Techsys FILTERFLUSH-001 User manual

1

FILTER CONTROLLER

Up

Enter

Down

Caution - Dangerous Voltage Inside

FILTER FLUSH CONTROLLER

Next Flush

60 Mins

Techsys

Cor p or at ion

To adjust program settings:

Step 1 Scroll to “Program Mode Adjust”

Step 2 Select “----- ON ---- ” by holding down

“Enter” and pressing “Up”

Step3 Scroll throughmenu options by pressing

“Up” or “Down”

Step 4 Adjust settings by holding down “Enter”

and pressing either “Up” or “Down”

Toperform aManual Flush:

Step 1 Scroll to “Manual Flush”

Step 2 To start, hold down “Enter”

press “Up”

Step3 and

To stop, hold down “Enter”

and press “Down”

2

REVISION HISTORY

The Filter Flush Controller forms part of the Techsys range of filtration controllers all designed to make

filtration more reliable and economical.

Techsys Engineering Pty Ltd

Unit 11/6 Nuban Street

Currumbin Waters QLD 4223

Phone: (07) 55341879

Email: sales@techsys.net.au

More information is also supplied on our WEB site

Internet contact www.techsys.net.au

This manual explains how to use the Techsys Filter Flush Controller.

There are other control systems available in the Filter Flush range which allow extended features to be

utilized. Contact your local Techsys representative for further information

REVISION HISTORY

First Edition 2/2/99 EPROM 0699

Second Edition 12/1/02 EPROM 0502

Third Edition 08/08/05 EPROM 4304

Current 01/06/09 EPROM 4911

3

CONTENTS

1. INTRODUCTION ............................................................................................................4

2. QUICK START ...............................................................................................................7

3. MENU ITEMS .................................................................................................................8

4. MENU DESCRIPTIONS .................................................................................................9

5. INFORMATION MESSAGES .......................................................................................16

6. ALARM MESSAGES....................................................................................................17

7. TERMINAL CONNECTIONS........................................................................................18

7.1. POWER INPUTS...................................................................................................19

7.2. INPUTS..................................................................................................................19

7.3. SOLENOID CONNECTION...................................................................................20

7.4. MOTOR CONNECTIONS......................................................................................21

MULTIPLE SAND FILTER ..................................................................................................23

4

Up

Enter

Down

Caution - Dangerous Voltage Inside

FILTER FLUSH CONTROLLER

Next Flush

60 Mins

Techsys

Cor p or at ion

To adjust pr ogram settings:

Step 1 Scroll to “Program Mode Adjust”

Step 2 Select “ --- -- ON ---- ” by holding down

“Enter” and pressi ng “ Up”

Step 3 Scroll through menu options by pressing

“U p” or “ Down”

Step 4 Adjust settings by holding down “Enter”

and pressi ng either “U p” or “ Down”

To perform a Manual Flush:

Step 1 Scroll to “M anual Flush”

Step 2 To start, hol d down “Enter”

press “U p”

Step 3 and

To stop, hold down “Enter”

and press “ Down”

