Tecnodue I.T.S. ST 1200 User manual

I.T.S.

by

Tecnodue

ST 1200

Operating Manual

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

2

This manual includes technical information onl .

I.T.S. Ital Trade Services srl has the right to make an modifications without an notice

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

3

ST 1200

Workshop hydraulic operated saw machine suitable for PE,PP,PVDF and other thermoplastic pipes

I.T.S. Ital Trade Services S.r.l.

Via Scarsellini 77

1 149 – Genova , Italy

Tel: +39-010 42339

Fax: +39-010 423513

E Mail [email protected]

Web Page: www.its-tecnodue.com

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

4

SAFETY RULES

( To be read carefull and appl while utilizing the ST 1200 )

Due to the specific use , this machine cannot be supplied with all kind of fix and removable

protections suitable to avoid any risk of accident.

The machine, therefore, must be utilized, adjusted and keep in the perfect functioning conditions by

skill operators.

Warning - Rules – Obligations

The use of machines composed by electrical components and movable parts , it's always a

potential danger. In order to avoid any kind of accident caused by electrical or mechanical sources

it' strongly suggested to read and follow carefully the following safety rules before operating the

machine.

TRANSPORT

-.

Machine

, Keep the maximum care while moving and it's compulsory to utilize

mechanical aids.

All the accessories supplied with the machine must be moved with the maximum care and it’s

compulsory to utilize mechanical aids.

ELECTRIC CONNECTIONS

The machine is operated by 400 Volts therefore be sure that the power supply plug is supplied with

the safety devices according to the standard requirements , also check that the power supply is

on the range of maximum 10% of the machine's nominal tension.

Check regularly the cables and the plug and in case substitute by qualified personnel.

Before carry out a reparation or maintenance all the plugs must with plug out from the power

Supply. Before opening the case wait at least for 3 minutes after unplugging the machine.

ENVIRONMENTAL CONDITIONS

The working area must be clean and duly lighted.

It's very dangerous to utilize the machine in case of rain or in wheat conditions or even close to

flammable liquids.

CLOTHES

Keep the maximum care while utilizing the machine, it's strongly suggested to use suitable gloves.

Avoid long clothes and avoid bracelets , necklaces that might be hooked into the machine.

CORRECT MACHINE'S OPERATION

Remember to check and read carefully the operating manual before utilizing the machine and

The accessories.

KEEP ALWAYS THE MAXIMUN ATTENTION

Be careful to the blades , it's strongly suggested to use suitable gloves.

During the cutting operation it's forbidden to take out the shavings

Avoid utilizing the machine after drinking or drugs use

Take care that all the people around the machine are at safety distance

ACOUSTIC POLLUTION

The acoustic pollution of the drill engine is less than 85 dB ( value measured at 1 meter distance

from the operator)

Due to some particular cases such as too much pressure during the facing the noise should be

increased , therefore it's suggested to utilize acoustic protections.

IMPORTANT !!!!

Keep the maximum care reading and following the above Warning - Rules - Obligations

Ital Trade Services S.r.l. declines all responsibilities if are not followed totall

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

5

Description

The ST 1200 is designed and fabricated in order to cut pipes in different kind of thermoplastic

materials such as: PP, PE, PVC, and PVDF from diameter 500 mm till 1200 mm

The cutting angle could be changed from 30,0° by means of turning the pipe holder to the left , and

8,0° by means of turning the pipe holder to the right.

The special designed hydraulic clamp hold safety the pipe.

