TECNOVAP CARMEN 3400 User manual

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 1

L ' A R T E D E L V A P O R E

CARMEN

Mod. 3400 & Mod. 3400S

1. PREFACE

Dear Client,

We would like to congratulate you in your choice.

With the goal of improving and continually updating production by always offering innovative

products, TECNOVAP has studied, designed and created the CARMEN; a combined machine for

cleaning which brings together the power of steam and the force of vacuuming.

This product, studied in collaboration with 20 years of experience from cleaning experts, is

custom-built and presents itself with an attractive design. It is equipped with a dependable

stainless steel 18/10 boiler which allows it to produce a powerful and consistent supply of steam.

With the power of steam meaning power of ecological cleaning, Tecnovap has combined a

powerful vacuum able to vacuum solids and liquids. The MODEL 3400S, thanks to the new filter

system for dust and dirt, may also be used for air purification.

All of this has been studied so you could have in possession a multi-functional appliance

designed using the most advanced technology with various fantastic possibilities of application

which will last you a lifetime.

Pay careful attention to the following instructions which will be helpful in operating your

CARMEN.

IMPORTANT

BEFORE USING THE STEAM GENERATOR CAREFULLY READ THIS MANUAL IN ALL ITS PARTS

THE MANUFACTURER RESERVES THE RIGHT TO BRING ANY MODIFICATION OR

IMPROVEMENT, TECHNICAL OR STRUCTURAL, WITHOUT PRIOR NOTICE.

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 2

2. TECHNICAL DRAWINGS

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 3

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 4

3. TECHNICAL CARACTERISTICS

3.1. TECHNICAL DATA OF THE STEAM GENERATOR

BODY IN PAINTED STEEL

STAINLESS STEEL BOILER (AISI 304), TÜV Certified

POWER SUPPLY: 230 ÷ 240 V / 50 ÷ 60 Hz

BOILER OUTPUT: 2200 Watt (with electronic power control)

BOILER VOLUME: 4 liters

BOILER CAPACITY: 3 liters

PRESSURE: 4 bar

POWER CORD: 5 meters

SAFETY VALVE CAP, TÜV Certified

3.2. TECHNICAL DATA OF THE VACUUM CLEANER

BODY IN PVC, CAPACITY 5,5 liters

POWER SUPPLY: 230 ÷ 240 V / 50 ÷ 60 Hz

VACUUM OUTPUT: 400 ÷ 1200 Watt (with electronic power regulator)

