1 Digital Output 2 JP Run On Time Transducer Value Restart Delay Timer Alt Cut In 2 Pump Starts 1

Program Input 2 Digital Output 3 JP In Delay Adjust Level No Flow Timer Alt Cut Out 3 Pump Starts 2

Program Input 3 Digital Output 4 Averaging Input Delay Timer Alt Cut In 3 Pump Starts 3

Program Input 4 Analogue Output 1

Jockey Pump Scale an Output Min Pump Run Tme Pump Starts 4

Program Input 5 Pump Flow Rate Pump Starts 5

Program Input 6

Outputs Auto Rotation Timing Pump Starts 6

Program Input 7 LoLevel Restarts

Settings Starts Last Hour

Program Input 8 Sensing Input Analogue Input 1

Program Input 9 Cycle Protection Analogue Output 1

Program Input 10 Low Limit Action Digital Input State

Program Input 11 High Limit Action Digital Output State

Program Input 12 User Acess Code

Pump Data Log

Inputs

www.techsys.com.au Version 1.3 11/12/11

12

Corpor at i on

MENUS

The SWORDFISH + controller has numerous adjustment menus to allow the system to

be tuned to suit each application. These are listed below and explained throughout this

manual and differ between single or multilevel settings.

Menus throughout this manual show the complete range of options available. If a menu is

not needed because the option is disabled then these screens will not appear. For

example if only 3 pumps are implemented, then screens with options for pumps 4 to 6 will

be hidden.

Main Menu Units Defaults Range

System Pressure number display 0 - 9999

Flow Rate /Min number display 0 - 9999

Main Menu Sub Menu Units Defaults Range

FAULTS

Fault 1 selection None None Logged

Logged Lo Press Shutdwn,

Fault 2 selection None Hi Press Shutdwn,

Logged No Flow Shutdwn,

Fault 3 selection None *Pump 1 - 6 Shutdown

Logged *Pump 1 - 6 No Flow

Fault 4 selection None Power Off

Logged Power Glitch

Fault 5 selection None Auto Reboot

Logged

* Pump 2-6 Shutdown are only displayed if "Number of pumps" is set accordingly

* Pump 2-6 No Flow are only displayed if "Number of pumps" is set accordingly

Main Menu Sub Menu Units Defaults Range

PUMP DATA LOG

Hours Run 1 hours display 0 - 65535

*Hours Run 2 hours display 0 - 65535

*Hours Run 3 hours display 0 - 65535

*Hours Run 4 hours display 0 - 65535

*Hours Run 5 hours display 0 - 65535

*Hours Run 6 hours display 0 - 65535

Pump Starts 1 number display 0 - 65535

*Pump Starts 2 number display 0 - 65535

*Pump Starts 3 number display 0 - 65535

*Pump Starts 4 number display 0 - 65535

*Pump Starts 5 number display 0 - 65535

*Pump Starts 6 number display 0 - 65535

Pump Starts Last Hr number display 0 - 65535

Analogue Input 1 % display 0.00 - 100.00

Analogue Output 1 % display 0.00 - 100.00

Digital Input State 1 - 12 display X for Active

Digital Output State 1 -4 display X for Active

Curr & max retry number display 0 – 50 0 – 50

Temperature degrees C display 0 - 999

* Hours Run 2-6 are only visible if "Number of pumps" is set accordingly

* Pump Start 2-6 are only visible if "Number of pumps" is set accordingly

Main Menu Units Defaults Range

Access Code number 21 0 - 250

www.techsys.com.au Version 1.3 11/12/11

13

Corpor at i on

Main Menu Sub Menu Units Defaults Range

SETTINGS

*LoLevel Shutdown *150 0 - 9999

*LoLevel Alarm *150 0 - 9999

*Low Limit *OFF *OFF

*Cut In Level (1,2,3) 200 0 - 9999

*Cut Out Level (1/2/3) 450 0 - 9999

*HiLevel Shutdown 650 0 - 9999

*HiLevel Alarm 650 0 - 9999

*High Limt *OFF *OFF

Alt Cut In 2 250 0 - 9999

Alt Cut Out 2 500 0 - 9999

Alt Cut In 3 300 0 - 9999

Alt Cut Out 3 600 0 - 9999

*Trip Point Low 300 0 - 9999

*Trip Point High 400 0 - 9999

* LoLevel Shutdown is dispalayed when "Low Level Action" is set to "Shutdown"

* LoLevel Alarm is dispalayed when "Low Limit Action" is set to "Alarm"

* Low Limit "OFF" is dispalayed when "Low Limit Action" is set to "OFF"

* HiLevel Shutdown is dispalayed when "HighLimit Action: is set to "Shutdown"

* HiLevel Alarm is dispalayed when "HighLimit Action: is set to "Alarm"