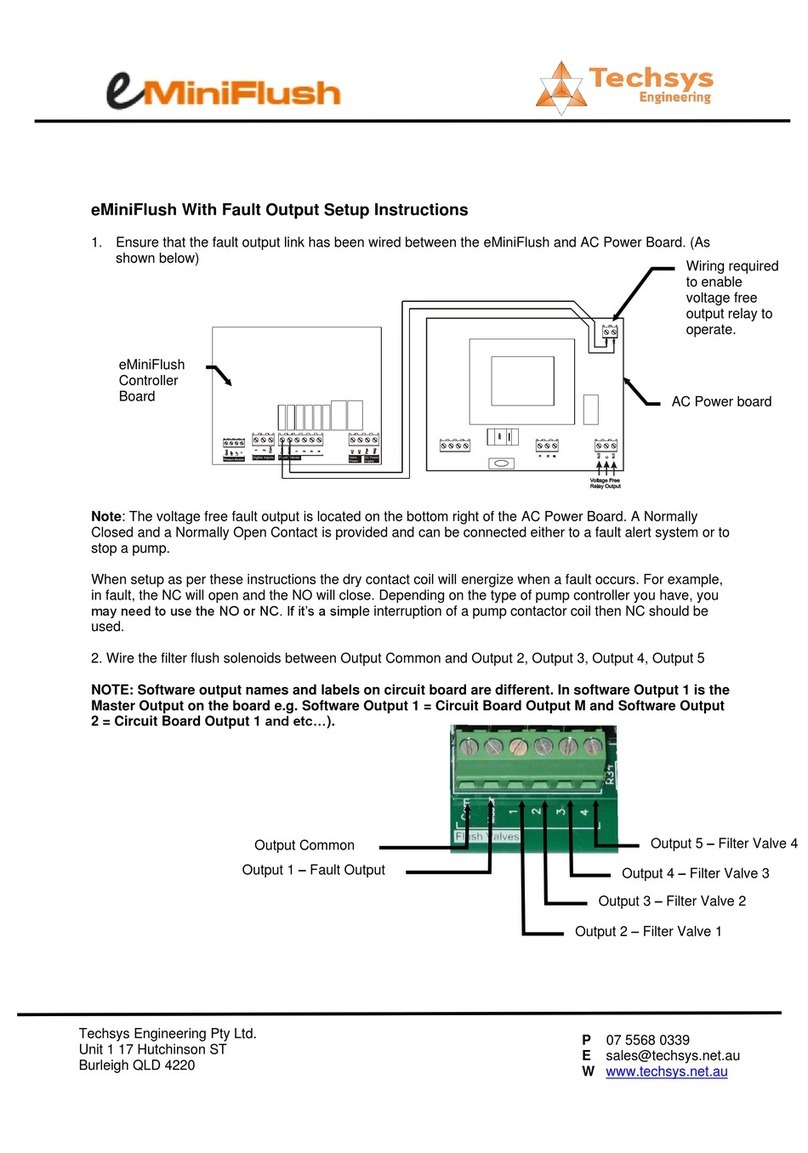

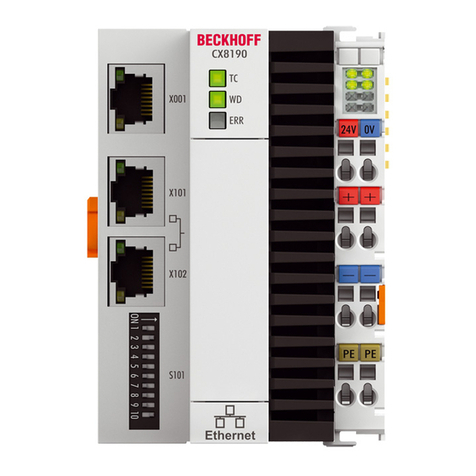

1. INTRODUCTION

The Techsys “Filter Flush Controller” is designed to

automatically backwash filters on “time”or “as-required”.

The controller has a microprocessor with scrolling menus that

users can access to adjust settings to suit each application.

Menus and adjustments are made by pressing the “UP” or

“DOWN” keys.

Up

Enter

Down

Caution - Dangerous Voltage Inside

FILTER FLUSH CONTROLLER

Next Flush

60 Mins

Techsys

C or p or at io n

Toadjust program settings:

Step 1 Scroll to “Progr am Mode Adjust”

Step 2 Select “--- -- ON ---- ” by holding down

“Enter” and pressing “Up”

Step3 Scroll throughm enu options by pressing

“Up” or “Down”

Step 4 Adjust settings by hol di ng down “Enter”

and pressing either “U p” or “ Down”

Toperform a Manual Flush:

Step 1 Scroll to “Manual Flush”

Step 2 To start, hold down “Enter”

press “ Up”

Step3 and

To stop, hold down “Enter ”

and press “Dow n”

To find the menu you wish to edit from the ‘Main Screen’ press the “UP” key.

Up

Enter

Down

Next Flush

60 Mins

Total flushes to date are now shown, press the “UP” key again.