MODEL 3400: WET/VAC WITH FLOATER

DRUM CAPACITY: 4 liters

DEPRESSION: 2200 mm

AIR FLOW: 200 m_ / h

MODEL 3400S: WET/VAC WITH SEPARATOR AND WATER FILTER

DRUM CAPACITY: 5,5 liters

DEPRESSION: 1700 mm

AIR FLOW: 170 m_ / h

3.3. TECHNICAL DATA OF THE STEAM IRON (OPTIONAL)

POWER SUPPLY: 230 ÷ 240 V / 50 ÷ 60 Hz

POWER OUTPUT: 800 Watt

3.4. TECHNICAL DATA OF THE COMPLETE CARMEN

POWER SUPPLY: 230 ÷ 240 V / 50 ÷ 60 Hz

MAXIMUM POWER: 2.200 Watt

LOW VOLTAGE HAND CONTROLS: 12V

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 5

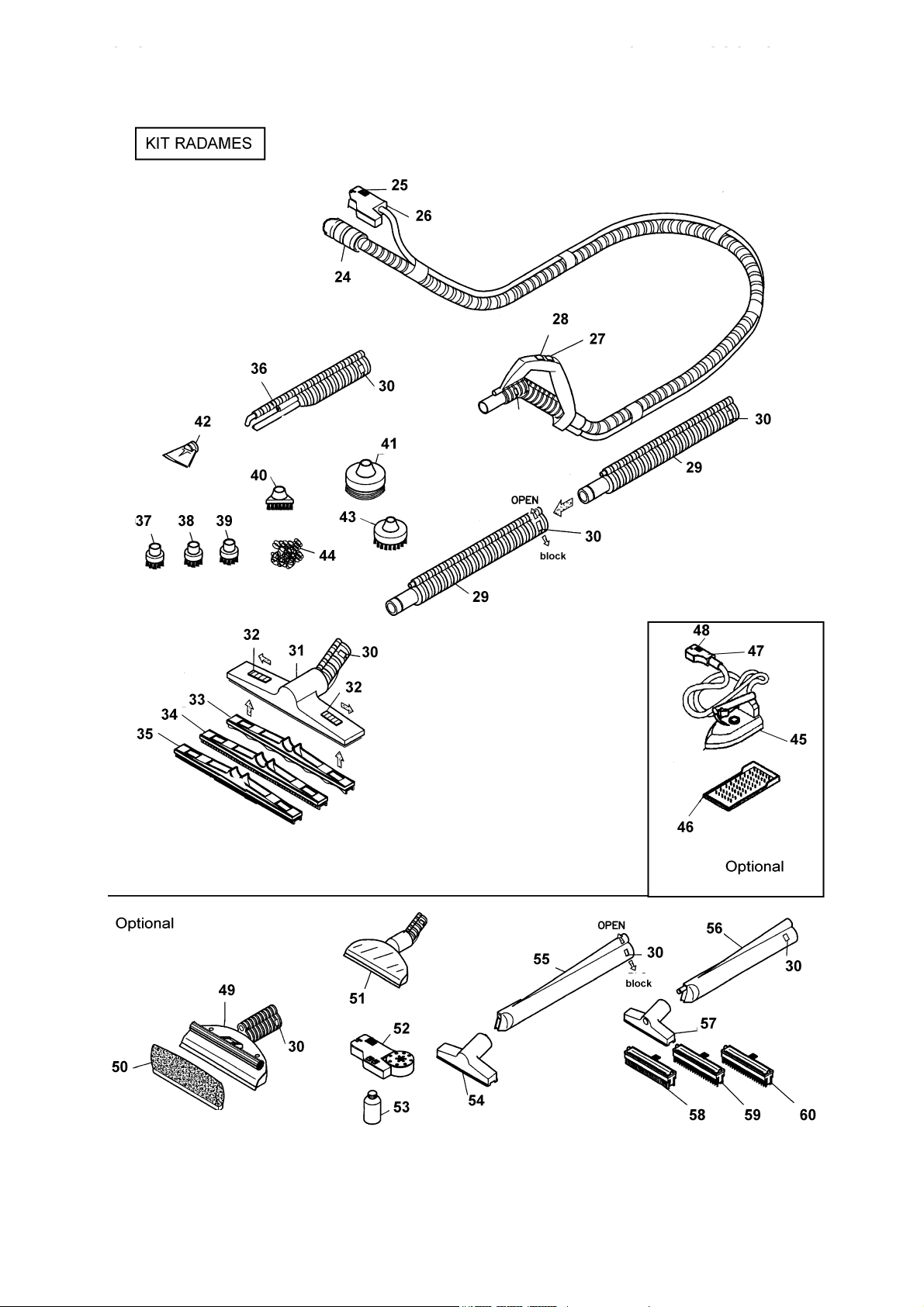

4. NOMENCLATURE

1) Vacuum head with motor

31) Floor tool multiple use

2) Vacuum power switch

32) Latches for blocking inserts

3) Power cord of vacuum cleaner

33) Carpet insert (L.375mm)

4) Variable power control knob

34) Insert squeegee/brush (L.375mm)

5) Vacuum drum in PVC

35) Insert squeegee/squeegee (L.375mm)

6) Latches for vacuum head clamping

36) Turbo lance steam/vacuum

7) Vacuum hose outlet

37) Small nylon brush (Ø 28mm)

8) Hose clamping latch

38) Small brass brush (Ø 28mm)

9) Separator (only model 3400S)

39) Small steel brush (Ø 28mm)

10) Grill protection for separator (only mod.3400S)

40) Small triangular brush

11) Nylon Filter (optional, only model 3400)

41) Steam plunger

12) "Ready steam" indicator (green)

42) Steam scraper

13) Boiler switch

43) Small nylon brush (Ø 60mm)

14) "Low water" indicator (red)

44) Steel wool

15) "Power" indicator “ (green)

45) Professional steam iron (optional)

16) Steam flow regulator Min-Max

46) Rubber rest pad for iron (optional)

17) Safety valve cap of the boiler

47) Steam plug of iron

18) Carrying handle for steam generator

48) Clamping hook of steam plug

19) Filling bottle (750cc)

49) Window cleaner (optional)

20) Electric socket for vacuum cleaner

50) Microfiber cloth for window cleaner (optional)

21) Steam socket

51) Brush for carpet (optional)

22) Drain cap

52) Steamer for steam/vacuum (optional)

23) Power cord of steam generator

53) Nebulizer (optional)

