Adtech ADT-DK300A User manual

ADT‐DK300A/400A

EngravingMachineControlSystem

Manufacturer’sManual

Adtech(Shenzhen)TechnologyCo.,Ltd.

Add:F/5,Bldg/27‐29,TianxiaICIndustrialPark,YiyuanRd,NanshanDistrict,Shenzhen

Postalcode:518052

Tel:0755‐26722719Fax:0755‐26722718

E‐mail:adtcnc@adtechcn.comhttp://www.adtechcn.com

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

I

Copyright

Adtech(Shenzhen)TechnologyCo.,Ltd.(Adtechhereafter)isinpossessionofthecopyrightofthis

manual.WithoutthepermissionofAdtech,theimitation,copy,transcriptionandtranslationbyany

organizationorindividualareprohibited.Thismanualdoesn’tcontainanyassurance,stanceor

implicationinanyform.Adtechandtheemployeesarenotresponsibleforanydirectorindirectdata

disclosure,profitslossorcauseterminationcausedbythismanualoranyinformationaboutmentioned

productsinthismanual.Inaddition,theproductsanddatainthismanualaresubjecttochanges

withoutpriornotice.

Allrightsreserved.

Adtech(Shenzhen)TechnologyCo.,Ltd.

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

II

VersionHistory

ItemNo.FirstuploadedVersionNo. PagesCompiledbyTypesetby

BZ001M056A2012‐10‐9A0101

ShiTingliang/

TangXiaobing

Revision

DateVersion/Pag ResultConfirmedby

2012‐9‐18 ShiTingliang

Remark:

WehavecollatedandcheckedthisManualstrictly,butwecan’tensurethattherearenoerrorand

omissioninthisManual.Duetoconstantimprovementofproductfunctionsandservicequality,any

productsandsoftwaredescribedinthismanualandthecontentofthemanualaresubjecttochanges

withoutpriornotice.

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

III

Contents

1.OVERVIEW.........................................................................................................................1

1.1SYSTEMFUNCTION..................................................................................................................1

1.1.1.Self‐diagnosis.....................................................................................................................................................1

1.1.2.Compensation...................................................................................................................................................1

1.1.3.Abundantinstructionsystem............................................................................................................................1

1.1.4.FullChinesemenuoperation&fullscreenedit................................................................................................1

1.1.5.Abundanterror‐correctionfunctions................................................................................................................1

1.1.6.ProgramexchangebetweenCNCsystemandPC..............................................................................................2

1.1.7.Systemoperatingcondition...............................................................................................................................2