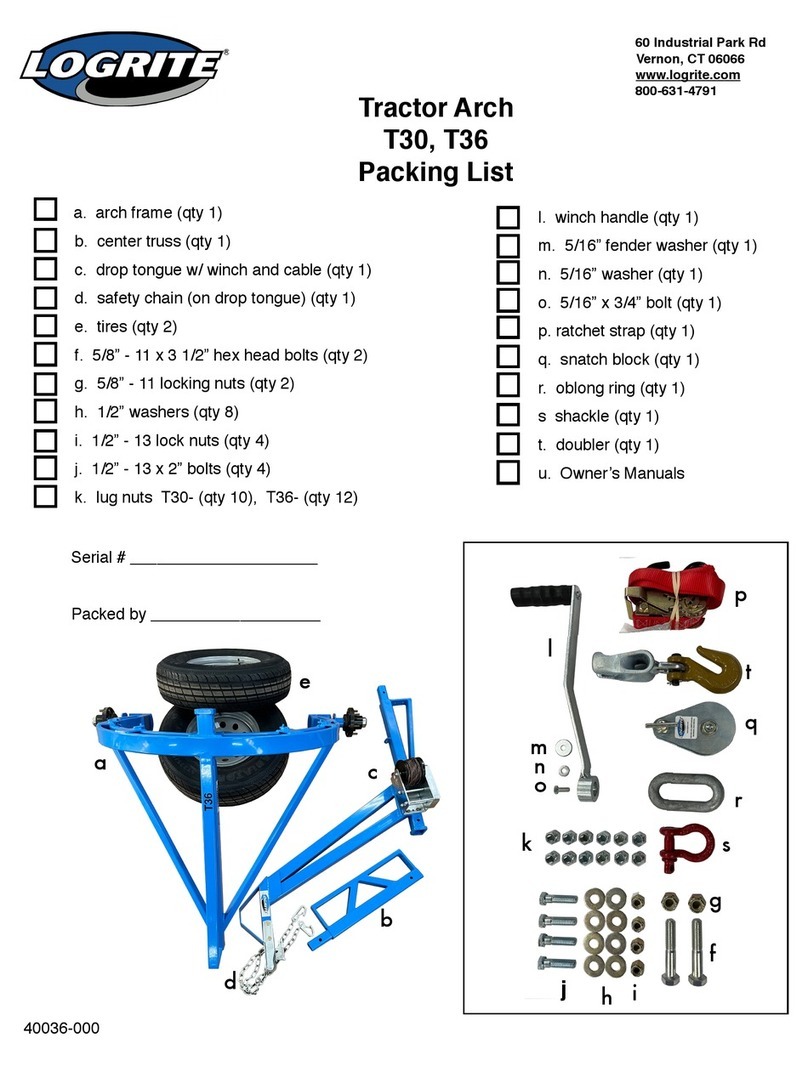

a. Pipe clamp

b. Arch

c. Lifting hook to be used during the arch assembl on the machine

d. Arch guide

e. Warning lamp

f. Blade protecting carter

g. Saw blade stretch adjustment nut

h. H draulic unit

i. Blade’s sliding guide

j. Adjusting angle cut s stem

k. Pipe’s roller

Figure 1. ST1200 components description

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

6

Electric Data

Voltage 400 V (3ph+1 N.+1Ground)

Frequency 50 Hz

Total Power Installed 5 KW 11A IP 54

Saw Blade Engine (2800 rpm) IP 55 4,00 KW

Hydraulic Unit IP 55 0,75 KW

H draulic & Pneumatic Data

Pump's Capacity ,1 l/min

Hydraulic Oil ISO 4

Oil Tank l

Pneumatic pressure requirement 20 bar

Mechanical data

Saw Blade Transmission System Reducing Gear 1/7

Saw Blade Maximum Speed 900 m/min

Arch down stroke speed range 0-3000mm/min

Maximum Cutting Left Angle 30,0°

Maximum Cutting Right Angle 8,0°

Total saw blade length 11700-11850 mm

Z 10 for hard material and small wall thickness

Z for medium wall thickness

Z 4 for big wall thickness

height 32 mm

Dimensions & Weight

Machine 5,10 x 5,20x 3,50 m , 2590 Kg

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

7

a. Machine's installation

In order to avoid any problems and to achieve the best performances from the machine we strongly

suggest to check the surface where the machine will be located. Check that the ground is solid

(concrete floors or other hard material floor are strongly suggested), otherwise take care to reinforce

the points of contact with the footholds of the machine. Check that the soil has a good flatness and

follow the installation procedures:

1. Position on a plane surface the central foot of the

machine

2. Assemble the columns

3. Assemble the crosspiece

4. Assemble the arch

Place two spacers under the arch extremity to maintain a

perfect parallelism of the arch with the ground.

