TABLE OF CONTENTS

1)

Safety instructions

2)

Technical data

3)

Warranty and liability

4)

Installation

5)

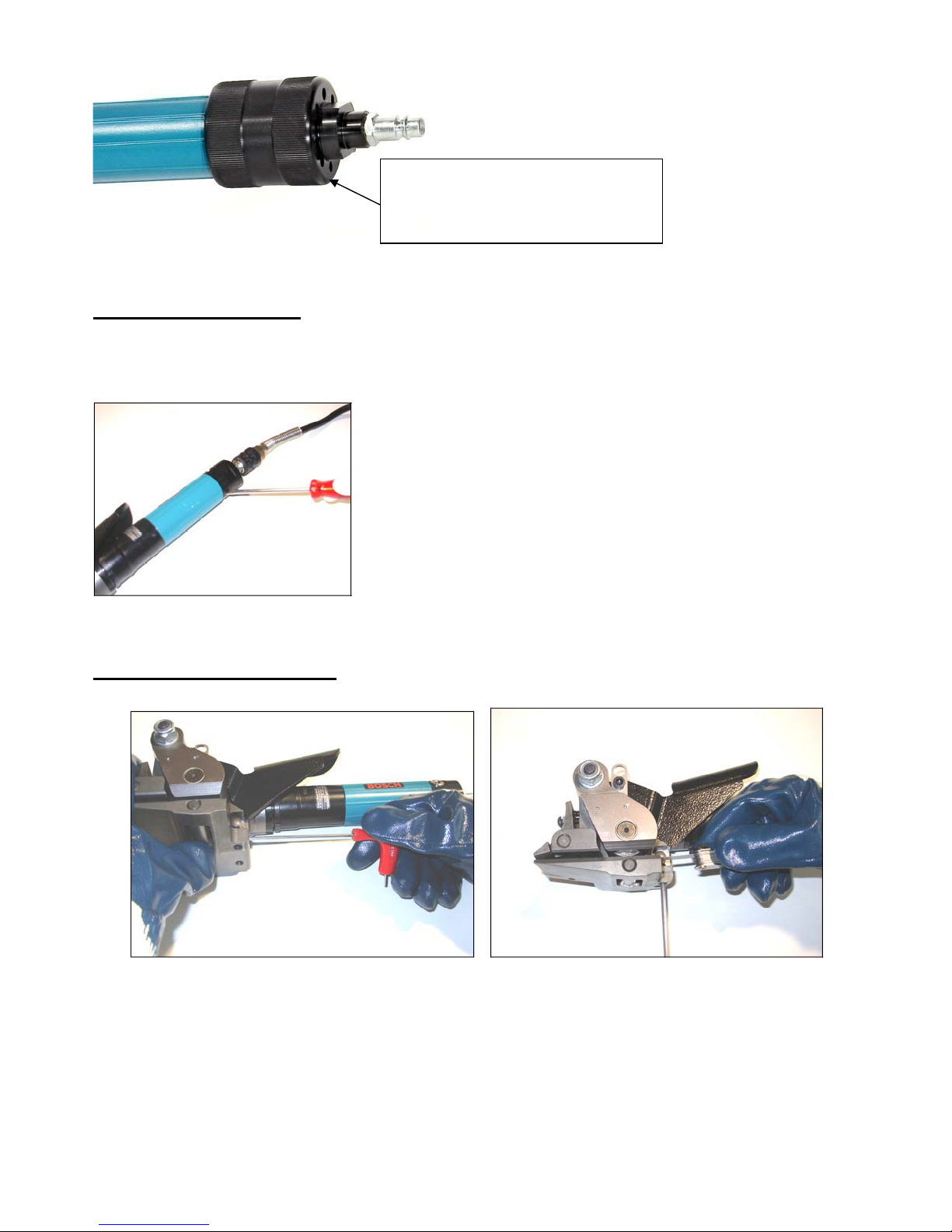

Operating elements

6)