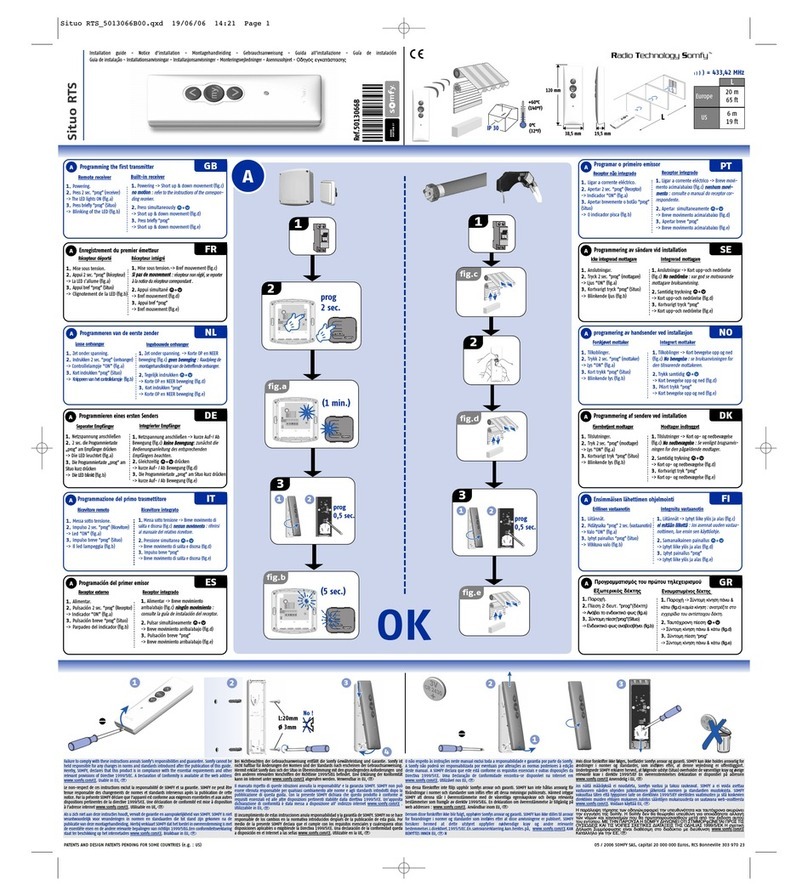

2.OPERATINGPANEL............................................................................................................3

2.1LCD/KEYPAD.........................................................................................................................3

2.2SYSTEMMENUS......................................................................................................................4

2.3OPERATINGKEYS....................................................................................................................7

3.MANUALOPERATION........................................................................................................9

3.1RETURNINGTOREFERENCEPOINTMANUALLY...............................................................................9

3.2CONTINUOUSFEEDINGMANUALLY...........................................................................................11

3.3SINGLESTEPFEEDING............................................................................................................11

3.4HANDWHEELFEEDING...........................................................................................................12

3.5MANUALAUXILIARYFUNCTIONOPERATION................................................................................12

3.6WORKINGCOORDINATESYSTEMSETTINGS(TOOLSETTING)...........................................................14

3.6.1.Entercurrentpositiontospecifiedcoordinatesystemdirectly(allaxes)........................................................14

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

IV

3.6.2.Coordinateaxissettings..................................................................................................................................16

3.6.3.Modifycoordinatevalue.................................................................................................................................18

3.7DATASETTINGS....................................................................................................................19

3.7.1.Toolcompensationdatasetting.......................................................................................................................19

3.7.2.Systemparametersetting...............................................................................................................................22

3.8FASTSYSTEMOPERATION.......................................................................................................22

4.AUTOMATICOPERATION................................................................................................24

4.1AUTOMATICOPERATION........................................................................................................24

4.2MDIOPERATION..................................................................................................................25

4.3USBDISKDNC....................................................................................................................26

4.4SPEEDRATEADJUSTMENT.......................................................................................................27

4.5SBKFUNCTION....................................................................................................................28

4.6BDTFUNCTION....................................................................................................................28

4.7STOPPINGAUTOMATICOPERATING...........................................................................................28

5.SAFEOPERATION.............................................................................................................29

5.1EMERGENCYSTOP.................................................................................................................29

5.2HARDLIMITOVERTRAVEL.......................................................................................................30

5.3SOFTLIMITOVERTRAVEL........................................................................................................30

6.ALARMANDSELF‐DIAGNOSISFUNCTION......................................................................30

6.1NCPROGRAMEXECUTIONALARM............................................................................................30

6.2SYSTEMENVIRONMENTALARM...............................................................................................33

6.3ALARMPROCESSING..............................................................................................................35

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

V

6.4SELF‐DIAGNOSISFUNCTION.....................................................................................................35

7.PROGRAMSAVING&EDITING........................................................................................36

7.1SAVINGTHEPROGRAMINTHEMEMORY....................................................................................36

7.1.1.Keypadinput(newprogram)...........................................................................................................................36

7.1.2.PCserialportinput..........................................................................................................................................37

7.1.3.CopyingprocessingfilesfromUSBdisk...........................................................................................................37

7.2READINGPROGRAMSINTOWORKAREA.....................................................................................37

7.2.1.Readingprogramsfromcontrollerintoworkarea..........................................................................................37

7.2.2.ReadingprogramsfromUSBdiskintoworkarea............................................................................................37

7.3EDITING&MODIFYINGPROGRAMS..........................................................................................38

7.4DELETINGFILES....................................................................................................................38