Up

Enter

Down

Total Flushes

100

To view other menus use

the Up and Down keys

5

Manual Start (backwash/flush) is now shown, press the “UP” key again.

Up

Enter

Down

Manual Start OFF

Start. Enter+Up

To proceed further, ‘Program Mode’ has to be turned ON. Press the “Enter” & then the “UP” key.

Up

Enter

Down

Program Mode

Adjust. Enter+Up

‘Program Mode’ will be turned to ‘ON’, press the “UP” key.

Up

Enter

Down

Program Mode

---- ON ----

The ‘Backflush Time’ (Backwash) screen is now displayed.

Up

Enter

Down

Backflush Time

30 Secs

6

To increase this setting, press and hold the “Enter” key down, and then press the “UP” key once for

each additional second. Alternatively keep your finger on the “UP” key and it will auto increment.

Up

Enter

Down

Backflush Time

31 Secs

To decrease the ‘Backflush Time’ setting, press and hold the “Enter” key down, and then press the

“DOWN” key once for each second less. Alternatively keep your finger on the “DOWN” key and it will

auto increment.

Up

Enter

Down

Backflush Time

29 Secs

The procedure for changing any of the settings on this control system is exactly the same as the

above.

7

2. QUICK START

5.5W50HZ24V

GEM-SOL

900 series shown - the procedure is identical for other models

1

Plug power cable into

power outlet.

2

Connect the filter motor

to the terminal strip

inside the controller as

detailed in section 7.4.

Caution! Turn off the

power supply. Only a

qualified electrician is

permitted to make the

electrical connections.

3

Connect the flush

solenoid to the terminal

strip inside the

controller as detailed in

section 7.3.

Caution! Turn off the

power supply. Only a

qualified electrician is

permitted to make the

electrical connections.

4

Set the:

•Flush time

•Flush cycle time

To the required times

5

The system is ready to

operate.

Filter motor

Flush solenoid

8

3. MENU ITEMS

MENU

DEFAULT

RANGE

1

Next flush

60

xxxx Mins

2

Flow Total

Not displayed

If flow meter fitted.

m3,

lt,

USg,

Impg,

Ml,

Kl

3

Flow rate

Not displayed

If flow meter fitted

m3/Hr,

l/s,

USg/m,

Impg/m,

Ml/day,

Kl/day

4

Total flushes

0

xxxxxxxx

5

Manual Flush

OFF

Start. Enter+Up

6

Program Running

ON

OFF

= Program Running=

Adjust. Enter+Up

7

Backflush Time

30

xxxx Secs

8

Flush cycle time

60

Off,xxxx Mins

9

Flush dwell time

0 Secs

xxxx Secs

10

No. of filters

1

1 to 8

11

Solenoid coil

12Volts DC

12Volts DC/24Volts AC

12

Solenoid type

Standard

Standard, 2 wire latched

13

Max Flushes / Hr

20

1-1000

14

Output Relay

Flushing

Flushing

Any Fault

Any Alarm

Excess Flow

Any Fault/Alarm

15

Flow sensing

None

Switch type

Pulse Meter

16

Flow Scale

None

Select volume per pulse.

17

Flush after

===OFF===

XXX (flow amount)

18

Design flow rate

===OFF===

XXX (flow rate)

The most common functions are underlined and these items usually require adjustment to suit the

application before the system will operate correctly. The other menus are for fine tuning and are

normally not required by operators after setup.

The menus in bold italics only appear if ‘Flow Sensing’ is set to ‘Pulse Meter’

9

4. MENU DESCRIPTIONS

This is a descriptive item to inform the time until the next flush. It is defaulted in minutes and these

units cannot be changed. The field will update every minute.

Press UP

once.

Up

Enter

Down

The total number of flushes are displayed.

To reset to zero press ENTER and DOWN simultaneously.

Press UP

once.

Up

Enter

Down

To run a manual flush cycle press “ENTER” and "UP" to run a flush cycle when this screen is visible.