24) Vacuum hose coupling

54) Upholstery nozzle (optional)

25) Clamping hook for steam plug

55) Steam/Vacuum lance (optional)

26) Steam plug

56) Steam/Vacuum lance with nozzle (optional)

27) Steam command switch

57) Perforated upholstery nozzle (optional)

28) Vacuum command switch

58) Insert squeegee/squeegee (L.145mm)(optional)

29) Extension tubes with O-Rings

59) Insert squeegee/brush (L.145mm) (optional)

30) Clamping latches for tubes and accessories

60) Insert brush/brush (L.145mm) (optional)

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 6

5. SAFETY REGULATIONS

IMPORTANT

IT IS RECOMMENDED THAT THE ELECTRIC SUPPLY TO THIS APPLIANCE SHOULD

INCLUDE EITHER A RESIDUAL CURRENT DEVICE THAT WILL INTERRUPT THE SUPPLY

IF THE LEAKAGE CURRENT TO EARTH EXCEEDS 30Ma FOR 30Ms OR A DEVICE, WHICH

WILL PROVE THE EARTH CIRCUIT.

WARNING

-PRESSURE JETS CAN BE DANGEROUS IF SUBJECT TO MISUSE. THE JET MUST NOT

BE DIRECTED AT PERSONS, LIVE ELECTRICAL EQUIPMENT UNDER PRESSURE, OR

THE APPLIANCE ITSELF.

-STEAM CLEANERS SHALL NOT BE USED BY CHILDREN OR UNTRAINED

PERSONNEL.

-TO ENSURE THE APPLIANCE SAFETY, USE ONLY ORIGINAL SPARE PARTS FROM

THE MANUFACTURER OR APPROVED BY THE MANUFACTURER.

-ENSURE THAT THE ELECTRICAL INSTALLATION IS EQUIPPED WITH AN EARTH

DEVICE.

-IF NECESSARY, THE POWER CORD MAY BE REPLACED ONLY BY AUTHORISED

PERONNEL OR SERVICE CENTER.

-FILL THE BOILER WITH CLEAN WATER ONLY. DO NOT ADD DETERGENTS OR

CHEMICAL PRODUCTS.

-PRESSURE HOSES, FITTING AND COUPLINGS ARE IMPORTANT FOR THE SAFETY OF

THE APPLIANCE. USE ONLY HOSES, FITTINGS AND COUPLINGS RECOMMENDED BY

THE MANUFACTURER.

-DO NOT USE THE APPLIANCE IF THE POWER CORD OR OTHER IMPORTANT PARTS

OF THE APPLIANCE ARE DAMAGED, I.E. SAFETY DEVICES, PRESSURE HOSES AND

TRIGGER GUN.

-IF AN EXTENSION CORD IS USED THE PLUG AND SOCKET MUST BE OF

WATERTIGHT CONSTRUCTION. INADEQUATE EXTENSION CORDS CAN BE

DANGEROUS.

-DO NOT DISASSEMBLE THE ACCESSORIES WHILE THE MACHINE IS SUPPLYING

STEAM.

-DO NOT OPERATE ELECTRIC APPLIANCES WITH WET HANDS.

-NEVER TURN THE MACHINE OVER OR ON ITS SIDE DURING USE.

-FAILURE TO OBSERVE THE REGULATIONS LISTED ABOVE WILL RENDER THE

MANUFACTURERS WARRANTY NULL AND VOID ON THE ENTIRE APPLIANCE.

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 7

6. USING INSTRUCTIONS

OPERATING THE CARMEN WITH THE KIT RADAMES

(a) Unscrew the boiler cap (17) and fill the boiler with the filling bottle (19). The bottle holds

approx. 75 cc of water and the boiler capacity is of about 3 liters. Screw on the safety valve

cap (17) correctly.

(b) Lift the vacuum head (1) from the drum (5) and clamp in place using the latches (6). Pour

approx. 1 liter of clean water in the drum making sure that the water level is sitting higher

than the lower part of the internal air intake tube. Reposition the vacuum head (1) onto the

drum (5) and clamp in place using the latches (6).

(c) Insert the electric plug of the vacuum cleaner (3) into the socket (20) found on the back of the

steam generator. Insert the power cord (23) from your CARMEN in an electric outlet making

sure that the voltage and amperage correspond to those found on the rating plate (located

underneath the unit and listed as well in section 3 of this manual). The presence of electrical

power is indicated by the green indicator light (15).

