ASV2

AirSaver F2

3

F2 Machine Setup

F2 MACHINE SETUP

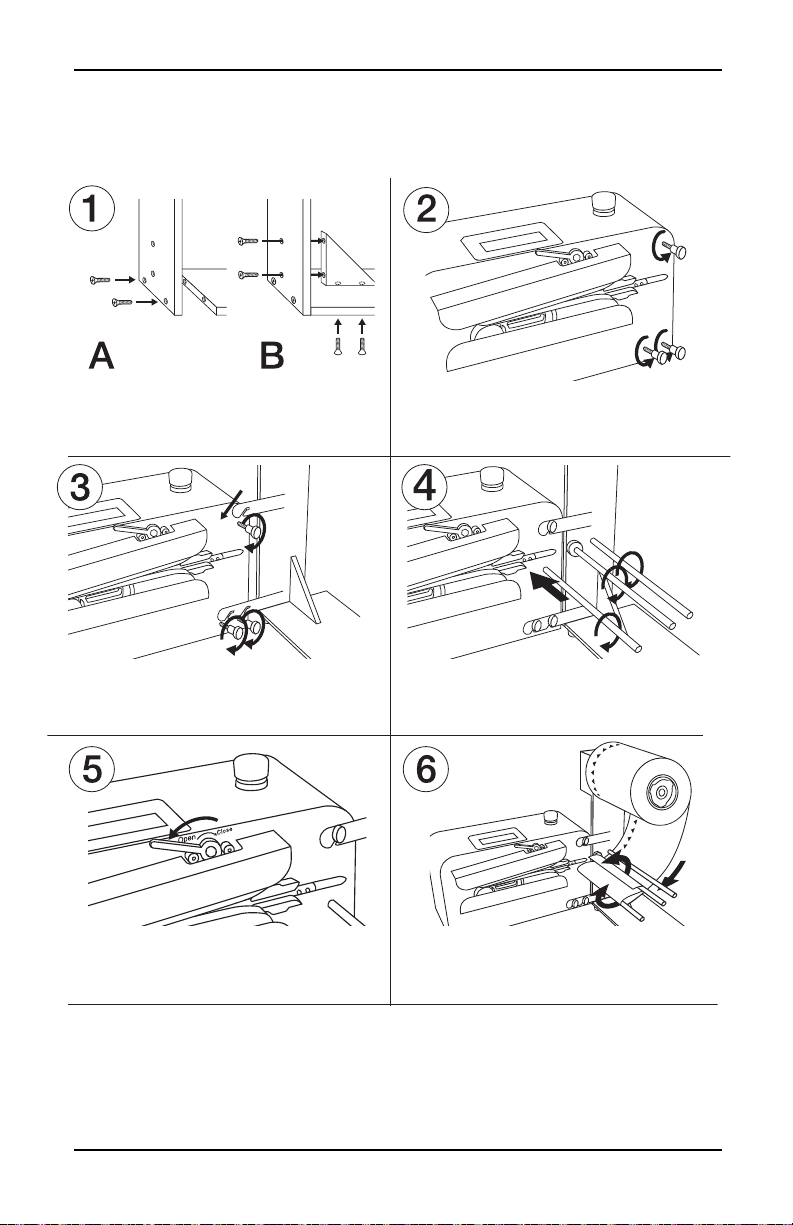

Please refer to above images A & B to assemble

the Film Roller. Use the six screws & triangle

brace provided.

Loosen (but DO NOT remove completely) the back

three hand screwson the F2 Machine.

Connect the assembled Film Roller to the back

three hands screws on the F2 Machine. Once in

place, tighten the three screws.

Screw in the three metal rods into the designated

screw holes (one on the F2 machine, Two on the lm

Roller). Once the rods are in place take the white

washer and place it through the middle rod.

Flip the lever located on top of the F2 Machine

to the Open position.

Load film onto the Film Roller ensuring that the text

Loads toward machineis in that direction. Afterthe

film has been loaded, refer to the above image to

properly feed the filmthrough the three metal rods.