* High Limit "OFF" is dispalayed when "High Limit Action" is set to "OFF"

*Trip Point Low & High are displayed when a "Digital Output" is set to "Trip Point"

*Cut In Level is start level for all pumps when "Operation Mode" set to "Single Level"

*Cut Out Level is stop level for all pumps when "Operating Mode" set to Single Level"

*Cut Out Level 1 /2 /3 etc is individual pump stop level when "Operating Mode" set to "Multi Level"

*Cut In Level 1/2/3 etcis start level for all pumps when "Operation Mode" set to "Single Level"

Main Menu Sub Menu Units Defaults Range

TIMING

*Lo Press Delay seconds 120 *OFF, 0 - 250

*High Press Delay seconds 4 *OFF, 0 - 250

In Delay Timer seconds 4 0 - 999

Out Delay Timer seconds 1 0 - 999

Restart Delay seconds 0 0 - 999

No Flow Timer seconds 0 0 - 250

Input Delay Timer seconds 120 0 - 999

*Press Trip Low Delay seconds 0 0 - 999

*Press Trip High Delay seconds 0 0 - 999

*Min Pump Runtime seconds 60 0 - 240

*Max Pump Starts per Hour 60 0 - 240

* Press Trip delays are only visible if an OUTPUT is set to "Pressure Trip"

* "Min Pump Runtime" Is displayed when "ExcessRun Prot'n" is set to "Minimum Run Time"

* "Max Pump Starts" Is displayed when "ExcessRun Prot'n" is set to "Max Starts PerHr"

* OFF is displayed in the "Lo Press Delay" screen when "Low Limit Action" is set to "OFF"

* OFF is displayed in the "Hi Press Delay" screen when "HighLimit Action" is set to "OFF"

www.techsys.com.au Version 1.3 11/12/11

14

Corpor at i on

Main Menu Sub Menu Units Defaults Range

CONFIGURE

Operating Mode selection MultiLevel Pressure, Flowrate,

Temperature, Single Level

Multi Level.

*Control Mode Tank Empty Tank Fill

Number of pumps number 3 0 - 6

*Transducer Zero unitless 0 - 9999

*Adjust Level unitless 0 - 9999

*Averaging number 20 0 - 50

Scale An Output number 1000

Pump Flow Rate per Min 5 1-9999 /Min

Auto Rotation selection Full Full, *Pump 1 - Pump 6,

Every 24 Hours, Low Hours.

LoLevel Restarts selection 0 0 - 250

Sensing Input selection Analogue Analogue, Switched

Cycle Protection selection Minimum Run Time Minimum Run Time,

Max Starts PerHr

Low Limit Action selection OFF OFF, Alarm, Shutdown

HighLimit Action selection OFF OFF, Alarm, Shutdown

User Access Code number 21 0 - 250

* "Transducer Zero", "Adjust Pressure" & "Averaging" are hidden when in "Switched" mode

* Pumps 2 - 6 are only visible if "Number of pumps" is set accordingly

* Pending Tank Fill or Tank Empty selection will reverse some logic . i.e Cut in level nowCut Out level etc

Main Menu

Sub Menu Units Defaults Range

JOCKEY PUMP

Jockey Pump selection ----Off---- ----Off----, ===On===

*JP Cut In Level 250 0 - 9999

*JP Cut Out Level 400 0 - 9999

*JP Run On Time seconds 2 0 - 999

"JP In Delay Time seconds 0 0 - 999

* JP Screens are only visible is "Jockey Pump" is set to " ===ON==="

www.techsys.com.au Version 1.3 11/12/11

15

Corpor at i on

Main Menu

Sub Menu Units Defaults Range

OUTPUTS

Digital Output 1 selection Shutdown Fault Shutdown Fault,

Lo Level Fault,

Hi Level Fault,

*Pump 1 - 6 Run,

Digital Output 2 selection Any Pump Shutdown *Pump 1 - 6 Fault,

System Paused,

Low Alarm, High Alarm,

Any Alarm,

Digital Output 3 selection Any Alarm Any Pump Shutdwn,

Any Pump Running,

Trip Point

Alternate Trip,

*Digital Output 4 selection Any Pump Running, Aux Output 1,

Aux Output 2,

Aux Output 3,

Shutdown Fault

Analogue Output 1 selection System Level System Level

* If the Jockey Pump is set to "ON" then Digital Output 4 will not be avaialable for other functions.