7.4.1.Deletingfilesinmemory.................................................................................................................................38

8.MAININTERFACESOFTHESYSTEM................................................................................38

8.1.POSITIONINTERFACE.............................................................................................................38

8.1.1.Absoluteposition............................................................................................................................................39

8.1.2.Relativeposition..............................................................................................................................................39

8.1.3.Comprehensivecoordinates............................................................................................................................40

8.2.EDITINTERFACE....................................................................................................................41

8.3.PROGRAMEDIT....................................................................................................................41

8.4.SYSTEMINFOINTERFACE........................................................................................................42

8.5.MDIINTERFACE...................................................................................................................43

8.6.FILEMANAGEMENT...............................................................................................................44

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

VI

8.7.GRAPHICSIMULATION...........................................................................................................45

8.8.PARAMETERINTERFACE.........................................................................................................46

8.9.COMPENSATIONINTERFACE....................................................................................................50

8.10.WORKPIECECOORDINATESYSTEMSETTINGINTERFACE..........................................................51

8.11.CONTROLLERDIAGNOSISINTERFACE(DIAGNOSIS).................................................................52

8.12.MACROVARIABLEVIEWINTERFACE(MACROVARIABLE).........................................................55

8.13.CURRENTMODEINSTRUCTIONINFO...................................................................................56

9.SYSTEMMAINTENANCE..................................................................................................58

9.1.RESTART.............................................................................................................................58

9.2.SYSTEMUPGRADE.................................................................................................................59

9.3.RESTOREFACTORYPARAMETERS..............................................................................................60

9.4.PARAMETERBACKUPANDRESTORE..........................................................................................61

9.5.ENTERINGBIOS...................................................................................................................62

10.SYSTEMPARAMETERS.....................................................................................................63

10.1.PARAMETERINDEXLIST...................................................................................................64

10.2.GENERALPARAMETER(P1.)............................................................................................86

10.3.AXISPARAMETERCONFIGURATION(P2.)..........................................................................106

10.4.MANAGEMENTPARAMETER(P3.)..................................................................................118

10.5.TOOLMAGAZINEPARAMETERS(P4.)...............................................................................124

10.6.PRINCIPALAXISPARAMETER(P5.)..................................................................................127

10.7.PORTCONFIGURATION(P6.).........................................................................................130

11.HARDWAREINTERFACEDEFINITIONANDCONNECTIONINSTRUCTIONS....................140

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

VII

11.1.INSTALLATIONLAYOUT..................................................................................................140

11.1.1.Externalinterfacediagram..........................................................................................................................140

11.1.2.Mountingdimensions.................................................................................................................................141

11.1.3.Installationprecautions...............................................................................................................................142

11.2.INTERFACEDEFINITION..................................................................................................144

11.2.1.Motordrivecontrolinterface(XS1…XS4)....................................................................................................144

11.2.2.Digitalinputinterface(XS5).........................................................................................................................148

11.2.3.Digitaloutputinterface(XS6)......................................................................................................................151

11.2.4.Handheldboxinterface(XS7)......................................................................................................................153

11.2.5.Analogoutputinterface(XS8).....................................................................................................................154

11.2.6.RS232transmissioninterface(XS9).............................................................................................................155

11.2.7.USBmemoryconnectioninterface(XS10)...................................................................................................156

11.2.8.PCUSBcommunicationinterface(XS11).....................................................................................................156

11.3.ELECTRICALCONNECTIONDIAGRAM.................................................................................156

11.3.1.Symbolschematicdiagram..........................................................................................................................156

11.3.2.Powerconnectiondiagram..........................................................................................................................157

11.3.3.Servodriveconnectiondiagram..................................................................................................................158

11.3.4.Stepconnectiondiagram.............................................................................................................................159

12.CONFIGURATIONANDSYSTEMFUNCTIONS.................................................................160

12.1SYSTEMCONFIGURATION..............................................................................................160

12.2SYSTEMTECHNICALPARAMETERS....................................................................................161

BZ001M056AADT‐DK300A/400AEngravingMachineManufacturer’sManual

VIII

Foreword

DK300A/400AnumericalcontrolsystemisdevelopedbyAdtech(Shenzhen)TechnologyCo.,Ltd.for

engravingindustry,whereDK300Aisthreeaxesmotioncontroller.