Up

Enter

Down

Total flushes

XXX

Manual Flush OFF

Start, Enter +Up

Next Flush

XX Mins

Manual Flush ON

Stop, Enter + Down

10

Manual mode now

In progress

XXXXXXXXXX

When the Manual Flush mode is operational the screen flashes between the following:

If you happen to scroll down to

the ‘main status screen’ it will

show that the system is in

Manual Flush Mode by displaying

this message.

Press UP

once.

Up

Enter

Down

To access additional menus press the “ENTER” button and the “UP” button to change the “Program

Mode” to “-----ON------“

Manual Flush ON

Stop, Enter + Down

Flush Completion

xxx sec

Flushing Number

x

Dwell timer

active

Stop, Enter + Down

When the ‘Dwell time’ is active

a delay between filters will

occur. When the Dwell is

active the above screen is

displayed.

Program Mode

Adjust. Enter+Up

11

Up

Enter

Down

If there are no key presses for 5 minutes the commission mode will automatically revert to “OFF”

Press UP

once.

Up

Enter

Down

The “FLUSH TIME” is the flushing time duration for each filter.

Press UP

once.

Up

Enter

Down

This is the time between flushes. It is defined as the time from when the last flush starts to the time

when the next flush begins. For continuous flushing select the cycle time to “0”. This will continuously

flush the filters.

To stop the controller operating on time based flushing hold the Enter and Up keys until the message

reads ‘PD Flush Only’ (PD = Pressure Differential).

Press UP

once.

Up

Enter

Down

Flush cycle time

60 Mins

Flush dwell time

0 Secs

Backflush Time

30 Secs

Program Mode

-----ON-----

Flush cycle time

PD Flush Only

12

The time between sequential flushing of the filters. This is only relevant when more than one filter is

being flushed.

Press UP

once.

Up

Enter

Down

The menu defines the number of filters to be flushed.

The maximum number possible with the standard system is eight.

Additional options can provide for up to 32 filters to be flushed. Contact Techsys for further

information.

Press UP

once.

Up

Enter

Down

This menu defines the voltage of the solenoid coil being used. The options are 24Volts AC or 12 Volts

DC. If operation is from an external 24VDC supply, select the 12V DC option and ensure that 24VDC

valve are used.

Press UP

once.

Up

Enter

Down

The FILTER CONTROLLER can activate different types of solenoids:

•“Standard” - Solenoids with fixed continuous voltage coils

•“2 wire Latched” –Latching solenoids

These are options for the solenoid activation types. If unsure contact Techsys or your local dealer to

confirm the type of solenoid coils that you are using.

NOTE: Menu options for 2 wire Latched solenoids will not display unless the 12 Volt DC Solenoid type

is selected in the previous menu.

No. of filters

1

Solenoid coil

12 Volts DC

Solenoid type

Standard

13

Last Flush XFlsh

XXXX min

Output Relay

Flushing

Press UP

once.

Up

Enter

Down

Input the maximum number of flushes per hour that you wish to allow. If this is exceeded then the

controller will display "XFlsh” indicating the set maximum flushes has been exceeded.

The XFlsh message does not stop flushing. The message will update every hour. To clear the

message press the "ENTER" key

Press UP

once.

Up

Enter

Down

The FILTER CONTROLLER has one programmable output that can be set to any one of the following

functions.

Program

Function

Description

Delay time

Flushing

Any filter flushing

1 sec

Any Fault

•Filter blocked

DP Input continuously

on.

5 sec

Any Alarm

•Excess Flush alarm

•Excess flow alarm

5 sec

Excess flow

Excess flow alarm

trip

5 sec

Any Fault/Alarm

Any alarm or fault

as detailed above

5 sec

The Programmable output is a relay rated to 5 amps; as such the power supply fuse must not exceed

5 amps. Failure to fit the correct fuse may cause early failure or damage to this Filter Flusher.

Max Flushes / Hr

20

14

Press UP

once.