On the side of the filmthat is closest to the machine,

create a small opening and thread it through the

feeding tube. Pull the film to the front of the machine.

Flip the lever located on the top of the F2 Machine

to the Close position.

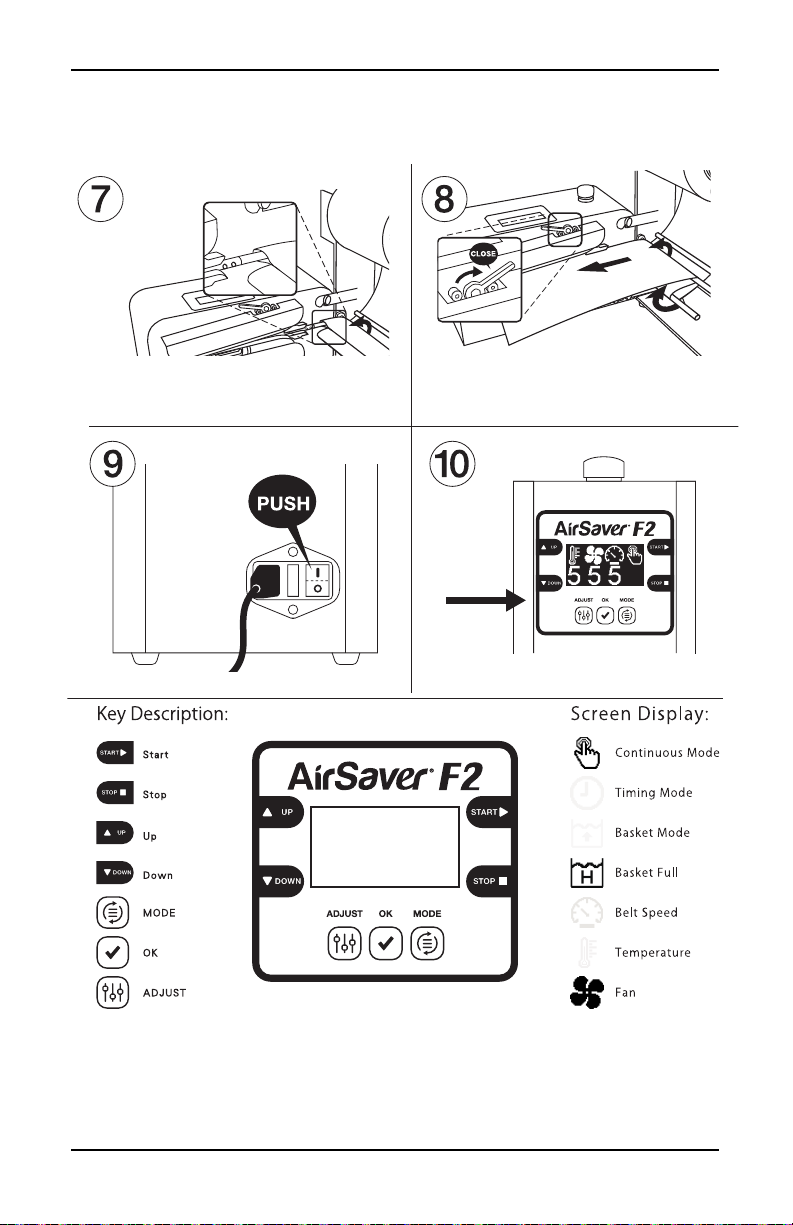

On the back of the F2 Machine, plug in the power

cable and turn on the power switch.

Press the Adjust button to configure the panel

with the recommended setting located on top of

the F2 Machine. Press and hold the Mode button

to cycle the various options provided.

Please refer to above images A & B to assemble

the Film Roller. Use the six screws & triangle

brace provided.

Loosen (but DO NOT remove completely) the back

three hand screwson the F2 Machine.

Connect the assembled Film Roller to the back

three hands screws on the F2 Machine. Once in

place, tighten the three screws.

Screw in the three metal rods into the designated

screw holes (one on the F2 machine, Two on the lm

Roller). Once the rods are in place take the white

washer and place it through the middle rod.