InstructionsandreadingconventionoftheManual

BeforeusingthisCNCsystem,pleasereadthisManualcarefullytooperateproperly.

TerminologynoteandreadingconventioninthisManual:

DK300AandDK400Aarecontrolsystemswithdifferentaxesandsamehardwarefunctions.Different

softwarehasdifferentfunctionsandmasks.

“CNCsystem”,“NCcontroller”and“DK300A”mentionedinthisManualallrefertoDK300A/DK400A;

Thearticlesmarkedwith“Caution”promptuserstopayspecialattentionforoperationorsetting,or

elsethisoperationmayfailorcertainactioncan’tbeperformed.

BZ001M056AADT‐DK300A/400AEngravingMachine

1

1. Overview

1.1 Systemfunction

1.1.1. Self‐diagnosis

DiagnoseCPU,memory,LCD,I/Ointerface,parameterstate,coordinatesandprocessingprogram

comprehensivelyeverytimethesystemisstartedorreset;diagnosepowersupply,principalaxis,limitandI/O

portsinreal‐timeduringoperating.

1.1.2. Compensation

Automaticreverseclearancecompensation

Automatictoollengthcompensation

Automatictoolradiuscompensation

Automatictoolradiusbiasingandautomatictooltiptransition

1.1.3. Abundantinstructionsystem

Scalinginstruction

Mirrorprocessinginstruction

Toolbiasinginstructions

Programcycle,programskip,programshift,programtransfer,differentendprocessingmodes,macro

definitionandprogrammanagementinstructions

Fixed‐pointinstructions:startingpoint,settingpoint,etc.

Linear,arcandspiralinterpolationinstructions

Sixworkpiececoordinatesystems,nineextensioncoordinatesystemsandonereferencepoint

1.1.4. FullChinesemenuoperation&fullscreenedit

DKsystemusescascadingmenustructureandfullChineseoperationtoensuresimpleoperationand

visibility.

1.1.5. Abundanterror‐correctionfunctions

Pointoutthenatureandcorrecttheerrorsinoperation.

BZ001M056AADT‐DK300A/400AEngravingMachine

2

1.1.6. ProgramexchangebetweenCNCsystemandPC

PerformCAD/CAM/CAPPauxiliaryprogrammingwithabundantsoftwareinPC,andthentransmitCNC

programtothesystemthroughcommunicationinterface(USBdisk,RS232interface),ortransmitthe

programsfromthesystemtoPC.

1.1.7. Systemoperatingcondition

Operatingvoltage24VDC(withfilter)

Operatingtemperature0℃~45℃

Optimumoperatingtemperature5℃~40℃

Operatinghumidity10%~90%(nocondensing)

Optimumoperatinghumidity20%~85%

Storagetemperature0℃~50℃

Storagehumidity10%~90%

Operatingenvironment

Noexcessivedust,acid,alkali,corrosiveandexplosivegases,nostrong

electromagneticinterference

BZ001M056AADT‐DK300A/400AEngravingMachine

3

2. Operatingpanel

2.1 LCD/keypad

Fig.3.1DK300AOperatingPanelDiagram

Caution:

Pressthesubmenubuttonstoperformtheoperationsofsubmenus.

Manualaxismovingandedit&inputarecomposite.Ithasdifferentdefinitionsaccordingtothemodes.

Systemworkingmodeswitchsectionisusedtoswitchworkingmodes,whichcanimprovethesecurity

andsystemperformance.HandwheelandsinglestepmodeareswitchedwithRepeatbutton.