(d) Insert the steam plug (26) of the Radames steam/vacuum hose into the steam socket (21),

ensuring that the clamping hook (25) correctly locks into place. Then insert the vacuum hose

coupling (24) into the vacuum hose outlet (7) found on the vacuum drum (5). Ensure that the

hose clamping latch (8) has secured the hose coupling and verify that the vacuum switch (2)

is in the "ON" position. The hand grip switches (27 and 28) are switc hed "OFF".

(e) Activate the main power switch of the boiler (13). Wait approximately 3 minutes for each liter

of water added to the boiler allowing the steam generator to reach operating pressure.

Operating pressure is reached when the green "ready steam" indicator (12) lights up.

(f) Your CARMEN is now ready for use. Choose the accessory best suited for the cleaning task

and connect to the steam/vacuum hose taking particular attention to secure the accessories

with the clamping unit in "BLOK" position (30).

To clean with the combination of steam and vacuum use one of the following accessories

most suitable for the task at hand:

Floor tool (31) with ideal insert (33,34,35). The various inserts are locked into place by sliding

the latches (32) to the "OPEN" position and hold the insert in place applying a little pressure

while sliding the latches in "BLOK" position. Remember that the command switches (27 and

28) on the handgrip should be in the "OFF" position.

Turbo lance steam/vacuum (36) to be used by itself or with the small brushes (37-43).

If necessary, attach the extension tubes (29) and lock them in place using the clamping units

(30) in "BLOK" position. It is possible to apply one extension only.

(g) To regulate the steam flow operate the steam ajustment knob (16) found on the steam

generator. To regulate the vacuum air flow operate the adjustment knob (4) situated on the

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 8

vacuum head (1). Activate the command switch (27) for steam flow and command switch (28)

for vacuum power found on the hand grip.

(h) Model 3400: The vacuum head (1) is equipped with a floater which stops the air flow when

the water has reached its maximum level in the vacuum drum (5). The appliance looses

suction power and there is a change in the noise of the motor.

Model 3400S: Also on this model, equipped with a separator, there is a loss in suction power

and a change in the noise of the motor when the water has reached its maximum level in the

vacuum drum (5).

(i) Turn off the vacuum power switch (2) and unplug the power cord (3). Lift the vacuum head

(1) from the vacuum drum (5) by releasing the latches (6) and empty the drum making sure to

have detached the vacuum hose (24) before. If necessary rince the drum and refill it as

described in step (b) of this section.

(j) When the red "low water" indicator (14) lights up, turn off the main power switch (13) of the

boiler and unplug the power cord (23) from the main current. Wait until the residual pressure

in the boiler decreases and permits you to remove the boiler cap (17). At this point you can

proceed with refilling the boiler as described in step (a) of this section. Warning: the boiler

cap, for safety purposes, does not permit removal with pressure inside the boiler.

(k) Once the cleaning task terminated, it is recommended to vacuum approximatively 4 liters of

clean water to rince internally the flexible hose and the vacuum tubes. Extract the vacuum

drum (5) and after having it emptied and rinced, let it dry in a well-aired place.

7. MAINTENANCE

7.1. MAINTENANCE OF THE STEAM GENERATOR

IMPORTANT

-SWITCH OFF THE ELECTRIC SUPPLY BEFORE PROCEEDING TO THE USER'S

MAINTENANCE.

-IT IS RECOMMENDED CLEANING THE BOILER ONLY WHEN THE MACHINE HAS

COOLED DOWN (FOR AT LEAST 5 HOURS).

ELIMINATION OF SCALE DEPOSITS FROM THE BOILER

We suggest cleaning the boiler after every 200 hours of use, or also if the machine produces

water or dirty steam.

Unscrew the boiler cap (17) and fill with clean water. Position the machine over a recipient

container and remove the boiler drain cap (22) located underneath the machine. Pieces of scale

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 9

could block the drain opening. In this case, a screwdriver can be used to free the outlet. Once the

water has drained replace the drain cap (22) and fill again the boiler with clean water. Repeat the

operation 2-3 times.

At this point the maintenance of the boiler is complete and your CARMEN is now ready for use.

7.2. MAINTENANCE OF THE VACUUM CLEANER

MODEL 3400S: Cleaning the separator

An operation to be done whenever the vacuum cleaner shows indications of vibrating during use

caused by dirt deposited on the separator unbalancing the alignement of the separator.

(a) Unhook the vacuum head (1) from the drum (5) using the latches (6).

(b) Remove the grill protection (10) turning it counter clockwise.

(c) Unscrew the locking nut and remove the separator (9).

