TECMASCHIN HU-P1316 User manual

Please read this manual before using the product and follow the instructions it contains!

OPERATING INSTRUCTIONS

Battery hand strapping tool

HU-P1316

2

CONTENT

Foreword 3

Safety instructions 3

Technical data 4

Main components 4

Operating instructions 5

Maintenance and repair 6

Troubleshooting 7

Packing and disposal 7

Warranty 7

GENERAL

MAINTENANCE &

WARRANTY

3

TECMASCHIN

FOREWORD

Congratulations on the purchase of your new HU-P1316 electric hand strapping tool. The easy-to-use battery-powered

device is made of high quality materials, specially designed for durable and reliable use. For your own safety and for the

correct operation of the strapping tool, please be sure to read and follow these operating instructions before using it.

It is best to keep these operating instructions. Check the device for transport damage. Damaged strapping tools should

not be put into use.

The HU-P1316 is used for electrical strapping and packaging of various packages and goods. Improper handling may result

in injury or damage to the machine. The operator / user must ensure correct use, making sure that it is only used by trained

and authorized persons.

SAFETY INSTRUCTIONS

Please read the instructions carefully, failure to do so may result in injury during operation.

• Only trained personnel may use this device.

• Only use the strapping tool if you have a firm footing.

• The device should not be used by mentally or physically impaired persons.

• Only use high-quality strapping tape that is suitable for this device. Pay particular attention

to width, thickness and tensioning force.

• Charge the battery only in dry rooms, at room temperature.

• Keep the device away from water, especially the battery.

• Remove the batteries before any maintenance.

• Use the device only at ambient temperatures between 5 °C - 45 °C.

• Wear safety glasses when using the device.

• Keep fingers away from blade and heating elements during use.

• Do not overstretch the strapping. Torn straps can cause property damage and serious injury.

• Bystanders should keep their distance if possible.

• Contamination of the device or on the strapping band can influence the result.

• Use only fully functional strapping tools.

TECMASCHIN

4

TECHNICAL DATA

No. Name

1 Battery box

2 Lever

3 Welding button

4 Tension knob

5 LED light

6DC5 5 Socket

7 Power-on toggle switch

MAIN COMPONENTS

Type Unit Value

Size (mm) 340 x 130 x 118

Weight (kg) 3,2

Battery (V/Ah) 12 / 4

Tension up to (N) 2800

Tensioning speed (mm/s) 100 – 200

Strip width (mm) 13 – 16

Strip thickness (mm) 0,5 – 1,2

Usable strapping: PET polyethylene / PP polypropylene

1 2

6 7

3 4 5

5

TECMASCHIN

BEFORE THE FIRST USE:

For safety reasons, the HU-P1316 hand strapping

tool and the spare battery pack arrive discharged.

Fully charge the batteries.

1. Pull the battery box cover up in the direction

of the arrow.

2. When the battery is inserted, the current charging

status is briefly indicated by a colored LED light

on the top.

Remove discharged batteries and recharge them to make

the device ready for use again.

If you use PP strapping, replace the internal spring with the

enclosed one. See section „Adjustment of the welding pressure“

for this.

Color Status

Blue Ready for use

Red flashing Low battery power

Red glow Machine error

Violet luminous Work finished

LED STATUS INDICATION

OPERATING INSTRUCTIONS

WELDING TIME ADJUSTMENT

1. Adjust the welding time if the strapping melts too much

or the band does not hold.

2. To do this, turn the right control clockwise to increase

the welding time.

ADJUSTMENT OF THE TENSIONING FORCE

1. Adjust the tensioning force if the strapping is too

loose or too taut.

2. To do this, turn the left control clockwise to increase

the tensioning force.

Start with a low welding time and a low tension force and slowly approach the desired result to avoid damage to the

fabric and injury from tearing straps.

