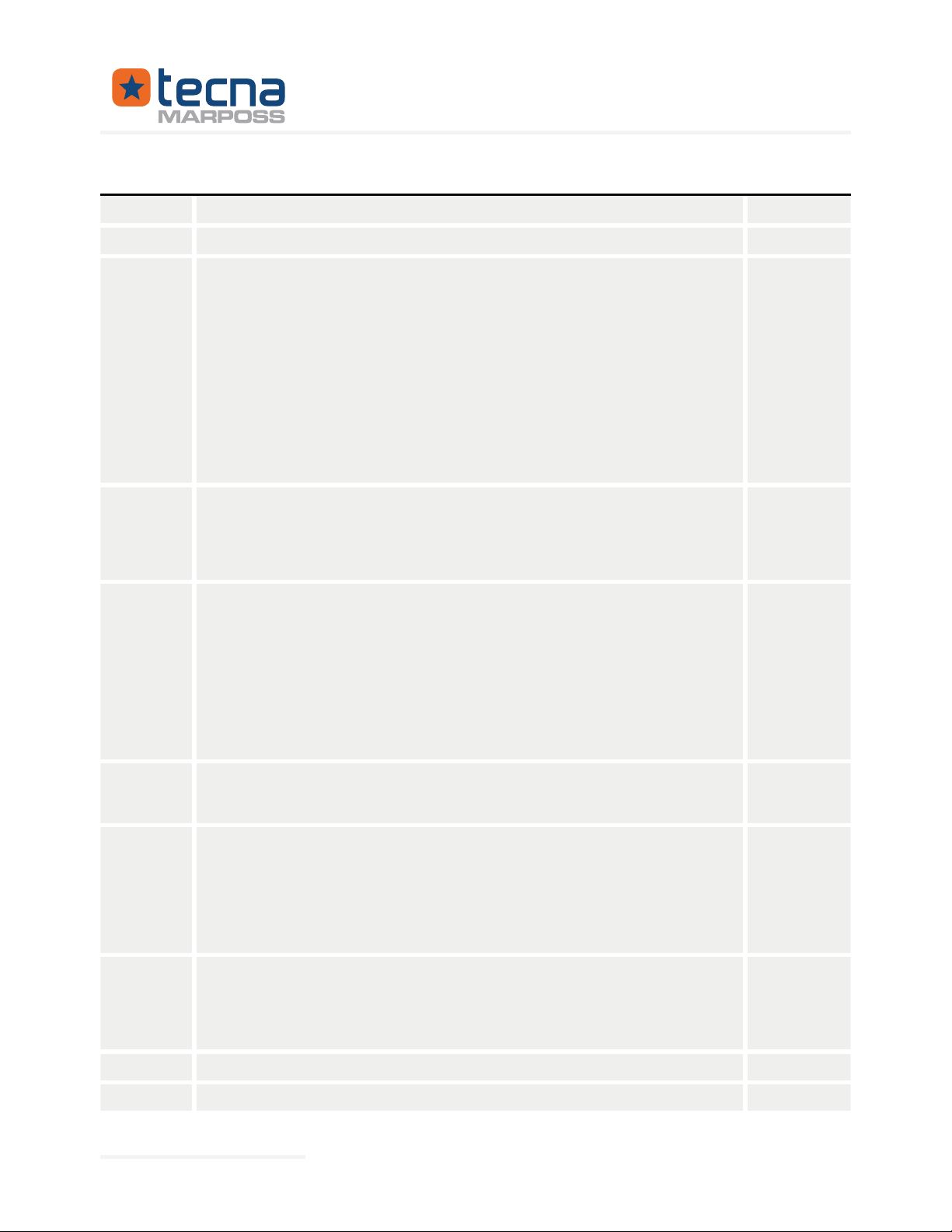

PROVASET T3LPF REV.20210610

2

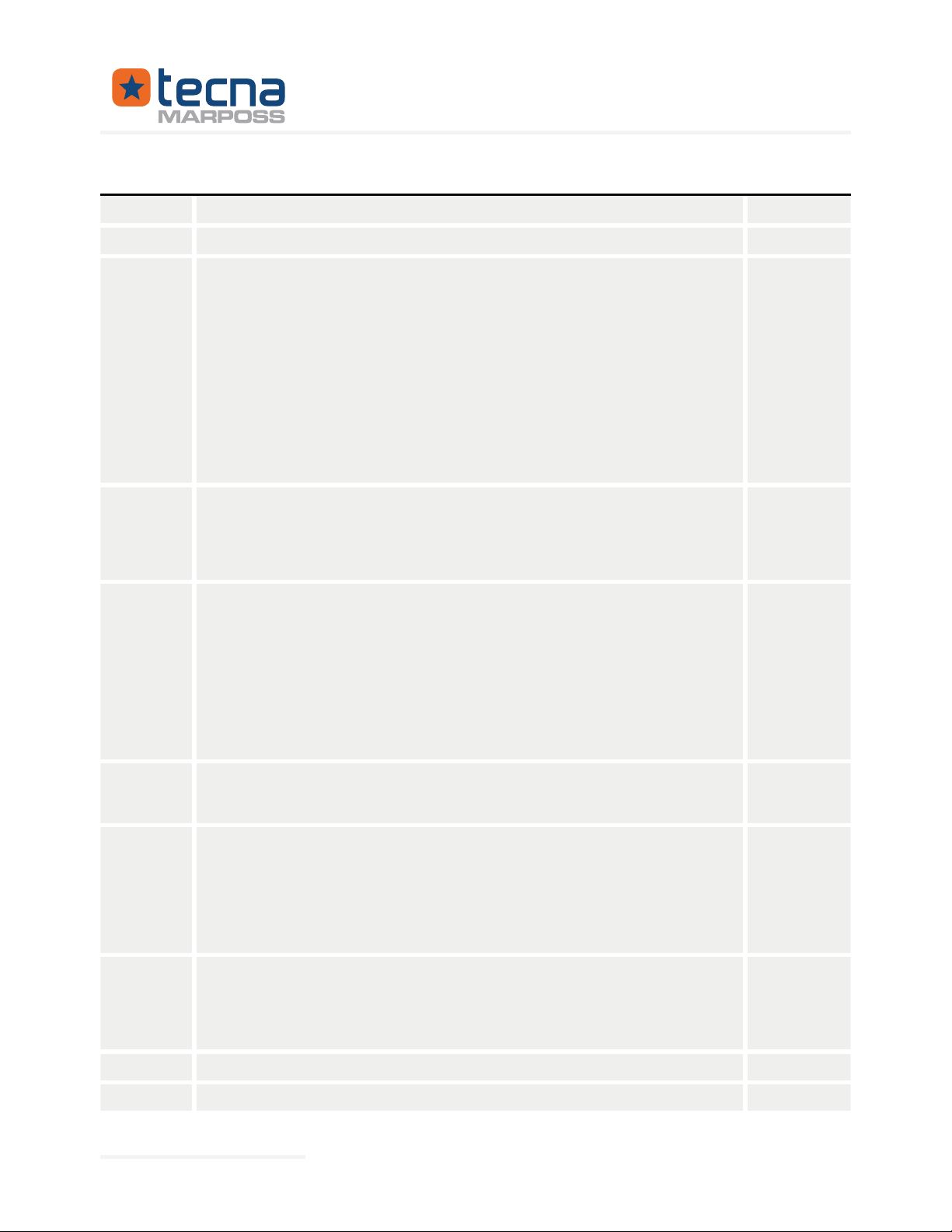

Revision Description Date

20190311 Issued 11/03/2019

20190612 French text update 12/06/2019

20190718

Chapter integration: Firmware Update page 94

Chapter integration: Collection of test data on the pen drive page 82

Paragraph integration: Programmable output parameters (SWPDO option) page

56

Parameter update Set product with: 'Via Ethernet' see Unit: barcode reader

(option) page 70

Paragraph update: Available options page 11

Paragraph update: Flow rate test: PASSED/FAILED result messages page 41

Paragraph update: Leak test: PASSED/FAILED result messages page 50

Paragraph update: Volume+leak test: PASSED/FAILED result messages page 54

Updating of the parameter ‘Enable code database': Unit: barcode reader (op-

tion) page 70

Weight update: Technical data page 96

18/07/2019

20190909

-

tion) page 70

Update products no. and programs no.: Description page 10

Updating of the PRODUCT or TEST PROGRAM selection for each test cycle: Testing

products and programs page 34

09/09/2019

20191015

Chapter integration: Printer page 84

Paragraph update: Barcode associations database group (option) page 72

Program code integration: Test program: name, type of test, mode page 37

board) page 68

Replacement of the term Permeability with Blockage for the English language

version

Constant temperature update: Leak test: leak rate Q page 49

Updating calibration sensor image with LTC Tecna pressure gauge:

Calibration of the relative pressure page 87

15/10/2019

20191204 Update Products / Programs parameter:

Unit: digital inputs page 62

Unit: digital outputs page 64 04/12/2019

20200722

Declaration of Conformity aligned

Update: QLP “Low-pressure" mode 30 mbar and "QLP extra digit" page 39

PN page 41

22/07/2020

20210212

Added paragraph 7.8 Unit: Ethernet (OPTION) page 66

7.9 Unit: Part11 Options(option) page 68

8.2 Utility: Autotest cycle page 77

8.3 Utility: Backup and Restore page 78

Added Leak in pressure per second as measuring scales

12/02/2021

20210505 Added hectoliters to units of measurement selectable 05/05/2021

20210511 Update 7.3 Unit: measuring scales page 62 11/05/2021

Represented By: GTEK AUTOMATION Lake Forest, CA 92630 Ph. 949-680-4242 www.gtek-automation.com