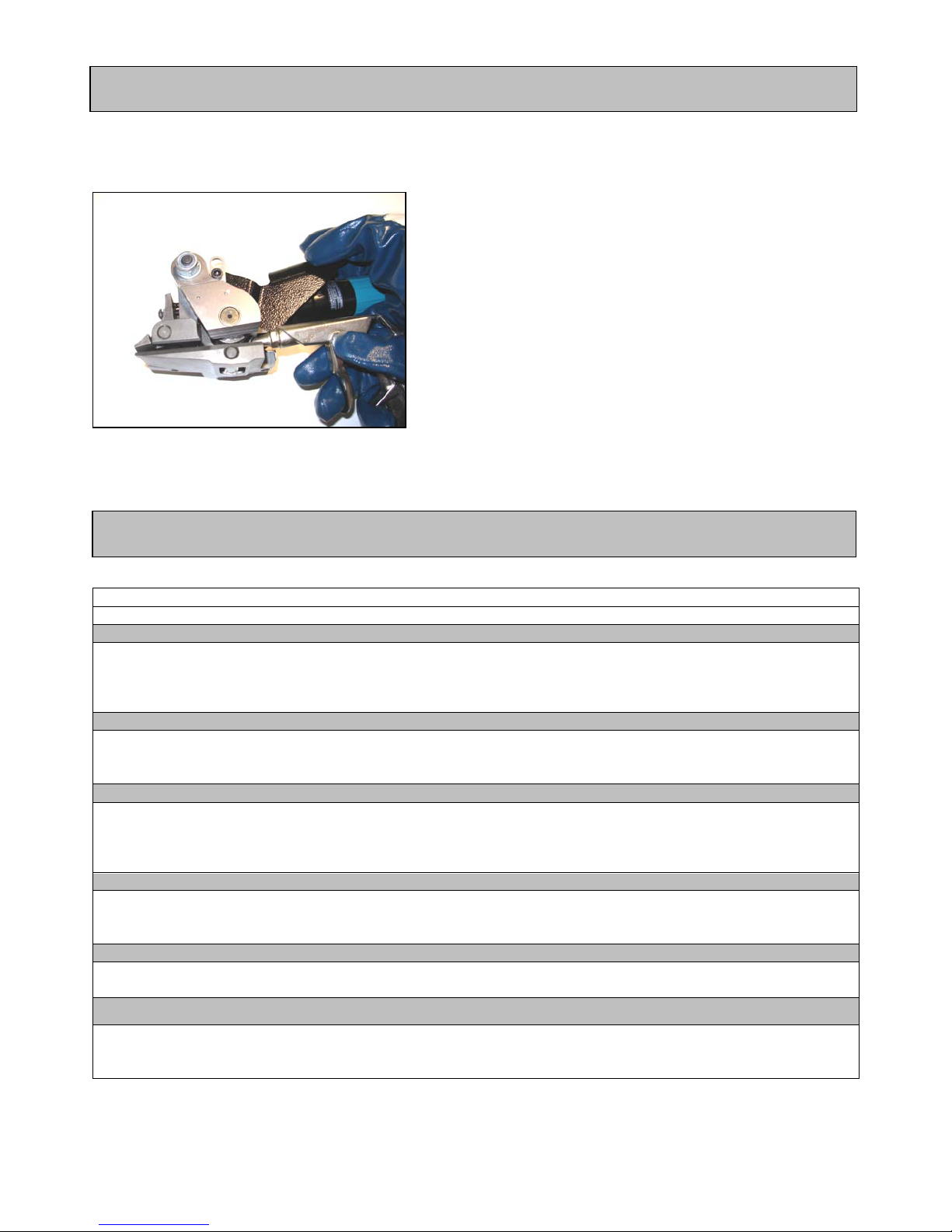

Operation

7)

Servicing and cleaning

8)

Troubleshooting

9)

