FDU

P. 2 / 2 EM-1428 Rev.5

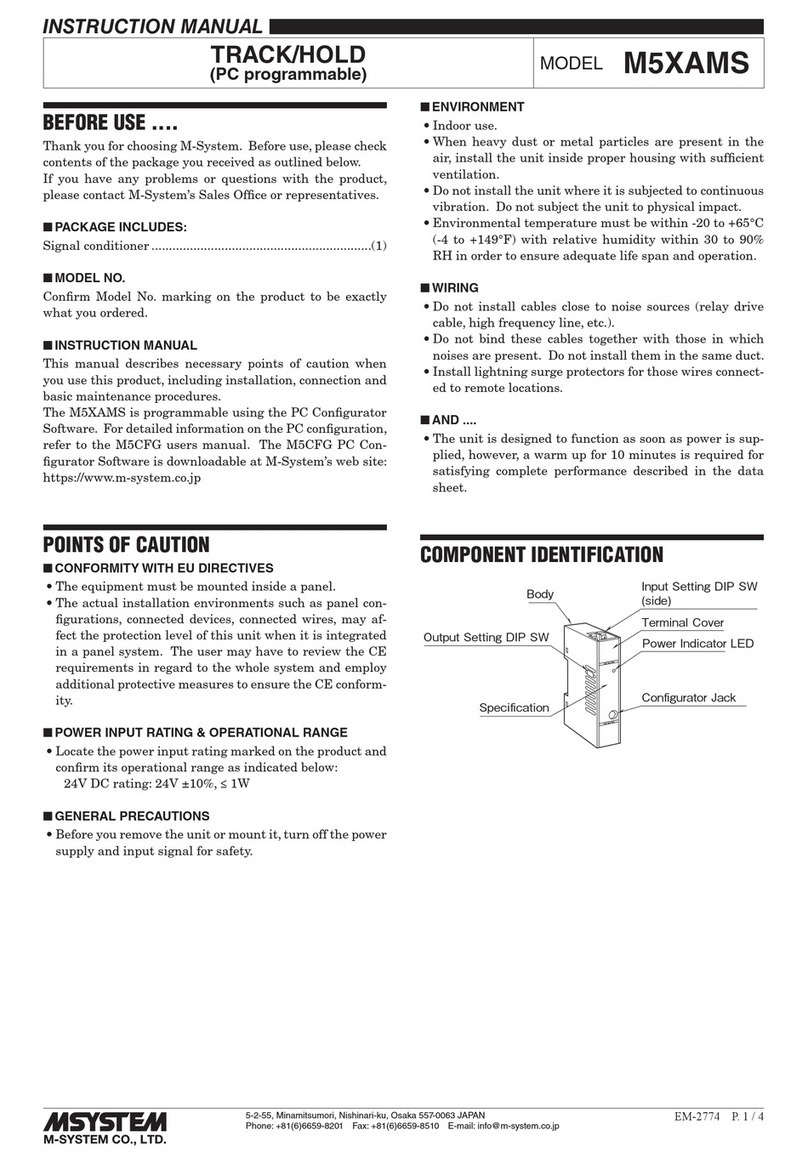

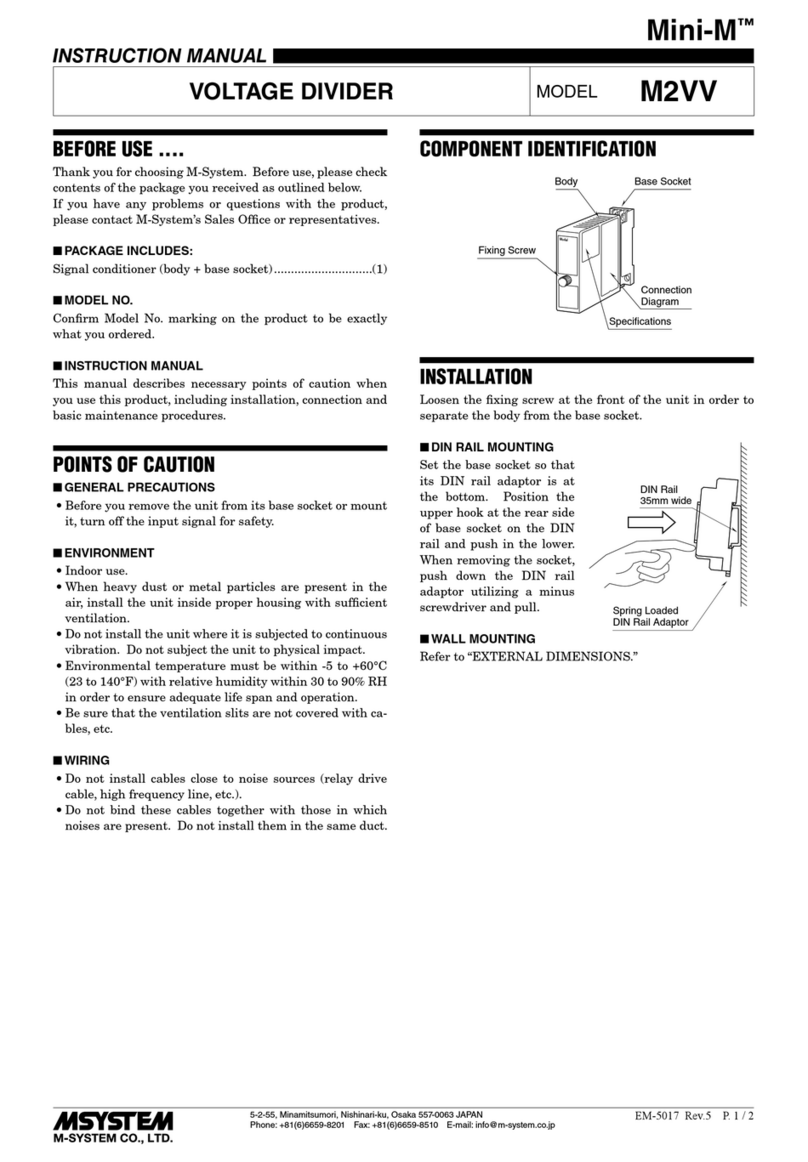

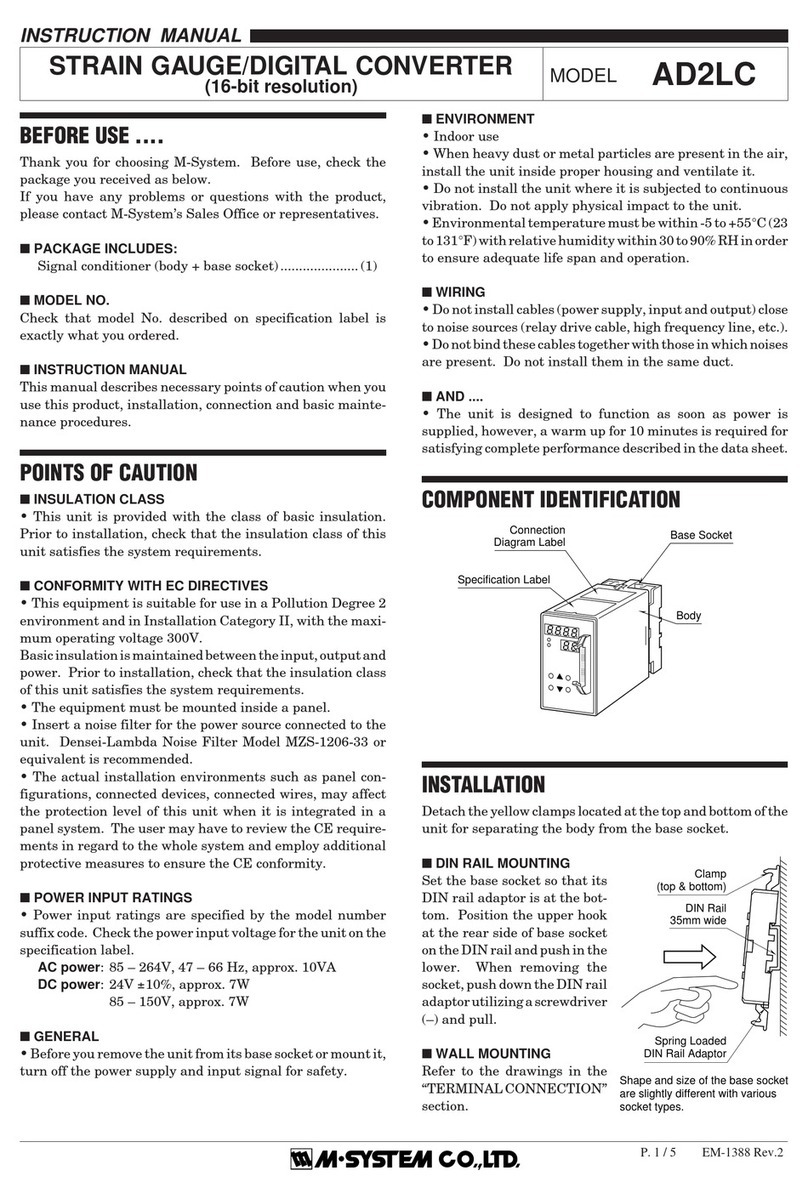

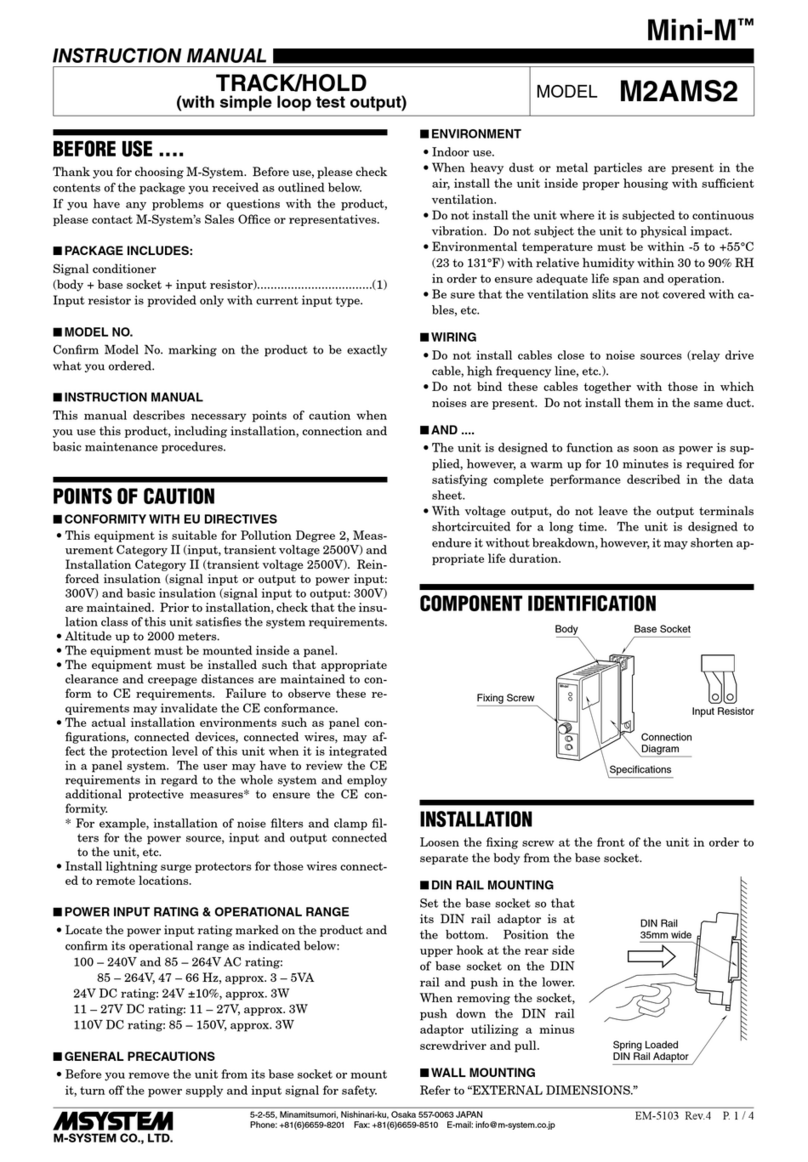

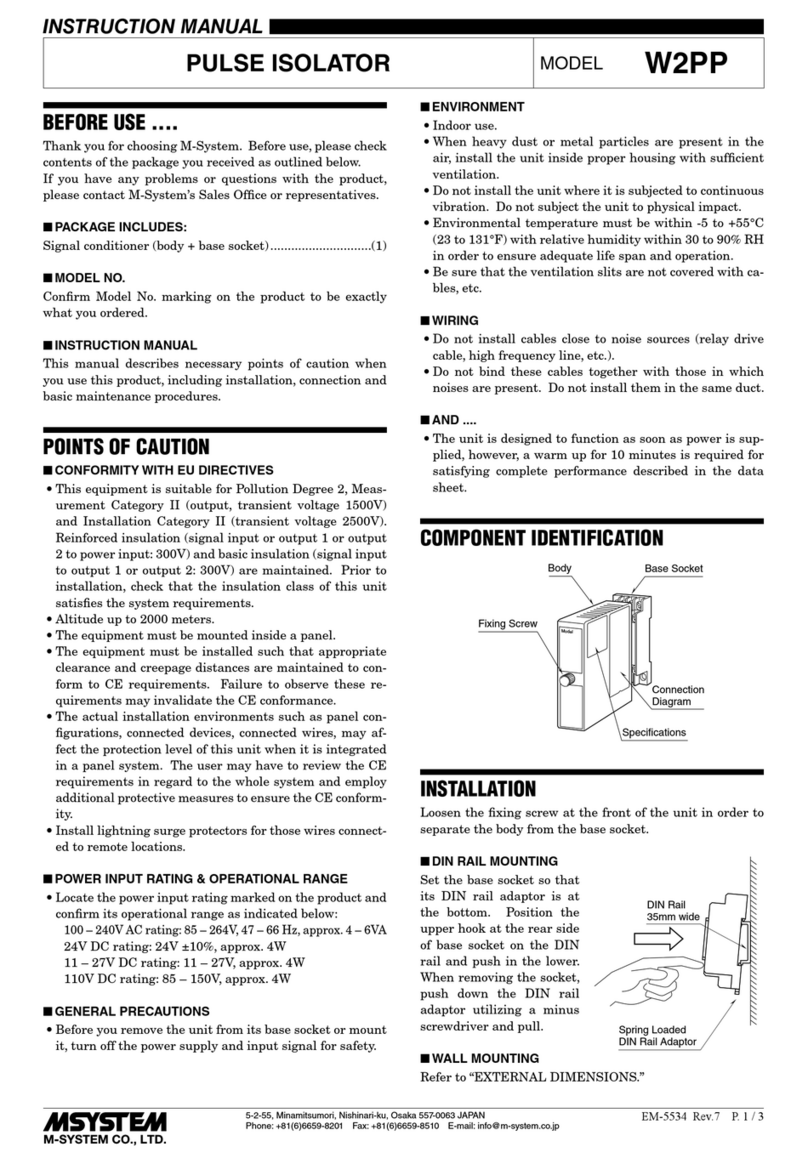

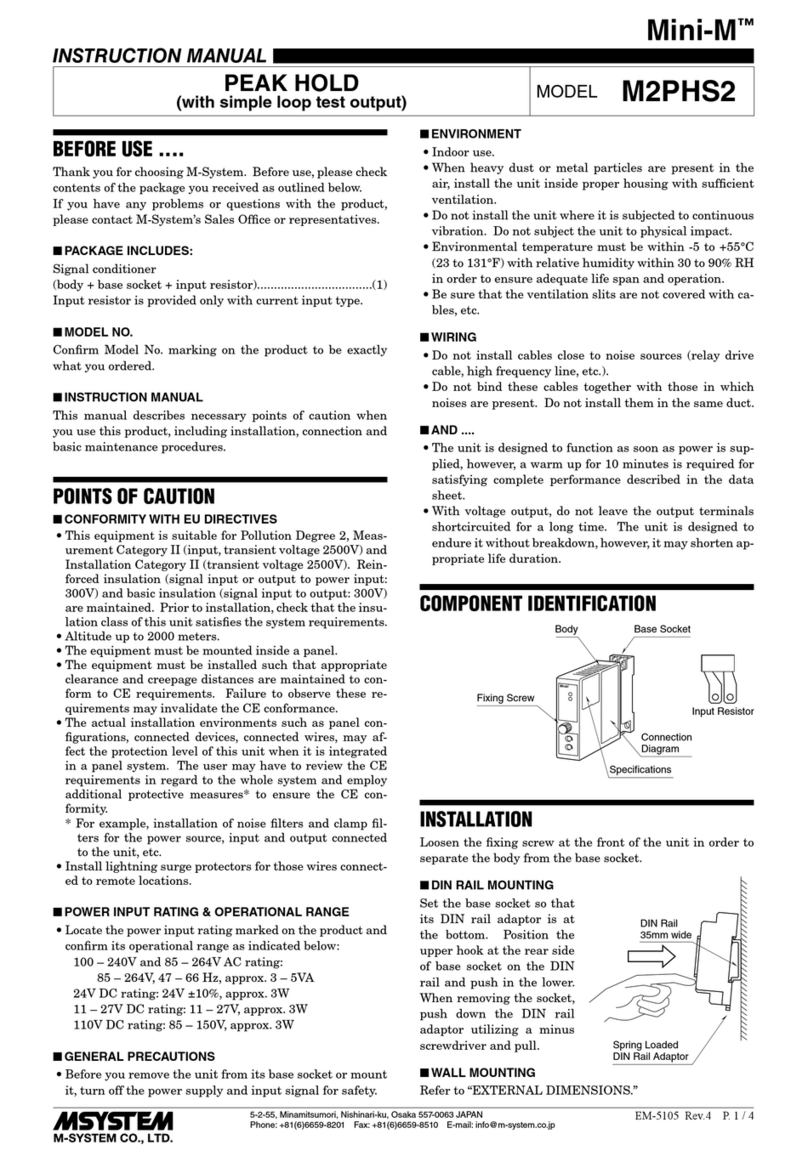

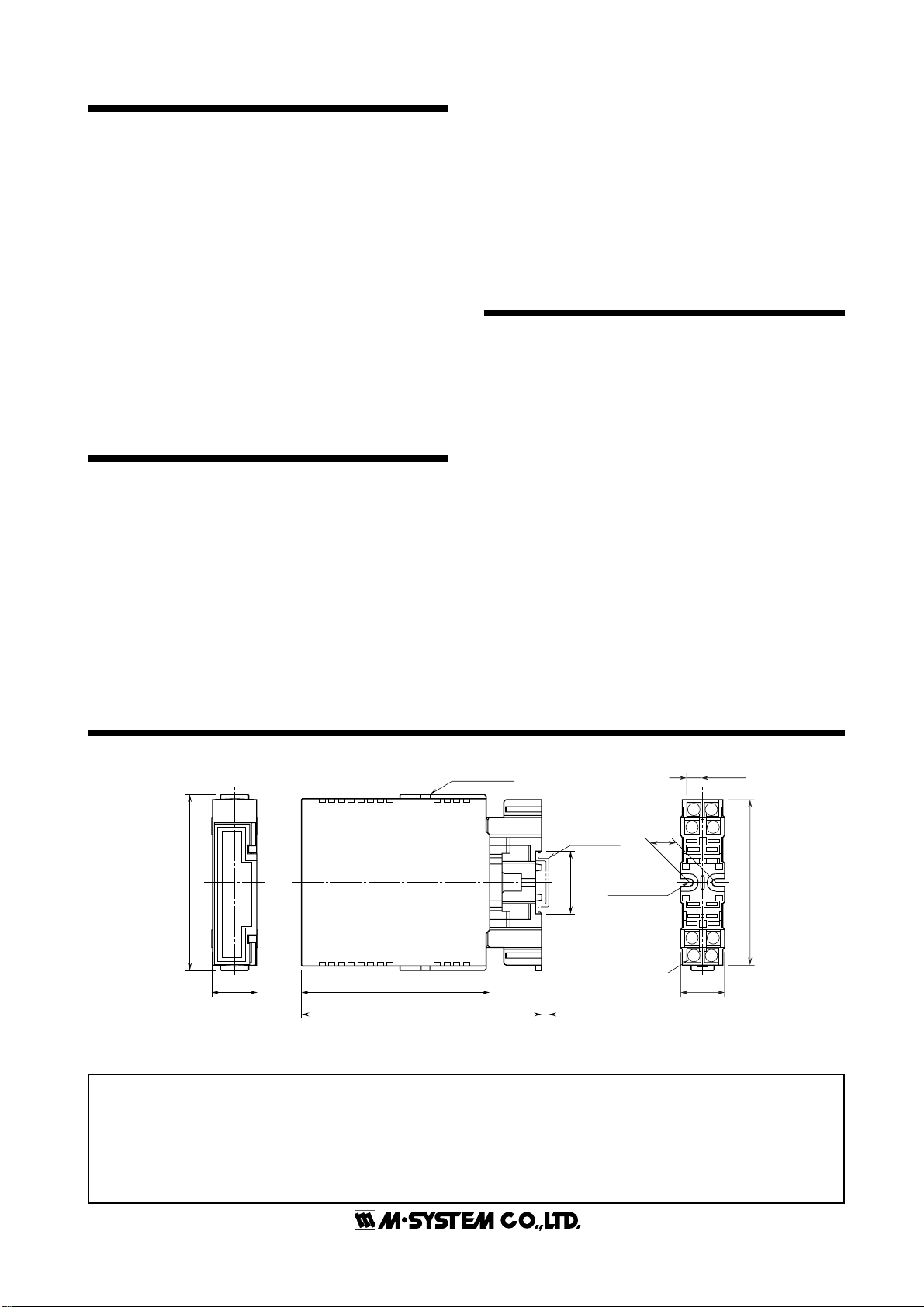

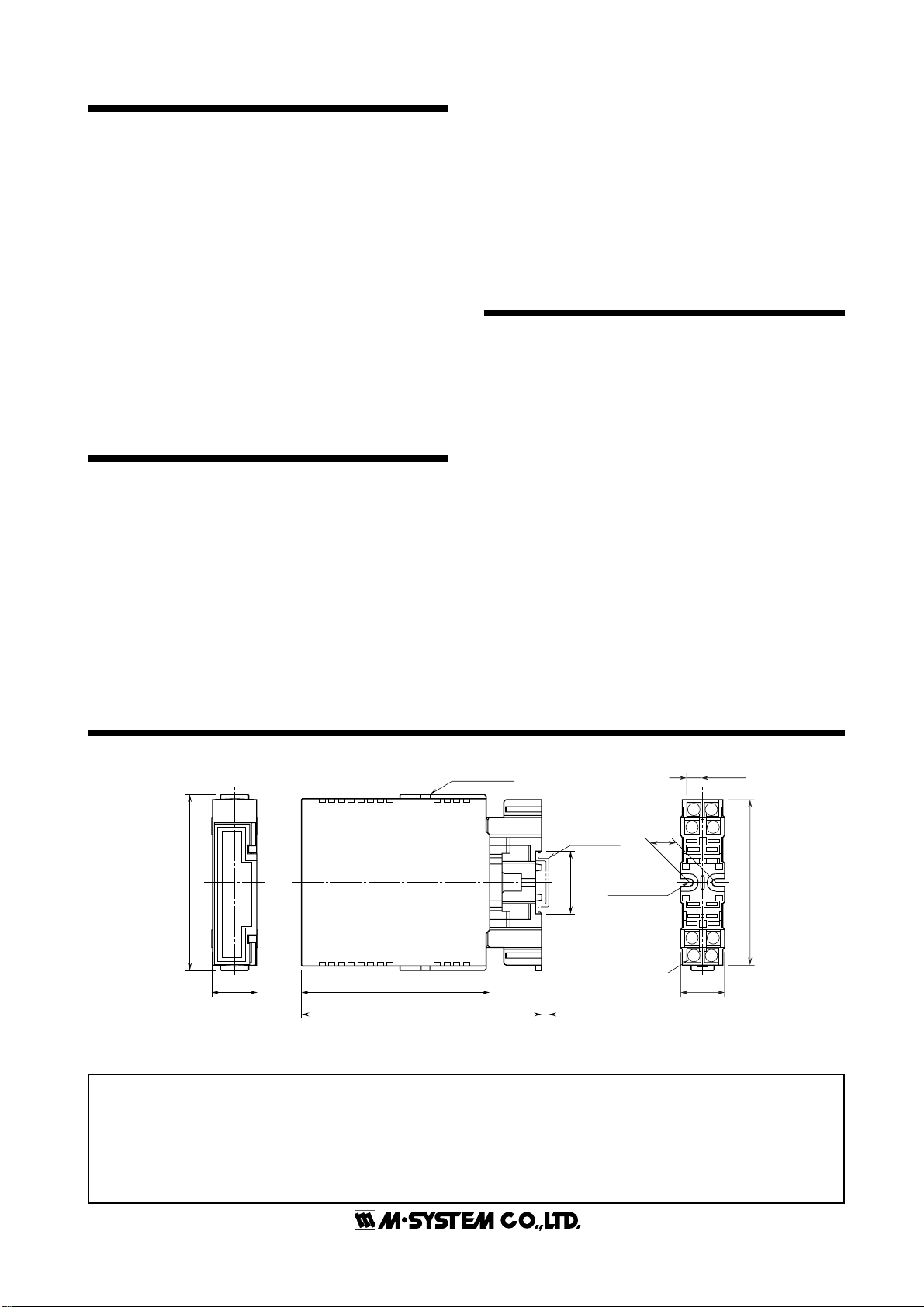

EXTERNAL DIMENSIONS mm (inch)

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any calibra-

tion.