BZ001M056AADT‐DK300A/400AEngravingMachine

4

LCDunit

ScreeninfoWorkingmodeSystemmainmenu

Submenus

Caution:

Screeninfoshowstheinformationofcurrentwindow

Workingmodeinfoshowscurrentlyselectedworkingmode

Systemmainscreenshowscurrentmainscreen.

Thesubmenuoptionsareusedtoswitchsubmenuswithlefttriangle,F1~F6andrighttriangle.Theright

arrowisusedtoturnpages,andtheleftarrowisusedtoclosethesubmenusinnextlevelandpreviousmenu.

2.2 Systemmenus

DK300Asystemusescascadingmenustructure.Youcanpressthefollowingkeystooperatethemenus.

PressakeytoshowthecorrespondingcontentinthebottomoftheLCD.

BZ001M056AADT‐DK300A/400AEngravingMachine

5

Keyintheleft :Returntopreviousmenu

Keyintheright :Turnpagestoshowothermenusofsamelevel

Themainmenusofthesysteminclude[],[],[],[ ]and[].Each

mainmenucontainsseveralsubmenus,whichareshownbelow:

[Monitor]

[Position]

[Track]

[MDI]

[AbsolutePosition]

[RelativePosition]

[ComprehensivePosition]

[Preview]

[SelectPlane]

Auxiliarycontrol

Macrovariable

[CAM]

BZ001M056AADT‐DK300A/400AEngravingMachine

6

[Coordinates]

[CoordinateSetting]

[Compensation]

[Edit]

[ProgramEdit]

[File]

Syntaxchecking

[Parameter]

[Comprehensive]

[AxisConfiguration]

[Management]

[ToolMagazine]

[PrincipalAxis]

[Port]