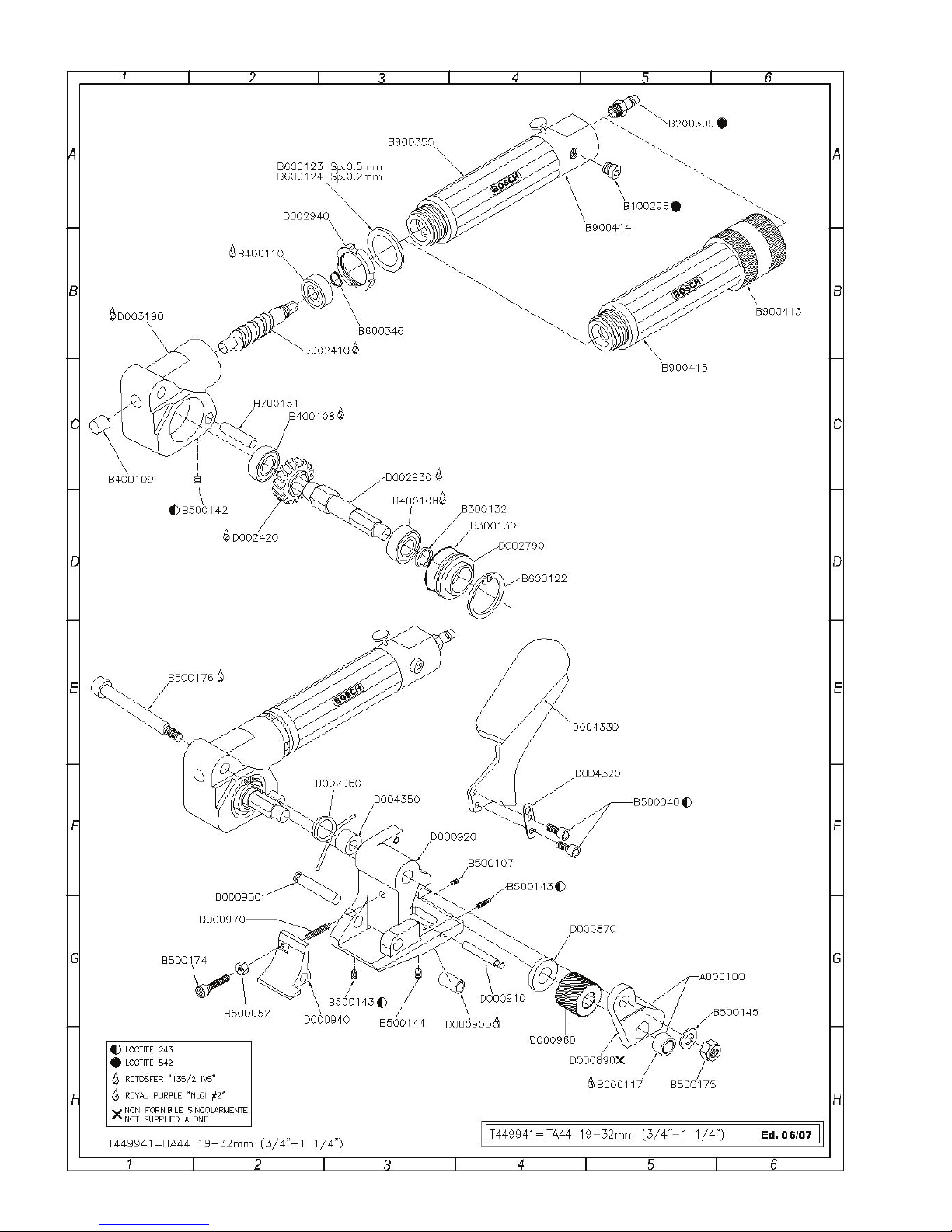

Layout – spare parts list

READ THE OPERATING INSTRUCTIONS CAREFULLY

WHEN OPERATING THE TOOL, WEAR EYE, FACE AND HAND SAFETY PROTECTION

The tool must be used by properly trained people. Failure to follow the operating instructions or

improper use could cause strap breakage, injuries, or package damages.

Check tool daily, do not use tool with worn or damaged parts. Use original spare parts for

replacement. Never modify any tool part.

Do not put fingers, hands or other body parts between the strap and package during the cycle.

It is your responsibility to check the seal joints made by your tool. Training about the weld time

adjustment will be useful to check the seal quality in order to avoid severe injury. Never move

goods with bad quality seals. Only use specific strap dispenser to dispense the strap. Keep your

working area clean and always use the tool in good balance and safety conditions. Never use

straps as a means of pulling or lifting goods.

Always use a proper safety strap cutter and keep other people and yourself at a safe distance

from strap, always stand to side of strap, away from direction of strap trajectory once cut. Hold the

upper strap portion and pay attention that the lower strap will snap forward away from you.

Improper operation, excessive tensioning, use of non-recommended strap, or sharp corners on the

package could cause a loss of strap tension and/or strap breakage that could lead to packaging

failure or injury. The following is recommended; use edge protectors if package has sharp corners,

place the strap correctly around a properly positioned package, stand in safety position (on one

side of strap) during strapping cycle, and use the correct strap quality, width, thickness, and break

strength as recommended in this manual.