For matching the signal to a receiving instrument or in case

of regular calibration, adjust the output as explained in the

following.

■ HOW TO CALIBRATE THE OUTPUT SIGNAL

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes.

1) ZERO: Apply 0% input and adjust output to 0%.

2) SPAN: Apply 100% input and adjust output to 100%.

3) Check ZERO adjustment again with 0% input.

4) When ZERO value is changed, repeat the above procedure

1) – 3).

POINTS OF CAUTION

■ GENERAL

• Before you remove the unit from its base socket or mount it,

turn off the power supply and input signal for safety.

■ ENVIRONMENT

• When heavy dust or metal particles are present in the air,

install the unit inside proper housing and ventilate it.

• Do not install the unit where it is subjected to continuous

vibration. Do not apply physical impact to the unit.

• Environmental temperature must be within -5 to +55°C (23

to131°F)withrelativehumiditywithin30to90%RHin order

to ensure adequate life span and operation.

■ WIRING

• Do not install cables (power supply, input and output) close

to noise sources (relay drive cable, high frequency line, etc.).

• Do not bind these cables together with those in which noises

are present. Do not install them in the same duct.

■ AND ....

• The unit is designed to function as soon as power is

supplied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data sheet.

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the "ADJUST-

MENT PROCEDURE" explained earlier.

12

34

76

8

5

26 (1.02)

93 (3.66)

15

(.59)

2–4.5 (.18)

HOLE

15 (.59) deep

8–M3.5

SCREW

7.8 (.31)

107 (4.21)

35.4 (1.39)

DIN RAIL

35mm wide

[3.3 (.13)]

CLAMP

(top & bottom)

137 (5.39)

•When mounting, no extra space is needed between units.

26 (1.02)

100 (3.94)

M-SYSTEM WARRANTY

M-System warrants such new M-System product which it manufactures to be free from defects in materials and workmanship during the 36-month period following the date that such

productwasoriginallypurchasedifsuchproducthasbeenusedundernormaloperatingconditionsandproperlymaintained,M-System'ssoleliability,andpurchaser'sexclusiveremedies,

under this warranty are, at M-System's option, the repair, replacement or refund of the purchase price of any M-System product which is defective under the terms of this warranty. To

submit a claim under this warranty, the purchaser must return, at its expense, the defective M-System product to the below address together with a copy of its original sales invoice.

THIS IS THE ONLY WARRANTY APPLICABLE TO M-SYSTEM PRODUCT AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. M-SYSTEM SHALL HAVE NO LIABILITY FOR CONSEQUENTIAL, INCIDENTAL OR

SPECIAL DAMAGES OF ANY KIND WHATSOEVER.

M-System

Co.,

Ltd.,

5-2-55,

Minamitsumori,

Nishinari-ku,

Osaka

557-0063

JAPAN,

Phone:

(06)

6659-8201,

Fax:

(06)

6659-8510,

E-mail:

[email protected]