(d) Proceed with cleaning the piece with a small brush or with steam using the turbo lance

steam/vacuum included.

(e) Remount the separator (9) making sure it fits correctly in the given slot.

(f) Screw on the locking nut and the grill protection (10).

The vacuum cleaner MODEL 3400 does not require any specific maintenance.

7.3. MAINTENANCE OF THE ACCESSORIES

Lubricate the joints of the tubes and accessories from time to time with a lubricating grease.

TECNOVAP CHATTANOOGA CARMEN

PAG. N. 10

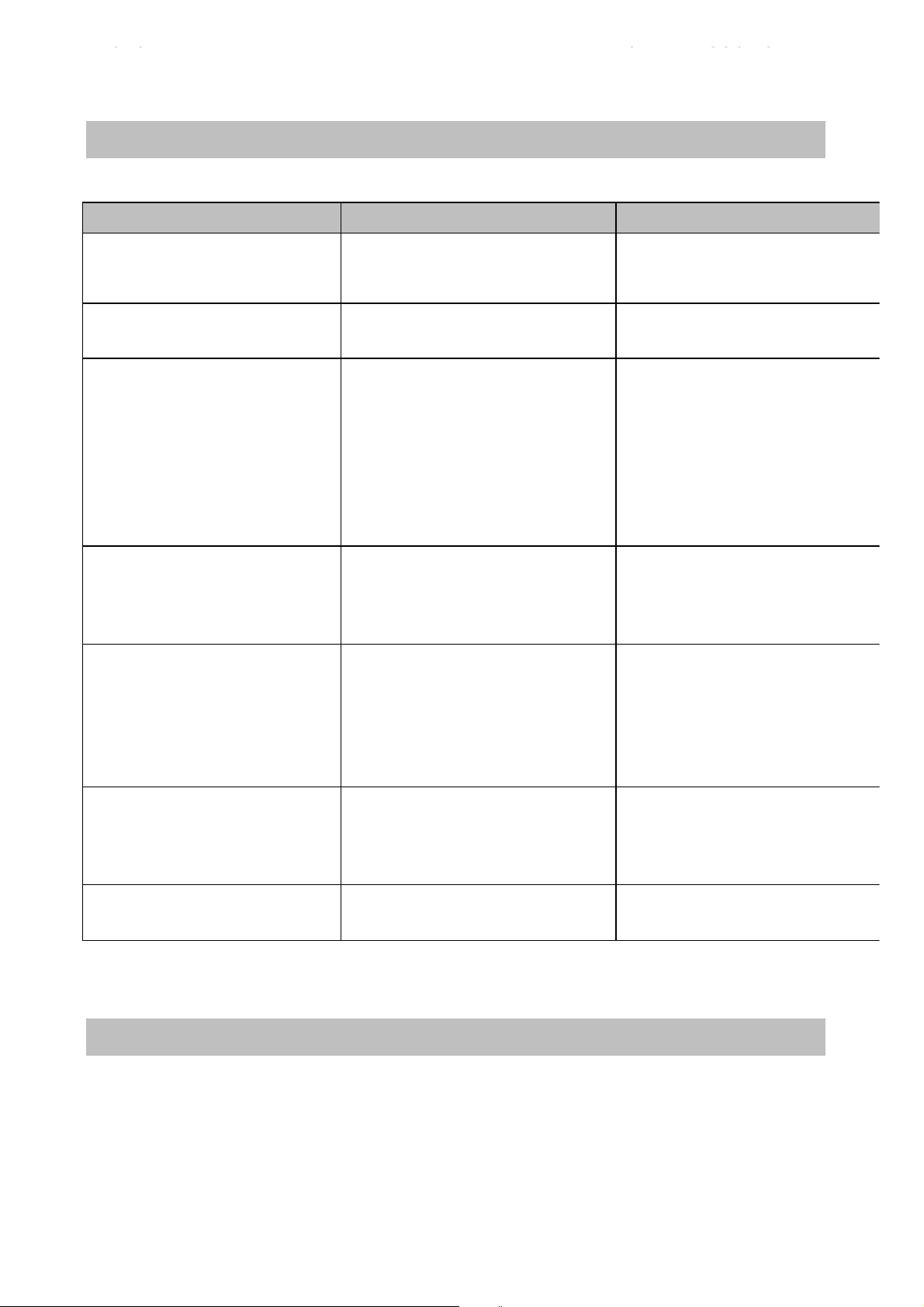

8. BEFORE REFERRING TO TECHNICAL ASSISTANCE

PROBLEMS

POSSIBLE CAUSES

REMEDY

APPLIANCE DOES NOT PRODUCE

STEAM AND VACUUM DOES NOT

WORK.