Up

Enter

Down

The FILTER CONTROLLER can detect flow and suspend flushing if there is “no flow”thereby saving

backwash water. The options are:

•None –no flow switch or flow meter is fitted

•Switch type –flow switch fitted

•Pulse meter –pulse meter fitted

(Select using Enter Up/Down )

Switch - a flow switch must be fitted if this option is selected. This is particularly useful for pressurised

systems that do not require flushing in a no-flow condition.

NOTE * If “Switch Type” is selected then the flow switch must have closed contacts for the

system to flush.

Press UP

once.

Up

Enter

Down

If a pulse flow meter is fitted and the previous screen is fitted this screen can be displayed. It allows

selection of a number of optional flow units.

•m3/Hr –Cubic metres per hour

•l/s –Litres per second

•USg/m –US Gallons per minute

•Impg/m –Imperial Gallons per minute

•ml/day –Megalitres per day

•kl/day –Kilolitres per day

Press UP

once.

Up

Enter

Down

This menu is used to set the flow per pulse.

Flow sensing

None

Flow units

l/s

Flow scale

10.00 xx

15

Press UP

once.

Up

Enter

Down

This menu is used to initiate volume based backwashing. It is normally turned off (===OFF===).

Entering a value in this menu disables the time based flushing and will then only flush after the flow

volume has been reached or the DP (Differential Pressure) input is activated.

Press UP

once.

Up

Enter

Down

If there is an upper flow rate limit it can be entered in this menu. If it is exceeded it will initiate an alarm

condition.

It is normally turned OFF. (===OFF===)

This is the last menu –press “Down” to scroll back through previous menus.

Up

Enter

Down

Flush after

1xx

Design flow rate

10 xx

16

Pause Activated

No flow detected

5. INFORMATION MESSAGES

The Techsys Filter Controller displays messages to list tasks that are being undertaken.

FLUSHING

Once a flush is iniated by either time, differential pressure or volume the Controller displays these

screens in a rotating sequence as the main display.

If the backwash was initiated by the differential pressure switch,

the first flush screen indicates this accordingly. The default

differential delay timer is set for 3 seconds.

When the PAUSE terminals are closed the Filter Controller stops will not initiate a backwash until the

PAUSE contacts are re-opened.

If the PAUSE input is activated midway through a backwash cycle the valves on the current filter are

closed. When the input is de-activated the unit will continue from where it left off.

The Filter Controller can be switched off if a flow switch input is fitted

and “no flow”is detected.

Auto Flush Cycle in

progress

Stop, Enter + Down

Flush Completion

xxx sec

Flushing Number

x

Dwell timer

active

Stop, Enter + Down

When the system is waiting

for the next filter in the cycle to

flush the controller displays

this message

Diff Press cycle

In progress

17

Filter Stalled

Last Flush XFlsh

XXXX min

Loading Data

From Memory

Techsys

Corporation

Version No. 0302

POWER FAILURE

About to restart

INITIALISATION MESSAGES

When the Filter Controller is first connected to power the following information messages are seen.

Data stored in the Filter controller is the last stored data. Data is

recalled after each power down.

The software version number is displayed for 1 second on initial power up.

After Power Failure, data is saved to the memory and all changes are saved. After a power failure the

following message is displayed:

6. ALARM MESSAGES

The FILTER CONTROLLER has display messages to inform the operator of out of specification

situations. Messages are cleared by pressing the “ENTER” key after the fault has been cleared.

If the differential pressure switch remains closed for more than 15

minutes it is assumed that the filter has Stalled/Blocked. This

message will remain active until the “Enter” button is pressed. The

filter operation will continue after the fault is registered and until the

fault is manually remedied on the filter. The fault alarm can be programmed to trip on this fault.

FLUSH ALARM

If the Total number of flushes in any one-hour period exceeds

the “MAX. FLUSHES / Hr” setting then the Filter Controller will

display this message. It is for informational purposes only to

inform the operator that the system is being strained with either

excess flow or excess contamination loading.

TEST MODE

When the TEST Mode menu is selected for test flushing the

screen will inform the operator that the filter is being flushed in

this mode.

TEST Mode ON

Stop, Enter + Down

18

7. TERMINAL CONNECTIONS

The Filter Controller has wire terminals to connect and enable optional features.