Please save this manual, as it is a part of the tool. This tool is manufactured without any

substances which could be dangerous to health. National instructions must be observed for

disposal of all the parts.

Never operate this tool using bottled air or other gas source. Do not exceed the air pressure

range as shown in this operation manual. For all adjustments, repairs or cleaning of the tool,

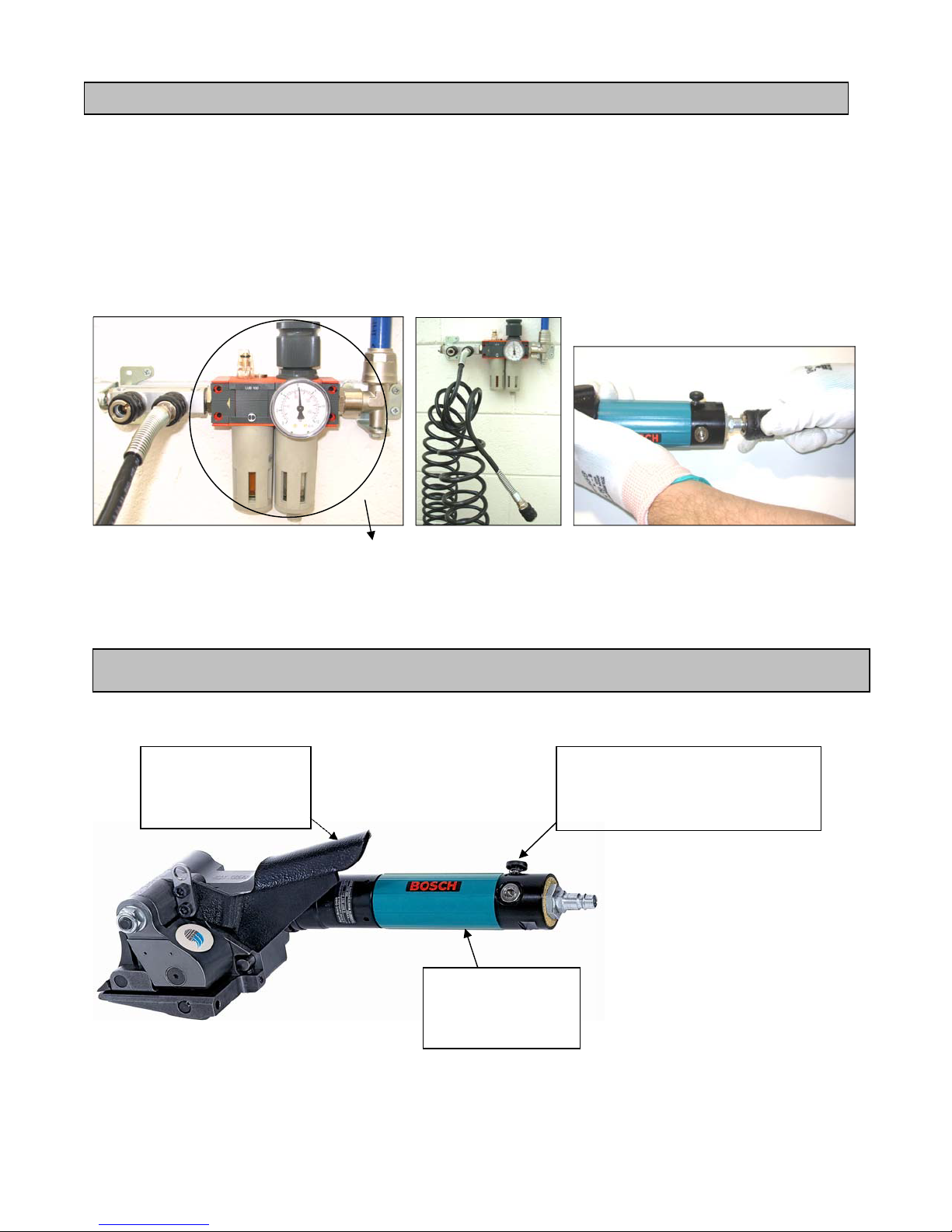

always disconnect air supply. Always use dry, clean and lubricated compressed air.