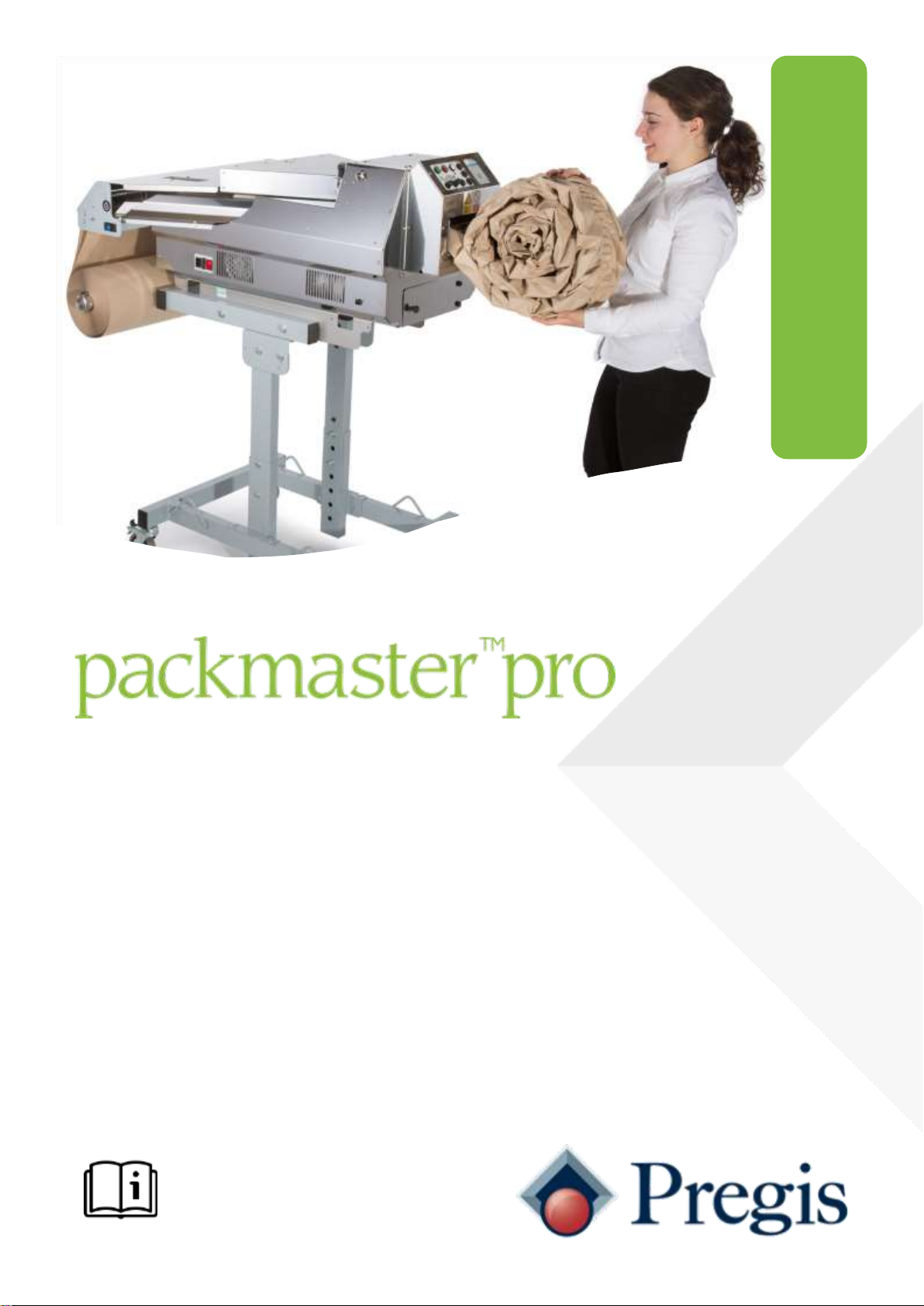

Pregis packmaster pro 383 User manual

Other Pregis Packaging Equipment manuals

Pregis

Pregis Easypack Quantum XT User manual

Pregis

Pregis Quantum Pro 4068969 User manual

Pregis

Pregis SHARP MAX-PRO User manual

Pregis

Pregis SHARP SX User manual

Pregis

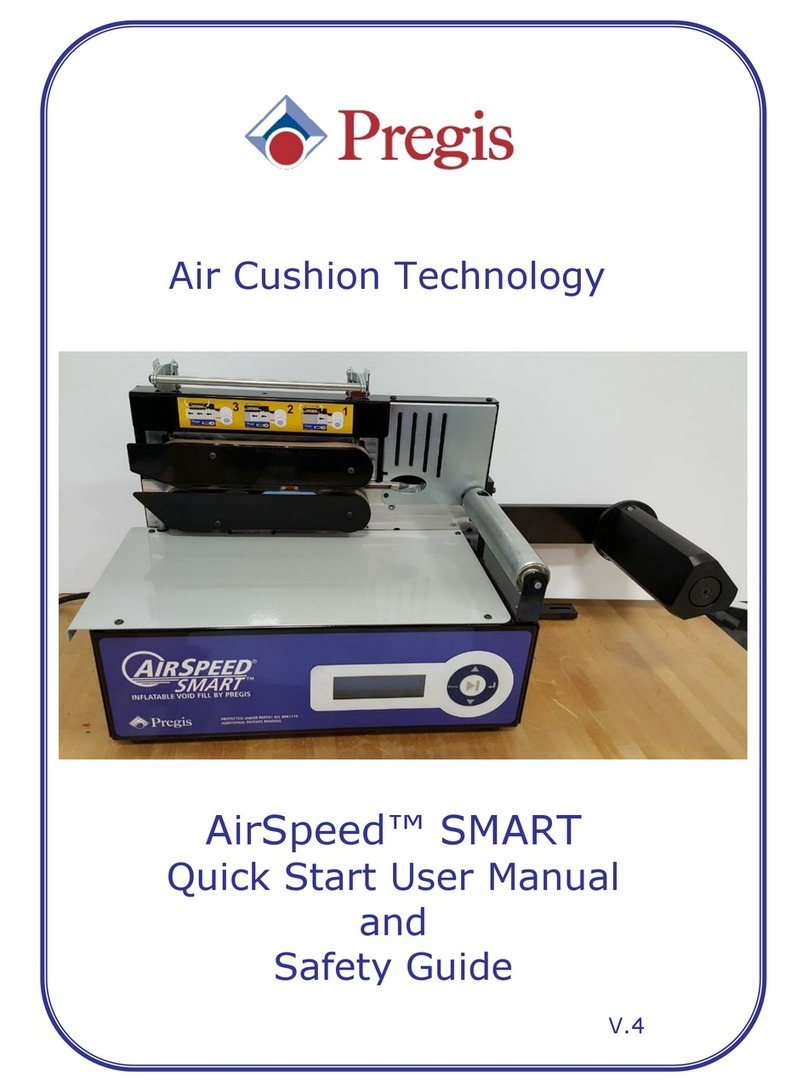

Pregis AirSpeed SMART Installation and operating manual

Pregis

Pregis Easypack coiler-lite User manual

Pregis

Pregis EASYPACK QUANTUM Series User manual

Pregis

Pregis SHARP MAX PRO 18 User manual