5. Assemble the pipe’s roller

Check that roller is in a flat position, you can act on the

appropriate regulations you can adjust the flatness

. Connect the hydraulic hoses of the machine to the

couplers under the handwheel adjusting the arch down

stroke

Warning: concerning the above steps, the screw must be not too tighten in view to let the

settlement of the various components of the machine

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

8

7. Connect the cable to the power supply, taking care that the two black wires and the

brown one are the phases, the blue wires is the Neutral and the yellow – green is the

ground (Warning: the differential switch

connected to the power suppl main switch could

grant a sensitivit of 300Ma)

8. Connect the power supply cable keeping care that the two black wires and the brown

wire are the phases and the yellow green wire is the ground

9. Switch on the machine by means of acting the main switch

10.

Push the Reset push button

11. Push the Reset button

12. By acting on the selectors “Clamp locked” and “Clamp unlocked” , if the engine turn

but the clamp is not moving it’s necessary invert the two phases on the control board

power cable in order to change the engine rotation

13. By acting on the selectors “Arch Up Stroke” lift the saw arch

14. After making different movement with the arch in view to settle the machine, tighten all

the screws

15. Mount the blade

Unwind the blade (using protecting gloves, keeping care to

avoid any contact with sharp side of the blade) remove the

protecting plates of the arch and position the blade

respecting the direction indicated by the stickers.

Apply the correct tension to the idler pulley.

Manually rotate the main pulley for at least 20 revolutions

checking the tension and that the blade is inside the guide

After checking that there is any person close to the machine, start the engine of the blade

at the minimum speed and check that the blade is running properly.

To better understand this operation check out the chapter e – Blade replacement.

Execute some complete movements with the locking clamp to flush out the air.

The installation of the saw machine 0214 0191 will be done by our technicians. Therefore

the instructions contained in this manual must to be considered as approximate

instructions.

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

9

b. Controls description

All the controls are located on the control panel

1. White light line light

2. Yellow light Blade engine overheating light

3. Yellow light Hydraulic unit engine overheating light

4. Green light Broken or slack blade light

5. Green light Blade case door open light

. Ke selector To select the different sawing mode

7. The blue Light Push Button Safety switches on (Once pushed does not permit the

unsafe start of the saw blade)

8. The White light push button This button resets the machine

9. The Blue Push Button this button locks the clamp

10.The Blue Push Button this button controlling the arch up stroke

11.The Green Light Push Button this button starts the saw blade

12.The Emergenc Push Button this button stops the machine

13.The Black Push Button this button unlocks the clamp

14.The Black Push Button this button controlling the arch down stroke

15.The Red Push Button this button stops the saw blade

1 .Wheel Controlling the blade rotation speed

17.Wheel

Controlling the arch down stroke speed

Figure 2. Control panel

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

10

c. Machine’s operation

01. Turn the pipe’s roller to the required cutting angle (for more details go to page 17)

02. Block the pipe holder by tightening the locking bolt (for more details go to page 13)

03. Insert the pipe into the pipe holder.

04. Block the clamp by pushing the relative push button

05. Adjust the blade’s sliding guide, please be sure that only the blade track used for the cut is

outside the blade’s protection (for more details go to page 17)

0 . Please carefull check that an person is outside the working perimeter of the machine.

07. By acting on the sliding potentiometer adjust the blade rotation speed. This speed depends on

the pipe to be cut.

08. By acting on the wheel adjust the arch down stroke to the minimum.

09. Push the black button for the arch down stroke. The arch will down stroke until when the blade

will be at few centimetres to the upper part of the pipe.

10. Push the blue light button for a safety start of the saw blade. For 5 seconds the machine gave

out an acoustic and light warning to advice that a new cutting cycle is starting.

11. Push the green light button to start the saw blade

Warning: It could happen that during this phase the arch up strikes for a little while before going

down. This is due to the state of the engine.