* Pump Run 2 - 6 are only visible if "Number of pumps" is set accordingly

* Pump Fault 2 - 6 are only visible if "Number of pumps" is set accordingly

www.techsys.com.au Version 1.3 11/12/11

16

Corpor at i on

Main Menu Sub Menu Units Defaults Range

INPUTS

Program Input 1 selection System Pause, *Alt 2 Settings

Program Input 2 selection Pump 1 Protection, *Alt 3 Settings

Program Input 3 selection Pump 2 Protection, *Cut In,

Program Input 4 selection Pump 3 Protection, *Cut Out,

Program Input 5 selection High Limit, Low Limit,

Program Input 6 selection Low Limit, High Limit,

Program Input 7 selection No Flow, System Pause,

Program Input 8 selection *Alt 2 Settings *Pump 1 - 6 Protection,

Program Input 9 selection *Alt 3 Settings *Pump 1 - 6 Stop,

Program Input 10 selection Reset, *Pump 1 - 6 Manual Run,

Program Input 11 selection Cycle Pumps, Fire Mode,

Program Input 12 selection Aux Input 1 Cycle Pumps,

Reset,

No Flow,

Aux 1, Aux 2, Aux 3,

*Pump 1 - 6 No Flow Prot,

*Level Cut In 1,

*Level Cut In 2,

*Level Cut In 3,

*Level Cut In 4,

*Level Cut In 5,

*Level Cut In 6,

*Level Cut Out 1,

*Level Cut Out 2,

*Level Cut Out 3,

*Level Cut Out 4,

*Level Cut Out 5,

*Level Cut Out 6,

* Alternate 2&3 settings only apply when operating in "Pressure", "Temperature", "Flow" or "Single Level" modes.

* "Cut In" and "Cut Out" are only visible when operating in "Switched" Mode

NOTE: Also not visible when "Switched" "Multi level" is in operation but are available in Single Level Operation

* Pump Protection 2 - 6 are only visible if "Number of pumps" is set accordingly

* Pump Stop 2 - 6 are only visible if "Number of pumps" is set accordingly

* Pump Manual Run 2 - 6 are only visible if "Number of pumps" is set accordingly

* Pump NoFlowProt 2 - 6 are only visible if "Number of pumps" is set accordingly

* Level Cut In 1-6 & Cut Out 1-6 are only visible when operating "Switched" "Multi level"

www.techsys.com.au Version 1.3 11/12/11

17

Corpor at i on

SYSTEM STATUS

System Level number display 0 - 9999

Flow Rate /Min number display 0 - 9999

System Level

The System Level is the direct measurement of the

level in the tank / sump of the system. It is read from

the level transducer and is displayed

on the Level Screen on the front of the switchboard.

This is the default display screen. It will display appropriate messages describing current

conditions. These include in order of priority: Emergency Stop, Hi Level Alarm, Lo Level

Shutdown, Fault, Pause Activated, etc.

After 25 minutes from the last key press the SWORDFISH + will revert to this screen

automatically.

Flow Rate

The SWORDFISH + can operate on a calculated flow

rate.

The Calculated flow rate uses information that is input into the Pump Flow rate screen to

provide an estimation of the flow rate at any time. This calculation automatically

compensates for the number of pumps operating - it is useful in determining the system

capacity. This is a calculated flow and must be treated as such. The time base for this

flow is in flow per MINUTES and is not adjustable.

FAULT HISTORY

FAULTS

Fault 1 selection None None Logged

Logged Lo Press Shutdwn,

Fault 2 selection None Hi Press Shutdwn,

Logged No Flow Shutdwn,

Fault 3 selection None *Pump 1 - 6 Shutdown

Logged *Pump 1 - 6 No Flow

Fault 4 selection None Power Off

Logged Power Glitch

Fault 5 selection None Auto Reboot

Logged

When a system fault is registered a “NEW FAULT” message will appear on the main

screen. It will also be logged in the FAULT HISTORY menu. There is space for up to 5

faults to be logged which scroll down as new faults are received.

Flow-Rate /Min

XXXXX*

System Level

XXXX

www.techsys.com.au Version 1.3 11/12/11

18

Corpor at i on

In the event of a new fault, which has been automatically

reset, the default screen will display the message “New

Fault”. Go to the FAULT HISTORY to view this fault. Faults

that are active will remain live on the screen until the ENTER Key is pressed to clear the

fault.

Faults will appear in the Fault sub menu in the following

format with the most recent fault being Fault 1.

Note: The FAULT HISTORY menu is cleared when the

system is first powered up.

“Pump 1 - 6 Shutdown” signifies that the corresponding

“Pump protect 1-6” input has been activated for the period of the input delay time.

“Auto Reboot” denotes that the SWORDFISH + has automatically restarted due to an

internal reset, whereas “Power Failure” records that the SWORDFISH + has recovered

from a power supply disconnection. A very short disconnection of power will record a

“Power Glitch” message, typically around 0.1seconds.

The FAULT HISTORY menu is always visible regardless of whether the Access Code is

correct.