Welding time

Tensioning force

TECMASCHIN

6

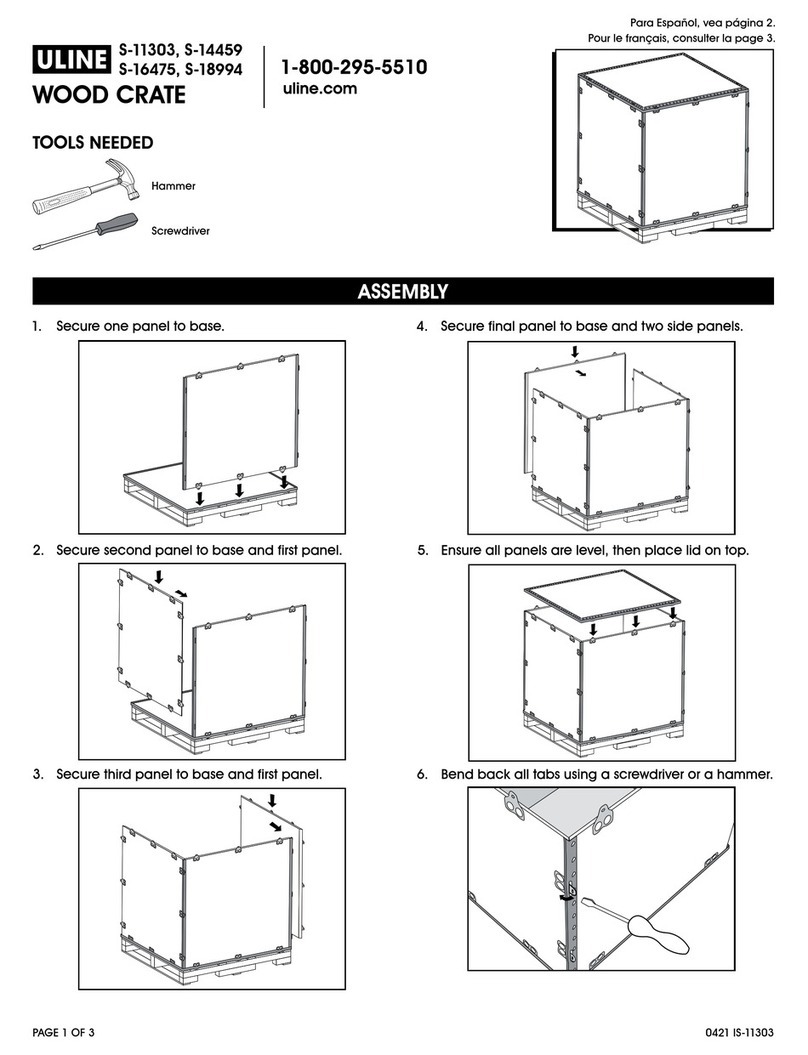

1. Wrap the package to be wrapped with the strapping tape so that the

ends overlap.

2. Lift the strap slightly so that you can drive under the strap with

the strapping tool. Hold the lever while doing this. Release the lever when

the tool is in the correct position.

3. Press the tensioning knob. After you have reached the desired clamping

force, release it again.

4. Weld the strap by pressing the welding button. Once the strap is cut,

you can remove the strapping tool.

5. Return the tensioning knob to the upper position by guiding the tensioning

knob upwards and move the device away from the packaging tape.

6. Check the strapping again for any damage or weak points.

Check the functionality of the device regularly. Pay particular attention to correct welding and Tension, as deviations may

occur here during prolonged use. In these cases, adjust the controllers. Remove the battery before any repair work in order

to exclude possible injury hazards.

ADJUSTMENT OF THE WELDING PRESSURE

If the welding pressure is too low or too high, this can

lead to faulty welding.

This circumstance depends on 2 factors:

The material thickness and the strip material itself.

1. Remove the battery from the housing of the device.

2. Open the left cover of the housing by loosening the

3 M4 screws.

3. Move the weld knob to the down position to expose

the silver M6 nut above the tension spring.

4. Tighten the nut to decrease the welding power.

To increase loosen the nut slightly.

STRAPPING PACKAGES

MAINTENANCE AND REPAIR

Correct welding

Welding time too short

Welding time too long

M4 screws

M6 nut

CUTTING FORCE ADJUSTMENT

If the strap is not cut or the blade cuts both strands of the strap,

it is necessary to adjust the cutting force.

1. Remove the battery from the housing of the device.

2. Open the left cover of the housing by loosening the 3 M4 screws.

3. Loosen the M4 screw directly on the blade of the device with

an Allen key.

4. Remove the blade of the device.

5. Replace the spring behind it.

6. Reassemble the device in reverse order.

Tip: The spring, which is already installed in the device, is used for

welding with PET tape. If you use PP tape, replace the spring with

the enclosed one before the first use.

7

TECMASCHIN

Problem Cause Solution

Control lamp does not

light up Battery is empty Replace the battery with a charged one and charge

the dead battery

The device does not

weld properly

Welding time too short Increase the welding time

Welding pressure too low Increase the welding pressure

The tape melts

too much

Welding time too high Reduce the welding time

Welding pressure too high Reduce the welding pressure

The device does not cut

properly Blade does not cut the tape completely Adjust the cutting force

The device cuts the

entire tape Blade moves down too far Reduce the cutting force

Red LED lights up

Tape is stuck in the device Remove the battery, cut the tape.

Open the device and remove the stuck tape

The motor does not turn Contact the manufacturer

TROUBLESHOOTING

PACKING AND DISPOSAL

PACKAGING

The packaging and individual components are made of recyclable materials. In detail these are:

PE (polyethylene) films and bags, cardboard packaging. We recommend keeping the packaging at least

during the warranty period.