Flip the lever located on top of the F2 Machine

to the Open position.

Load film onto the Film Roller ensuring that the text

Loads toward machineis in that direction. Afterthe

film has been loaded, refer to the above image to

properly feed the filmthrough the three metal rods.

On the side of the filmthat is closest to the machine,

create a small opening and thread it through the

feeding tube. Pull the film to the front of the machine.

Flip the lever located on the top of the F2 Machine

to the Close position.

On the back of the F2 Machine, plug in the power

cable and turn on the power switch.

Press the Adjust button to configure the panel

with the recommended setting located on top of

the F2 Machine. Press and hold the Mode button

to cycle the various options provided.

Please refer to above images A & B to assemble

the Film Roller. Use the six screws & triangle

brace provided.

Loosen (but DO NOT remove completely) the back

three hand screwson the F2 Machine.

Connect the assembled Film Roller to the back

three hands screws on the F2 Machine. Once in

place, tighten the three screws.

Screw in the three metal rods into the designated

screw holes (one on the F2 machine, Two on the lm

Roller). Once the rods are in place take the white

washer and place it through the middle rod.

Flip the lever located on top of the F2 Machine

to the Open position.

Load film onto the Film Roller ensuring that the text

Loads toward machineis in that direction. Afterthe

film has been loaded, refer to the above image to

properly feed the filmthrough the three metal rods.

On the side of the filmthat is closest to the machine,

create a small opening and thread it through the

feeding tube. Pull the film to the front of the machine.

Flip the lever located on the top of the F2 Machine

to the Close position.

On the back of the F2 Machine, plug in the power

cable and turn on the power switch.

Press the Adjust button to configure the panel

with the recommended setting located on top of

the F2 Machine. Press and hold the Mode button

to cycle the various options provided.

Please refer to above images A & B to assemble

the Film Roller. Use the six screws & triangle

brace provided.

Loosen (but DO NOT remove completely) the back

three hand screwson the F2 Machine.

Connect the assembled Film Roller to the back

three hands screws on the F2 Machine. Once in

place, tighten the three screws.

Screw in the three metal rods into the designated

screw holes (one on the F2 machine, Two on the lm

Roller). Once the rods are in place take the white

washer and place it through the middle rod.

Flip the lever located on top of the F2 Machine

to the Open position.

Load film onto the Film Roller ensuring that the text

Loads toward machineis in that direction. Afterthe

film has been loaded, refer to the above image to

properly feed the filmthrough the three metal rods.

On the side of the filmthat is closest to the machine,

create a small opening and thread it through the

feeding tube. Pull the film to the front of the machine.

Flip the lever located on the top of the F2 Machine

to the Close position.

On the back of the F2 Machine, plug in the power

cable and turn on the power switch.

Press the Adjust button to configure the panel

with the recommended setting located on top of

the F2 Machine. Press and hold the Mode button

to cycle the various options provided.

Please refer to above images A & B to assemble

the Film Roller. Use the six screws & triangle

brace provided.

Loosen (but DO NOT remove completely) the back

three hand screwson the F2 Machine.

Connect the assembled Film Roller to the back

three hands screws on the F2 Machine. Once in

place, tighten the three screws.

Screw in the three metal rods into the designated

screw holes (one on the F2 machine, Two on the lm

Roller). Once the rods are in place take the white

washer and place it through the middle rod.

Flip the lever located on top of the F2 Machine

to the Open position.

Load film onto the Film Roller ensuring that the text

Loads toward machineis in that direction. Afterth

film has been loaded, refer to the above image to

properly feed the filmthrough the three metal rods.

On the side of the filmthat is closest to the machine,

create a small opening and thread it through the

feeding tube. Pull the film to the front of the machine.

Flip the lever located on the top of the F2 Machine

to the Close position.

On the back of the F2 Machine, plug in the power

cable and turn on the power switch.

Press the Adjust button to configure the panel

with the recommended setting located on top of

the F2 Machine. Press and hold the Mode button

to cycle the various options provided.