BZ001M056AADT‐DK300A/400AEngravingMachine

7

Functiontestsubmenu

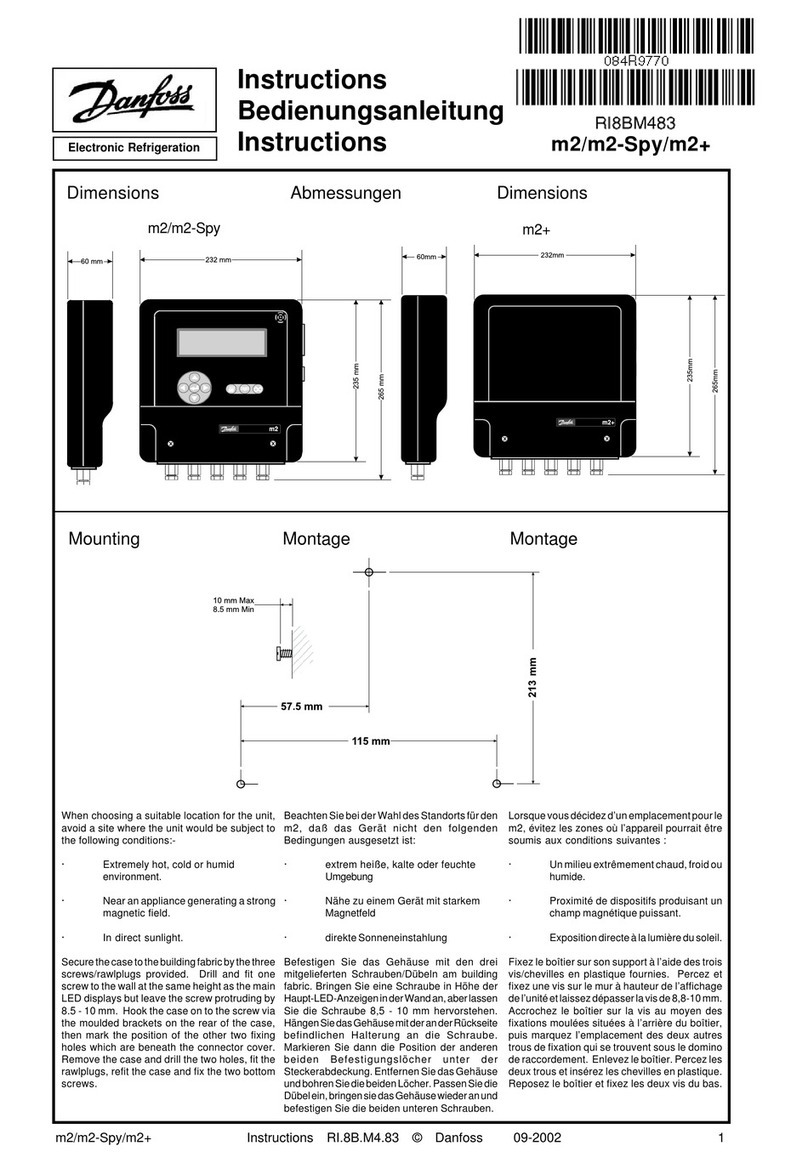

2.3 Operatingkeys

ThekeysofDK300Asystemaredefinedbelow:

KeyFigurePurpose

[复位/RESET]

Cancelalarm,resetCNC

Address/numberkeys

,……

,……

Enterletters,numbers,etc.

[EOB],[取消/CAN]

,

Confirmorcanceloperation

[EOB],[取消/CAN],[删除/DEL]

,,

Programedit(insert,delete,modify)

Modeswitchkey

,,

,

Selectoperatingmode

[Diagnosis]

[AlarmInfo]

[InputDiagnosis]

[OutputDiagnosis]

[FunctionTest]

[SystemInfo]

BZ001M056AADT‐DK300A/400AEngravingMachine

8

KeyFigurePurpose

Cursormovingkey

,

,

Fourkeysareavailable:Up/Down:adjust

ration,movecursorbetweensubsections;

Left/Right:movecursortoleft/right

Pagekey

,

Up/Down:Turnpages

Menukeys

,,

,

Selectthemenus

Principalaxispositiverotation

Pressittorotatetheprincipalaxis

positively,andpressitagaintostop

rotating

Principalaxisreverserotation

Pressittorotatetheprincipalaxis

reversely,andpressitagaintostop

rotating

Coolant

Coolanton/off

Lubricant

Lubricanton/off

[跳选/BDT]

Blockdeleteon/off

[单段/SBK]

Singleblockfunctionon/off

[暂停/PAUSE]

Pauseautomaticrunning

BZ001M056AADT‐DK300A/400AEngravingMachine

9

KeyFigurePurpose

[启动/START]

Startautomaticrunning

3. Manualoperation

3.1 Returningtoreferencepointmanually

Theengravingmachinetoolhasspecificmechanicalposition,whichiscalledasreferencepointandfor

toolexchangeandcoordinatessetting.Generally,whenthepowersupplyisconnected,thetoolshouldbe

movedtothereferencepoint.Thisoperationisalsocalledashomeoperation,whichwillmaketheCNC

systemconfirmtheoriginofmachinetool.

Thehomeoperationincludesprogramandmechanicalmode:

Forprogramhome,theactioncompleteswhenthecoordinatesofmachinetoolare0,andwon’tcheck

whetheroriginswitchisinposition;

Formechanicalhome,theexternalhomesensorswitchisusedtolocatetheoriginofthemachinetool;

twocheckingmodesareavailable:

Withtheexternalsensorswitch,thehomeoperationcompleteswhenthesensingissuccessfully

repeatedly.

Theexternalsensorswitchisusedasdecelerationswitch,andtheservohomeisenabledashomesignal

aftersensingandthenthesensingstops.

Youcansetthe“Homemode”in[Parameter][Generalparameter],andmovetocomprehensivehome

mode(36#parameter)EOBtoselect.Youcanalsopress[SBK]keyinhomemodetoswitchamong

“Mechanical–Program–Mechanical…”quickly.Thismethoddoesn’tconflictwithparametersetting.Youcan

selectaccordingly.Touseservohomeasthehomesignal,youneedtoset“AxisphaseZhomeenable”to“1”

in[Parameter][AxisConfiguration]inmechanicalhomemode,andthesettingwilltakeeffectinnexthome

checking.