LACK OF POWER.

MAKE SURE THE PLUG IS WELL

INSERTED (23) AND THE POWER SWITCH

OF THE HOUSE IS TURNED ON.

THE RED "LOW WATER" INDICATOR

(14) LIGHTS UP.

ALL THE WATER HAS BEEN CONSUMED.

REFILL THE BOILER (17) WITH CLEAN

WATER (MAX 3 LITERS).

SUCTION POWER IS MISSING.

A) THE VACUUM TUBE IS

OBSTRUCTED.

B) THE VACUUM DRUM (5) IS FULL OF

WATER.

C) LACK OF POWER TO THE VACUUM

CLEANER.

A) CLEAN TUBE AND ACCESSORY

USED.

B) EMPTY THE VACUUM DRUM (5).

THEN REFILL IT WITH APPROX. 1

LITER OF CLEAN WATER.

C) MAKE SURE THE SWITCH (2) IS "ON"

AND THE PLUG (3) IS WELL

INSERTED.

WATER LEAKS THROUGH THE

CONNECTIONS OF THE

ACCESSORIES.

CHECK THE WEAR OF THE O-RING.

CLEAN AND LUBRICATE THE O-RING

WITH GREASE.

IF NECESSARY, REPLACE WITH ONE OF

THE SPARES SUPPLIED.

STEAM DOES NOT COME OUT.

A) BOILER HAS NOT YET REACHED

THE OPERATIONAL PRESSURE

(GREEN LIGHT (12) IS STILL OFF).

B) STEAM REGULATOR (16) IS OFF.

A) WAIT A FEW MINUTES.

B) TURN THE STEAM REGULATOR (16)

ON (TO THE LEFT).

DROPS OF WATER COME OUT OF THE

ACCESSORIES.

AT BEGINNING OF WORK WATER

CONDENSES IN THE TUBES AND

ACCESSORIES DUE TO THE

DIFFÉRENCE IN TEMPERATURE.

AFTER A FEW MINUTES OF USE THIS

PROBLEM WILL CEASE.

IF IT CONTINUES, PROCÉED TO THE

CLEANING OF THE BOILER.

ACCESSORIES DO NOT FIT

PERFECTLY.

THERE IS DIRT BUILD UP IN THE JOINTS

AND LOCK/RELEASE LATCHES (30).

CLEAN AND LUBRICATE THE JOINTS OF

THE ACCESSORIES.

9. CERTIFICATIONS AND HOMOLOGATIONS

CE

MACHINE MANUFACTURED ACCORDING TO THE EUROPEAN NORMS

EN 6335-2-3+A1+A52, EN 60335-2-79, EN 55014, EN 61000-3-2, EN 61000-3-3.

TECNOVAP CHATTANOOGA CARMEN

PAG N. 11

10. SOCIETY TECNOVAP

10.1. CERTIFIED QUALITY SYSTEM ISO 9002

10.2. ASSOCIATED AFIDAMP

TECNOVAP CHATTANOOGA CARMEN

PAG N. 12

11. SOMMARY

1. PREFACE 1

2. TECHNICAL DRAWINGS 2

3. TECHNICAL CARACTERISTICS 4

3.1. TECHNICAL DATA OF THE STEAM GENERATOR 4

3.2. TECHNICAL DATA OF THE VACUUM CLEANER 4

3.3. TECHNICAL DATA OF THE STEAM IRON (OPTIONAL) 4

3.4. TECHNICAL DATA OF THE COMPLETE CARMEN 4

4. NOMENCLATURE 5

5. SAFETY REGULATIONS 6

6. USING INSTRUCTIONS 7

7. MAINTENANCE 8

7.1. MAINTENANCE OF THE STEAM GENERATOR 8

7.2. MAINTENANCE OF THE VACUUM CLEANER 9

7.3. MAINTENANCE OF THE ACCESSORIES 9

8. BEFORE REFERRING TO THE TECHNICAL ASSITANCE 10

9. CERTIFICATIONS AND HOMOLOGATIONS 10

10. SOCIETY TECNOVAP 11

10.1. CERTIFIED QUALITY SYSTEM ISO 9002 11

10.2. ASSOCIATED AFIDAMP 11

11. SOMMARY 12

This manual suits for next models

1

Table of contents

Other TECNOVAP Iron manuals