10

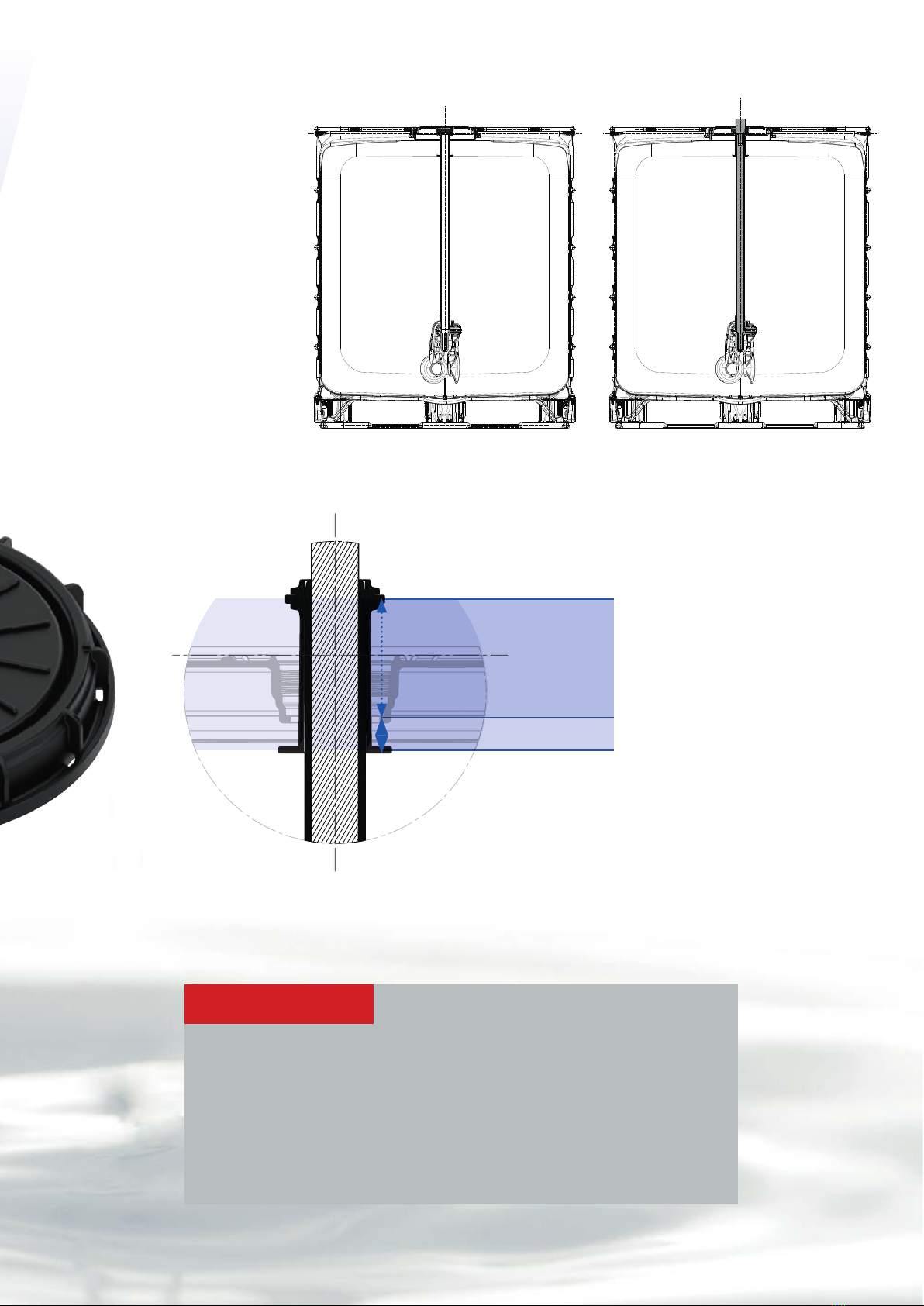

Stirring

The specific viscosity and other properties of the filling product determine the speed

and duration of the stirring process. The optimum speed for each product must be

determined by the user; alternatively, ask the maker of the drive for guidance.

The process data (speed and duration) recorded during stirring with a similar steel

stirrer can be used as a rough guideline.

General instructions:

z The drive should be switched on only when the IMPELLER is fully immersed.

z After switching on the drive, increase the speed gradually and continuously until

the required speed has been reached.

z Depending on the product, the IMPELLER will open even at low speeds of 60 to 80 rpm

after a short time due to the drive forces generated by the stirring process.

z As a rule, but depending on the product, speeds of up to 200 rev/min should be used

in a bucket agitator. If necessary, the SCHÜTZ IMPELLER can be used at speeds of up to

350 rev/min. This speed and a maximum torque of 100 Nm should not be exceeded under

any circumstances (see page 4 for further information on the drive).

z Once the stirring process has been completed the steel shaft can be removed by pulling

it out with a firm tug, and it can be used for the next application.

Stirring processes with flammable liquids with a flashpoint of

(< = 60°C) or in EX zones.

Although IBCs are not constructed to be used as mixing vessels or reaction

containers it may be necessary to homogenize the contents by stirring before filling

or emptying the IBC. As these processes are likely to cause powerful charging the

following precautions should be taken:

z Only use an EX zone compliant IBC.

z Only use an explosion-protected drive unit.

z Only use a conductive, original SCHÜTZ IMPELLER.

z Ensure that the IBC, the drive and the immersed IMPELLER are earthed.

z The rotation speed of the IMPELLER must be limited to 200 rev/min.

INFORMATION FOR EMPTIERS