Pregis

Pregis SHARP MAX 1143 User manual

Pregis

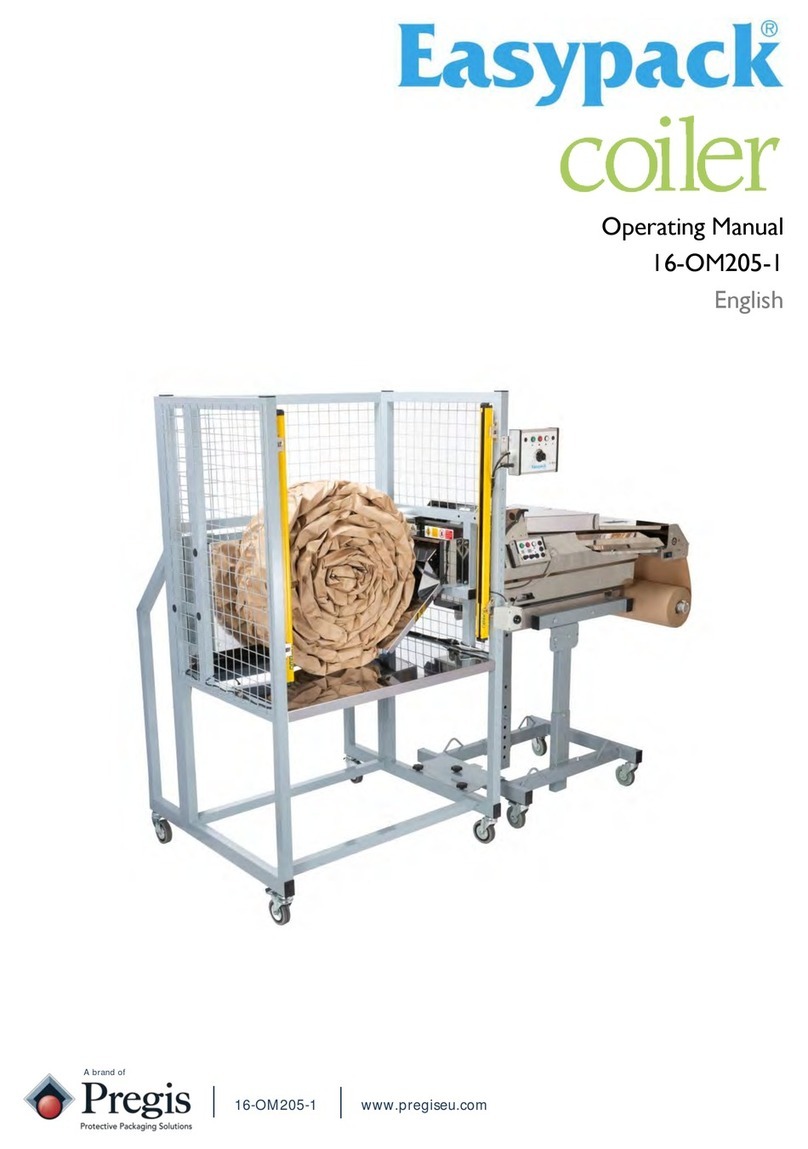

Pregis Easypack Coiler User manual

Popular Packaging Equipment manuals by other brands

AirSaver

AirSaver F2 Safety instructions, setup & installation manual

HUALIAN

HUALIAN M-PE Series Operation manual

Pro Pack Solutions

Pro Pack Solutions Eagle 710 Operation manual

Oliver

Oliver 1808-D User's operation

Kronos

Kronos H-46 Series Operation, safety and spare parts manual

Robopac

Robopac ROBOT S7 Use and maintenance manual