To reset the complete FAULT HISTORY by pressing ENTER then DOWN and then

ENTER again when at Fault 1. Individual Faults can be reset by completing the same

action while displaying the Fault screen to be reset.

** NEW FAULT **

Last Fault (No.1

Lo Level Shutdown

Fault 2

Auto Reboot

www.techsys.com.au Version 1.3 11/12/11

19

Corpor at i on

PUMP DATA LOG

Main Menu Sub Menu Units Defaults Range

PUMP DATA LOG

Hours Run 1 hours display 0 - 65535

*Hours Run 2 hours display 0 - 65535

*Hours Run 3 hours display 0 - 65535

*Hours Run 4 hours display 0 - 65535

*Hours Run 5 hours display 0 - 65535

*Hours Run 6 hours display 0 - 65535

Pump Starts 1 number display 0 - 65535

*Pump Starts 2 number display 0 - 65535

*Pump Starts 3 number display 0 - 65535

*Pump Starts 4 number display 0 - 65535

*Pump Starts 5 number display 0 - 65535

*Pump Starts 6 number display 0 - 65535

Pump Starts Last Hr number display 0 - 65535

Analogue Input 1 % display 0.00 - 100.00

Analogue Output 1 % display 0.00 - 100.00

Digital Input State 1 - 12 display X for Active

Digital Output State 1 -4 display X for Active

Curr & max retry number display 0 – 50 0 – 50

Temperature degrees C display 0 - 999

* Hours Run 2-6 are only visible if "Number of pumps" is set accordingly

* Pump Start 2-6 are only visible if "Number of pumps" is set accordingly

Hours Run Pump 1-6

Each pump has an hour run meter attached to record the

actual run time for each pump. The hour log will

accumulate all of the operation time for each pump in both

AUTOMATIC and MANUAL modes.

To reset the time press ENTER then DOWN and then ENTER again.

Pump 1-6 Starts

The SWORDFISH + registers the number of starts that

each pump accumulates to assist in the tuning of the

system. This number can assist in the selection of the Cut In and Cut Out levels and the

run time settings. The starts do not increment when selected in MANUAL as this is

considered to be an override function.

To reset press ENTER then DOWN and then ENTER again.

Starts Last Hour

This registers the numbers of starts that the TOTAL

SYSTEM had over the past hour. This is the accumulation

of all of the Starts for all of the pumps and is designed to

assist in trouble shooting. The new number is accumulated

over a 10-min period and is updated at 10-minute intervals. To get a true hourly reading

the system must have been running for at least 1 hour. After the first hour the last 6

previous 10-minute readings are added together to get the Starts last hour reading.

To reset press ENTER then DOWN and then ENTER again.

Hours Run Pump1

XXXXX

Pump Starts 1

XXXXX

Starts Last Hour

XXXXX

www.techsys.com.au Version 1.3 11/12/11

20

Corpor at i on

Analogue Input

This screen displays the actual Analogue Input reading in

percentage.

It shows the actual possible full scale reading and is not

zeroed or scaled to level. It is used to determine input functionality.

Analogue Output

This screen displays the actual Analogue Output reading

in percentage. This output mimics the Analogue 1 Input

and can be re-scaled in the configuration settings.

Digital Input State

This screen displays the state of the Digital inputs

X = energized

- = de-energized

See INPUTS for configurable options for this item.

Digital Output State

This screen displays the state of the Digital outputs

X = energized

-= de-energized

See OUTPUTS for configurable options for this item.

Curr & Max Retry

The number under "Curr" is the current number of times

the main processor has not been able to communicate

with the analogue system. If it is not at Zero it indicates

that the analogue system has been subject to noise and

may have had to restart itself. If this number continues to

increment up to 20, then resets to 0, and continues incrementing

again it indicates a major malfunction with the analogue system

The number under "Max Retry" is the maximum number of times the

main processor has not been able to communicate with the analogue

circuitry. If it is at 20 there may have been a major disruption in the

analogue system and was unable to restart itself and the main

processor has more than likely forced it to restart.

Temperature

Displayed is the current temperature in degrees C,

read via the temperature sensor on the circuit board.

Analogue Output 1

XXX.XX%

Dig Output State

X - - -

Dig Input State

X- - X- - - - X - - X

Analogue Input 1

XXX.XX%

Temperature

XXX degrees C

Curr & Max Retry

XX XX

Table of contents

Other Techsys Control System manuals

Popular Control System manuals by other brands

TouchTronics

TouchTronics PowerTouch 1000 owner's manual

Julabo

Julabo Presto LH 45 operating manual

BERGHOF

BERGHOF B-Fortis CC-Slim Series user manual

Mitsubishi Electric

Mitsubishi Electric MELDAS C6 Maintenance manual

Bosch

Bosch rexroth SYDFE1 2X Series operating instructions

CAME

CAME Barriere GARD quick start guide