Severalmethodsareavailablefortoolreturningtoreferencepointandthestepsfollow:

(1)Eachaxisreturnstoreferencepointseparately

BZ001M056AADT‐DK300A/400AEngravingMachine

10

Pressthemodeswitchkey[ ]toselecthomeoperation;

Pressthecompositekey[ ],[ ],[ ],[ ]inthenumberssectiontoreturnthe

correspondingaxistoreferencepoint.

(2)Theaxesreturntoreferencepointsimultaneously

Pressthemodeswitchkey[ ]toselecthomeoperation;

Pressthe[ ]keytoreturnZaxistoreferencepoint,andotheraxesreturntoreferencepointsimultaneously.The

automatichomesequencecanbeconfiguredintheparameters.

(3)Resetmachinetoolposition

Pressthemodeswitchkey[ ]toselecthomeoperation;

In[AbsolutePosition]and[CoordinateSystem]screen,press[ ],[ ],[ ],[ ]respectively

toshowthevalueofcorrespondingaxis,andthenpressthe[]keytoresettheabsolutepositionofcurrentaxis.

Afterthisoperation,thesystemconsidersitasahomeaction.Therefore,whentheprogramisrunning,thealarmofnot

homewon’toccur.Ifyoupressbymistake,itwillswitchthescreenandcancelselectionautomatically.

(4)Resetrelativepositionmanually

Pressthemodeswitchkey[ ]toselectmanualoperation;

In[RelativePosition]and[CoordinateSystem]screen,press[ ],[ ],[ ],[ ]respectively

toshowthevalueofcorrespondingaxis,andthenpressthe[]keytoresettherelativepositionofcurrentaxis.

BZ001M056AADT‐DK300A/400AEngravingMachine

11

)Note

Thetoolalsocanreturntoreferencepointaccordingtoprograminstruction,i.e.returningtoreferencepoint

automatically.

0Caution:

Generally,thesystemwillperformhomeoperationafterconnectingthepowersupply.Ifthepowerfailswhilethe

machinetoolismoving,thesystemalsowillreturntoreferencepointwhenthepowersupplyisconnectedagain.Return

toZaxistopreventtoolandworkpiecefromcolliding,anddamagingtool,workpieceandclamp.

3.2 Continuousfeedingmanually

Pressthekeysontheoperationpanelorhandwheeltomovethetoolalongeveryaxis.

Theoperationfollows:

⑴Pressthemodeswitchkey[]toselectmanualoperation;

(2)Presscompositekeys[],[];[],[];[],[];[],

[]innumbersareatomovethetoolalongselectedaxis.

Inmanualmode, keycanbeusedtoswitchthemanualspeedandrapidtraversespeed.The

rapidtraversespeedofeveryaxisdependsonGeneralparameter009‐012(rapidtraversespeedsetting).

Afterswitchingtorapidtraversespeed,themanualspeedofthepositioninterfacewillbehighlighted,while

theactualspeedofthepositioninterfaceissampledfromthemovingspeedofcurrentaxis.Thisvaluecan

trulyreflectthemovingspeedofcurrentaxis(unit:mm/min);

)Note:

Onlysingleaxismotionisavailableinmanualmode.

3.3 Singlestepfeeding

Singlestepmodeissimilartomanualmode,theoperationsaresame,butonlymovesaspecifiedpulse

incrementeverytimepressthekey.

This manual suits for next models

1

Table of contents

Other Adtech Control System manuals

Adtech

Adtech ADT-CNC4220 User manual

Adtech

Adtech ZM430A-A01 User manual

Adtech

Adtech NCT-04 User manual

Adtech

Adtech ADTECH4 CNC Series User manual

Adtech

Adtech Q2BYG806DK User manual

Adtech

Adtech CNC9 Series User manual

Adtech

Adtech ADT-RC400 User manual

Adtech

Adtech TV5600-B01 Series User manual

Adtech

Adtech 4 Series User manual

Adtech

Adtech ADT-09 Series User manual