CONTENTS

IOM manual active pulsation dampeners 2

EC DECLARATION OF CONFORMITY 01/EC/DT/2016............................................................................. 4

EU DECLARATION OF CONFORMITY 01/ATEX/DT/2016........................................................................ 5

0. GENERAL......................................................................................................................................... 6

0.1. Introduction................................................................................................................................ 6

0.2. Warning symbols ....................................................................................................................... 6

0.3. Qualification and training of personnel................................................................................... 6

1. INSTALLATION ............................................................................................................................... 7

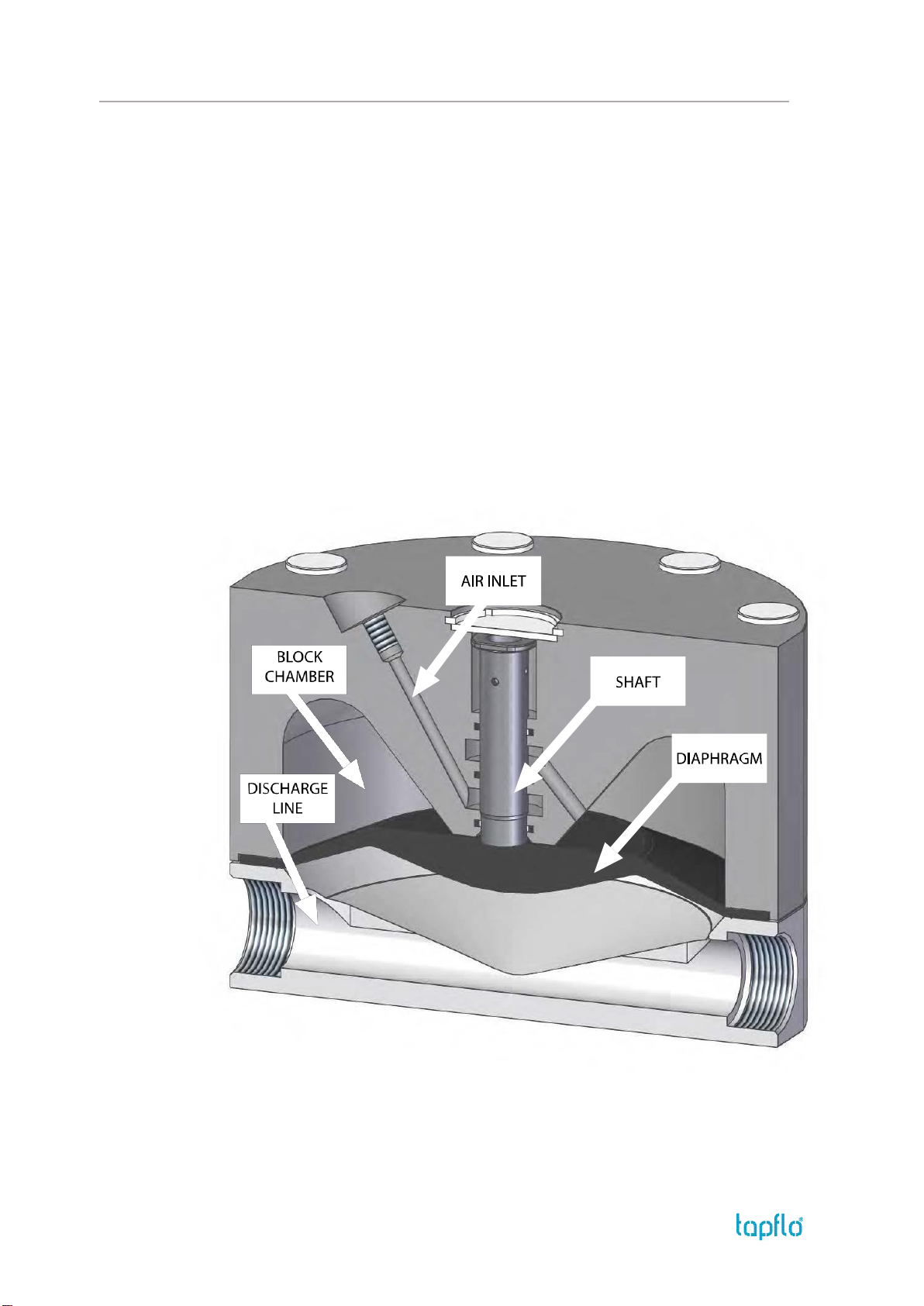

1.1. Operation principle.................................................................................................................... 7

1.2. Receiving inspection.................................................................................................................. 8

1.3. Storage........................................................................................................................................ 8

1.4. Health and safety ....................................................................................................................... 8

1.4.1. Protection ........................................................................................................................... 8

1.4.2. Explosion hazardous environments –ATEX..................................................................... 9

1.4.3. Air pressure......................................................................................................................... 9

1.4.4. Noise level .......................................................................................................................... 9

1.4.5. Temperature hazards....................................................................................................... 10

1.5. Air connection .......................................................................................................................... 10

1.6. Example of installation............................................................................................................ 11

1.6.1. Standard pump................................................................................................................. 11

1.6.2. TF pump ............................................................................................................................ 11

2. OPERATION .................................................................................................................................. 12

2.1. Before operating the dampener ............................................................................................. 12

2.2. Disposal after expiration of the expected lifetime ............................................................... 12

2.3. Actions in emergency .............................................................................................................. 12

2.4. Residual risks ............................................................................................................................ 12

3. MAINTENANCE ............................................................................................................................ 13

3.1. When the dampener is new or reassembled.......................................................................... 13

3.2. Routine inspection ................................................................................................................... 13

3.3. Complete inspection ................................................................................................................ 13

3.4. Location of faults ..................................................................................................................... 14

3.5. Disassembly of the dampener................................................................................................. 15

3.5.1. Before the disassembly procedure ................................................................................. 15

3.5.2. Disassembly procedure.................................................................................................... 15

3.6. Assembly of the dampener ..................................................................................................... 17

3.6.1. Test run ............................................................................................................................. 19