See below for connection of most common applications.

EPROM

Relay

Relay

Relay

Pause

Differential Pressure Switch

Flow Input

Input Common

Flushing Valve 1

Flushing Valve 2

Flushing Valve 3

Flushing Valve 4

Spare

Flushing Valve 5

Flushing Valve 6

Flushing Valve 7

Flushing Valve 8

Master Solenoid

Solenoid common

Solenoid common

Earth

110/ Neutral

240 VAC

24VAC

24VAC

12/24VDC -

12/24VDC +

Output Relay

Voltage Free

230V

Fuse

Voltage

Selector

Switch

19

7.1. POWER INPUTS

Use a qualified Electrician to make power connections.

Power terminals are labeled and on the bottom of the circuit board.

Earth

Neutral

110VAC active

240VAC active

24VAC -

24VAC +

12VDC -

12VDC +

Motor power in

Motor switched output

240 or 110VAC connection:

Select the correct operating voltage on the selector switch.

Connect the Active, Earth and Neutral wires to the relevant terminals.

12VDC POWER SUPPLY

FIT EXTERNAL FUSE

If the power supply is 12VDC (battery or solar power) connect the power via a fuse to the 12VDC

terminals. These are polarity sensitive and need to be checked prior to connection. The unit will also

operate from 24VDC on these terminals.

**If the polarity is incorrect the board will be damaged**

All power supplies connected with 12-24 VDC require an in line fuse of no more than 2.5 amps to be

fitted.

24VAC POWER SUPPLY

Connection to the 24V AC-power supply is not polarity sensitive. Any of the 24 VAC wires can be

connected to the 24VAC terminals. If a motor is used with this option it will need to be wired to the

motor switch terminal. See Motor Connections. Be sure to provide a FUSED POWER SUPPLY for this

option.

7.2. INPUTS

PAUSE

To pause the system, close the contact between the Pause and Input common terminals

Pause

Differential Pressure Switch

Flow Input

Input Common

Normal

Operation

System

Paused

DIFFERENTIAL PRESSURE (PD)

A closed contact will activate a flush cycle. Closure of these contacts will override the time based flush

command. Once the system flushes, the timer for the time based flushing will reset.

Pause

Differential Pressure Switch

Flow Input

Input Common

Normal

Operation

Start flush

cycle

20

Filter type

Solenoid

Pause

Differential Pressure Switcht

Flow Input

Input Common

Normal

Operation Filter will

not flush

FLOW SWITCH OR PULSED FLOW METER

When a flow switch is connected and the system is set up accordingly, activation of the input will

prevent a backwash. This stops unwanted flushing in pressurised systems when there is no flow.

Connecting a pulsed flow meter on these terminals will allow flow based operation when set up to suit.

7.3. SOLENOID CONNECTION

STANDARD SOLENOID

The standard solenoid should be connected to the terminal strip as

shown. As more filters are required, connect the flushing valve solenoids

to the terminals sequentially.

e.g. Filter 2 connects to terminal “Solenoid 2 and the Solenoid

common”

The voltage is set in the menu item “SOLENOID COIL” The options are 12VDC or 24VAC.

LATCHED SOLENOID

2 Wire Latched

This is wired identically to the Standard option. The 2 wire latched option must be selected in the

"SOLENOID TYPE" menu

The terminal strip has 2 Solenoid common terminals to allow additional wires to be fitted with ease.

Solenoid type

Standard

Solenoid type

2 wire latched

Table of contents

Other Techsys Control System manuals

Popular Control System manuals by other brands

Anilam

Anilam 4200T Programming and operations manual

ETC

ETC Eos Apex 5 user manual

W.E.S.T. Elektronik

W.E.S.T. Elektronik POS-123-P Technical documentation

RKC INSTRUMENT

RKC INSTRUMENT FAREX SR MINI SYSTEM Communication instruction manual

Timewatch

Timewatch TW6000DCLD manual

NuTone

NuTone AD-500 Facility Manager’s Guide