DISPOSE OF OLD EQUIPMENT

OLD DEVICES MUST NOT BE DISPOSED OF WITH WASTE!

If the device can no longer be used, every consumer is required by law to dispose of old devices

separately from household waste, e.g., at a collection point in his or her municipality / district.

This ensures that old appliances are recycled properly and that negative effects on the environment

are avoided. For this reason, electrical appliances are marked with the adjacent symbol.

WARRANTY

The warranty of one year from the date of invoice covers material, manufacturing and construction defects.

Damages, which are due to natural wear and tear, improper handling or unauthorized modification are not covered by

the warranty. We grant a voluntary functional guarantee of 6 months from the date of purchase on the accumulator.

V 16.08.21

TOPREGAL UK Ltd.

Carlton Drive Pen Y Fan Industrial Estate

Crumlin Newport | Gwent NP11 4EA

01495 707222 | [email protected]

www.topregal.co.uk

Table of contents

Popular Packaging Equipment manuals by other brands

Transpak

Transpak TP-6000 Technical Questions and Answers

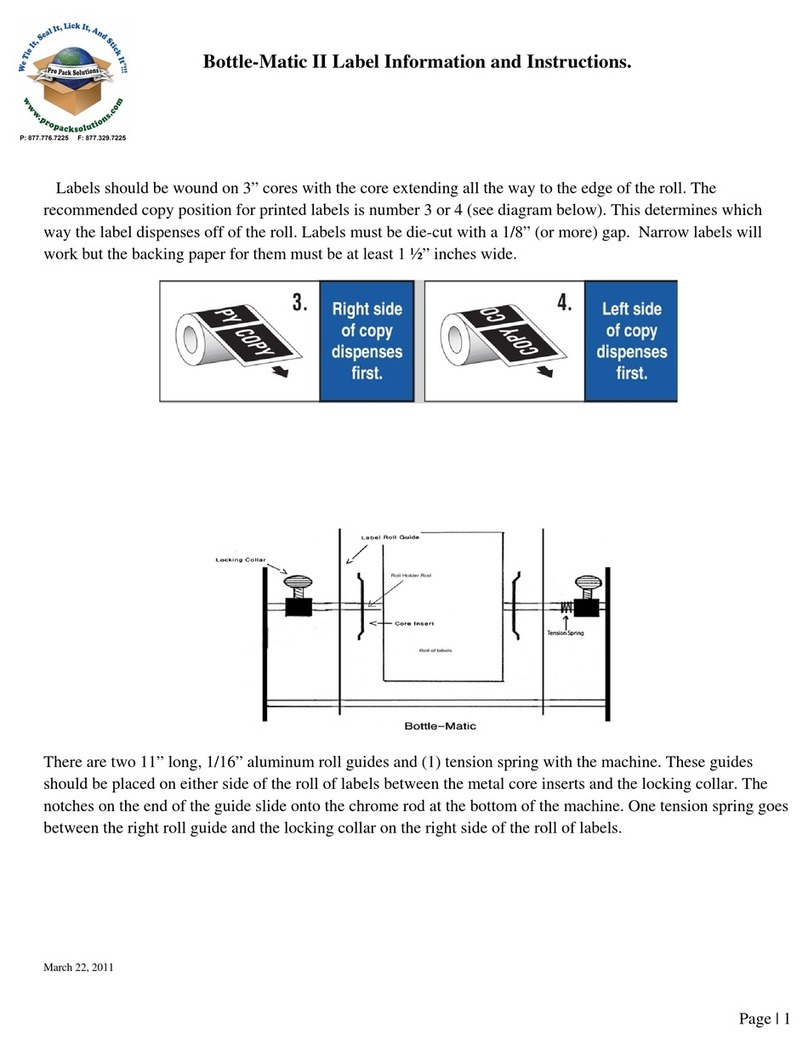

Dispens-a-Matic

Dispens-a-Matic Bottle-Matic II Information and instructions

Polychem

Polychem SP3100 Operation manual and spare parts list

Pregis

Pregis packmaster pro 383 operating manual

hawo

hawo hd 650 D EcoPak operating instructions

M.J. MALLIS GROUP

M.J. MALLIS GROUP SIAT K11R Instructions and Spare Parts List

ITW Mima

ITW Mima Girotec RDL 1800 Service and installation manual

Orgapack

Orgapack OR-H 47 operating instructions

EMGA

EMGA 516.030 manual

vc999

vc999 07P Series Operator's manual

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

Kronos

Kronos H-46 Series Operation, safety and spare parts manual