12. Adjust the down stroke speed by acting on the wheel (no.1 )

13. Once reached the limit stop of the arch the machine automatically stops the saw blade

rotation

14. Remove the cut pipe

15. Push the blue light button to completely lift the saw arch. Please kindly note that If you do not

remove the left pipe from the pipe holder, the photoelectric cells will stop the arch few

centimetres above the pipe.

Some suggestions

•

Keep the blade guides close the external profile of the pipe: this will assure a longer

life to the blade because you will avoid a strong torsion.

•

Keep the clamp in the correspondence of the axis of the pipe.

•

Keep the moveable trolley and auxiliary side rail close to the cutting area

With some cutting angle the trolle s, side rail and blade guide, could collide one against

other. Therefore, during the preparation of the cut, kindl check that on the blade there is

an component of the machine.

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

11

d. Adjustments

1. Rollers

Rollers are bench equipped with rollers that let

the pipe slide.

The picture shows the moveable trolley.

The arrows indicate the pin to remove the

clamp set and the screw locking the trolley

movement.

With the machine is supplied an auxiliary roller,

that can be placed on different positions. This

additional roller is useful to avoid accidental

fall of the pipe on the right side of the

machine.

There is a moveable side rail in view to contain

the cut pipe.

The screw, indicated by the arrow, locks the

side rail.

Note: it is always suggested, for each type of

cut and type of pipe, to use the side rail. The

pipe must always lean on side rail you can

achieve this goal by using the clamp.

The front and back part or the trolley are

equipped with a self-levelling system to

compensate possible height differences of the

floor.

The adjustment must be done by the brass nut

shown by the arrow only during the installation

procedure.

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

12

2. Clamp pressure adjustment

Working with different pipe diameter and

pipe material it could be necessary to

adjust clamp locking pressure.

To adjust this pressure by pushing the blue

button no. 9 (see page 8) act on the wheel

marked as b in the picture on the left.

You can read the pressure on the pressure

gauge a. On the pressure gauge c you can

check the working pressure of the hydraulic

unit.

3. Clamp position adjustment

You can adjust the horizontal

position of the pipe’s clamp by

slacking on the handwheel a to

translate the position of the clamp

and on the handwheel b to rotate

the clamp. Once achieved the

correct position of the clamp

close again the handwheels

Figure 3. H draulic unit

Figure 4. Adjusting the pipe’s clamp

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

13

The pipe’s clamp must work in two

different positions accordingly with the

OD of the pipe to be cut

You must fix the cylinder of the pipe’s

clamp in the hole A to cut pipes in the

range 500-800mm

You must fix the cylinder of the pipe’s

clamp in the hole A to cut pipes in the

range 800-1200mm

In the Figure 5 you can see the holes a

and b to be used to fix the cylinder

To change configuration of the pipe’s clamp cylinder follow this procedure:

Support the pipe’s clamp by using a piece of

pipe as shown in figure

Figure 5. Holes a and b to fix the c linder

Figure 6 .Supporting the pipe’s clamps

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

14

Remove the split pin (see figure 7)

Remove the pin blocking the cylinder’s sliding (see

figure 8). Now the cylinder is free to slide (as per figure

5)

If you need help to move the pipe’s clamp simply push the button no. 9 for locking the clamp. The

cylinder stem will be moved down and centring the hole b will be easier.

Figure 7. Removing the split pin

Figure 8.Removing the pin

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

15

4. Saw Blade Stretch Adjustment

In order to stretch the saw blade it’s

necessary to act on the nut located

on the left side of the arch A. You

can read the stretch value on the

scale B

The machine is supplied with an

alloy blade and you must adjust the

stretch blade between 250 and 300

kgs. Please ask to your supplier the

right stretch to apply to the

purchased blades!

Manually rotate the main pulley for at least 20 revolutions checking the tension and that

the blade is inside the guide.

Close the protecting plates and after checking that there is any person close to the

machine, start the engine of the blade at the minimum speed and check that the blade is

running properly.

Figure 9. Nut regulating the blade stretch

Figure 10. Scale with blade stretch values in kgs

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

16

5. Pulle adjustment

To adjust the idler pulley A act on the screw B. This operation is useful to avoid the coming out of

the blade from the housing. HOWEVER IS STRONGLY DISCOURAGED TO PROCEED WITH THIS KIND

OF ADJUSTMENT, due to the fact that is operation must be carried out during the test by our

technicians.

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

17

6. Adjusting angle cut

The cutting angle could be changed from 30,0° by

means of turning the pipe holder to the left , and 8,0°

by means of turning the pipe holder to the right.

To adjust the cutting angle follows the points here

below:

1) Release the bolt on the graduated scale

2) Turn the pipe holder to the desired position

3) Tighten the bolt on the graduated scale

7. Blade’s Guide and blade protection

Adjustment

In order to maintain the saw blade into the correct

position during the cutting , it’s necessary that the

blade’s guide is adjusted according to the pipe’s

diameter to be cut, therefore the operator to

adjust should act on the screws A and B by loosen

and tighten them.

Figure 11. The blade’s guide

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

18

e. Blade Replacement

In order to replace the blade, the following operations must be carried out:

Disconnect the machine from the power supply

Open the protecting plates

Remove the old blade by loosing the stretch adjusting nut

A and pull out the blade from the housings

Mount the blade into the pulleys respecting the sense

indicted by stickers . Use appropriate garments and gloves.

Rotate the blade and insert it into the blade housing

(check that the broken and slack blade led is switched

off)

Close the protecting plates.

Important!

During this operation ou must wear protective gloves.

The blade’s guides are supplied with two small

wheels to keep the blade in the correct cutting

position. One of the wheels (see X on drawing) is

mounted on an eccentric screw to adjust the beam

of the blade.

Every time you change the blade is better to slack

the screw and after tighten it again to reduce or

eliminate the beam.

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

19

g. Tools to ease the cutting procedure

The machine is supplied with two

tools (see picture and drawings)

to reduce the pipe deformation

during the cutting procedure.

Both tools can be adjusted to

different diameters and cutting

conditions.

Warning: After placing the tools,

double check that the blade will

not interfere with the blade run

inside the pipe.

I.T.S. Ital Trade Services srl ST 1200 Operating Manual

20

h. Maintenance

BASIC MACHINE - ROLLERS

It's strongly suggested to keep always the machine clean with particular care of the cylinder's

stems and sliding bars .

Keep attention while insert pipes on the rollers avoiding to damage the machine's slide bars.

Keep always clean the machine by using compressed air in order to remove material shavings

ARCH

Check weekly the wearing state of the blade and controlling if there are cracks at the base of the

teeth

Monthly, open the protecting plates and remove the shavings.

Grease the trolley of the idler pulley when necessary.

HYDRAULIC UNIT

Check periodically the oil level. If the oil level is under 5 cm from the upper edge of the tank, add oil

by using oil type: EESSO NUTO H 8, MOBIL DTE 2 , SHELL TELLUS 8, AGIP OSO 4 0, ISO 4 .

Keep the hydraulic unit clean.

CONTROL BOARD

Clean the control board only with detergents for electric/electronics components

Keep always clean the electrical part of the machine by using compressed air in order to blow

away dust and dirt. Keep care to gently blow, to avoid any damage to the devices.

Each six months clean the filters of the fans.

GENERAL CONTROL

In case something will happen on the machine or in one component, kindly contact our technical

assistance department.

Warning: Do not use water to clean the machine!!!

Table of contents

Other Tecnodue Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SAMCHULLY

SAMCHULLY HRS-174 instruction manual

PCB Piezotronics

PCB Piezotronics 080A153 Installation and operating manual

AL-KO

AL-KO INDUSTRY Series Operating and installation instructions

PVA

PVA Spectra UV Operation manual

Zepro

Zepro ZHD 3000-150 Installation instruction

Toro

Toro Workman 07224-90001 Operator's, Set-up, and Parts Catalog